BudP,

Wow! those Walsh speakers are cool, I've never seen anything like those before. Can you PM me with more info. Just curious being a noob.

Ron

Wow! those Walsh speakers are cool, I've never seen anything like those before. Can you PM me with more info. Just curious being a noob.

Ron

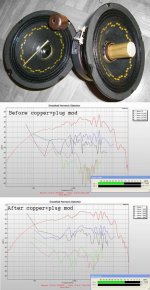

John L, I suggest you put copper cap below phase plug.

I tried it with pa160 driver, and it does reduce distortion.

(mostly 4th and 5th order) those caps are sold in home depot,

in plumbing supply section. and cost about $2 each.

you just need to drill a hole in that cap and attach it with

brass screw, going through magnet and cap into phase plug.

I tried it with pa160 driver, and it does reduce distortion.

(mostly 4th and 5th order) those caps are sold in home depot,

in plumbing supply section. and cost about $2 each.

you just need to drill a hole in that cap and attach it with

brass screw, going through magnet and cap into phase plug.

MisterTwister said:John L, I suggest you put copper cap below phase plug.

I tried it with pa160 driver, and it does reduce distortion.

(mostly 4th and 5th order) those caps are sold in home depot,

in plumbing supply section. and cost about $2 each.

you just need to drill a hole in that cap and attach it with

brass screw, going through magnet and cap into phase plug.

interesting. do you have any literature I can read about this copper advantage? Also, I cannot place a screw in the middle of the phase plug, because that is where the wiring will travel to the rear of the B20, through the new hole in the pole piece.

I don't know where you can read about copper advantage. I did my own distortion measurements. I'll post some pictures later. I mistyped driver's model, it's pa165

MisterTwister said:I don't know where you can read about copper advantage. I did my own distortion measurements. I'll post some pictures later. I mistyped driver's model, it's pa165

Both the PA165 and the PA130 seem to have great potential. They are inexpensive AND quite efficient. They are not the prettiest in the world, but still look good enough.

Wouldn't the copper cap in that position work as a copper shorting ring and a copper heat sink all at once? That can't be bad for performance.

Kensai

Kensai

MisterTwister said:I suggest you put copper cap below phase plug.

Are you talking about a copper disk or a cap...

dave

planet10 said:

Are you talking about a copper disk or a cap...

dave

Good question. If a disk, I don't have to get a smaller dowel. With I cap, I will.

John L said:

Good question. If a disk, I don't have to get a smaller dowel. With I cap, I will.

The problem with a cap is that it needs to cap the pole piece not the plug.

dave

here is the picture. I couldn't find after mod measurements. I just made a new one, so these are not very accurate. but like in previous measurement there is obvious improvement below 1Khz. I just got these speakers ready for my car. they have very small xmax, so I plan to cross them at 175hz.

Attachments

here are impedance measurements. they probably make more sence. it is better not to use screw through pole piece. you can just glue cap on top of pole, and ran tweeter wires through hole as intended. the thicker and closer copper cap to voice coil, the better results.

p.s. drilled hole in copper cap is required, so it becomes a ring 🙂

p.s. drilled hole in copper cap is required, so it becomes a ring 🙂

Attachments

MisterTwister,

A bit of a non standard EnABL pattern. Do you have a subjective evaluation to report?

Bud

A bit of a non standard EnABL pattern. Do you have a subjective evaluation to report?

Bud

I never tried these speakers in a box. I listened them only free air. I can't say that I noticed any difference. I guess I did it wrong way if you noticed that it's non standard. at least it looks cool 🙂

B20 mods

John,

have you finished your B20 modification with the tweeter on center pole (plug)? How did it change the sound of the driver? impressions?

If the results are good I might give it a shot.

Branko

John,

have you finished your B20 modification with the tweeter on center pole (plug)? How did it change the sound of the driver? impressions?

If the results are good I might give it a shot.

Branko

What kind of glue for the cone?

I am seriously thinking about mounting the tweeter on top of the plug but I do not feel like drilling through the center pole so I would like to just "thread it right through the cone like it is done on these http://www.parts-express.com/pe/showdetl.cfm?Partnumber=299-275

However, being completely new to this, I have no idea what kind of glue (sealer) to use to seal the wires in place (just like in the picture) or even what kind of wires to use. I read somewhere in these forums about using magnetic wire, but I have no clue what that means or where to get it or what is its retail name.

I would appreciate any input.

branko

I am seriously thinking about mounting the tweeter on top of the plug but I do not feel like drilling through the center pole so I would like to just "thread it right through the cone like it is done on these http://www.parts-express.com/pe/showdetl.cfm?Partnumber=299-275

However, being completely new to this, I have no idea what kind of glue (sealer) to use to seal the wires in place (just like in the picture) or even what kind of wires to use. I read somewhere in these forums about using magnetic wire, but I have no clue what that means or where to get it or what is its retail name.

I would appreciate any input.

branko

go to any radio shack and ask for magnet wire. You'll get a multispool pack for a few dollars. Works well for interconnects too.

thank you ZOBSKY,

I will have to make a trip to Radio Shack. Any ideas on what stuff is used to glue/seal the wires to the cone?

Brankovie

I will have to make a trip to Radio Shack. Any ideas on what stuff is used to glue/seal the wires to the cone?

Brankovie

If you are putting t he wire THROUGH the cone, magnet wire is probably not a great idea. It is the single strand wire coated with a varnish insulator that is often used for motor coils, inductors, electro-magnets, things like that. It isn't very flexible so will fatigue, although very fine diameters are more flexible. "Real" loudspeakers use "tinsel" leads through the cone, I believe they are metal coated fine plastic strips woven into a fine cable. You could find some on a cheap car stereo speaker maybe, going to the tweeter.

However, if the wire pair were twisted and came out of the baffle and arced over the cone to the tweeter, then there would be no movement, and magnet wire would be fine. And it could be pretty thin too, so very very unlikely to affect the sound in any way..

Might actually look cool..

Mark

However, if the wire pair were twisted and came out of the baffle and arced over the cone to the tweeter, then there would be no movement, and magnet wire would be fine. And it could be pretty thin too, so very very unlikely to affect the sound in any way..

Might actually look cool..

Mark

Variac said:If you are putting t he wire THROUGH the cone, magnet wire is probably not a great idea. It is the single strand wire coated with a varnish insulator that is often used for motor coils, inductors, electro-magnets, things like that. It isn't very flexible so will fatigue, although very fine diameters are more flexible. "Real" loudspeakers use "tinsel" leads through the cone, I believe they are metal coated fine plastic strips woven into a fine cable. You could find some on a cheap car stereo speaker maybe, going to the tweeter.

However, if the wire pair were twisted and came out of the baffle and arced over the cone to the tweeter, then there would be no movement, and magnet wire would be fine. And it could be pretty thin too, so very very unlikely to affect the sound in any way..

Might actually look cool..

Mark

my thoughts too

thanks guys

Thanks guys,

perhaps I will drill through the pole piece after all. I have made the plugs/tweeter holder assemblies out of a piece of wood (a post hole digger handle in the spot where it was 32 mm thick) and a piece of transparent amber colored plastic pipe from an old flag post from my father-in-law's garage. I drilled a hole through the wood. put 3 steel screws in it, warmed the pipe with a heat gun (i think I cut it 52 mm long), and slid the wood piece in it flush wit the edge. I soldered the wires to the tweeter, hated the pipe again, threaded the wires through the hole in the would part of the plug and inserted the tweeter into the pipe. Repeated the process on the other plug.

Now I have a Tweeter/plug that is one piece (sort of) and kind of retro looking (thanks to the color of the aged plastic pipe).

I took me one afternoon to do it but I am happy with the results.

Originally I was trying to set the tweeter in to the wood, but the diameters were too close and it was not feasable. I was just trying to avoid using tape to hold the tweeter to the plug, since it will be visible and I don't think it would look too good.

I will post pictures later.

Now is time for removing the dust cap and drilling (when I have time).

Brankovie

Thanks guys,

perhaps I will drill through the pole piece after all. I have made the plugs/tweeter holder assemblies out of a piece of wood (a post hole digger handle in the spot where it was 32 mm thick) and a piece of transparent amber colored plastic pipe from an old flag post from my father-in-law's garage. I drilled a hole through the wood. put 3 steel screws in it, warmed the pipe with a heat gun (i think I cut it 52 mm long), and slid the wood piece in it flush wit the edge. I soldered the wires to the tweeter, hated the pipe again, threaded the wires through the hole in the would part of the plug and inserted the tweeter into the pipe. Repeated the process on the other plug.

Now I have a Tweeter/plug that is one piece (sort of) and kind of retro looking (thanks to the color of the aged plastic pipe).

I took me one afternoon to do it but I am happy with the results.

Originally I was trying to set the tweeter in to the wood, but the diameters were too close and it was not feasable. I was just trying to avoid using tape to hold the tweeter to the plug, since it will be visible and I don't think it would look too good.

I will post pictures later.

Now is time for removing the dust cap and drilling (when I have time).

Brankovie

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Full Range

- Pioneer 8" B20