Reliable semiconductor?

Mosfet?

Perhaps no.

Even if you succeed, a handful of blown mosfets will be the by-product.Fast,powerful,reliable devices tend to be expensive!

A single transient kickback can kill a monster FET, but this is not the case with tubes.Once i tried with mosfet, and immediately failed ( bitter experience).Generally speaking tubes can withstand overload conditions for long time, so they are particularly siuted for this kind of operation.The bigger, the better!

However don't be worried about HF radiation, good shielding always helps!

Mosfet?

Perhaps no.

Even if you succeed, a handful of blown mosfets will be the by-product.Fast,powerful,reliable devices tend to be expensive!

A single transient kickback can kill a monster FET, but this is not the case with tubes.Once i tried with mosfet, and immediately failed ( bitter experience).Generally speaking tubes can withstand overload conditions for long time, so they are particularly siuted for this kind of operation.The bigger, the better!

However don't be worried about HF radiation, good shielding always helps!

I have no idea what device I could use. I only know how to use a pentode. Could we use cascoded triodes to simulate a tetrode? We could then use 211's or something like that. The cost will rise though, and I would rather not use a useful and rare device like that as the oscillator.

Could we invent a bigulator, and blow up a 6sn7 to 1:20 scale 😎

Could we invent a bigulator, and blow up a 6sn7 to 1:20 scale 😎

Don't worry

There is a myriad of suitable devices 807,813, russian equivalents

GU-13,GK-71,GU-81M etc...

There is a myriad of suitable devices 807,813, russian equivalents

GU-13,GK-71,GU-81M etc...

I have too much on to go promising to do this right now, but I am open to the possibility of a future project.

I do have another idea. One thing I was working on earlier was a horn. I don't feel like doing the math right now but it wouldn't surprise me if going from full space radiation to horn loaded would give us greater than 18dB.

I do like the concept of the ultimate point source radiator, but you know, practicality and all. I can't see why a nice tractrix wouldn't sound good. Even though I wonder just how effective it will be as there is no mass involved except for the air itself.

I suppose the horn may act just as a waveguide. Even concentrating the sound would be helpful.

I did cast a horn from plaster, as I think I mentioned and it killed the flame. I stumbled on the idea to use egg timers to create the horn throat.

My wife suggested she knew where to get them and promptly returned with a couple of rotating mechanical timers 😀

I picked up some glass tube types. I wanted to cut them in half at the narrowest point, remove the rounded end from one half and poke it over the electrode. I promptly broke them trying to cut them.

Then I decided to cut them using the plasma flame , great idea.

, great idea.

Anyway, I think the horn is a worthwhile idea. I did manage to get moderate SPL's this way, and may have been able to tweak something half decent if I'd continued.

I do have another idea. One thing I was working on earlier was a horn. I don't feel like doing the math right now but it wouldn't surprise me if going from full space radiation to horn loaded would give us greater than 18dB.

I do like the concept of the ultimate point source radiator, but you know, practicality and all. I can't see why a nice tractrix wouldn't sound good. Even though I wonder just how effective it will be as there is no mass involved except for the air itself.

I suppose the horn may act just as a waveguide. Even concentrating the sound would be helpful.

I did cast a horn from plaster, as I think I mentioned and it killed the flame. I stumbled on the idea to use egg timers to create the horn throat.

My wife suggested she knew where to get them and promptly returned with a couple of rotating mechanical timers 😀

I picked up some glass tube types. I wanted to cut them in half at the narrowest point, remove the rounded end from one half and poke it over the electrode. I promptly broke them trying to cut them.

Then I decided to cut them using the plasma flame

, great idea.

, great idea.Anyway, I think the horn is a worthwhile idea. I did manage to get moderate SPL's this way, and may have been able to tweak something half decent if I'd continued.

Recommended readings:

http://www.ionovac.com/dshistory1.htm

http://www.roger-russell.com/ionovac/ionovac.htm

http://www.ionovac.com/dshistory1.htm

http://www.roger-russell.com/ionovac/ionovac.htm

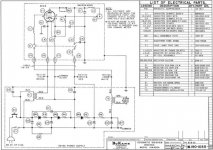

Attachments

Another point of research is the Hill Plasmatronic speaker.

Driven by 4 x 572B, iirc.

There may be threads in the archive here too...

Oh, ceramic insulators? Easy. Ur local farm supply will have them as electric fence insulators. Many hardware stores will have them too. Ur electric company is a possibility. As is almost any pottery shop, or person who does pottery.

But, if ur efficiency is right you should be able to use air coils held by styrene plastic no problem - thats a typical "Airdux" RF coil construction, used in commercial and ham radio rigs. Rf chokes are a different construction - check a ham radio book! 😉

_-_-bear

Driven by 4 x 572B, iirc.

There may be threads in the archive here too...

Oh, ceramic insulators? Easy. Ur local farm supply will have them as electric fence insulators. Many hardware stores will have them too. Ur electric company is a possibility. As is almost any pottery shop, or person who does pottery.

But, if ur efficiency is right you should be able to use air coils held by styrene plastic no problem - thats a typical "Airdux" RF coil construction, used in commercial and ham radio rigs. Rf chokes are a different construction - check a ham radio book! 😉

_-_-bear

No kidding. Hill's design beats all the other ones by virtue of using a glow discharge rather than a corona or arc, as all the other ones do. My modifications to do away with the helium tank are described in several existing threads.

One thing I'm wondering is, how do you get rid of the ozone, other than venting?

I remember seeing a plasma tweeter in a magazine a couple of years ago that somehow used an electric field to get rid of it?

Pherhaps if a sort of a foil like enclosure is built around the flame to contain any gasses that are emitted by the flame.

Then there is only the problem of the foil melting because of the heat.

I remember seeing a plasma tweeter in a magazine a couple of years ago that somehow used an electric field to get rid of it?

Pherhaps if a sort of a foil like enclosure is built around the flame to contain any gasses that are emitted by the flame.

Then there is only the problem of the foil melting because of the heat.

Grid plated with catalyst.

My solution is to remove away most of it outside, very low airflow is sufficient. By varying temperature you can minimize ozone produced anyway.

My solution is to remove away most of it outside, very low airflow is sufficient. By varying temperature you can minimize ozone produced anyway.

I just rememberd it could have been UV as well.

A catalyst is also a good option, as long as it doesn't burn because of the heat.

I've also read somewhere that a plasma tweeter produces some kinds of nitrogen oxide that cause the smell.

A catalyst is also a good option, as long as it doesn't burn because of the heat.

I've also read somewhere that a plasma tweeter produces some kinds of nitrogen oxide that cause the smell.

Yes, UV can be a problem.

The catalyst won't burn if you space it enough from the discharge. And yes, NO2 is produced (which reacts with water and oxygen in the lungs to make nitric acid, and in sufficient amounts cause pulmonary edema), but the catalyst deals with that too. Cars usually use platinum/rhodium to reduce it to N2 and O2.

The catalyst won't burn if you space it enough from the discharge. And yes, NO2 is produced (which reacts with water and oxygen in the lungs to make nitric acid, and in sufficient amounts cause pulmonary edema), but the catalyst deals with that too. Cars usually use platinum/rhodium to reduce it to N2 and O2.

Nixie said:No kidding. Hill's design beats all the other ones by virtue of using a glow discharge rather than a corona or arc, as all the other ones do. My modifications to do away with the helium tank are described in several existing threads.

Could you post the link?

I searched ur posts and did not notice it. I am curious about your method(s)...

Or email me privately...

_-_-bear

I used to be known as Prune.

Hill's patent is US4,219,705. My updates are based on microhollow discharges as electron sources for the main discharge instead of simple cathodes, which removes cathode fall instabilities and creates a stable air plasma; thus, you don't need to refill helium tanks as in Hill's design. See "Direct Current Glow Discharges in Atmospheric Air" (IEEE Transactions on Plasma Science, Vol. 30, No. 1, February 2002) and "Formation of Large-volume, High-pressure Plasmas in Microhollow Cathode Discharges" (Applied Physics Letters, Vol. 82, No. 19, 12 May 2003).

See this thread starting with post #12.

Unfortunately, jayphil's page is offline so you can't see the waterfall plot and other measurements he did on his Plasmatronics, but believe me they were excellent, even when he lowered the crossover from 1 kHz to 700 Hz. I'm aiming for 500 Hz, but have 50-100% increase in power dissipation to get that.

Hill's patent is US4,219,705. My updates are based on microhollow discharges as electron sources for the main discharge instead of simple cathodes, which removes cathode fall instabilities and creates a stable air plasma; thus, you don't need to refill helium tanks as in Hill's design. See "Direct Current Glow Discharges in Atmospheric Air" (IEEE Transactions on Plasma Science, Vol. 30, No. 1, February 2002) and "Formation of Large-volume, High-pressure Plasmas in Microhollow Cathode Discharges" (Applied Physics Letters, Vol. 82, No. 19, 12 May 2003).

See this thread starting with post #12.

Unfortunately, jayphil's page is offline so you can't see the waterfall plot and other measurements he did on his Plasmatronics, but believe me they were excellent, even when he lowered the crossover from 1 kHz to 700 Hz. I'm aiming for 500 Hz, but have 50-100% increase in power dissipation to get that.

Nixie said:Yes, UV can be a problem.

The catalyst won't burn if you space it enough from the discharge. And yes, NO2 is produced (which reacts with water and oxygen in the lungs to make nitric acid, and in sufficient amounts cause pulmonary edema), but the catalyst deals with that too. Cars usually use platinum/rhodium to reduce it to N2 and O2.

So could I buy a catalyst from a scrapyard and use that?

How would it be used?

No. There's no way to convert the geometry of the ceramic honeycomb to something you can use. Also, car converters contain both reducing and oxidizing catalysts, in series; you don't need the latter. You need a mesh and have it plated with platinum and rhodium, then space from the heat of the discharge it so it stays in its effective temperature window.

Not really. You'd use a tiny fraction of the amount of plating that is in a car's catalytic converter -- I couldn't imagine needing more than $30 worth of the precious metals. As for the plating, you can likely do it yourself. Platinum for example dissolves by electrolysis in HCl (muriatic acid from the hardware store) without the need of aqua regia -- I've plated tungsten electrodes with chloroplatinic acid made this way. Not sure about the rhodium, but it's probably similar.

You can also buy platinum coated connectors, pherhaps a platinum coated metal strip from a scart connector will do.

They look sort of brass like.

Is there any need for rhodium when using platinum?

There are also rhodium coated connectors.

They look sort of brass like.

Is there any need for rhodium when using platinum?

There are also rhodium coated connectors.

Yes. The reducing catalyst is platinum/rhodium, whereas the oxidizing one is platinum/palladium.bobo1on1 said:Is there any need for rhodium when using platinum?

- Home

- Loudspeakers

- Planars & Exotics

- plasma tweeter