Very nice build!

I think you will find though that in due time, the insulation will degrade on the wiring to your filament connections of the output tubes. We use a bit of Teflon tubing that is placed over the wire in these locations- so if the insulation melts, its held in place by the Teflon tubing which melts at a much higher temperature. 1/2 inch of tubing should be sufficient for each connection.

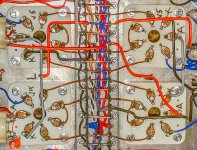

Good idea. I used 1.75 mm solid stiff copper wire with no insulation for all the filament wiring and brought them all out to a central tag-strip.

Very nice build!

I think you will find though that in due time, the insulation will degrade on the wiring to your filament connections of the output tubes. We use a bit of Teflon tubing that is placed over the wire in these locations- so if the insulation melts, its held in place by the Teflon tubing which melts at a much higher temperature. 1/2 inch of tubing should be sufficient for each connection.

thanks for the heads up...will keep that in mind,

i have teflon insulated wires and will use then in my next build....

My tube base wiring.Good idea. I used 1.75 mm solid stiff copper wire with no insulation for all the filament wiring and brought them all out to a central tag-strip.

Attachments

i lost one 6c33 tube to g1-k shorts.....

otherwise the amp is fine now hovering at 320 watts power draw....

playing sweet music....

i ended up using NEC 12AX7 and 6267's for now....

anyone tried a 12AT7 in the first hole?

otherwise the amp is fine now hovering at 320 watts power draw....

playing sweet music....

i ended up using NEC 12AX7 and 6267's for now....

anyone tried a 12AT7 in the first hole?

i lost one 6c33 tube to g1-k shorts.....

otherwise the amp is fine now hovering at 320 watts power draw....

playing sweet music....

i ended up using NEC 12AX7 and 6267's for now....

anyone tried a 12AT7 in the first hole?

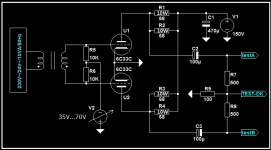

Never tried the 12AT7. I'm very happy with my NOS Svetlana 6J32Ps. I bought a job lot of 18 in Russia and every one was perfect. GMs were mostly on the high side (1.9) and I was able to choose 7 matched pairs, 4 very closely matched. You just can't trust so-called matched pairs from tube sellers; you have to do it yourself. I built a tube tester from a few bits I had lying around the workshop.

Attachments

Never tried the 12AT7. I'm very happy with my NOS Svetlana 6J32Ps. I bought a job lot of 18 in Russia and every one was perfect. GMs were mostly on the high side (1.9) and I was able to choose 7 matched pairs, 4 very closely matched. You just can't trust so-called matched pairs from tube sellers; you have to do it yourself. I built a tube tester from a few bits I had lying around the workshop.

Can you put some schematics? Have you ever tried to match the 6c33?

Sure. I'll draw one out because I designed it as I built. I never tried to match the 6C33Cs and I'm not going to try. Buying enough of them to match would be too expensive.Can you put some schematics? Have you ever tried to match the 6c33?

Sure. I'll draw one out because I designed it as I built. I never tried to match the 6C33Cs and I'm not going to try. Buying enough of them to match would be too expensive.

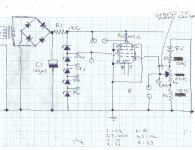

You are right, but at least mathing 2+2 from 6 can help. I tried a simple dynamic circuit using the OTL psu and it worked.

Attachments

Last edited:

Never tried the 12AT7. I'm very happy with my NOS Svetlana 6J32Ps. I bought a job lot of 18 in Russia and every one was perfect. GMs were mostly on the high side (1.9) and I was able to choose 7 matched pairs, 4 very closely matched. You just can't trust so-called matched pairs from tube sellers; you have to do it yourself. I built a tube tester from a few bits I had lying around the workshop.

thanks, i will make one for myself....

what i have in mind us to use the actual operating points as test voltages and find the closest match...

thanks, i will make one for myself....

what i have in mind us to use the actual operating points as test voltages and find the closest match...

I just opened up the box and noticed that I made R4 22K and R3 82K. This gives much finer control over the grid bias voltage, enabling more accurate measurement over smaller variations, thus approximating to to the small signal GM. I kept the pot at 50K, but be sure to wire the wiper to the top to make it fail-safe in the event that the wiper loses contact with the track. 100 Ohms is about right for R2 assuming you are using a good digital voltmeter. Online calculators are handy for working out the value of R1, depending on what initial voltage comes out of the bridge. I changed the position of C1 to go after R1 to form a Low-Pass filter - better smoothing.

All this assumes also that you use the same HT = 195V and screen = 156V. 39V Zeners are readily available and cheap for a packet of 5.

The maximum plate dissipation of the EF86 and 6J32P is 1 Watt, so this has to be kept in mind when adjusting the bias pot.

i finally settled on a power draw of 350 watts at idle, this makes the output tubes dissipate about 35 watts a piece....

Looks really great. I'll bet it sounds that way too.

Looks really great. I'll bet it sounds that way too.

thanks, i am looking to build my second OTL, this time mono-blocks using 10 or

12 pcs of 40KD6's in triode mode.....(i can get them very cheap)

looking to use a beefier pentode like the 12GN7's/6P15P's for better control of the output tube miller caps...

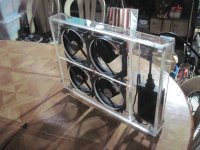

That will do it, but 4 fans seems excessive as far as noise?

I would put some series diodes to stagger each fan at different speeds to eliminate any beat

Frequency that might mutiply a noise peak and mount each fan on velcro, but it looks like your satisfied and done.

At least you solved the heat issue with brute force.

Regards

David

I would put some series diodes to stagger each fan at different speeds to eliminate any beat

Frequency that might mutiply a noise peak and mount each fan on velcro, but it looks like your satisfied and done.

At least you solved the heat issue with brute force.

Regards

David

Last edited:

It is possible to manage heat in this kind of OTL without fans, the trick is to allow free flow of air around the output tubes and allow free flow through the bottom plate, high feet helps. If there are free space around the output tubes they will create a chimney effect and draw air from below.

We have made extensive measurements of the effectiveness of our design and we easily achieve as low as 15 - 20 degree temperature rise above ambient of the components attached to the underside of the chassis, the highest temperature is then on the components closest to the tube sockets. 20 degree temperature rise means that standard components specified to 70 degrees survive with margin even when ambient temperatures are high.

Most of the heat transferred to the chassis from the 6C33C tubes is from radiation and it will heat the chassis but not the components below if air can flow freely.

We have made extensive measurements of the effectiveness of our design and we easily achieve as low as 15 - 20 degree temperature rise above ambient of the components attached to the underside of the chassis, the highest temperature is then on the components closest to the tube sockets. 20 degree temperature rise means that standard components specified to 70 degrees survive with margin even when ambient temperatures are high.

Most of the heat transferred to the chassis from the 6C33C tubes is from radiation and it will heat the chassis but not the components below if air can flow freely.

That will do it, but 4 fans seems excessive as far as noise?

I would put some series diodes to stagger each fan at different speeds to eliminate any beat

Frequency that might mutiply a noise peak and mount each fan on velcro, but it looks like your satisfied and done.

At least you solved the heat issue with brute force.

Regards

David

thanks, these are low current fans and so are quite silent.....

i will know just how silent when we set it up in the hotel room where we are displaying the amp in an audio show...

It is possible to manage heat in this kind of OTL without fans, the trick is to allow free flow of air around the output tubes and allow free flow through the bottom plate, high feet helps. If there are free space around the output tubes they will create a chimney effect and draw air from below.

We have made extensive measurements of the effectiveness of our design and we easily achieve as low as 15 - 20 degree temperature rise above ambient of the components attached to the underside of the chassis, the highest temperature is then on the components closest to the tube sockets. 20 degree temperature rise means that standard components specified to 70 degrees survive with margin even when ambient temperatures are high.

Most of the heat transferred to the chassis from the 6C33C tubes is from radiation and it will heat the chassis but not the components below if air can flow freely.

on hindsight, i should have opted for a more roomy chassis,

my next build will do that....i have plans in my mind as to how to do it...

on hindsight, i should have opted for a more roomy chassis,

my next build will do that....i have plans in my mind as to how to do it...

In the first OTL I built that can be seen Pictures of my tube amplifiers here I drilled holes around the 6C33C tubes. I never had a problem with overheating and the amplifier is working well 16 years later. In the commercial OTLs we build for Q-tron Audio we have milled the top-plate so that there are only small "ears" left for mounting the socket, in reality there are almost 5mm space almost all around the sockets, it works very well.

- Home

- Amplifiers

- Tubes / Valves

- New Tim Mellows OTL project