Lets start again at the beginning. The fluctuating readings are odd so we need to look at a couple of basic issues first. If you are measuring on the PCB print or even directly on component legs and leads then its quite common for oxidation and lacquer to be present that prevent the probe making a good contact. Measuring on print and its easily dealt with by firmly pressing the probe point into the board or the solder and twisting it to really push the point home. Component legs are more tricky because its so easy to slip and short something out. So you need to be careful. Also be sure that the black lead is securely attached to an appropriate ground point on the chassis so that it has a good connection.

Measurements.... All these are with the black lead on the chassis.

1/ Recheck the voltage on the 0.5 ohms. Be clear when describing a voltage because the polarity matters. Is it 40 volts positive for example, or 40 negative.

Whatever you see here should be constant. If it genuinely isn't then we need to start looking at other things.

2/ We always check supplies as a first golden rule of fault-finding. There are six important ones per channel here.

a/ Plus 40 volts on the collectors of Q12 and Q16.

b/ Minus 40 volts on the collectors of Q14 and Q18

Those are the four output transistors.

c/ There should be plus 40 volts on both sides of D6

d/ There should be minus 40 volts on both sides of D8

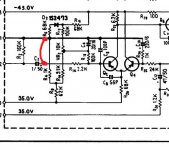

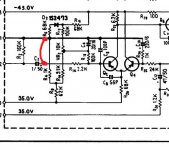

Now look at the lower left of the diagram and the points marked '13', '10' and '17' and the voltages shown.

e/ There should be minus 40 volts on both sides of resistor R28 (100 ohm)

f/ The two voltages marked '35 volts' at the lower left should be present on one end of both R8, R20 and R30.

Note... service manuals aren't always very exact in voltage given so don't worry if the 40v is 43v or 47v and the 35v is a bit different and so on.

Lets how you get on with that for starters.

Measurements.... All these are with the black lead on the chassis.

1/ Recheck the voltage on the 0.5 ohms. Be clear when describing a voltage because the polarity matters. Is it 40 volts positive for example, or 40 negative.

Whatever you see here should be constant. If it genuinely isn't then we need to start looking at other things.

2/ We always check supplies as a first golden rule of fault-finding. There are six important ones per channel here.

a/ Plus 40 volts on the collectors of Q12 and Q16.

b/ Minus 40 volts on the collectors of Q14 and Q18

Those are the four output transistors.

c/ There should be plus 40 volts on both sides of D6

d/ There should be minus 40 volts on both sides of D8

Now look at the lower left of the diagram and the points marked '13', '10' and '17' and the voltages shown.

e/ There should be minus 40 volts on both sides of resistor R28 (100 ohm)

f/ The two voltages marked '35 volts' at the lower left should be present on one end of both R8, R20 and R30.

Note... service manuals aren't always very exact in voltage given so don't worry if the 40v is 43v or 47v and the 35v is a bit different and so on.

Lets how you get on with that for starters.

Attachments

Hi Chris, so I rechecked the Vbe's and they are:

Q2: .578

Q4: .592

Q6: .603

Q8: .603

Q10: .603

Sorry, being new to this sort of benchwork, I didn't know that .6 to .7 was not a good way of providing readings/numbers. I'll be more specific with each measurement going forward.

Also, I tried posting one diagram, but resolution gets lost when pulling page from PDF and converting to JPEG. And the diagrams in the service manual PDF are hard enough to read as they are. I pulled my service manual from hifi engine if you can get it from there.

As for the protection relay, for what its worth, it had been kicking in fairly regularly when I first tested the unit. I would hear the first click seconds after turning on the unit, followed by a click every 20 seconds or so. Now when I turn the amp on, I don't even get the initial click.

Q2: .578

Q4: .592

Q6: .603

Q8: .603

Q10: .603

Sorry, being new to this sort of benchwork, I didn't know that .6 to .7 was not a good way of providing readings/numbers. I'll be more specific with each measurement going forward.

Also, I tried posting one diagram, but resolution gets lost when pulling page from PDF and converting to JPEG. And the diagrams in the service manual PDF are hard enough to read as they are. I pulled my service manual from hifi engine if you can get it from there.

As for the protection relay, for what its worth, it had been kicking in fairly regularly when I first tested the unit. I would hear the first click seconds after turning on the unit, followed by a click every 20 seconds or so. Now when I turn the amp on, I don't even get the initial click.

Mooly, thanks for the advice on taking accurate measurements, I'll try and take them all from solder points going forward. I have to put some work in this morning so I will try and take your suggested readings later this afternoon.

As for the protection relay, for what its worth, it had been kicking in fairly regularly when I first tested the unit. I would hear the first click seconds after turning on the unit, followed by a click every 20 seconds or so. Now when I turn the amp on, I don't even get the initial click.

The relay behaving like this suggests that the DC voltage really could be fluctuating... we'll see when you get to the measurements. Its worth looking at the board closely for any dry joints, particularly on hot running components + the transistors. Poor joints aren't always obvious.

Mooly, thanks for the advice on taking accurate measurements, I'll try and take them all from solder points going forward. I have to put some work in this morning so I will try and take your suggested readings later this afternoon.

OK, sounds like a plan 🙂

Mooly, I have some numbers for you:

1. 4 x .5 ohm are 0 V left; but -3 to -9 V on the right

2. a) Q12 and Q16: +43 V

b) Q14 and Q18: -43 V

c) D6: one side 43.1 V, other side 42.6 V

d) D8: one side -43.1 V, other side -42.6 V

e) R28 100 ohm: one side -42.6 V, other side -43.5 V

f) R8 62K: one side 35.6 V, other side .4 V (compared to left ch. 35.7/.4)

R20 68K: one side 35.6 V, other side -8 V (compared to left ch. 35.7/.5)

R30 1.2K: one side 37.7, other side fluctuates 20-24 V (compared to left ch. 37.7/27)

1. 4 x .5 ohm are 0 V left; but -3 to -9 V on the right

2. a) Q12 and Q16: +43 V

b) Q14 and Q18: -43 V

c) D6: one side 43.1 V, other side 42.6 V

d) D8: one side -43.1 V, other side -42.6 V

e) R28 100 ohm: one side -42.6 V, other side -43.5 V

f) R8 62K: one side 35.6 V, other side .4 V (compared to left ch. 35.7/.4)

R20 68K: one side 35.6 V, other side -8 V (compared to left ch. 35.7/.5)

R30 1.2K: one side 37.7, other side fluctuates 20-24 V (compared to left ch. 37.7/27)

Interesting 🙂

OK, so the results from 'F' are the ones in error. The fact the readings are varying seems to indicate an intermittent breakdown of a component (probably altering many times a second).

(and just to explain that an amplifier like this operates 'as a loop' and this is why we seem to have to do seemingly random measurements at a lot of places on the circuit. A problem in one part of the circuit doesn't just affect the operation and voltages at that one point, it throws all the others out as the 'loop' tries to correct the error)

Here is what I would do.

1/ I think Chris mentioned way back at the start that the input caps were a known trouble area. Did you actually remove C2 (the 1uf cap) to see if it altered things. You can leave that out for testing. That might be worth doing anyway to totally isolate the power amp from the preamp.

2/ Lets measure the voltage on Q8 base. This is measured from chassis (black lead here) to the base. The base is the junction of C16/R32 etc.

Now the amplifier output voltage (on the 0.5 ohms) should be a replica of what is on Q8 base. So if the output is fluctuating -3 to -9 v then we should see similar on the base of Q8.

What we are looking for as a fault is the base trying to go more positive than the output. If that is happening then it indicates a problem around Q8.

As a double check on this result can you also now measure from the base (red lead here) and the 0.5 ohms (black lead here). You should not see more than around + 1.4 to + 1.5 v. (Edit... you should always see this small positive voltage across these two points even though the output may be at some negative voltage. If the voltage between these two points exceeds around 1.5 volts then we have a problem around this transistor)

3/ There are a few more suspects lined up but testing some of these by simple voltage measurement with a meter isn't easy or always conclusive.

Swapping Q1 and Q3 with Q2 and Q4 would be easy and definitive proof of a problem with those input transistors.

Q6 ! If that were breaking down and going leaky from C to E then it could give this fault. Q6 is the one transistor in the power amp that runs continuously hot under idle conditions and that makes it a prime suspect in many ways. Have you checked the soldering on this one ?

Swapping it with Q5 is a valid way to prove it. Also if you measure across B and E then you should not see any voltage spikes over 0.7 volts. If it went much higher than that then that would be good proof its faulty.

The unlikely suspects...

C14 and C18 marked 10P and 47P on the diagram. These are very tiny values but if they were leaky (particularly C14) then that would cause this problem as it turned on Q6 and pulls the output negative. C18 could do similar but its perhaps more unlikely to 'survive' in that faulty state. Possible though.

-----------------------------------------------------------------------------------------------

Another hugely useful technique on faults like this is freezer spray. It really works in many cases. If you haven't got any (and it is relatively expensive as its a greenhouse gas) then you can use a cheap can of 'air duster' and use it by inverting the can. Although this isn't as good as freezer it still chills very significantly.

You need to be able to dispense the stuff literally a drop at a time through the straw on the can and onto the suspect parts, so practice the technique of controlling the aerosol to do this. Blasting a whole area simply chills everything and you end up not knowing what you cooled.

If you connect your meter to the 0.5 ohms to monitor the output voltage then hopefully you should see a dramatic jump in the reading when the faulty part is cooled. Cooling a good part should have no effect at all. You can even try this by simply cooling the solder joints of the relevant part on the pcb itself, the cold travels instantly into the component.

The transistor Q6 is the one part that might need a good blast directly onto it to chill it.

OK, so the results from 'F' are the ones in error. The fact the readings are varying seems to indicate an intermittent breakdown of a component (probably altering many times a second).

(and just to explain that an amplifier like this operates 'as a loop' and this is why we seem to have to do seemingly random measurements at a lot of places on the circuit. A problem in one part of the circuit doesn't just affect the operation and voltages at that one point, it throws all the others out as the 'loop' tries to correct the error)

Here is what I would do.

1/ I think Chris mentioned way back at the start that the input caps were a known trouble area. Did you actually remove C2 (the 1uf cap) to see if it altered things. You can leave that out for testing. That might be worth doing anyway to totally isolate the power amp from the preamp.

2/ Lets measure the voltage on Q8 base. This is measured from chassis (black lead here) to the base. The base is the junction of C16/R32 etc.

Now the amplifier output voltage (on the 0.5 ohms) should be a replica of what is on Q8 base. So if the output is fluctuating -3 to -9 v then we should see similar on the base of Q8.

What we are looking for as a fault is the base trying to go more positive than the output. If that is happening then it indicates a problem around Q8.

As a double check on this result can you also now measure from the base (red lead here) and the 0.5 ohms (black lead here). You should not see more than around + 1.4 to + 1.5 v. (Edit... you should always see this small positive voltage across these two points even though the output may be at some negative voltage. If the voltage between these two points exceeds around 1.5 volts then we have a problem around this transistor)

3/ There are a few more suspects lined up but testing some of these by simple voltage measurement with a meter isn't easy or always conclusive.

Swapping Q1 and Q3 with Q2 and Q4 would be easy and definitive proof of a problem with those input transistors.

Q6 ! If that were breaking down and going leaky from C to E then it could give this fault. Q6 is the one transistor in the power amp that runs continuously hot under idle conditions and that makes it a prime suspect in many ways. Have you checked the soldering on this one ?

Swapping it with Q5 is a valid way to prove it. Also if you measure across B and E then you should not see any voltage spikes over 0.7 volts. If it went much higher than that then that would be good proof its faulty.

The unlikely suspects...

C14 and C18 marked 10P and 47P on the diagram. These are very tiny values but if they were leaky (particularly C14) then that would cause this problem as it turned on Q6 and pulls the output negative. C18 could do similar but its perhaps more unlikely to 'survive' in that faulty state. Possible though.

-----------------------------------------------------------------------------------------------

Another hugely useful technique on faults like this is freezer spray. It really works in many cases. If you haven't got any (and it is relatively expensive as its a greenhouse gas) then you can use a cheap can of 'air duster' and use it by inverting the can. Although this isn't as good as freezer it still chills very significantly.

You need to be able to dispense the stuff literally a drop at a time through the straw on the can and onto the suspect parts, so practice the technique of controlling the aerosol to do this. Blasting a whole area simply chills everything and you end up not knowing what you cooled.

If you connect your meter to the 0.5 ohms to monitor the output voltage then hopefully you should see a dramatic jump in the reading when the faulty part is cooled. Cooling a good part should have no effect at all. You can even try this by simply cooling the solder joints of the relevant part on the pcb itself, the cold travels instantly into the component.

The transistor Q6 is the one part that might need a good blast directly onto it to chill it.

At work today, but just wanted to pass this along. I measured Q8 earlier in this thread and had these numbers:

One more set of measurements. Q8.

1 Lead should be 45, I get 43.7 V

Other leads should be 1.2 V and .6 V, I get -22 to -30 on one lead and -12 to -20 V on the other.

So yes, I have fluctuation in this area.

I have not removed the input cap C2 (0.47 uF 25V) yet.

Also, from earlier post:

Just rechecked Q2/4/6/8/10 and where I should have 0 V and .6 V, all are reading 3-9 V (likely -3 to -9, same as 0.5 Ohm) fluctuating constantly (same as the .5 ohm resistors). As a comparison, the left channel Q1/3/5/7/9 are all properly reading 0 V and .6 V.

I can pull the input capacitor this evening when I get home...

Thanks again Mooly and Chris for all your help here. I'm learning quite a bit about troubleshooting and look forward to pinpointing the problem component(s).

One more set of measurements. Q8.

1 Lead should be 45, I get 43.7 V

Other leads should be 1.2 V and .6 V, I get -22 to -30 on one lead and -12 to -20 V on the other.

So yes, I have fluctuation in this area.

I have not removed the input cap C2 (0.47 uF 25V) yet.

Also, from earlier post:

Just rechecked Q2/4/6/8/10 and where I should have 0 V and .6 V, all are reading 3-9 V (likely -3 to -9, same as 0.5 Ohm) fluctuating constantly (same as the .5 ohm resistors). As a comparison, the left channel Q1/3/5/7/9 are all properly reading 0 V and .6 V.

I can pull the input capacitor this evening when I get home...

Thanks again Mooly and Chris for all your help here. I'm learning quite a bit about troubleshooting and look forward to pinpointing the problem component(s).

Those Q8 voltages are more than a little suspect. Your readings seem to suggest a differential of around 10 volts between the base and the emitter.

Crunch time 😉 If you put your red meter lead on the base and the black on the emitter what do you get ? If there is more than 0.8 v or so then the transistor is looking faulty.

The reason the polarity is important here is because 7 v (seven) or so is around the voltage a base/emitter junction will tend to level out at if its reversed biased... which is non valid mode of operation. So if the emitter is the more positive one of the two then that could explain away that result. 7 is an approximate figure and it can range from as low as 4 or 5 to what ? 10 maybe ??? depending on the specific device in question.

That reading is highly suspect though

And another thought entirely but it tallies with your readings. Do you see the two resistors that connect in series to the base, R30 and R32. If one of those had failed and gone 'high' in value then it would cause the output to swing negative as you are getting now. If one was open circuit or very high in value then it would also leave the base of Q8 'dangling' or 'floating' and that would tie in with a reverse bias condition across the B/E junction.

Its not possible to measure these resistors in circuit, you would have to pull one end free to read it accurately.

Crunch time 😉 If you put your red meter lead on the base and the black on the emitter what do you get ? If there is more than 0.8 v or so then the transistor is looking faulty.

The reason the polarity is important here is because 7 v (seven) or so is around the voltage a base/emitter junction will tend to level out at if its reversed biased... which is non valid mode of operation. So if the emitter is the more positive one of the two then that could explain away that result. 7 is an approximate figure and it can range from as low as 4 or 5 to what ? 10 maybe ??? depending on the specific device in question.

That reading is highly suspect though

And another thought entirely but it tallies with your readings. Do you see the two resistors that connect in series to the base, R30 and R32. If one of those had failed and gone 'high' in value then it would cause the output to swing negative as you are getting now. If one was open circuit or very high in value then it would also leave the base of Q8 'dangling' or 'floating' and that would tie in with a reverse bias condition across the B/E junction.

Its not possible to measure these resistors in circuit, you would have to pull one end free to read it accurately.

Give those resistors a check first. A quick and dirty way...

you have 3.6k and 1.2k in series. The volts across each should be in proportion to the resistance. For example you have say your measured 37 volts at one end and say -22 v at the other end (the base of Q8). That's 59 volts in total across the two. The 3.6k would have around 45 volts across it and the 1.2k would have around 14 volts across it.

If one resistor has all the 57 (or whatever it is) voltage across it then its going to be open circuit.

Another super quick check... they should be quite hot with that sort of voltage across them.

Ok, for Q8...

For the right channel 1.2k and 3.6k...

I get +35.5 on the #17 side

I get +25 to +26 where they meet (fluctuating)

I get -2 to -5 (fluctuating) on the Q8 side

Voltage across: R30 is +10-11V, R32 is +31-32V (fluctuating)

By comparison, on the left channel I get these numbers:

I get +35.7 on the #45 side

I get +27 where they meet

I get +1.1 on the Q7 side

Voltage across: R29 is +8.5, R31 is +25.8

The R32 resistor felt hotter than the R30, but so did R31 over R29. Kind of hard to get my fingers in there to check easily.

New finding: I connected the SA-8500 up as a pre-amp to another amp I have and all controls appeared to work on the SA-8500. Music sounded clear out of both channels.

I've yet to pull the C2 input capacitor. Do you still want me to go down that path?

I'm getting +.613 V when first tested, .597 V after it warmed up 10 minutes.Crunch timeIf you put your red meter lead on the base and the black on the emitter what do you get ? If there is more than 0.8 v or so then the transistor is looking faulty.

For the right channel 1.2k and 3.6k...

I get +35.5 on the #17 side

I get +25 to +26 where they meet (fluctuating)

I get -2 to -5 (fluctuating) on the Q8 side

Voltage across: R30 is +10-11V, R32 is +31-32V (fluctuating)

By comparison, on the left channel I get these numbers:

I get +35.7 on the #45 side

I get +27 where they meet

I get +1.1 on the Q7 side

Voltage across: R29 is +8.5, R31 is +25.8

The R32 resistor felt hotter than the R30, but so did R31 over R29. Kind of hard to get my fingers in there to check easily.

New finding: I connected the SA-8500 up as a pre-amp to another amp I have and all controls appeared to work on the SA-8500. Music sounded clear out of both channels.

I've yet to pull the C2 input capacitor. Do you still want me to go down that path?

Last edited:

Those resistors seem to be OK as they are dropping the voltage in the correct proportions... roughly three times as much over the 3.6k as the 1.2k. We had to check though.

Q8... The fluctuating nature of the voltages is a little confusing but the 0.613/0.597 is fine.

And it must be very frustrating for you, a bit like playing postal chess 😉 but its great that you are sticking with it and hopefully we'll get a result on this.

C2. Chris mentioned these as a known failure item so we have to just pull it and see.

If I had the amp in front of me I would do this a little differently but this is more of a sure fire way without having to interpret readings at a distance. What is odd here is that the fault isn't what we call a 'hard fault' which 99% of problems are. By that, I mean that a 'hard fault' typically swings the output fully one way or the other to the rails and is caused by a catastrophic breakdown of a component. That isn't happening here, its much more subtle... anyhow after giving it more thought here is the plan and in this order.

(all your readings have shown that the problem seems to be caused by Q6 conducting a little more than it should but there are a few possible reasons why)

So I'm going to attack this from another angle to begin with, and that is that the main amplifier could be OK and that its actually responding to some unwanted input voltage.

1/ Remove C2 and see if the problem is resolved.

2/ Do you see VR2 next to C2. That trims the DC offset to zero. Could there be a problem in that area ? Trimmer resistors can go intermittent and there could be a problem with D2 that is used to generate a stable 0.6 volts reference. You could first just try altering the trimmer slightly to see if it has a major impact on the offset. If it had gone a bit dicky then a slight tweak would see the offset shoot all over the place.

If altering the trimmer has no effect then we can eliminate the whole caboodle by shorting R14 to ground as shown here.

Shorting these points out would prove if the problem were at the front end. The offset would now be steady (but would not be quite zero).

If we're still left with the fault then we carry on as before,

2/ Swap Q5 and Q6 over. These two are the 'hot' running devices and so always suspect for that reason.

3/ We can swap Q1 and Q3 with Q2 and Q4.

4/ The odd ball components that could still cause this are C14 and C16, the 10pf and 47pf caps. Again swapping them over would prove the point.

How it all works...

The two input transistors are like a set of scales or a balance. The output voltage from the amp is fed back to Q4 via R26 (the feedback resistor). The input to the amplifier (Q2) is zero because we have nothing playing. The output from that pair of scales drives the other transistors to maintain equilibrium. If the output wanders (your fluctuating minus output voltage) then the balance is upset and Q6 would be turned a little harder on or off to maintain the output at zero volts.

That's not happening, but what is a little odd here is that the problem isn't a 'hard' DC fault where the output typically swings to the supply rail.

Q8... The fluctuating nature of the voltages is a little confusing but the 0.613/0.597 is fine.

And it must be very frustrating for you, a bit like playing postal chess 😉 but its great that you are sticking with it and hopefully we'll get a result on this.

C2. Chris mentioned these as a known failure item so we have to just pull it and see.

If I had the amp in front of me I would do this a little differently but this is more of a sure fire way without having to interpret readings at a distance. What is odd here is that the fault isn't what we call a 'hard fault' which 99% of problems are. By that, I mean that a 'hard fault' typically swings the output fully one way or the other to the rails and is caused by a catastrophic breakdown of a component. That isn't happening here, its much more subtle... anyhow after giving it more thought here is the plan and in this order.

(all your readings have shown that the problem seems to be caused by Q6 conducting a little more than it should but there are a few possible reasons why)

So I'm going to attack this from another angle to begin with, and that is that the main amplifier could be OK and that its actually responding to some unwanted input voltage.

1/ Remove C2 and see if the problem is resolved.

2/ Do you see VR2 next to C2. That trims the DC offset to zero. Could there be a problem in that area ? Trimmer resistors can go intermittent and there could be a problem with D2 that is used to generate a stable 0.6 volts reference. You could first just try altering the trimmer slightly to see if it has a major impact on the offset. If it had gone a bit dicky then a slight tweak would see the offset shoot all over the place.

If altering the trimmer has no effect then we can eliminate the whole caboodle by shorting R14 to ground as shown here.

Shorting these points out would prove if the problem were at the front end. The offset would now be steady (but would not be quite zero).

If we're still left with the fault then we carry on as before,

2/ Swap Q5 and Q6 over. These two are the 'hot' running devices and so always suspect for that reason.

3/ We can swap Q1 and Q3 with Q2 and Q4.

4/ The odd ball components that could still cause this are C14 and C16, the 10pf and 47pf caps. Again swapping them over would prove the point.

How it all works...

The two input transistors are like a set of scales or a balance. The output voltage from the amp is fed back to Q4 via R26 (the feedback resistor). The input to the amplifier (Q2) is zero because we have nothing playing. The output from that pair of scales drives the other transistors to maintain equilibrium. If the output wanders (your fluctuating minus output voltage) then the balance is upset and Q6 would be turned a little harder on or off to maintain the output at zero volts.

That's not happening, but what is a little odd here is that the problem isn't a 'hard' DC fault where the output typically swings to the supply rail.

Getting somewhere...

1. I pulled C2 and still had -7 to -9 V at the .5 ohms.

2. I had previously turned VR2 to both ends with no effect on readings. I placed the jumper where you indicated and the .5 ohms now read +0.1 V and appear steady. Note, this is with C2 still removed.

Bad VR2 pot?

Your move Mooly ;-)

1. I pulled C2 and still had -7 to -9 V at the .5 ohms.

2. I had previously turned VR2 to both ends with no effect on readings. I placed the jumper where you indicated and the .5 ohms now read +0.1 V and appear steady. Note, this is with C2 still removed.

Bad VR2 pot?

Your move Mooly ;-)

Excellent. Now we might be getting somewhere.

Its well worth measuring the voltage across D2 before doing anything else. It should be steady but with a tiny voltage drift as it warms. Yes, it could be the pot itself... it could also be any of the other components around there as well.

What you could do as a test is this,

1/ Leave the short in place.

2/ Lift R18 (the 100k)

3/ Measure the voltage across C4. It should be steady.

Looks like we are on to the problem though.

Its well worth measuring the voltage across D2 before doing anything else. It should be steady but with a tiny voltage drift as it warms. Yes, it could be the pot itself... it could also be any of the other components around there as well.

What you could do as a test is this,

1/ Leave the short in place.

2/ Lift R18 (the 100k)

3/ Measure the voltage across C4. It should be steady.

Looks like we are on to the problem though.

OK, I will take the next steps when I get home from work this evening. So I understand, with the short in place, lifting R18 will isolate C4 and bypass VR2 completely? And same goes for D2, it will bypass VR2 as well?

Hi Tom,

Whatever you do, do not swap parts from one channel into the other. You are on the right track now.

The input capacitors have a habit of going leaky or short. They should be replaced as a matter of course.

-Chris

Whatever you do, do not swap parts from one channel into the other. You are on the right track now.

The input capacitors have a habit of going leaky or short. They should be replaced as a matter of course.

-Chris

That's right, the short is actually a valid condition for biasing the transistor Q2. What you have is the base of Q2 returned directly to ground via R14, the 2.2k resistor. We leave the short in place while you lift R18 as Q2 base must never be left floating. It keeps the amp happy.

The network of resistors, VR2 and the diode simply allow Q2 base to be swung a little in each direction and so trim the offset to zero. As measured from ground the control VR2 will have something like +0.2 volts on one and -0.2 on the other. You can check the other channel to confirm that. The voltage on each end of the control should be rock steady. All this allows for Q2 base to be pulled a little each way depending where the control is set to, and that allows us to trim the offset to 0.000 volts (when its fixed 😉).

So the big question... what if its not the control or the diode ?

Well any of those resistors around the diode and control could be faulty but its unlikely. What we would do in that case is one further simple test which is this.

1/ You remove the short previously applied and refit R18.

2/ You now short out C4 instead which now holds the base of Q2 to ground via the 100k (R18). That's a much higher resistance than the 2.2k it was seeing before with the first shorting link but as long as Q2 is OK then it should behave exactly the same.

What would that show... well it should still give a stable DC offset at the amp output just as before. The offset will be a little higher or lower but that's no concern if its steady. If it passes that then we know for certain that the problem is with that little network of resistors, or the control, the diode or C4.

If by chance the fault still showed in this condition then the finger of suspicion would move straight away to Q2 or one of those two small caps connected to the base (the 56pf and 100pf).

Applying a short as we have done at the moment (the first one) is a brute force method that firmly holds the base of Q2 at approximately the correct value for everything to work. If Q2 had failed in some bizarre way (intermittent and/or intermittent low gain) then its failure could be masked by the brute force method of the first short we applied. The second way bringing the 100k into play instead would show if that were the case.

The network of resistors, VR2 and the diode simply allow Q2 base to be swung a little in each direction and so trim the offset to zero. As measured from ground the control VR2 will have something like +0.2 volts on one and -0.2 on the other. You can check the other channel to confirm that. The voltage on each end of the control should be rock steady. All this allows for Q2 base to be pulled a little each way depending where the control is set to, and that allows us to trim the offset to 0.000 volts (when its fixed 😉).

So the big question... what if its not the control or the diode ?

Well any of those resistors around the diode and control could be faulty but its unlikely. What we would do in that case is one further simple test which is this.

1/ You remove the short previously applied and refit R18.

2/ You now short out C4 instead which now holds the base of Q2 to ground via the 100k (R18). That's a much higher resistance than the 2.2k it was seeing before with the first shorting link but as long as Q2 is OK then it should behave exactly the same.

What would that show... well it should still give a stable DC offset at the amp output just as before. The offset will be a little higher or lower but that's no concern if its steady. If it passes that then we know for certain that the problem is with that little network of resistors, or the control, the diode or C4.

If by chance the fault still showed in this condition then the finger of suspicion would move straight away to Q2 or one of those two small caps connected to the base (the 56pf and 100pf).

Applying a short as we have done at the moment (the first one) is a brute force method that firmly holds the base of Q2 at approximately the correct value for everything to work. If Q2 had failed in some bizarre way (intermittent and/or intermittent low gain) then its failure could be masked by the brute force method of the first short we applied. The second way bringing the 100k into play instead would show if that were the case.

Thanks anatech, didn't really want to go that route either. I'll buy new and replace suspect components. If it comes down to one of the transistors or diodes, I may need help sourcing a replacement.

I think I've already found replacement mini pots at mouser.com that sound like the right replacements:

VR1/2: 652-3296W-1-103LF Bourns Trimmer Resistors - Through Hole 3/8" 10K ohms Sealed Vertical Adjust

VR3/4: 652-3386W-1-101LF Bourns Trimmer Resistors - Through Hole 3/8IN 100 OHMS 10% 0.5 Watts Square

As for the input caps and other electrolytics on this circuit board, I see parts express sells regular and high temperature variants. Should I go with high temp?

I think I've already found replacement mini pots at mouser.com that sound like the right replacements:

VR1/2: 652-3296W-1-103LF Bourns Trimmer Resistors - Through Hole 3/8" 10K ohms Sealed Vertical Adjust

VR3/4: 652-3386W-1-101LF Bourns Trimmer Resistors - Through Hole 3/8IN 100 OHMS 10% 0.5 Watts Square

As for the input caps and other electrolytics on this circuit board, I see parts express sells regular and high temperature variants. Should I go with high temp?

- Status

- Not open for further replies.

- Home

- Amplifiers

- Solid State

- Pioneer SA-8500 Voltage/DC Offset Issue