Holy large faceplate, Batman!My son does prototyping on a pretty fancy resin printer. Not sure what file types he works with but I’m sure I can get him do some prints for you guys. Let me know what the file extension is and i’ll ask him. The resin he uses take paint very well too.

I’ve been kicking around waveguide retrofits to the Peerless Corundum tweeter who’s low Fs and roll off look like a real winner with a lens

Peerless DA32TX00-08 1-1/4" Corundum Dome Tweeter

If I understand this correctly, theoretically the 6.5 inch wave-guide should be the best match but I don't think it's all that critical (from 5 to 6.5 inch).

Why is that? At xo, the woofer don't play the cone as a piston but probabbly radiate from the center i.e. the transducer is not really 6,5 inch at say 2,5 khz?

Or - anyone know for sure?

//

What are your thoughts on having an exposed beryllium dome? I love the idea of the T25B in a waveguide - and your results confirm that this could be an excellent way to go - but I just can't accept the risk of damage.

I am also worried about a scratch along the way. I keep having visions getting up from my desk and magically keys or some paper clip goes flying into the thin film.

@augerpro Thanks for testing out all of the sizes and all the other work/time going into this. I look forward to trying out the files once you post them.

Is there any way of having a t25B-6 in a less than perfect waveguide while keeping the factory mesh?

Intriguing thread. Wish I understood things better.

I think I am hearing that you will get best match of dispersion on a midrange to tweeter crossover if you use a waveguide whose width matches that of the midrange and whose depth matches the alignment difference between the two voice coils.

Is that essentially correct?

I have a 6.5” midrange (actually a fullrange) I want to cross to a tweeter at about 2.2khz. I have not yet selected a tweeter. mid at about 96db/W.

I was looking at TW29RN-B...but seems this thread has some great combinations.

I will study much more...any suggestions would be appreciated.

Could two identical waveguides be used back to back to create an effective dipole driver “pod” for the top of open baffles?

I think I am hearing that you will get best match of dispersion on a midrange to tweeter crossover if you use a waveguide whose width matches that of the midrange and whose depth matches the alignment difference between the two voice coils.

Is that essentially correct?

I have a 6.5” midrange (actually a fullrange) I want to cross to a tweeter at about 2.2khz. I have not yet selected a tweeter. mid at about 96db/W.

I was looking at TW29RN-B...but seems this thread has some great combinations.

I will study much more...any suggestions would be appreciated.

Could two identical waveguides be used back to back to create an effective dipole driver “pod” for the top of open baffles?

Last edited:

I think I am hearing that you will get best match of dispersion on a midrange to tweeter crossover if you use a waveguide whose width matches that of the midrange and whose depth matches the alignment difference between the two voice coils.

Is that essentially correct?

Yes, that is essentially correct, so long as the waveguide has around 90° dispersion and the crossover point is at the wavelength of the driver / waveguide.

Could two identical waveguides be used back to back to create an effective dipole driver “pod” for the top of open baffles?

I haven't seen much work done on this. May be worth creating a thread to discuss.

Last edited:

Matching width is a good rule of thumb, but I laid out a more exacting method earlier in this thread. Ideally at the crossover point the on axis and 60 degree off axis of both the waveguide and mid range driver will be the same, with about 3.5dB difference between the two axes.

Ok I have ordered a pair of SB26STAC-C000-4, and am printing the 8” waveguide, might also try the 5”. They both look similar to my midrange dispersion at about 2,25 kHz or so, so should match on that and on sensitivity.

Thanks to augerpro for this...really great to discover what’s been done here.

Thanks to augerpro for this...really great to discover what’s been done here.

Depends on which throat size would accommodate that tweeter. I would switch the tweeter out for something else if a waveguide is required🙂

augerpro - this comment got me thinking a bit, and made me realize that my in-progress project (which is based around drivers I've had laying around for years) is using a somewhat budget oriented tweeter with a mid/woofer combo that are higher end. It hit me that I probably am selling myself short re-using the dayton tweeter out of convenience, so I'm now starting to consider upgrading to a nicer tweeter that pairs well with my mids.

Maybe I missed it, but do you have .frd files available for your 'final' designs? I've always been a soft dome fan, so I'm initially interested in evaluating how the SB26STAC pairs with my mid

Matching width is a good rule of thumb, but I laid out a more exacting method earlier in this thread. Ideally at the crossover point the on axis and 60 degree off axis of both the waveguide and mid range driver will be the same, with about 3.5dB difference between the two axes.

I remain a bit mystified on one aspect of these waveguides. How did you decide the “attack angle” of the waveguide at the throat?

For example, if I wanted to adjust one of your waveguides to be, say slightly deeper, I might want a slightly steeper initial throat angle.

Would the waveguide’s performance critically depend on that initial angle?

Completely iteratively and how it integrated with the given mouth/throat/depth dimensions. Other than some experiments with elliptical section wall profiles, these are all constant radius wall profiles (circle section). Early on I would print two versions where the radius was different. Steeper at the throat generally did better.

I would like to revisit variable radius profiles, but it is such a PITA to design for (and scale properly with dimensions changes) that I almost feel I need to first model in some sim software to find the best candidates before I go down a never-ending path of iterative tweaks.

I would like to revisit variable radius profiles, but it is such a PITA to design for (and scale properly with dimensions changes) that I almost feel I need to first model in some sim software to find the best candidates before I go down a never-ending path of iterative tweaks.

Hi Brandon

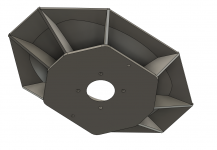

Was going to print the 8” waveguide you created, but my guy was worried it might not print without additional support...here are pix of what he will be printing...I will advise once we have made first print attempt.

Was going to print the 8” waveguide you created, but my guy was worried it might not print without additional support...here are pix of what he will be printing...I will advise once we have made first print attempt.

Attachments

Last edited:

I've started a gofundme for this project now that I'll have to depend on commercial printers. Initial goal is for finalizing designs for the SB21 and SB26 families, and continuing development for the Bliesma T25B. Fundraiser: Waveguides for CNC and 3D printing!

Last edited:

Good stuff! I just added a few bucks to say Thank You for doing this. Your waveguides are a great contribution to the DIY community, and they are superb in the Open Source Monkey Coffin!I've started a gofundme for this project now that I'll have to depend on commercial printers. Initial goal is for finalizing designs for the SB21 and SB26 families, and continuing development for the Bliesma T25B. Fundraiser: Waveguides for CNC and 3D printing!

- Home

- Loudspeakers

- Multi-Way

- Open source Waveguides for CNC & 3D printing!