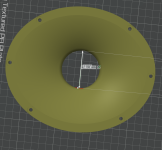

Took a lot of filling and sanding and filling and sanding, but I'm happy with the results on this waveguide. They're sadly probably going to sit in my driver closest for some time until money isn't scarce. Might just see if someone on here wants them.

wafflesomd,

Good job - finish looks very nice, and the look is transformed from the picture of the units shared in post #2496.

Good job - finish looks very nice, and the look is transformed from the picture of the units shared in post #2496.

Realy nice !

How did you do the last finish ?

Just a simple spray can of rustoleum flat enamel. It's my go to for making speaker stuff black.

Same stuff on a big 3 way baffle. Seems to always come out pretty nice and they sell it in comically large can if you need big coverage. I tend to do quite a few light coats. Don't want to over do it and get runs.

Pretty nice. It seems to not be available in Eu. Just need to find an other brand that works well ...

hi augerpro,

We are waiting for your DIY model 1 and model 2 speaker designs with great excitement. Can we get information about the latest status of the project?

We are waiting for your DIY model 1 and model 2 speaker designs with great excitement. Can we get information about the latest status of the project?

I spent last weekend finishing the boxes and this weekend I'll put all the drivers in. I should be able to get my measurements during this time also and begin crossover work. In the case of the model 2, I already have the crossover done with the roundovered baffle, but I made a box with chamfers and want to see if that will improve the crossover complexity.

I'm interested in testing out waveguides for a 2 inch broadband driver, one to be crossed with a 6 and the other with 8 inch. I scaled X and Y to 118 percent on the satori 6 inch for a mouth opening diameter to clear the rubber surround. I can do the same with the 8 inch Satori. The broadband doesn't need a projection just like the satori.

Any issues with this plan or is there more involved? Could it work reasonably well?

Any issues with this plan or is there more involved? Could it work reasonably well?

Attachments

Might work if you are lucky. The screw holes are going to be oversized.

I printed one and mounted the 2 inch driver and it measured poorly! That plan is cancelled until I can design a waveguide from scratch

Maybe I should try to scale up uniform and accept the extra offset

Maybe I should try to scale up uniform and accept the extra offset

Last edited:

Measuring all 4 prototypes today. Verifying the baffle diffraction model and whether roundover or chamfer works best. I tried my best match the baffle diffraction to the native response of the drivers - mostly the woofer. Model 1 is Satori textreme and Be, Model 2 is SB "ceramic", Model 3 is SB's entry level drivers, and Model 5 is Scanspeak Discovery and either SB26STAC or CAT308. All tweeters on waveguides of course.

Yes, that's the one.

Looks like I nailed a good waveguide profile (2 actually) for the Morel CAT308/378 right off the bat!

Looks like I nailed a good waveguide profile (2 actually) for the Morel CAT308/378 right off the bat!

Hey Brandon,

Will you be trying the new SB17NRX2L35-4?

The bigger motor results in slightly higher sensitivity (~2dB); but the SB17CAC has not (yet) been released with the new motors.

But for DIYers, the motors are interchangeable.

Compare: OLD DRIVERS β = BL^2 / Re

4 ohm ; 8 ohm β = 7.12 ; 4.88

to NEW DRIVERS

4 ohm, 8 ohm β = 13.42; 10.78

No improvements have been made to the suspension, so no improvement with significant cone excursion eg. sub-bass.

But if you're planning subwoofer crossing around 120Hz, no improvements in suspension needed, really.

If you'd like to collaborate, just let me know...

Will you be trying the new SB17NRX2L35-4?

The bigger motor results in slightly higher sensitivity (~2dB); but the SB17CAC has not (yet) been released with the new motors.

But for DIYers, the motors are interchangeable.

Compare: OLD DRIVERS β = BL^2 / Re

4 ohm ; 8 ohm β = 7.12 ; 4.88

to NEW DRIVERS

4 ohm, 8 ohm β = 13.42; 10.78

No improvements have been made to the suspension, so no improvement with significant cone excursion eg. sub-bass.

But if you're planning subwoofer crossing around 120Hz, no improvements in suspension needed, really.

If you'd like to collaborate, just let me know...

Last edited:

I didn't plan on using the new ones. This project is already about 2 years behind! Are these new drivers replacing the older ones? Or just higher sensitivity/less bass tradeoff for those who want that?

My guess is as good as yours. At the end of the day it's about sales- what's the point of releasing something if no-one buys it.

And for the traditional SB17 range, the NRX are the most popular of the bunch, so my guess is they launched with that cone.

People are a bit allergic to hard cones, IMHO, due to historical reasons.

A) Who could blame them when they had difficulties measuring = difficult time doing crossovers for drivers with high Q resonances; not being able to simulate via software = not being able to do series notch filters; not being able to measure = not being able to verify etc Catch 22. The wandering breakup modes and slight imprecision of inductors/caps don't help to strike the resonance.

B) 2 decades ago I help some friends build this speaker: Zaph's All Metal System

It was OK but I never did quite enjoy it in the long term ie. >10 mins listening.

This was long before I had any measurement equipment to verify what I built.

According to John, here's what his crossover was supposed to do:

This is what it actually did:

Our friend John accepted it, saying "...the notch does not take the extra high frequency garbage out as much as expected, but it's still 30 dB down and essentially off the radar"

(bold: my emphasis)

I finally got a chance to measure my friends- this is what my crossover actually did

only 22dB down !!!

A far cry from the original 40dB as planned.

22dB is not far off what Joe D managed on his Thor kit for SEAS, using the W18E001 drivers. (7Khz resonance is 23dB down; page 20, Figure 14)

And yes, of course I can correct it now by fine tuning the inductor and/or capacitor in the parallel notch.

But that actually takes measurements to verify.

A DIYer without measurement equipment could be excused for wondering why hard cone drivers suck (or has "extra detail" ?)

These days, we know a series notch filter is better (because it also takes care of H3), and therefore allows us to cross higher (unlike the late SL's insistence of crossing the W22EX and jkrutke's insistence of crossing the L18RNX/P at 1/3 the resonant frequency), and getting a better directivity match (if we're not using a waveguide). But it still takes measurement equipment.

And for the traditional SB17 range, the NRX are the most popular of the bunch, so my guess is they launched with that cone.

***

People are a bit allergic to hard cones, IMHO, due to historical reasons.

A) Who could blame them when they had difficulties measuring = difficult time doing crossovers for drivers with high Q resonances; not being able to simulate via software = not being able to do series notch filters; not being able to measure = not being able to verify etc Catch 22. The wandering breakup modes and slight imprecision of inductors/caps don't help to strike the resonance.

B) 2 decades ago I help some friends build this speaker: Zaph's All Metal System

It was OK but I never did quite enjoy it in the long term ie. >10 mins listening.

This was long before I had any measurement equipment to verify what I built.

According to John, here's what his crossover was supposed to do:

This is what it actually did:

Our friend John accepted it, saying "...the notch does not take the extra high frequency garbage out as much as expected, but it's still 30 dB down and essentially off the radar"

(bold: my emphasis)

I finally got a chance to measure my friends- this is what my crossover actually did

only 22dB down !!!

A far cry from the original 40dB as planned.

22dB is not far off what Joe D managed on his Thor kit for SEAS, using the W18E001 drivers. (7Khz resonance is 23dB down; page 20, Figure 14)

And yes, of course I can correct it now by fine tuning the inductor and/or capacitor in the parallel notch.

But that actually takes measurements to verify.

A DIYer without measurement equipment could be excused for wondering why hard cone drivers suck (or has "extra detail" ?)

***

These days, we know a series notch filter is better (because it also takes care of H3), and therefore allows us to cross higher (unlike the late SL's insistence of crossing the W22EX and jkrutke's insistence of crossing the L18RNX/P at 1/3 the resonant frequency), and getting a better directivity match (if we're not using a waveguide). But it still takes measurement equipment.

Last edited:

- Home

- Loudspeakers

- Multi-Way

- Open source Waveguides for CNC & 3D printing!