Not many DiFET's around. I think Johnc124 said somewhere that it is a very expensive process and nearly extinct. Not many opamps have an input that can go +2 V above and -2 V below the supply voltage like OPA627.

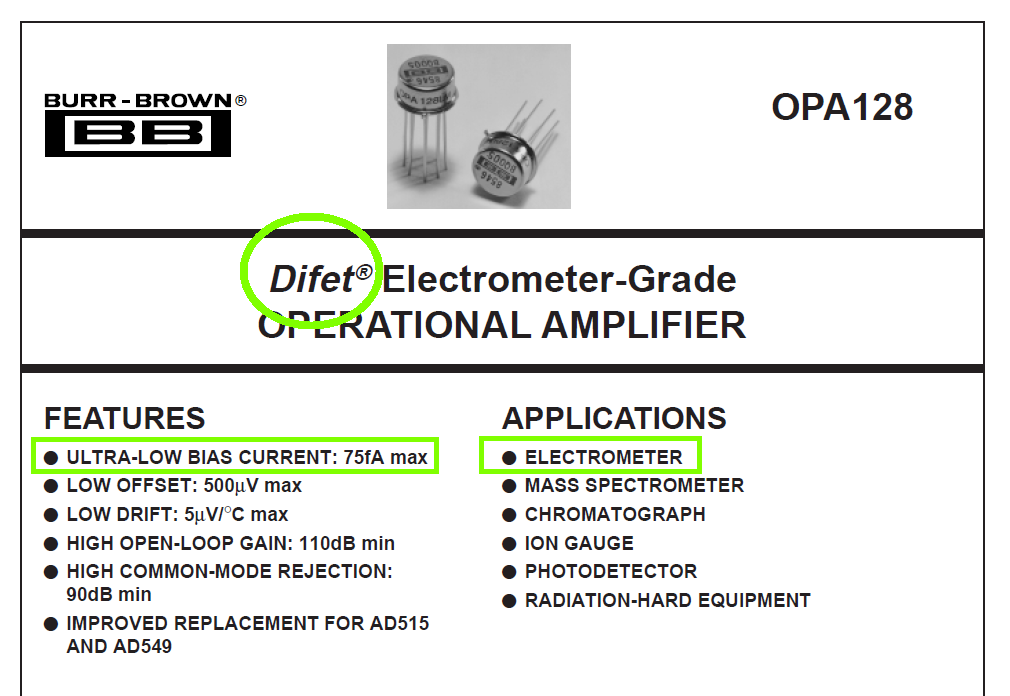

DIFET is dielectrically isolated JFET-Bipolar process. Its purpose is to achieve the absolutely lowest possible input leakage, in order to build electrometers. The fact that audio people have a weird, all-consuming fetish for those parts, is a happy accident.

_

_

Attachments

There are also those that throw out everything with an analog dial. I once found a perfectly functional Keithley 602 electrometer (then $3000) in the trash. It has 15x lower leakage current than the OPA128.

Just to clarify a few things:

1. "DiFET" is a name Burr-Brown applied to a particular dielectrically-isolated bipolar process that included JFETs. Dielectric isolation means that the transistors are surrounded on all sides by silicon dioxide as opposed to junction isolation, where there is essentially a reverse-biased diode between all transistors and the substrate. Dielectric isolation does reduce leakage by isolating the back gate of a JFET from the substrate, but that is not the only benefit in conveys. It also stabilizes the the back-gate to substrate capacitance, reducing distortion in many circuits. More info here: https://www.ti.com/lit/an/slyt595/slyt595.pdf

2. The Burr-Brown DiFET process is OLD and used a now-obsolete method of creating the SiO2 tubs the transistors sit in.

3. OPA828 is still on a dielectrically isolated process, and it does use JFETS, so it is still a dielectrically isolated JFET op amp. It just happens to be on a far newer, more advanced (and better in pretty much every conceivable way) process that doesn't use the Burr-Brown "DiFET" branding.

1. "DiFET" is a name Burr-Brown applied to a particular dielectrically-isolated bipolar process that included JFETs. Dielectric isolation means that the transistors are surrounded on all sides by silicon dioxide as opposed to junction isolation, where there is essentially a reverse-biased diode between all transistors and the substrate. Dielectric isolation does reduce leakage by isolating the back gate of a JFET from the substrate, but that is not the only benefit in conveys. It also stabilizes the the back-gate to substrate capacitance, reducing distortion in many circuits. More info here: https://www.ti.com/lit/an/slyt595/slyt595.pdf

2. The Burr-Brown DiFET process is OLD and used a now-obsolete method of creating the SiO2 tubs the transistors sit in.

3. OPA828 is still on a dielectrically isolated process, and it does use JFETS, so it is still a dielectrically isolated JFET op amp. It just happens to be on a far newer, more advanced (and better in pretty much every conceivable way) process that doesn't use the Burr-Brown "DiFET" branding.

Thx John,

Very informative.

It’s getting harder and harder to make your choice with the enormous amount of existing op-amps on the market.

On top of that, once you think to have found the right one, lead times can be as long as to mid 2022. 😡

Hans

Very informative.

It’s getting harder and harder to make your choice with the enormous amount of existing op-amps on the market.

On top of that, once you think to have found the right one, lead times can be as long as to mid 2022. 😡

Hans

The global supply chain is screwed up big time. There are some good guys out there still. TI is one, and Central Semiconductor is another. Toshiba semi seems to be in good shape

But the big fab plants have dried up. OnSemi seems to be one of the big offenders in this regard, with even vanilla transistors on second to third quarter '22 delivery.

There has been a major ad campaign for the Audi e-tron running on UK TV. The first thing you see on the Audi website is:

"Update on delivery times

We’re sorry that due to global supply chain issues, in particular those relating to semi-conductor chips, delivery times on some of our model lines are currently longer than we would like..."

Big outfits like Audi will survive. I feel for the small electronics companies, whose continued existence will be in question; I'd like to see the statistics on how many have already gone to the wall as a result of component shortages.

Craig

But the big fab plants have dried up. OnSemi seems to be one of the big offenders in this regard, with even vanilla transistors on second to third quarter '22 delivery.

There has been a major ad campaign for the Audi e-tron running on UK TV. The first thing you see on the Audi website is:

"Update on delivery times

We’re sorry that due to global supply chain issues, in particular those relating to semi-conductor chips, delivery times on some of our model lines are currently longer than we would like..."

Big outfits like Audi will survive. I feel for the small electronics companies, whose continued existence will be in question; I'd like to see the statistics on how many have already gone to the wall as a result of component shortages.

Craig

TI quoted me 53 weeks for DC converters that 'everyone' needs. Mouser has 86 OPA1656's, when they are gone it's 73 weeks.

They are ALL affected, but you can strike out lucky in some nooks and crannies.

@Mark: OPA128 are still available in small quantities starting at about $ 80 a shot.

Jan

They are ALL affected, but you can strike out lucky in some nooks and crannies.

@Mark: OPA128 are still available in small quantities starting at about $ 80 a shot.

Jan

Last edited:

This will invite speculators, letting the price explode as soon as they are in control.

Almost killing all AudioDIY initiatives.

Hans

Almost killing all AudioDIY initiatives.

Hans

Sometimes you can get lucky. In my recent order from Mouser I had couple of components (MCUs) that were listed as backordered (and available sometime next year) when I made the order. However these were shipped to me in 3 days together with the rest.

/Martti

/Martti

Yes, there are definitely plans, the team is just spread really thin at the moment. But stay tuned, the single and quad channel options are on the way.

Any update on the single channel (OPA1656)?

Is there something about the single-chan OPA827 that doesn't fit your needs? Just really curious.

I do not really see the advantage of a single unless it is for power reduction, dissipation, battery op, cost etc. They do not even use offset and comp pins anymore for singles do they?Any update on the single channel (OPA1656)?

With the way fab capacity is these days, even if the single and quad were production releases, it would still be the capacity issue in getting them. Just think how long the queue is for fab, your lookn at the end of 2022 and on ..

I wonder what companies like TI think, we have orders on the books for a year+, oh boy this is going to take a while to clear up the back log, when will life ever get back to normal? 🙂

Its like doing your new design based on what Mouser and Dig-Key have in stock today, buy up your production inventories first, then finish your design, mfg, god forbid you have an ECO 🙂 Cart in front of horse pcb design 🙂 The way of the land perhaps til when?

On OPA827 I'd say $ for some, but it is a nice part for sure. Damn expensive jfets 🙂 OPA828 are cheaper and faster, whats up, I am lookn at differences

Last edited:

I am using OPA1656 for duals. However I have a couple PCB that use singles. Previously they were JRC5534 then OPA134 and I was looking for something like the OPA1656 but single. The only thing I could find was OPA1641 and not even the right package. But I think careful gentle bending and soldering will make it fit.

Now that i think of it, kinda crazy that a semi design team is busy, knowing that your design will not see production for a year +, because of fab capacity backlog. You would think it would be a call for all hands on deck, we need more fab, not more products, like now? But wait, we cant make more fab because we cant get the parts, oh boy time for a beer.

In what package?Previously they were JRC5534 then OPA134

Last edited:

On similar parts I am seeing lead times of more than a year! Of course I am looking for 30,000 or more pieces! The current prices are so low I can understand why production capability might be more profitably used elsewhere.

In what package?

I just ordered the OPA1641 in 8-VSSOP from Mouser because that is all they had. The original boards were DIP then SOIC. Hopefully I can gently bend the VSSOP and solder to SOIC footprint without damage. I also don't like the thermals of the VSSOP.

Last edited:

Texas Instruments (TI) has announced plans to begin construction next year on its new 300-millimeter semiconductor wafer fabs in Sherman, Texas.

Construction of the first and second fabs is set to begin in 2022, said TI, adding that the North Texas site has the potential for up to four fabs.

Production from the first new fab is expected as early as 2025, according to TI. With the option to include up to four fabs, total investment potential at the site could reach approximately US$30 billion and support 3,000 direct jobs over time.

"TI's future analog and embedded processing 300-mm fabs at the Sherman site are part of our long-term capacity planning to continue to strengthen our manufacturing and technology competitive advantage and support our customers' demand in the coming decades," said Rich Templeton, TI's chairman, president and CEO.

The new fabs will complement TI's existing 300-mm fabs which include DMOS6 (Dallas, Texas), RFAB1 and the soon-to-be-completed RFAB2 (both in Richardson, Texas), which is expected to start production in the second half of 2022. Additionally, LFAB (Lehi, Utah), which TI recently acquired, is expected to begin production in early 2023.

Construction of the first and second fabs is set to begin in 2022, said TI, adding that the North Texas site has the potential for up to four fabs.

Production from the first new fab is expected as early as 2025, according to TI. With the option to include up to four fabs, total investment potential at the site could reach approximately US$30 billion and support 3,000 direct jobs over time.

"TI's future analog and embedded processing 300-mm fabs at the Sherman site are part of our long-term capacity planning to continue to strengthen our manufacturing and technology competitive advantage and support our customers' demand in the coming decades," said Rich Templeton, TI's chairman, president and CEO.

The new fabs will complement TI's existing 300-mm fabs which include DMOS6 (Dallas, Texas), RFAB1 and the soon-to-be-completed RFAB2 (both in Richardson, Texas), which is expected to start production in the second half of 2022. Additionally, LFAB (Lehi, Utah), which TI recently acquired, is expected to begin production in early 2023.

A vssop is pitch=0.65mm? and soic is 1.27mm, that’s a stretch, send a pic

TI has an adapter pcb for sale, I have one, it covers a lot of smt packages to dip

TI has an adapter pcb for sale, I have one, it covers a lot of smt packages to dip

Yes, I think I will just use the old DIP PCB instead of the SOIC PCB. A TSSOP8 to DIP8 adapter should work.

- Home

- Vendor's Bazaar

- OPA1656: High-Performance CMOS Audio Op Amp