jzagaja said:el`Ol,

How we manage to change exciter position? I mean don't we destroy delicate coil centring?

They recommend pressing the exciter to the panel with the double-sided glue covered until the ideal position is found and remove the covers only for final placement. I glued one exciter on the panel and forgot to remove the cover of the voice coil. I had to remove the exciter and the result was that most of the glue of the feet was gone and one food went off spontaneously. So better don´t make any mistakes.

The positioning of the exciter as Dayton specifies only relates to a solid structure such as a table top, window🙂rolleyes: ), door etc.

When you start with ''free'' panles and suspensions, we are entering a different world where placement is not dictated by NXT principles as much.

When you start with ''free'' panles and suspensions, we are entering a different world where placement is not dictated by NXT principles as much.

is here someone who ever measured these kind of speakers? im folowing the thread for weeks now, but opinions are a bit vaag. then they sound incredible and the next day they suck. day after they sound superb again. also i find it hard to believe that a panel driven at a few spots can sound good and realistic although one exiter has to drive all this mass, wich is even wobbly as well. even the so called high end versionsposted on moons audio , are to be found total crap by most people that heard it on the shows.

Measurements mean nothing. The type and size of the panel will have VERY different measurements if you are talking about frequency response.

A normal small NXT panel(picture size) will have a frequency response from 100hz to 15khz on average.The sensitivity will be low because most only use a single exciter per speaker, thus the need for multiple exciters in ''serious'' versions.

The reason for some inconsistent opinions(including my own) is that they are source revealing/dependant and are affected by the way they are mounted, not mounted, positioned.....whatever.

The slightest error with a loose, hanging or touching wire at the back and you will hear it - no problem.

This is a very different breed of animal to your usual monkeys and lions at the zoo.

The reviews I have read have been mostly positive, not negative.

First impressions at ''shows'' has very little to do with the actual thing in your own home, connected with painstaking care to the correct source equipment and set up correctly.....this is critical with this type of panel loudspeaker.

The room plays a vital role in the resulting quality of sound so , it would be unlikely that a showroom would be anywhere near good enough to display the speaker's ability.

I have found out the hard way about all this and am still amazed to this day how a speaker like this can tell you instantly that you have made a correct or incorrect choice of cable/connector/amplifier, cd player and so on.

Yes, the Gatorfoam I use is not entirely rigid and can be ''wobbly'' as you say, but this does not stop 6 evenly spaced vertical exciters moving massive amounts of air from a gigantic surface, totally full range, no crossover - a real experience........believe me, or just believe that they are crap.....please yourself😉

A normal small NXT panel(picture size) will have a frequency response from 100hz to 15khz on average.The sensitivity will be low because most only use a single exciter per speaker, thus the need for multiple exciters in ''serious'' versions.

The reason for some inconsistent opinions(including my own) is that they are source revealing/dependant and are affected by the way they are mounted, not mounted, positioned.....whatever.

The slightest error with a loose, hanging or touching wire at the back and you will hear it - no problem.

This is a very different breed of animal to your usual monkeys and lions at the zoo.

The reviews I have read have been mostly positive, not negative.

First impressions at ''shows'' has very little to do with the actual thing in your own home, connected with painstaking care to the correct source equipment and set up correctly.....this is critical with this type of panel loudspeaker.

The room plays a vital role in the resulting quality of sound so , it would be unlikely that a showroom would be anywhere near good enough to display the speaker's ability.

I have found out the hard way about all this and am still amazed to this day how a speaker like this can tell you instantly that you have made a correct or incorrect choice of cable/connector/amplifier, cd player and so on.

Yes, the Gatorfoam I use is not entirely rigid and can be ''wobbly'' as you say, but this does not stop 6 evenly spaced vertical exciters moving massive amounts of air from a gigantic surface, totally full range, no crossover - a real experience........believe me, or just believe that they are crap.....please yourself😉

I've found foam-x or kapa quite cheap EUR 10,00/m2. Looks similar to gatorfoam. 10mm thickness is 0.85kg/m2.

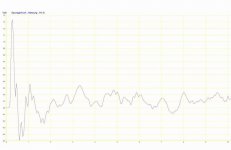

I have made some measure on a starbass driver, another kind of DML

http://eazy-world.com/images_et_son/enceintes/ENC-STARBASS.htm

here is a wav.zip attached, it's a convolution of logsweep, so you can examine amplitude response, harmonic distorsion and phase and so on. The wav has been resampled to 44/8bits to fit in a small file

The dip at 10kHZ comes from the standing waves in the thick board I used, (my computer board)

I should get 10 pairs of DAEX25 next week...

more to come

POL

http://eazy-world.com/images_et_son/enceintes/ENC-STARBASS.htm

here is a wav.zip attached, it's a convolution of logsweep, so you can examine amplitude response, harmonic distorsion and phase and so on. The wav has been resampled to 44/8bits to fit in a small file

The dip at 10kHZ comes from the standing waves in the thick board I used, (my computer board)

I should get 10 pairs of DAEX25 next week...

more to come

POL

Attachments

Hi Pol,

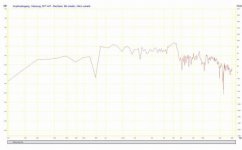

ARTA + Photoshop. Noise taken before main pulse. If you examine this wav file you will see harmonic distortion as a main pulse and echoes so I truncated in Adobe Audition.

Regards,

Jack

ARTA + Photoshop. Noise taken before main pulse. If you examine this wav file you will see harmonic distortion as a main pulse and echoes so I truncated in Adobe Audition.

Regards,

Jack

Jzagaja

ok I thought it was ARTA but I did not get the fotoshop trick

in this .wav you find a main pulse at the right, this is the response

and a suite of smaller pulses to the left, those are not echoes

but harmonics (distorsion), from this transducer (and microphone)

This is related to the FARINA's method of capturing a logsweep

and doing a convolution with the inverse of logsweep.

http://www.melaudia.net/zdoc/sweepSine.PDF

This is by far the best, easiest and more complete method

of one shot measurment on a transducer or gear.

POL

http://pagesperso-orange.fr/pol.bct/exemples/DIY.htm

ok I thought it was ARTA but I did not get the fotoshop trick

in this .wav you find a main pulse at the right, this is the response

and a suite of smaller pulses to the left, those are not echoes

but harmonics (distorsion), from this transducer (and microphone)

This is related to the FARINA's method of capturing a logsweep

and doing a convolution with the inverse of logsweep.

http://www.melaudia.net/zdoc/sweepSine.PDF

This is by far the best, easiest and more complete method

of one shot measurment on a transducer or gear.

POL

http://pagesperso-orange.fr/pol.bct/exemples/DIY.htm

ARTA can do one shot sine sweep with distortion plot so you don't have to play a Russian roulette with Aurora plug-ins 🙂

jzagaja..........exactly what have you measured in your frequency response?😕.......the STARBASS driver?

If so, we have something similar in Australia............sounds like crap, no matter where you put it.

If so, we have something similar in Australia............sounds like crap, no matter where you put it.

Since this driver operates modal above 800 Hz,

it would be useful to average over several

microphone positions.

As for all DML speakers a single on axis microphone

position does not tell enough to estimate the behaviour

of the driver. Frequency response varies even with small

changes in angle, which is typical for DML.

When tuning the driver to be nearly flat above 5Khz,

it sounds "overbrilliant" and "nasty".

Auditively the driver sounds rather good by now,

the presence region is not as natural as it should be.

There is still a peak around 5Khz, which can be smoothed

easily using a notch, which i omitted for the measurement.

But i heard a lot of conventional fullrangers which sound worse,

and need more amounts of compensation ...

it would be useful to average over several

microphone positions.

As for all DML speakers a single on axis microphone

position does not tell enough to estimate the behaviour

of the driver. Frequency response varies even with small

changes in angle, which is typical for DML.

When tuning the driver to be nearly flat above 5Khz,

it sounds "overbrilliant" and "nasty".

Auditively the driver sounds rather good by now,

the presence region is not as natural as it should be.

There is still a peak around 5Khz, which can be smoothed

easily using a notch, which i omitted for the measurement.

But i heard a lot of conventional fullrangers which sound worse,

and need more amounts of compensation ...

As shown DML with added mass merely alters the distribution of modes because modal density in DML is high and in BMR is low.

Hi jzagaya,

you have shown interesting investigations.

As far as i understand, there is a main problem which is

common to all transducers which rely on propagation of

bending waves:

Low modal density at the bottom end of operation. Low modal

density of a DML is nearly a synonym for "low quality" in the

frequency range under question.

I can identify the following strategies to circumvent that

Problem in current (commercial, established) systems:

1: Balance the modes by adding mass (and optional damping),

and align the diaphragm to have usable modes for balancing

-> "BMR"

2 a: Avoiding the range of low modal density

2 b: Making the diaphragm (excited panel) large enough

to have high modal density in the low frequency range.

---

2a Leads to multiway systems, incorporating conventional

dynamic bass drivers. A very pragmatical way to go IMO,

which may lead to good results, when implemented properly.

2b Leads to very large sized panels, causing the well known

acceptance problems (at least in the "non audiophile"

rest of the world ).

IMO there would be a third strategy:

Think about increasing the modal density at low frequencies,

without increasing the diaphragm ...

When going this way solely by searching for appropriate

materials, we end up with materials that have low speed

of wave propagation leading to low efficiency.

Kind regards

you have shown interesting investigations.

As far as i understand, there is a main problem which is

common to all transducers which rely on propagation of

bending waves:

Low modal density at the bottom end of operation. Low modal

density of a DML is nearly a synonym for "low quality" in the

frequency range under question.

I can identify the following strategies to circumvent that

Problem in current (commercial, established) systems:

1: Balance the modes by adding mass (and optional damping),

and align the diaphragm to have usable modes for balancing

-> "BMR"

2 a: Avoiding the range of low modal density

2 b: Making the diaphragm (excited panel) large enough

to have high modal density in the low frequency range.

---

2a Leads to multiway systems, incorporating conventional

dynamic bass drivers. A very pragmatical way to go IMO,

which may lead to good results, when implemented properly.

2b Leads to very large sized panels, causing the well known

acceptance problems (at least in the "non audiophile"

rest of the world ).

IMO there would be a third strategy:

Think about increasing the modal density at low frequencies,

without increasing the diaphragm ...

When going this way solely by searching for appropriate

materials, we end up with materials that have low speed

of wave propagation leading to low efficiency.

Kind regards

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Planars & Exotics

- PIEZO NXT type panel