I found that I needed at least 2 full inches of space underneath my single fan for much greater efficiency of air volume movement. Also, the extra height stops turbulence noise generated from a sudden 90 degree change of air-flow direction. I'm trying to come up with my own solution involving a special amplifier table top with a filter box underneath the entry to the fan to stop recirculation of household dust and also to bring the noise level down even further.listening tests were acceptable, only the heating issues remain,

so i came up with this solution.....

Last edited:

more pictures:

Attachments

A fine social gathering, AJT; all audiophiles, no doubt. Could you do me a favour and put up a photo of a side view of your fan intake assembly? I'm finding it difficult to come up with a design for my own amp cooling system. Thanks. Goddlediddles.more pictures:

A fine social gathering, AJT; all audiophiles, no doubt. Could you do me a favour and put up a photo of a side view of your fan intake assembly? I'm finding it difficult to come up with a design for my own amp cooling system. Thanks. Goddlediddles.

the fans are about 20mm thick, 100mm types...

made of clear plexiglas, top portion is 6mm thick,

front, back and sides are 9mm thick,12 x 17 x 1,75 inchea height...

the fans are 12v 015A types connected in series paralllel

powered by an ibm laptop psu, rated 24 volts at 3 amps...

the fans are about 20mm thick, 100mm types...

made of clear plexiglas, top portion is 6mm thick,

front, back and sides are 9mm thick,12 x 17 x 1,75 inchea height...

the fans are 12v 015A types connected in series paralllel

powered by an ibm laptop psu, rated 24 volts at 3 amps...

Thanks for that, AJT. I'm still puzzled as to where the air enters the assembly. Is it through the narrow gap at the bottom of the closed plexiglass side panels?

Thanks for that, AJT. I'm still puzzled as to where the air enters the assembly. Is it through the narrow gap at the bottom of the closed plexiglass side panels?

oh, i made 4 blocks of plexiglass 3/8 x 1 1/2 squared for the 4 corners of the cooler, that is where air enters

Some progress

2 pcs .250" thick 6061 T6 material for 2 monoblocks

Regards

David

Very nice looking speakers. Can you tell us more about them?

12 inch Altec Lansing woofer, altech lansing compression driver in a le cleach 'horn, electro voice tweeter....not recall model numbers now....i did not make those.....

i am considering using mosfet CCS for the 12ax7 and ef86 stages,

a 1 ma and 4mA adjustable around this value,

any thoughts on this? recommendations will be welcome...

looking good, in myupcoming build, i am giving heat issues first priority

now that i have confirmed how good this amp is...

Last edited by a moderator:

View attachment 583426

View attachment 583427

Some progress

2 pcs .250" thick 6061 T6 material for 2 monoblocks

Regards

David

Very solid. By the way, how did you manage to get the photos up in super large size?

I put them in an album on an Ipad pro taken with the same camera. And hit "invite all"

I never could figure out the attached thumbnails as I could not manage the pics for whatever reason

I could only post 1 pic at a time

Just straight resolution and no downsizing on the Ipad

I never could figure out the attached thumbnails as I could not manage the pics for whatever reason

I could only post 1 pic at a time

Just straight resolution and no downsizing on the Ipad

more pictures:

Very nice looking speakers. Can you tell us more about them?

View attachment 583426

View attachment 583427

Some progress

2 pcs .250" thick 6061 T6 material for 2 monoblocks

Regards

David

12 inch Altec Lansing woofer, altech lansing compression driver in a le cleach 'horn, electro voice tweeter....not recall model numbers now....i did not make those.....

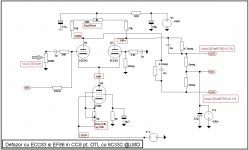

i am considering using mosfet CCS for the 12ax7 and ef86 stages,

a 1 ma and 4mA adjustable around this value,

any thoughts on this? recommendations will be welcome...

looking good, in myupcoming build, i am giving heat issues first priority

now that i have confirmed how good this amp is...

I use allready a ccs for the ecc83, has been usefull (2sk117 ) but I strongly think to change in all valve design, so let be an ef86 ccs...

Attachments

AJT, please confess your sins in public. I think it would be good for you, ha ha.😡😡oops made a terrible mistake, i am asking an admin to look at it...

AJT, please confess your sins in public. I think it would be good for you, ha ha.😡😡

yes, first i quoted your posts and replied to each, so then having three posts in succession, i decided to merge all to make just one post....begging for your forgiveness...

Finally my version of the Tim Mellow amp is running on a dummyload.

After some assembly errors 🙁 the amp works fine.

The transformer cover needs some paint but it is too cold outside. I am still searching for an output protection, because I am using the delicate AER-driver (full range).

After some assembly errors 🙁 the amp works fine.

The transformer cover needs some paint but it is too cold outside. I am still searching for an output protection, because I am using the delicate AER-driver (full range).

- Home

- Amplifiers

- Tubes / Valves

- New Tim Mellows OTL project