Mooly, with this second short you speak of, can you illustrate on the diagram so I get it right. Thanks.

Hi Tom,

You can approximate the pot with a pair of fixed resistors before running out to buy the controls. You would like to know what you need before placing another order.

-Chris

You can approximate the pot with a pair of fixed resistors before running out to buy the controls. You would like to know what you need before placing another order.

-Chris

OK, one more thing. Should I replace the C2 input cap before these next steps:

1/ Leave the short in place.

2/ Lift R18 (the 100k)

3/ Measure the voltage across C4. It should be steady.

4/ D2 should have around 0.6 volts across it by the way.

So the big question... what if its not the control or the diode ?

Well any of those resistors around the diode and control could be faulty but its unlikely. What we would do in that case is one further simple test which is this.

1/ You remove the short previously applied and refit R18.

2/ You now short out C4 instead which now holds the base of Q2 to ground via the 100k (R18). That's a much higher resistance than the 2.2k it was seeing before with the first shorting link but as long as Q2 is OK then it should behave exactly the same.

1/ Leave the short in place.

2/ Lift R18 (the 100k)

3/ Measure the voltage across C4. It should be steady.

4/ D2 should have around 0.6 volts across it by the way.

So the big question... what if its not the control or the diode ?

Well any of those resistors around the diode and control could be faulty but its unlikely. What we would do in that case is one further simple test which is this.

1/ You remove the short previously applied and refit R18.

2/ You now short out C4 instead which now holds the base of Q2 to ground via the 100k (R18). That's a much higher resistance than the 2.2k it was seeing before with the first shorting link but as long as Q2 is OK then it should behave exactly the same.

Ok, with R18 lifted,

C4 is steady at +.065 V

And D2 is +.592 V Across

I'm also hearing the relay click on startup now, but also a couple times with power on for a few minutes during each test.

With the second short, Q2 Vbe is .59

B V is -15 to -16 V (small fluc)

E V is -13.2 to -13.3 V (small fluc)

C V is -40.9 V

Q4 Vbe is .53 to .54 (sm fluc)

B V is -10 V

E V is -14 V

C V is -43.5 V

Those Base and Emitter values should be down at 1.2V and .06V, right?

C4 is steady at +.065 V

And D2 is +.592 V Across

I'm also hearing the relay click on startup now, but also a couple times with power on for a few minutes during each test.

With the second short, Q2 Vbe is .59

B V is -15 to -16 V (small fluc)

E V is -13.2 to -13.3 V (small fluc)

C V is -40.9 V

Q4 Vbe is .53 to .54 (sm fluc)

B V is -10 V

E V is -14 V

C V is -43.5 V

Those Base and Emitter values should be down at 1.2V and .06V, right?

Where are we up to ? The measured C4 and D2 voltages look OK

We're so close at this point 🙂

--------------------------------------------------------------------------------------------

Relay clicking. This could well happen if you are measuring voltages around Q2 and Q4. Applying the meter can suddenly change the DC conditions and the relay circuitry thinks there is a fault and isolates the speaker. When you are not measuring then the relay should click once at power on (as it normally would).

At this stage you should still be at the condition where the DC offset was steady at around 0.1 volts.

Is that correct ?

-------------------------------------------------------------------------------------------

If the above holds true then we move on to replacing the first short with the second.

So you should now be at the stage of the amp being configured as in post #63 above. The first shorting link has been removed, and a new short added across C4. I think you still have C2 removed at this point... that's OK.

The amplifier should still behave as it did in the earlier step. Offset steady, even if its a little higher or lower than the 0.1 volts you measured. As long as the offset isn't to far from zero and is steady then the relay should click once as normal to connect the speakers.

Does it pass or fail at this point ?

If it fails, refit C2 and retest. (there's a valid reason for doing that)

If its still not behaving and the offset is not steady and low in value then we look at replacing Q2 and Q4

We're so close at this point 🙂

--------------------------------------------------------------------------------------------

Relay clicking. This could well happen if you are measuring voltages around Q2 and Q4. Applying the meter can suddenly change the DC conditions and the relay circuitry thinks there is a fault and isolates the speaker. When you are not measuring then the relay should click once at power on (as it normally would).

At this stage you should still be at the condition where the DC offset was steady at around 0.1 volts.

Is that correct ?

-------------------------------------------------------------------------------------------

If the above holds true then we move on to replacing the first short with the second.

So you should now be at the stage of the amp being configured as in post #63 above. The first shorting link has been removed, and a new short added across C4. I think you still have C2 removed at this point... that's OK.

The amplifier should still behave as it did in the earlier step. Offset steady, even if its a little higher or lower than the 0.1 volts you measured. As long as the offset isn't to far from zero and is steady then the relay should click once as normal to connect the speakers.

Does it pass or fail at this point ?

If it fails, refit C2 and retest. (there's a valid reason for doing that)

If its still not behaving and the offset is not steady and low in value then we look at replacing Q2 and Q4

Mooly, a bit frustrated...

I went back and rechecked everything starting here:

1. C2 input cap removed.

2. .5 Ohm: 0 to -4 V fluctuating

3. Short in place between C4 and R6.

4. .5 Ohm fluctuating -.04 to -.16 V (i thought I had a steady reading yesterday)

5. Lifted R18

6. V across C4: .05 V and steady

7. V across D2: 0.58 V and steady

8. Moved short to C4+ and R18 lifted hole (VR2 side)

8. .5 Ohm shot up to -35 V and right channel heat sink got noticeably warm

9. Shut things down and removed 2nd short.

10. Replaced C2.

11. .5 Ohm: -.02 to -.21V

So now I'm at a loss? Thought we were making headway, but with the first short in place and voltage still fluctuating???

Have to head to work, but I will recheck that 2nd short location one more time when I get home this evening.

I went back and rechecked everything starting here:

1. C2 input cap removed.

2. .5 Ohm: 0 to -4 V fluctuating

3. Short in place between C4 and R6.

4. .5 Ohm fluctuating -.04 to -.16 V (i thought I had a steady reading yesterday)

5. Lifted R18

6. V across C4: .05 V and steady

7. V across D2: 0.58 V and steady

8. Moved short to C4+ and R18 lifted hole (VR2 side)

8. .5 Ohm shot up to -35 V and right channel heat sink got noticeably warm

9. Shut things down and removed 2nd short.

10. Replaced C2.

11. .5 Ohm: -.02 to -.21V

So now I'm at a loss? Thought we were making headway, but with the first short in place and voltage still fluctuating???

Have to head to work, but I will recheck that 2nd short location one more time when I get home this evening.

Step 8 above. You need the 100k (R18) back in place. That's why the output shot to -35 volts.

Is the offset steady under those conditions ?

Is the offset steady under those conditions ?

I know Chris advises against this, and I know you weren't keen, but I really think swapping Q2 and Q4 with those in the other channel would just prove this one way or the other. If you haven't an easy source of parts available then its the only quick way to prove this.

If you are confident unsoldering parts then its two minutes work to do. Solder braid is excellent for desoldering components. That allows you to instantly remove the solder leaving the part free. Don't heat the transistor legs and start pulling and bending it to free it and get it out... that's not the way to do it and could damage them.

Also if you have anything like the 'air duster' spray I mentioned earlier then that is great for showing suspect parts up. Invert the can and use it as freezer to chill the suspect part.

If you are confident unsoldering parts then its two minutes work to do. Solder braid is excellent for desoldering components. That allows you to instantly remove the solder leaving the part free. Don't heat the transistor legs and start pulling and bending it to free it and get it out... that's not the way to do it and could damage them.

Also if you have anything like the 'air duster' spray I mentioned earlier then that is great for showing suspect parts up. Invert the can and use it as freezer to chill the suspect part.

Tom, I'm just going to add a bit more here 🙂

We are making headway, very much so in fact, but when diagnosing things at a distance and interpreting readings without actually being there, then there comes a point where we have to replace or swap any suspect item. I think we are at that point with Q2 and Q4

The other option is to order parts 'on spec' but that can be hit and miss and very frustrating if you keep ordering just an odd part or two.

We've done a lot of measurements and they have led us to believe that the problem is actually right at the input of the amplifier. Its either responding to an unwanted voltage that's appearing, or its a failure of a component in that very area.

(Chris I'm sure will have seen this many times as have I... another possibility neither of us have mentioned is that of anything slightly conductive having made its way onto the board. That can range from obvious spillage to the far more subtle effects of say a capacitor leaking slightly. If any component legs have a corroded look to them then that is a warning sign)

Mooly, a bit frustrated... So now I'm at a loss? Thought we were making headway, but with the first short in place and voltage still fluctuating???.............................

Have to head to work, but I will recheck that 2nd short location one more time when I get home this evening.

We are making headway, very much so in fact, but when diagnosing things at a distance and interpreting readings without actually being there, then there comes a point where we have to replace or swap any suspect item. I think we are at that point with Q2 and Q4

The other option is to order parts 'on spec' but that can be hit and miss and very frustrating if you keep ordering just an odd part or two.

We've done a lot of measurements and they have led us to believe that the problem is actually right at the input of the amplifier. Its either responding to an unwanted voltage that's appearing, or its a failure of a component in that very area.

(Chris I'm sure will have seen this many times as have I... another possibility neither of us have mentioned is that of anything slightly conductive having made its way onto the board. That can range from obvious spillage to the far more subtle effects of say a capacitor leaking slightly. If any component legs have a corroded look to them then that is a warning sign)

Step 8 above. You need the 100k (R18) back in place. That's why the output shot to -35 volts.

Is the offset steady under those conditions ?

Yes, I believe it was steady at -35 V.

Well I F'd the R18 hole on the board w my iron but was able to reinstall the resistor and verify it is a good connection to adjacent component. So I'm Reluctant to mess w left channel. I'm using a 35 watt iron. Should I switch to a 25 watt for this work?

I don't mind ordering new parts. Can you help me source Q2 and Q4. Not sure what specs those trannies have.

Thanks for all the encouragement mooly. I'm learning quite a bit and for only a $20 investment, this is probably the best test bed to hone my skills on ;-)

I don't mind ordering new parts. Can you help me source Q2 and Q4. Not sure what specs those trannies have.

Thanks for all the encouragement mooly. I'm learning quite a bit and for only a $20 investment, this is probably the best test bed to hone my skills on ;-)

Thanks for all the encouragement mooly. I'm learning quite a bit and for only a $20 investment, this is probably the best test bed to hone my skills on ;-)

You're very welcome 🙂

Sooo... has this amp got an unknown history ? If (if !) it has then don't overlook the possibility of spillage. Its not always obvious but the damage it does can linger.

Replacements for Q2 and Q4. It depends very much on what is available in your locale but the old favourites of 2N5401 come to mind. I'll have a think though.

For soldering, well a good iron with a large tip is very useful as it holds the heat. With practice you should be able to desolder parts in an instant and be able to replace them such that you cant tell. That takes practice and the right tools. The two favourites are 'solder braid' and /or a solder sucker (I never liked those even though I used them a lot in the past).

You can see braid here and the size of tip and iron I use. This would cover all work on your amp.

http://www.diyaudio.com/forums/parts/127924-working-smd-how-do-without-specialised-tools.html

Amp does have unknown history. Spillage is a possibility, but I see no signs of it. I bought it a couple of weeks ago from a guy who said it was having problems cutting out and he didn't want to fix it. He is at least the 2nd owner. I'm at minimum the third owner.

Is this the 2N5401 you are referring to?

2N5401 Central Semiconductor | Mouser

Is this the 2N5401 you are referring to?

2N5401 Central Semiconductor | Mouser

Also, I do have solder braid. Used it to remove solder and replace crossover caps on my HPM-100s. But I found with that job that my 25 watt iron wasn't getting hot enough to remove solder. So I picked up a 35 watter.

Yes, they are the ones. A coincidence but I looked up the 2SA726 in my old T.D. Towers (pre internet by a couple of decades) and the 2N5401 was the suggested replacement. We forget how old these devices are... yet they are still current.

Braid does need a good iron as well as a large tip to really to hold the heat.

Braid does need a good iron as well as a large tip to really to hold the heat.

OK, have ordered those, the mini pots and the electrolytic caps as well. I will try the 2nd short tonight with R18 in place and let you know the outcome. Then I'll take a breather (and give you one) and wait for parts to come in early next week...

OK, it sounds like a plan.

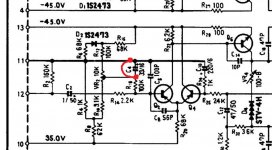

The second short should look like this. All the other components to be in place.

There are only two possible outcomes.

1/ The amp works correctly with a stable and steady DC offset that will be a little removed from zero. If its not to high then the relay should click and the amp should play music.

2/ The offset is still varying which points us to the transistors as being suspect.

(That statement is based on the earlier result that the offset was very much improved from its original -5 to -8 volt value and had come down to just 0.1 volts or so when we did the first shorting link)

And watch the pinouts on the 5401, they will probably be different to the originals... we can sort that when you get them.

The second short should look like this. All the other components to be in place.

There are only two possible outcomes.

1/ The amp works correctly with a stable and steady DC offset that will be a little removed from zero. If its not to high then the relay should click and the amp should play music.

2/ The offset is still varying which points us to the transistors as being suspect.

(That statement is based on the earlier result that the offset was very much improved from its original -5 to -8 volt value and had come down to just 0.1 volts or so when we did the first shorting link)

And watch the pinouts on the 5401, they will probably be different to the originals... we can sort that when you get them.

Hi Mooly,

My post just went Pffft - gone. Grrrrrr.

I would suggest replacing the diff pair (Q2, Q4) with 2N5401 and the Vas with 2N5551 transistors. Tie Q2 and Q4 together so that the cases touch.

Don't forget that Pioneer also had defective resistors throughout this time period. They can go intermittent. Probably bad end caps but difficult to find.

Spills - yes. Many times. Clean the area while the transistors are out with alcohol, IPA is the best (99.9%).

Hi Tom,

If this hobby appeals to you, the number 1 thing to do is buy a real soldering station. There is a model (SL-30) that is OEMed for many brand names. It has digital temperature set and read, and for the $100 USD it costs, or less, it would be a basic need. You're going to use it for years. My SL-30 is over 20 years old now, and I rebuilt it once. I can't say enough good about these things. Other comparable soldering stations that do the same thing will probably run $180 ~ 250 USD. This can be decided later, but you will immediately see how much easier soldering is. The heater is temperature controlled. In the ones you have now, the tip temperature becomes too hot between soldering jobs, and cools too far when you are soldering things. Not an easy way to enjoy what you are doing. It's sort of like going hunting with a rifle that has a wandering zero. Oh what fun that is.

-Chris

My post just went Pffft - gone. Grrrrrr.

I would suggest replacing the diff pair (Q2, Q4) with 2N5401 and the Vas with 2N5551 transistors. Tie Q2 and Q4 together so that the cases touch.

Don't forget that Pioneer also had defective resistors throughout this time period. They can go intermittent. Probably bad end caps but difficult to find.

Spills - yes. Many times. Clean the area while the transistors are out with alcohol, IPA is the best (99.9%).

Hi Tom,

If this hobby appeals to you, the number 1 thing to do is buy a real soldering station. There is a model (SL-30) that is OEMed for many brand names. It has digital temperature set and read, and for the $100 USD it costs, or less, it would be a basic need. You're going to use it for years. My SL-30 is over 20 years old now, and I rebuilt it once. I can't say enough good about these things. Other comparable soldering stations that do the same thing will probably run $180 ~ 250 USD. This can be decided later, but you will immediately see how much easier soldering is. The heater is temperature controlled. In the ones you have now, the tip temperature becomes too hot between soldering jobs, and cools too far when you are soldering things. Not an easy way to enjoy what you are doing. It's sort of like going hunting with a rifle that has a wandering zero. Oh what fun that is.

-Chris

Its so infuriating when that happens and a post disappears. It has happened to me on odd occasions in the past.

Seen more cases of spillage than I care to remember... and not just spills... cats, dogs. As soon as you touch the iron on the print you just know by the smell (if its recent). If its old then the parts usually fall to bits from corrosion, legs drop off transistors. Happy days though 🙂

Seen more cases of spillage than I care to remember... and not just spills... cats, dogs. As soon as you touch the iron on the print you just know by the smell (if its recent). If its old then the parts usually fall to bits from corrosion, legs drop off transistors. Happy days though 🙂

- Status

- Not open for further replies.

- Home

- Amplifiers

- Solid State

- Pioneer SA-8500 Voltage/DC Offset Issue