http://www.alliedelec.com/aavid-thermalloy-575200b00000g/70115224

Sent from my Nexus 5 using Tapatalk

Sent from my Nexus 5 using Tapatalk

Great looking build - you should be proud. 🙂

Out of curiosity I've just taken a quick look at the ebay listings for your case and it looks as though there are vents on the top. Apparently the NAP200 board is designed to be used in a sealed enclosure otherwise the amp can be subject to thermal runaway. I found a Chinese forum with posts relating to this kit and, with the help of Google Translate, found that this had actually happened to some kit-builders and with bad consequences. If your case has vents then you may wish to consider sealing them if you haven't already done so.

Chris

Thanks for that Chris, I'll sort out the vents. Though Naim cases don't seal the air completely, so I don't want to make it fully airtight.

Ian has it spot on with the case, it's the case in his picture. I had to reverse the back panel to get the power socket on the right side.

I had it playing for several hours yesterday, if anything it's staying on the cool side. For bias testing, I'm measuring the voltage across R12 (0R22), both channels staying at around 6.5 mV.

One issue might be that at switch-on the reading actually is higher, at around 7or 8 mV and reduces to 6.5mV after a few minutes! I was expecting it to increase as the amp warmed up - may be sign I've messed something up 🙁

Robert

Great looking build - you should be proud. 🙂

Out of curiosity I've just taken a quick look at the ebay listings for your case and it looks as though there are vents on the top. Apparently the NAP200 board is designed to be used in a sealed enclosure otherwise the amp can be subject to thermal runaway. I found a Chinese forum with posts relating to this kit and, with the help of Google Translate, found that this had actually happened to some kit-builders and with bad consequences. If your case has vents then you may wish to consider sealing them if you haven't already done so.

Chris

Naim art, what is your speaker diameters ?

They seem small for middle and bass effects that This Kit can produce. In terms of speakers, the bigger is Always better/y)

I like your heat sinking on ZTX transistors, are these homemade ?

Hi Rensli , yes I agree , I need bigger speakers 🙂 and something to keep them off the ground.

I'm new to DIY for Amps but I did build a Speaker Kit 10 years ago called WD25A from World Designs, still using them, despite protests from the family (the speakers are not the best looking 🙂)

WD25A Design Pg1

They use a great 10" SEAS bass/mid driver, quality bass if not quantity!!

Atupi has listed the heat sink I used for the ZTX, I got mine from CPC or RS spares, but the same item.

Robert

It is done, burning for some watts as I write 😉

-Custom made 300VA transformer, on 600VA core, dual 56Vct for the amp and 48Vct for the preamp supply, with shield and GOES band. Dual 117V primaries.

-LTP using selected BC239C with 10% difference HFE, and covered with thermal coupling aluminum block.

-Polystyrene caps at key location, as Naim do

-Original Tantalum input caps replaced by MKK film caps

-Original Naim DIN input 4 pins connector

-KENDEIL caps 10000μF, 63V for the amp supply

-KENDEIL 4700μF, 50V

-Internal wiring done Naim style...

-Front power-On indicator, green led and Naim Logo

-Feedback 27K resistor changed for Vishay CFM55 50 ppm type to reduce thermal modulation

-24V Preamp supply standard LM317 upgraded with DIY Jung Regulator

-R14 Speaker Output 0R22 ohms bypassed and Zobel installed (15R/2W and home made coil 16T, 1mm enamelled copper wire, on 6.3mm drill bit)

-75C thermal protection cutoff installed on bottom panel (as the original)

-Power-On switch hidden under the front right corner.

-Custom made 300VA transformer, on 600VA core, dual 56Vct for the amp and 48Vct for the preamp supply, with shield and GOES band. Dual 117V primaries.

-LTP using selected BC239C with 10% difference HFE, and covered with thermal coupling aluminum block.

-Polystyrene caps at key location, as Naim do

-Original Tantalum input caps replaced by MKK film caps

-Original Naim DIN input 4 pins connector

-KENDEIL caps 10000μF, 63V for the amp supply

-KENDEIL 4700μF, 50V

-Internal wiring done Naim style...

-Front power-On indicator, green led and Naim Logo

-Feedback 27K resistor changed for Vishay CFM55 50 ppm type to reduce thermal modulation

-24V Preamp supply standard LM317 upgraded with DIY Jung Regulator

-R14 Speaker Output 0R22 ohms bypassed and Zobel installed (15R/2W and home made coil 16T, 1mm enamelled copper wire, on 6.3mm drill bit)

-75C thermal protection cutoff installed on bottom panel (as the original)

-Power-On switch hidden under the front right corner.

Attachments

Wow, it looks soo good. Congratulations!

Did you used modushop case ? The bottom cover is the heatsink also ? Is a aluminium bottom cover ?

Great finished diy product !

Sent from my Nexus 5 using Tapatalk

Did you used modushop case ? The bottom cover is the heatsink also ? Is a aluminium bottom cover ?

Great finished diy product !

Sent from my Nexus 5 using Tapatalk

...-R14 Speaker Output 0R22 ohms bypassed and Zobel installed (15R/2W and home made coil 16T, 1mm enamelled copper wire, on 6.3mm drill bit)

-75C thermal protection cutoff installed on bottom panel (as the original)...

Can you elaborate on these mods a little?

thx

al

-75C thermal protection cutoff installed on bottom panel (as the original)...

Can you elaborate on these mods a little?

thx

al

Thanks for the comments, yes I used the modushop case, with the cover without hole option. I blocked the bottom cover holes.

The output transistors are mounted on a brass bar I made, and it is firmly mounted on the bottom plate, with thermal grease.

Yes I know about the brass thermal resistance being worst than aluminum... In normal use the amp goes barely warm.

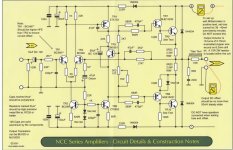

I got the Zobel idea from Avondale, see schematic. Apparently the Naim amps can oscillate with some speaker cables, and the output 0R22 ohms resistor increase the amp output impedance, reducing the damping.

See the NAP200 user manual, they mention 70C thermal protection:

'' Section 46.2 Protection Notes - If the amplifier’s external case reaches 70°C due to prolonged running at high power, the mains supply will be interrupted and the illuminated logo will switch off until the amplifier has cooled down. This may take up to thirty minutes.''.

Hence it is not a mods but a feature on the original Naim amp. It can also be seen on the original amp picture, see the two wires going under the board? They are connected to a 70C thermal cutoff switch installed on the bottom cover, near the output transistors that turns off the amp in case of thermal runaway...

I used this thermal protection I had in stock:

5 Pcs Temperature Switch Thermostat 75°C N C KSD9700 Normal Close New | eBay

The output transistors are mounted on a brass bar I made, and it is firmly mounted on the bottom plate, with thermal grease.

Yes I know about the brass thermal resistance being worst than aluminum... In normal use the amp goes barely warm.

I got the Zobel idea from Avondale, see schematic. Apparently the Naim amps can oscillate with some speaker cables, and the output 0R22 ohms resistor increase the amp output impedance, reducing the damping.

See the NAP200 user manual, they mention 70C thermal protection:

'' Section 46.2 Protection Notes - If the amplifier’s external case reaches 70°C due to prolonged running at high power, the mains supply will be interrupted and the illuminated logo will switch off until the amplifier has cooled down. This may take up to thirty minutes.''.

Hence it is not a mods but a feature on the original Naim amp. It can also be seen on the original amp picture, see the two wires going under the board? They are connected to a 70C thermal cutoff switch installed on the bottom cover, near the output transistors that turns off the amp in case of thermal runaway...

I used this thermal protection I had in stock:

5 Pcs Temperature Switch Thermostat 75°C N C KSD9700 Normal Close New | eBay

Attachments

Last edited:

Lovely work!

Yes, even if run all day my amp does not get above 28 - 30 °C and I've closed off the top vent now. I was slightly worried that the bias was being set too low - the DMM reads consistently 6 mV across the R12 (0R22).

Am I correct to think that it's setting the Bias too high that may send a power amp into thermal runaway as it tends to class A operation? - or is that too simplistic?

I used this type of thermal switch - 2455R 82-191 L100C | Honeywell NC 10 A Thermostat, Tab Termination | Honeywell but it does make a mess of the wiring 🙂 That type looks to be a better solution.

I fully admit that I'm building this out of a long love of Naim amps and wanting to see If 1) I can build it, 2) can it work (safely!) and only then can it sound good.

I had it working with little or no issues (I'm only using a non Naim Pre) but while the sound had lots of dynamics, was very clean sounding and had, to my mind, very good imaging (albeit with small speakers), its sound was not as interesting as my other kit.

I then realised that I'd 'matched' the TR1/TR2 pair of transistors incorrectly, I was using BC550C's (after the discussions in previous posts) but I had matched them to be equal and not with Tr2 10% lower than Tr1😱.

I had some BC546C's- recommended in other Forums - which I've now swapped in for the BC550's, now getting about 10mV DC Offset on both channels.

To me the sound is much better, still dynamic - perhaps not with such a sharp image as before - but just more enjoyable. The difference surprised me!

Robert

Yes I know about the brass thermal resistance being worst than aluminum... In normal use the amp goes barely warm.

Yes, even if run all day my amp does not get above 28 - 30 °C and I've closed off the top vent now. I was slightly worried that the bias was being set too low - the DMM reads consistently 6 mV across the R12 (0R22).

Am I correct to think that it's setting the Bias too high that may send a power amp into thermal runaway as it tends to class A operation? - or is that too simplistic?

...in case of thermal runaway...

I used this thermal protection I had in stock:

5 Pcs Temperature Switch Thermostat 75°C N C KSD9700 Normal Close New | eBay

I used this type of thermal switch - 2455R 82-191 L100C | Honeywell NC 10 A Thermostat, Tab Termination | Honeywell but it does make a mess of the wiring 🙂 That type looks to be a better solution.

I fully admit that I'm building this out of a long love of Naim amps and wanting to see If 1) I can build it, 2) can it work (safely!) and only then can it sound good.

I had it working with little or no issues (I'm only using a non Naim Pre) but while the sound had lots of dynamics, was very clean sounding and had, to my mind, very good imaging (albeit with small speakers), its sound was not as interesting as my other kit.

I then realised that I'd 'matched' the TR1/TR2 pair of transistors incorrectly, I was using BC550C's (after the discussions in previous posts) but I had matched them to be equal and not with Tr2 10% lower than Tr1😱.

I had some BC546C's- recommended in other Forums - which I've now swapped in for the BC550's, now getting about 10mV DC Offset on both channels.

To me the sound is much better, still dynamic - perhaps not with such a sharp image as before - but just more enjoyable. The difference surprised me!

Robert

Bias recommendation seems to be around 13mV across both 0R22 resistors (equals to 30ma, easier to measure double volt value). See this excellent page about the bias/THD: Naim, NAPs, Naits, distortion and bias-current settings

Personally I found the sound to be Naim like. It is not a power house with either speakers I tried with it. The amp/NAC112 preamp combo sounds best with classical and acoustic music. Imaging and tempo are pretty good. I don't think that is a good amp for compressed and rock recordings. It is in line with others Naim setup I heard over the years.

Sound is maybe a little analytical, and dry. I'm used to Class-A PassLabs style amp. This is a different beast.

An other member Chris built the amp and he has other Naim gears. He said that the amp sound very Naim like as well. Even the slight white noise we hear close to the speakers is typical of other Naim amps according to him.

All in all it seems to be a pretty good clone of the real thing.

Personally I found the sound to be Naim like. It is not a power house with either speakers I tried with it. The amp/NAC112 preamp combo sounds best with classical and acoustic music. Imaging and tempo are pretty good. I don't think that is a good amp for compressed and rock recordings. It is in line with others Naim setup I heard over the years.

Sound is maybe a little analytical, and dry. I'm used to Class-A PassLabs style amp. This is a different beast.

An other member Chris built the amp and he has other Naim gears. He said that the amp sound very Naim like as well. Even the slight white noise we hear close to the speakers is typical of other Naim amps according to him.

All in all it seems to be a pretty good clone of the real thing.

Thermal switch is installed in series with primary winding ?

Sent from my Nexus 5 using Tapatalk

Sent from my Nexus 5 using Tapatalk

That's correct.Thermal switch is installed in series with primary winding ?

Sent from my Nexus 5 using Tapatalk

Not too simplistic, because the lower you set bias, the less heating of the output stage transistors and less room for thermal instability. The bias current is too low to cause a heat problem alone but in combination with heating due to efficiency losses, the possibility grows.Am I correct to think that it's setting the Bias too high that may send a power amp into thermal runaway as it tends to class A operation? - or is that too simplistic?

Unfortunately, Naim's Quasi-complementary design means there is a series of compromises for bias setting, first because the best bias for TR11 is very different to that for TR12, yet they need to share the same compromise current, chosen for lowest distortion. Then the appropriate temperature reference points are different too so it soon gets messy and the opportunity for thermal runaway increases.

It seems that manufacturers opt to avoid close thermal sensing and control, just sensing air temp inside the case. It's a very slow acting form of bias regulation but if refined and tested properly, seems to work fine in a domestic setting, despite being a dire problem for amps working at the max. in warm environments.

The Naim bias setting thankfully, is not terribly critical but the maximum limit really is a max. as stated by Neil Mc bride on his site (linked by Algar_emi)

When you open the case to measure bias, the warm air disperses and you eventually arrive at a steady reading, leading you to thing it's stable. Then close the amp with thin, well insulated meter leads in place and read the bias over time. My own 140 clone takes 20 -25 mins to stabilize after opening/closing the case - no problem in a stable environment but hot weather (here at least ) can still provoke runaway if you try playing at clipping levels with limiters removed.

Algar;

any source for these caps in USA?

-KENDEIL caps 10000μF, 63V for the amp supply

-KENDEIL 4700μF, 50V

any source for these caps in USA?

-KENDEIL caps 10000μF, 63V for the amp supply

-KENDEIL 4700μF, 50V

When needing cheaper caps Samwa Conputer grade will do . The Big sized ones also as they have good sound. They have double rippple ratings or there about, they become rarer as size is all important. EPCOS computer grades. Audio seems to market computer grade as better sounding. Some Audio grades are cheaper it should be said. Cerafin was one. 100 V caps sound better if space and cost OK.

Not too simplistic, because the lower you set bias, the less heating of the output stage transistors and less room for thermal instability. The bias current is too low to cause a heat problem alone but in combination with heating due to efficiency losses, the possibility grows.

Unfortunately, Naim's Quasi-complementary design means there is a series of compromises for bias setting, first because the best bias for TR11 is very different to that for TR12, yet they need to share the same compromise current, chosen for lowest distortion. Then the appropriate temperature reference points are different too so it soon gets messy and the opportunity for thermal runaway increases.

It seems that manufacturers opt to avoid close thermal sensing and control, just sensing air temp inside the case. It's a very slow acting form of bias regulation but if refined and tested properly, seems to work fine in a domestic setting, despite being a dire problem for amps working at the max. in warm environments.

The Naim bias setting thankfully, is not terribly critical but the maximum limit really is a max. as stated by Neil Mc bride on his site (linked by Algar_emi)

When you open the case to measure bias, the warm air disperses and you eventually arrive at a steady reading, leading you to thing it's stable. Then close the amp with thin, well insulated meter leads in place and read the bias over time. My own 140 clone takes 20 -25 mins to stabilize after opening/closing the case - no problem in a stable environment but hot weather (here at least ) can still provoke runaway if you try playing at clipping levels with limiters removed.

Thanks Ian

I've tested it that way and have set the bias to around 13mV across the both 0R22 resistors .

Thanks also for the previous mention of the Silastic 732 - great stuff ! - I have a 2mm aluminium plate bonded to the underside of the previously, vented top plate!

Attachments

- Home

- Amplifiers

- Solid State

- NAP-140 Clone Amp Kit on eBay