Hi Ivan,

What was the over sampling rate of these recordings?

Hi Ryan,

CDDA->HQP-> 176.4kHz (Sinc-S)

No, it is in my plans only.Do you have room treatment?

Can you tell us more about your system?

Well, it is easier to show. I have another larger room and it sounds better there for sure, but I prefer to have access to it 24/7 rather than negotiating with my household every time I need to check this or that. So this tiny room (~9 sq.m.) is the technical room at the same time.

Video (xiaomi A3) is exact the moment of the record takened by ribbon-mic, showned on previous post.

Shared album - ???? ???? - Google Photos

I do not limiting myself by my system only. I have access if needed (and time to time it is really needed) to many "cool enough" systems of my friends/familiar as well.

Last edited:

Thanks for sharing the photos, some interesting systems there.

What drivers do you have on the open baffle? Did you use these to record the bass demo track? (LF_sample_160.mp4)

What drivers do you have on the open baffle? Did you use these to record the bass demo track? (LF_sample_160.mp4)

Panels are the NXT technology of some russian guys. It uses so called shakers. Dayton may be? I don't know. Yes, LF_sample_160.mp4 is exactly what is shown in video, smartphones are simply can't record LF as professional mics.

Here is what can happens if the mic is in the room resonance area. Sorry for clips occured. Same system.

View attachment How_Deep.mp4

View attachment How_Deep.mp4

Nice gear for listening 🙂

Which combination was recorded with Nils Lofgren? If i read correctly first version is with phone second with mic ...connected and recorded to..?

Which combination was recorded with Nils Lofgren? If i read correctly first version is with phone second with mic ...connected and recorded to..?

Hi Davorin,

Yes, it's correct. I have shown how it was connected/recorded, watch the video in post #581 please.

Yes, it's correct. I have shown how it was connected/recorded, watch the video in post #581 please.

That is some impressive audio stuff you’ve got!

Can you also make transformers with Finemet core material?

I would be interested in top performing transformers for a balanced RyanJ D3 TDA1541A IV stage.

Can you also make transformers with Finemet core material?

I would be interested in top performing transformers for a balanced RyanJ D3 TDA1541A IV stage.

That is some impressive audio stuff you’ve got!

Can you also make transformers with Finemet core material?

Hi Stefan.

Yes, there was some comparisons from TioFrancotirador, read his posts in this thread please.

I would be interested in top performing transformers for a balanced RyanJ D3 TDA1541A IV stage.

Regarding the the i/v stage for TDA1541A (or other rare DACs from the past), I reminding again, you will never hear "Hi-End" sound form them until you goes down the 20 ohms. The showned tracks are done at 1.4 Ohm of i/v. I believe it is very far from adequate i/v stages comparison, when you trying to get the sound at such a huge values of the i/v resistor like 50 or even more Ohms impedance seen by DAC itself.

To all who uses tube stages in their systems.

Do you know "tube guys" why is your tube stages sounds best at so high input levels like 2, 3 or even 4 volts of input signal? Because the input impedance of your preamps/amps is TOO high to transfer what is really matters, the signal power! Not the current or voltage, but the wattage, the both together: I*A.

Thus instead of beating/hiting the DAC itself by irrationaly high load impedance (i/v) trying to get the high signal voltage (noise level is horribly high), much better approach is to:

1) decrease the output impedance after i/v stage;

2) decrease the input impedance of the preamp/amp.

I have 14 Ohm of the DAC output impedance and 300 Ohm of the input impedance of amplifier. Of course it is not possible to do for the DAC, without active components like jfet buffer for example (voltage amplification is less than 1). Another really well sounding DACs are these which uses trafos+tubes with high mu of voltage amplification. BUT I prefer to use a better (as for me) approach - to use another one transformer for voltage amplification+jfet buffer to get suitable voltage swing at lower output impedance. Transistors for voltage amplification are just faulty for my ears, no matter the technology (fets, bipolar, silicon, germanium...), but the current amplification on jfets is just a briliant for sound.

Here is the direct recording from my DAC to ADC using 3!!! trafos in series: TDA1541A->1.5Ohm->1:15trafo||4.7k->buffer->1:8trafo||4.7k->buffer->RCA_cable->1:8trafo||10k->ADC1.

View attachment Keith Don't Go_3trafos.mp4

View attachment Keith Don't Go_3trafos.mp4

Hi Stefan.

Yes, there was some comparisons from TioFrancotirador, read his posts in this thread please.

Regarding the the i/v stage for TDA1541A (or other rare DACs from the past), I reminding again, you will never hear "Hi-End" sound form them until you goes down the 20 ohms. The showned tracks are done at 1.4 Ohm of i/v. I believe it is very far from adequate i/v stages comparison, when you trying to get the sound at such a huge values of the i/v resistor like 50 or even more Ohms impedance seen by DAC itself.

To all who uses tube stages in their systems.

Do you know "tube guys" why is your tube stages sounds best at so high input levels like 2, 3 or even 4 volts of input signal? Because the input impedance of your preamps/amps is TOO high to transfer what is really matters, the signal power! Not the current or voltage, but the wattage, the both together: I*A.

Thus instead of beating/hiting the DAC itself by irrationaly high load impedance (i/v) trying to get the high signal voltage (noise level is horribly high), much better approach is to:

1) decrease the output impedance after i/v stage;

2) decrease the input impedance of the preamp/amp.

I have 14 Ohm of the DAC output impedance and 300 Ohm of the input impedance of amplifier. Of course it is not possible to do for the DAC, without active components like jfet buffer for example (voltage amplification is less than 1). Another really well sounding DACs are these which uses trafos+tubes with high mu of voltage amplification. BUT I prefer to use a better (as for me) approach - to use another one transformer for voltage amplification+jfet buffer to get suitable voltage swing at lower output impedance. Transistors for voltage amplification are just faulty for my ears, no matter the technology (fets, bipolar, silicon, germanium...), but the current amplification on jfets is just a briliant for sound.

Hi,

I have read the comparison you referenced and he prefers your transformer over a Finemet transformer. I cannot judge this verdict because I do not know the other variants of both transformers (winding technique and winding ratio), I do not know how he tested, with what kind of system (what is his reference) and how his overall listening experience is.

I just wondered if you could get your hands on finemet core material and design a transformer with it.

I also do not understand what you mean with the IV stage problems of the old TDA1541A. I use an IV resistor of 27ohms with a tube stage after the resisitor. The dac sees a low impedance so it wil transfer I into V with low distortion.

A tube stage for amplifying this low level signal is nothing special IMHO. There are numerous phono stage designs with tubes for MC and MM cartridges.

The best way for MC is even a step up transformer with following tube stage.

So I would guess the same can be done with this dac. But maybe I am missing something 🙁

Hi,Hi,

I have read the comparison you referenced and he prefers your transformer over a Finemet transformer. I cannot judge this verdict because I do not know the other variants of both transformers (winding technique and winding ratio), I do not know how he tested, with what kind of system (what is his reference) and how his overall listening experience is.

OK.

OK.Well... I hope, you understand that Finemet is just a brand name of Hitachi Metals Ltd material. I do not see any reason to use exact this brand name as there are japanese masters available I suppose like Teramoto for example. Take a look for prices on their transformers BTW too. 😉I just wondered if you could get your hands on finemet core material and design a transformer with it.

It depends on what you call low distortion and from your own preferences. But 27 Ohms is OK I think. Step-up transformer will allow to decrease i/v even more anyway. I remind best i/v for DAC is ZERO.I also do not understand what you mean with the IV stage problems of the old TDA1541A. I use an IV resistor of 27ohms with a tube stage after the resisitor. The dac sees a low impedance so it wil transfer I into V with low distortion.

Sure, I just shared my experience of using trafos/bufs cascades instead. It is up to user.A tube stage for amplifying this low level signal is nothing special IMHO. There are numerous phono stage designs with tubes for MC and MM cartridges.

The best way for MC is even a step up transformer with following tube stage.

No, you didn't!So I would guess the same can be done with this dac. But maybe I am missing something 🙁

Last edited:

Hi,

I know Fimenet is a trade mark of Hitachi. They claim it is a very high quality amorphous core material with some specific quality that can be advantageous for our audio signal transfer.

I use f.i. nickel, permalloy and amorphous core transformers in my amplifiers and recognize the differences, that is why I have the feeling that this Finamet material can be a very nice choice for the low level signals your products are used for.

I have no clue if there are other suppliers of this material. Is Teramoto just a brand that is using the Hitachi core materials under their own brand name for instance?

I think however that production of such material is expensive and only big companies with big offset market can produce such stuff. So it would not surprise me if all Finamet material in the world is produced at one factory and used under other brand names.

Regarding the prices of Teramoto and such: I have been in the audio business and know that the asking price of a product, in a lot of cases, is not related to the costs of the product or the final quality! In the High-end audio market there is a lot of crap put a nice case that is sold with some marketing and a nice brand name for big bucks to dumb people with money 😀

So are you willing to use this material?

I know Fimenet is a trade mark of Hitachi. They claim it is a very high quality amorphous core material with some specific quality that can be advantageous for our audio signal transfer.

I use f.i. nickel, permalloy and amorphous core transformers in my amplifiers and recognize the differences, that is why I have the feeling that this Finamet material can be a very nice choice for the low level signals your products are used for.

I have no clue if there are other suppliers of this material. Is Teramoto just a brand that is using the Hitachi core materials under their own brand name for instance?

I think however that production of such material is expensive and only big companies with big offset market can produce such stuff. So it would not surprise me if all Finamet material in the world is produced at one factory and used under other brand names.

Regarding the prices of Teramoto and such: I have been in the audio business and know that the asking price of a product, in a lot of cases, is not related to the costs of the product or the final quality! In the High-end audio market there is a lot of crap put a nice case that is sold with some marketing and a nice brand name for big bucks to dumb people with money 😀

So are you willing to use this material?

Last edited:

Yes. Hithachi cores are new and obtainable. For some steady and constant quality production it is a choice.

Personaly I prefer M types Siemens style (probably made by VAC?) high permaloy laminations. But they are close to unobtainable and in case of find some that is not so big quanitities 🙁 for few transformers only.

And they are hard to form the core. Thick, sensitive and M types. Also is harder to find with smaller gap. Byt for my opp they are the best sounding (with propper implementation of windings and all additional construction elements.)

Personaly I prefer M types Siemens style (probably made by VAC?) high permaloy laminations. But they are close to unobtainable and in case of find some that is not so big quanitities 🙁 for few transformers only.

And they are hard to form the core. Thick, sensitive and M types. Also is harder to find with smaller gap. Byt for my opp they are the best sounding (with propper implementation of windings and all additional construction elements.)

Finemet is not amorphous material.Hi,

I know Fimenet is a trade mark of Hitachi. They claim it is a very high quality amorphous core material with some specific quality that can be advantageous for our audio signal transfer.

I cannot know for sure and of course only they themselves know the answer, but I have not seen any mention of the other material usage within their products.I have no clue if there are other suppliers of this material. Is Teramoto just a brand that is using the Hitachi core materials under their own brand name for instance?

No, it is not so. There are manufacturers in Europe, Russia and China as well.I think however that production of such material is expensive and only big companies with big offset market can produce such stuff. So it would not surprise me if all Finamet material in the world is produced at one factory and used under other brand names.

So are you willing to use this material?

I see absolutely no point for this, since the initial data I need to know about cores is in their datasheet. Nothing extraordinary I see in their specs compared to what I use. All the futher sucess depends on the practical implementation and usage. In this terms most likely it will be Teramoto who is the measure of quality when using it's material in the field of audio. I mean there is hardly a more authoritative opinion in the framework of audio than Teramoto, which Hitachi will refer to. If they will refer at all, of course. I hope you understand that no one has ever made cores specifically for audio. Audio is just a fortunate by-product of these cores and materials. These materials were created for energetics, however, a similar story with radio lamps, and indeed with almost all other radio components. Well, you know I suppose the circumstances...

But what I am disagree... In this context, I do not like at all how ineptly uses all the advantages of such a unique core material for low-signal transformers in Teramoto products for example. Cutting such a core is just a mistake. When I take the naked core in my hand, it is very flexible, like it is made from a jelly. I mean it is impossible to tight the two pieces together with precise accuracy without stressly squizzing it... Gapped, strong big trafos/chokes for big currents/swings, working at a constant current offsets (tubes interstage, output trafos) - is just another story.

That is why I am able to see competitors for my technique/trafos within the toroidal transformers only. It is not Teramoto at least. In this terms winding in automatic mode (like Teramoto, for example) using my hand winding technique simply won't work. Well, unless you start using something very similar to two human hands. The cost and complexity of such a machine will clearly be beyond the scope of the DIY I believe.

Last edited:

Hi Ivan,

I now understand that you do not feel the need to use the Finemet material. 😉

A note however that it IS an amorphous material as stated here: FINEMET Transformer

“ FINEMET® is Nanocrystalline soft magnetic metal which is special amorphous metal. It's phase characteristics is far better than conventional core material such as Ni and Co-based amorphous metal.”

I now understand that you do not feel the need to use the Finemet material. 😉

A note however that it IS an amorphous material as stated here: FINEMET Transformer

“ FINEMET® is Nanocrystalline soft magnetic metal which is special amorphous metal. It's phase characteristics is far better than conventional core material such as Ni and Co-based amorphous metal.”

Hi Stefan. Well, I haven't seen such interpretation within the metal manufacturers (amorphous usually mentioned as a predecessor). Teramoto as a user is free to call it how they want/feel to be understanded by customers I suppose.

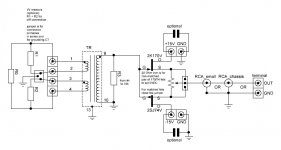

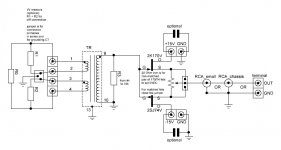

Here is the version of PCB using jfet buffers. SE output ONLY.

Some tips:

1) To have quick access to both PCB sides (for jumpers re-settings, components resolderings, etc.) it is better to have possibility of transformers dismounting using the receptacles:

5391-0-15-15-07-27-10-0 Mill-Max | Mouser Europe

2) M3 spacers 4mm in height for proper gap between PCB components and transformer plate will be needed to place as well.

3) Better to use a matched pair of 2SK170V/2SJ74V (output impedance better, no offset) instead of using the trimmer between transistors Sources (for set zero output offset).

4) For better thermal/current simmetry stability it is better to tight this pair of transistors together using a copper foil and/or small radiator.

5) The PSU quality is VERY important. Based on my experience I highly recommend to use UCs or/and battery PSU for powering jfets.

All the corresponding files (CAD, gerbers) can be found here:

View attachment jfet.zip

Some tips:

1) To have quick access to both PCB sides (for jumpers re-settings, components resolderings, etc.) it is better to have possibility of transformers dismounting using the receptacles:

5391-0-15-15-07-27-10-0 Mill-Max | Mouser Europe

2) M3 spacers 4mm in height for proper gap between PCB components and transformer plate will be needed to place as well.

3) Better to use a matched pair of 2SK170V/2SJ74V (output impedance better, no offset) instead of using the trimmer between transistors Sources (for set zero output offset).

4) For better thermal/current simmetry stability it is better to tight this pair of transistors together using a copper foil and/or small radiator.

5) The PSU quality is VERY important. Based on my experience I highly recommend to use UCs or/and battery PSU for powering jfets.

All the corresponding files (CAD, gerbers) can be found here:

View attachment jfet.zip

Last edited by a moderator:

- Home

- Vendor's Bazaar

- Output transformers for DACs