I ll check all joints again, resistors etc to confirm it is well soldered.

Plus it can be burnt component, if I applied too much heat..

Plus it can be burnt component, if I applied too much heat..

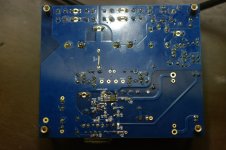

Connected boards.

One is working fine.

Second is not. No click and no led.

can you please tell me what to check.

The first thing to do is posting pics (possibly magnified)

Quite all problemes come from solder bridges, bad joits and similar.

BTW don't worry, most of the times if something broke it's LM318.

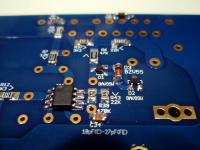

On June 7th I brought home the package with boards and parts from the post. Everything came in great order! Don't have enough words to thank Dario properly! Great work! So, as per 'tutorial', first came the SMD components. Flux used was Russian brand. Somewhat fluid 42% neutral rosin gel. For solder there was a choice between Asahi Sn60 Pb40 and Chemet Sn63 Pb37. It was my first adventure with SMD parts and with many issues too. I was cautious not to overheat the parts. The proper method from tutorial failed to work for me. The solder string just refused to melt. Even when temperature was raised to 300 C. This method certainly needs getting used to! I ended picking tiny balls of solder with iron tip and applying them to the parts. If the ball was too large, it was rejected by whiping the tip. Something like one of three attempts to pick the right ammount of solder turned out successful. Strangely enough the Asahi 60/40 solder proved easier to work with. The result is far from perfect, of course, but possibly acceptable. Hope to try out the boards in a week or so.

Attachments

On June 7th I brought home the package with boards and parts from the post. Everything came in great order! Don't have enough words to thank Dario properly! Great work!

You're welcome 🙂

The proper method from tutorial failed to work for me. The solder string just refused to melt. Even when temperature was raised to 300 C. This method certainly needs getting used to!

What counts is result, any method is good until it works 😉

The result is far from perfect, of course, but possibly acceptable. Hope to try out the boards in a week or so.

Seems pretty good from pic. 🙂

The MyRef puts out a maximum of ~50W into 8r0.

Two channels will total 100W.

Use a transformer from 100VA to 200VA for satisfactory operation.

For good performance I would go towards the upper end (160VA or 225VA).

Using a higher VA transformer does no harm.

Two channels will total 100W.

Use a transformer from 100VA to 200VA for satisfactory operation.

For good performance I would go towards the upper end (160VA or 225VA).

Using a higher VA transformer does no harm.

can I use 1 toroid for 2 board?

It's possible and has been done but the original designer (Penasa) warned againt possible hum/ground problems.

You can start with one transformer and in case of problems you can buy a second one (identical).

what is the minimum value for the toroid?

Andrew already answered.

BTW I would add that R-Core 120VA (like Selectronic ones) seem to perform better than 225VA toroids (at least for the Toroid brand).

is 300VA 2x25 like this is enough? or maybe 225 is quite enough for My Ref FE ?

In case of toroids, higher VA means more subjective 'body' to the sound.

Also the answer vary according transformer number... 1 or 2?

For a pair od boards I would not go lower than 300VA, for dual mono (so TWO trasnformer) I would not go lower than 160VA.

If you choose to use toroids the orvekill config is two 300VA

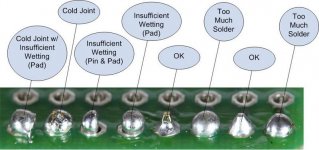

Looks to me like you are shy of solder on almost all of the through hole spots. Know you don't want to burn anything, but I see a great need to reheat them and add some solder. The photo shows how easily one can miss a bad joint.

Attachments

Last edited:

If you don't have quick access to a commercial cleaner right now, Finger Nail Polish Remover and an old toothbrush will do a good job.

I tried that, but it has got fragrance and leaves artefacts on board. Will get nail cleaner tomorrow or go to maplin, if they sell any of sprays...

Values on board seems to be ok (14 v and 32) .. I ll check it again to confirm. Plus 3886 gets warm while powered. Don't know if this say anything...

- Home

- Amplifiers

- Chip Amps

- My_Ref Fremen Edition - Build thread and tutorial