Down to the end of making the pensils. I gave my friend the published dimension for the driver cutout: 139mm. The hole, as measured with calipers yesterday came out at just under 140mm. Awesome....not! The pictures attached show a basket width of 136mm. I measured the driver and the gasket of the Alpair 10p.

Has anyone else seen this? I suggested to Mark's employee to look into it....

I just went and measured one. My calipiers don't have long enuff jaws to get a real accurate measure but 138+ mm would be my guess. The holes in the FHXL here are 139mm.

dave

The gasket was laid flat and measured...136mm. Anyways, a supra baffle may need to be fitted to cover the 'mistake' of a 140mm hole not necessarily to improve on wavelaunch or BS.

Stuffing will certainly be a lengthy experimentation. I have stuffed other speakers I have built so I'm intimately aware of the dramatic changes available. The removable back is excellent for this.

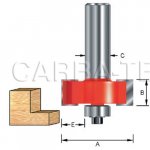

Chamfering will need to be done somehow. My friend overlooked two important details: speaker rebate and the chamfer...sheesh.

Stuffing will certainly be a lengthy experimentation. I have stuffed other speakers I have built so I'm intimately aware of the dramatic changes available. The removable back is excellent for this.

Chamfering will need to be done somehow. My friend overlooked two important details: speaker rebate and the chamfer...sheesh.

Last edited:

Just to add, the oval supra-baffle is Bob's signature look... you can try a simpler SB like one which is a circular in shape with round/chamfered outer edges.

Zman01, I have been sketching today and think I will be trying a rectangular based truncated pyramid that extends to the top and side edges. The bottom edge will match the top edge. Perhaps for a future build I will try a whole front baffle that is one large tapering pyramid.

As earlier suggested zman01 a rasp can be used to enlarge the hole but that leaves you with the rebate issue.

My suggestions would be with router and circle jig in hand ...

1) Cut another circle the same diameter as the baffle hole diameter and use it as a plug and glue it in position. Then use a 2 part liquid epoxy to fill the rebate until it is slightly proud of the surface, sand, then cut the correct size hole.

2) Almost the same as above but cut a hole in the baffle which includes the rebate then cut a new circle and fill the hole, (Position piece of wood in hole to accept centre pin of jig ) then cut the correct sized hole.

3) Make a rectangular cut in the baffle removing the hole. Remove it from the enclosure then make a "patch" with another rectangular piece and glue in position and cut the hole as required.

Its no big deal to correct.

All you need is a router circle jig

I have done all the above, (3) is easiest.

Hope that helps.

My suggestions would be with router and circle jig in hand ...

1) Cut another circle the same diameter as the baffle hole diameter and use it as a plug and glue it in position. Then use a 2 part liquid epoxy to fill the rebate until it is slightly proud of the surface, sand, then cut the correct size hole.

2) Almost the same as above but cut a hole in the baffle which includes the rebate then cut a new circle and fill the hole, (Position piece of wood in hole to accept centre pin of jig ) then cut the correct sized hole.

3) Make a rectangular cut in the baffle removing the hole. Remove it from the enclosure then make a "patch" with another rectangular piece and glue in position and cut the hole as required.

Its no big deal to correct.

All you need is a router circle jig

I have done all the above, (3) is easiest.

Hope that helps.

Hey Andrew

The hole is about 4 mm too big. I think number 3 is similar to my idea of a supra baffle. This additional piece will be solid wood, with the rebate and correct hole size in it.

The hole is about 4 mm too big. I think number 3 is similar to my idea of a supra baffle. This additional piece will be solid wood, with the rebate and correct hole size in it.

35mm looks a bit on the thicker side...

Btw, have you tried placing the drivers on the cut-out and seeing how the holes line up. 3-4mm more on the cut-out diameter is not a big deal unless the the seal is compromised and screws don't get a decent purchase into the wood.

Btw, have you tried placing the drivers on the cut-out and seeing how the holes line up. 3-4mm more on the cut-out diameter is not a big deal unless the the seal is compromised and screws don't get a decent purchase into the wood.

Zman, the hole is too big for the gasket and there's not enough real estate for screws. ( I actually haven't decided on screws yet. Back home I could find "MDF Screws"...)

I'm considering supra baffle A) in my sketch. The driver will be flush mounted.

35mm may be a little thick. At this thickness the angle on the sides is less than 45 degrees and the rake top and bottom is much less than 45 degrees.

Less than 35 mm the angles start to become very shallow, especially above and below the driver; at this point I'd consider a frisbee shape.

I'm considering supra baffle A) in my sketch. The driver will be flush mounted.

35mm may be a little thick. At this thickness the angle on the sides is less than 45 degrees and the rake top and bottom is much less than 45 degrees.

Less than 35 mm the angles start to become very shallow, especially above and below the driver; at this point I'd consider a frisbee shape.

Last edited:

3-4mm more on the cut-out diameter is not a big deal unless the the seal is compromised and screws don't get a decent purchase into the wood.

From checking our work, it is not that far out… measuring the existing cutout in one of our FHXL and in a set of Pensil10.3 is 139mm… Chris uses a dead A10 basket for all his fitting.

The gasket does measure 136.5/137 mm.

Faithintruth, as Zia suggests, try fitting the driver in the hole and see.

dave

Faith- I almost always use only the socket head screws supplied with the drivers - AFAIC, they're more than adequate for the job. Sure, they're longer than necessary when using a single layer of 18mm plywood, but I welcome anyone to point to rigorous testing/measurements that prove the extra length protruding through the rear of mounting panel causes any deleterious effect.

I'd also agree with Zia says about 35mm being excessive - if for no other reason that if fully that thickness over the entire panel, chamfering the rear side of opening would be even more critical and tricky / time consuming

That said, I do rather like the aesthetic of option A

I'd also agree with Zia says about 35mm being excessive - if for no other reason that if fully that thickness over the entire panel, chamfering the rear side of opening would be even more critical and tricky / time consuming

That said, I do rather like the aesthetic of option A

Thanks for the input Dave, Chris, Jimbro, Larry

I'm thinking 35mm is a little much....maybe just 25mm will be enough and go nuts with a rasp...could be fun. Cutting a very acute angle with the table saw will involve a little vertical jig...hmmm

I had a friend cut the holes for me. I told 140 would be fine....he took it upon himself to go to 142 thinking I hadn't already added wiggle room. No dice on mounting. The seal will be dodgy as will the screws.

Larry. ..interesting to try a 90 degree rotation. I wanted to keep the supra baffle inside the cabinet's outer dimensions....more hmmm....

I'm thinking 35mm is a little much....maybe just 25mm will be enough and go nuts with a rasp...could be fun. Cutting a very acute angle with the table saw will involve a little vertical jig...hmmm

I had a friend cut the holes for me. I told 140 would be fine....he took it upon himself to go to 142 thinking I hadn't already added wiggle room. No dice on mounting. The seal will be dodgy as will the screws.

Larry. ..interesting to try a 90 degree rotation. I wanted to keep the supra baffle inside the cabinet's outer dimensions....more hmmm....

139 leaves just a bit of wiggle room, 142 would not leave much if anything for the screws they are very close to the basket legs.

dave

dave

faithintruth,

Since the supra-baffle looks like the only option now, I would suggest that you make the hole a bit bigger and rectangular in shape (option 3 suggested by Andrewbee in post #126). Keep enough material on the baffle for the Supra-baffle to get attached though 🙂. Use a gasket on the SB.

Since the supra-baffle looks like the only option now, I would suggest that you make the hole a bit bigger and rectangular in shape (option 3 suggested by Andrewbee in post #126). Keep enough material on the baffle for the Supra-baffle to get attached though 🙂. Use a gasket on the SB.

I would suggest that you make the hole a bit bigger and rectangular in shape

Here is a snapshot of the FH3 sB drawing that will show you how big we made the hole in the baffle.

dave

Attachments

- Home

- Loudspeakers

- Full Range

- Pensils for Alpair 10.3 & Alpair 10p