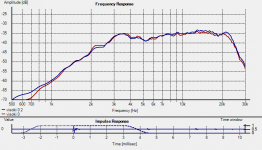

I have also done "non-gated" measurements with smoothing, down to 1/3 octave smoothing. In the right room environment or outdoors, it can deliver a response similar to the quasi-anechoic response (as you showed).

Yes, this is also my experience. However, the low frequency results (which are not accessible by the gating method) really show the acoustics of the room, not so much the speaker.

Thank you all for the kind notes.

I attached photos from measurement set. Woofer axis was 2meters above the floor.

Next time I will get some damping material and place it on the floor and in the speaker stand, this may reduce reflections and allow for longer window.

Higher my friend, higher 🙂

Last edited:

2m was easy, we were two and we got it on the stand easily by hands from the floor. So I think 3m would require more stands even for us to get speaker up that high.

Zvu, what is status of your 3way project from the photo? I noticed it earlier, you already showed some measurements,.....

It awaits second set of measurements. But... Since i hate to haul the loudspeakers back and forward all the time, i'm building few projects at once and probably gonna stay a whole day at basketball hall to do measurements. It's about 6 projects that need to be measured. Finishing the crossover and tweaking is sweet part of the design.

- There is three way you mention and measurements you are talking about. I'm also developing two versions with different tweeters (AMT and dome). I need to add facets to the front baffles:

- There is two way high eff using FaitalPro 12pr320-8 with Mabat's ST260 waveguide and Peerless DFM253500-08 compression driver. Looking forward to this one 🙂

- There is also a three way with Kef R series dual-concentrics and two OAudio woofers per side that i'm working on. Needless to say that i'm very much fond of Kef's mid-tweet so can't wait to do some measurements.

- Friend that measured ST260 waveguides with me needs to do test cabinets for his Deltalite II 2515, he wants to combine it with Mabat's waveguides.

So, we need to make all cabinets and do the wiring and damping, haul the speakers to the nearby school and generate files for crossover development for all of the speakers.

All in all, i'm not in a hurry. We're having so much fun doing this and i'm taking my time 🙂

- There is three way you mention and measurements you are talking about. I'm also developing two versions with different tweeters (AMT and dome). I need to add facets to the front baffles:

- There is two way high eff using FaitalPro 12pr320-8 with Mabat's ST260 waveguide and Peerless DFM253500-08 compression driver. Looking forward to this one 🙂

- There is also a three way with Kef R series dual-concentrics and two OAudio woofers per side that i'm working on. Needless to say that i'm very much fond of Kef's mid-tweet so can't wait to do some measurements.

- Friend that measured ST260 waveguides with me needs to do test cabinets for his Deltalite II 2515, he wants to combine it with Mabat's waveguides.

So, we need to make all cabinets and do the wiring and damping, haul the speakers to the nearby school and generate files for crossover development for all of the speakers.

All in all, i'm not in a hurry. We're having so much fun doing this and i'm taking my time 🙂

Last edited:

It's actually some generic AMT tweeter. Martin Logan uses it in their Motion 4i loudspeaker. I've obtained it under name Omnes Audio AMT50, a local brand from Germany. It is also available as Harwood AM20. ML Motion 4i is measured at ASR website and tweeter performance looks pretty good, disregarding non optimal implementation. I think it can work well with small 3" midrange crossed at 3-3.5 kHz.

Zvu, you have very nice projects ongoing...

You are right with moving speakers and equipment forth and back, next time I go to the hall for the measurements I will take another three different speakers. The most time consuming is getting it all there and back, a set it up in the hall. Mesurements themself are quite short.

You are right with moving speakers and equipment forth and back, next time I go to the hall for the measurements I will take another three different speakers. The most time consuming is getting it all there and back, a set it up in the hall. Mesurements themself are quite short.

Material?

Hi Petr

I’m also really impressed by your integration of the waveguide with one of the best looking baffle faces + roundovers I’ve ever seen. Either DIY … or commercial

(I've got some really good drivers for a few speaker projects, that I recently got the space to work on. So the 3D CAD learning curve should be justified …

I’d think that most of us would think of getting those pieces 3D printed. Well, I did. Maybe you didn’t because of the piece’s size? (must be ~ 0.7 * 0.24 m)

You went for machining by CNC. I can’t tell from the picture, is it some sort of vinyl(?) What’s the best option for you in the Czech Republic could be different for others. (e.g. I’m on the other side of the world)

What did you use? Can you say a few words about what you considered but rejected, and/ or what might be a shortlist of good options?

Cheers

draki, hifijim, thank you...

diyggy, thank you, actually it is easy 🙂 it takes some modelling in Solidworks, sending data to the company and have it machined on CNC.

All woodwork and finishing is done by the carpenter, we already collaborate for a years and my projects would not be possible without him.

Hi Petr

I’m also really impressed by your integration of the waveguide with one of the best looking baffle faces + roundovers I’ve ever seen. Either DIY … or commercial

(I've got some really good drivers for a few speaker projects, that I recently got the space to work on. So the 3D CAD learning curve should be justified …

I’d think that most of us would think of getting those pieces 3D printed. Well, I did. Maybe you didn’t because of the piece’s size? (must be ~ 0.7 * 0.24 m)

You went for machining by CNC. I can’t tell from the picture, is it some sort of vinyl(?) What’s the best option for you in the Czech Republic could be different for others. (e.g. I’m on the other side of the world)

What did you use? Can you say a few words about what you considered but rejected, and/ or what might be a shortlist of good options?

Cheers

Hi Otto, thank you. I was also self-learner with Solidworks, it took me hours and hours figuring out how to model these curves around drivers. I think BBB was my first project where I needed this, and I spent really a lot of time "shaping" the baffle to make it look good. After several projects I have eye for it, also developed some Solidworks skills. I got a lot of positive feedback on those baffles esthetics so it is now my proven solution for any project with sufficient budget.

I also have to point out that those baffles work very well also technically/acoustically.

So far all project with such a baffles had MDF sandwich, machined on CNC, and spray painting finish. It may sound easy and simple, but there is a lot of delicate work and know how involved. I had good luck to cooperate with skilled carpenter, and he is responsible for almost all cabinets, veneering, and finishing of my projects. I cannot provide details, as I do not know them.

So far this is proven and quite cost effective solution. I have the eye for details, and all my projects must be finished in sellable quality. This is always the first thing we discuss with carpenter when starting new project. This is the reason I did not try 3D printing or other alternatives yet. Though I admit these options become more and more attractive.

One of alternatives was CNC of aluminium alloy, but this would be really expensive for just 2 baffles.

Generally CNC and 3D printing are well available in Czech, but companies are not much interested in making just two baffles.

I also have to point out that those baffles work very well also technically/acoustically.

So far all project with such a baffles had MDF sandwich, machined on CNC, and spray painting finish. It may sound easy and simple, but there is a lot of delicate work and know how involved. I had good luck to cooperate with skilled carpenter, and he is responsible for almost all cabinets, veneering, and finishing of my projects. I cannot provide details, as I do not know them.

So far this is proven and quite cost effective solution. I have the eye for details, and all my projects must be finished in sellable quality. This is always the first thing we discuss with carpenter when starting new project. This is the reason I did not try 3D printing or other alternatives yet. Though I admit these options become more and more attractive.

One of alternatives was CNC of aluminium alloy, but this would be really expensive for just 2 baffles.

Generally CNC and 3D printing are well available in Czech, but companies are not much interested in making just two baffles.

Hi Petr,

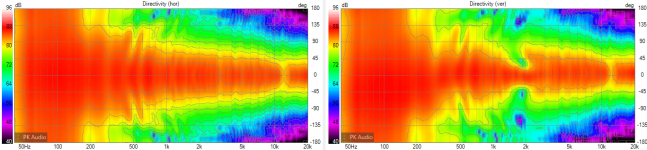

Amazing results ! I'm particularly impressed by the vertical plot for such a design. Where was the mic placed ? on tweeter axis maybe ?

Amazing results ! I'm particularly impressed by the vertical plot for such a design. Where was the mic placed ? on tweeter axis maybe ?

For me it would be perfect, but the price...That Eton ER4 is a nice HF driver. Highly underrated.

https://hificompass.com/en/speakers/measurements/eton/eton-er4

https://www.lautsprechershop.de/chassis/eton_en.htm

Bravo, looks excellent! The sound should match too.I made some progress with this project and it is almost ready for the first startup and listening.

At the height in the middle of tweeter and midrange, mic distance 3000m.. Where was the mic placed ? on tweeter axis maybe ?

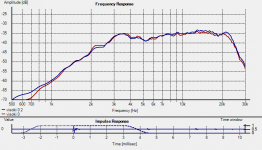

I managed to fully prepare both loudspeakers and to connect crossovers. After ~1hour of listening I can say this sounds really promising considering this was initial crossover. Actually it was really good and I am curious to listen to it after a days when it will be more burnt-in.

Midrange and treble are very similar to Ellips-A, bass is different, bassreflex just sounds different. As this is 8" it does not go as deep as 12", but it has similar sound characteristics as 32W.

Last edited:

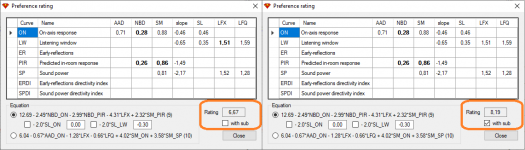

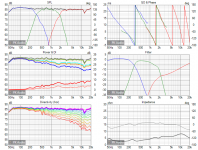

I agree. That extra +1 dB on the tweeter will get you a much more accurate spectral balance. Of course, once the component values are decided, it may be possible to include a switch to move between the two responses.Very nice indeed ! If possible with your passive crossover, I would try to add + 1 dB on the T25B in waveguide

The simulations look very promising. It will be interesting to learn of your thoughts after extensive listening tests. If anything can be gleaned from the on-axis simulations, the tweeter energy still seems to be a little bit low, maybe 0.5 dB lower than ideal. This will likely produce a non-fatiguing listening experience, but may come across to some listeners as lacking in sparkle when reproducing cymbals and the high frequency harmonics of other instruments.I made some progress with this project and it is almost ready for the first startup and listening.

Your initial listening tests seem to be producing very encouraging results for your design and build.

- Home

- Loudspeakers

- Multi-Way

- New project: 3way 22W/4851, MW16TX-8, T25B in WG