Hi again,

it has been a while since I posted in this topic. for about 6 months ago I built a tapered u-frame line array woofer suggested by Calvin using the RS180-4 driver, 6 drivers per channel.

I just made them from rest-sheets of mutilayered wood, about 15mm thickness. Just routed the driver holes and cut them under an angle to get the wings taper-in. (hope my English is ok...)

As I am very busy with restoring my old house, I forgot to add damping materials to the woofers. So I connected them and started experimenting with DSP crossovers and PEQ, without considering the damping materials. A bit stupid mistake...

I compared the new woofer to my esl's in full-range mode and to the Peerless SLS 12 dipole line array woofer, using 4 drivers, just a plain baffle, no u-frame.

I concluded, just as my girlfriend, that both woofers don't add anything audibly positive: the Peerless woofer baffle sounded maybe a little bit better than the u-frame woofer, but still less "clean" compared to the esl in full range mode. The lf extension was negligible.

So I decided to listen to just the esl's in full range mode. Then last week I read a thread on the audiosciencereview forum about mistakes in open baffle desings. It compared H to U frame and flat baffles and I read some intersting articles about stuffing U frame baffles to overcome problems because of the assymetrical baffle shape and inherent unwanted radiaton patterns:

https://www.audiosciencereview.com/forum/index.php?threads/open-baffle-speaker-pitfalls.39216/

http://musicanddesign.speakerdesign.net/NaO-II-U-frame.html

Then I decided to just try to add some acoustical damping material to 1 channel. I only had sheep wool, so I added this to one channel and made measurements and did some listening tests.

After some testing I can conclude that I prefer the sound of the new U frame woofer with stuffing to the unstuffed one. I also prefer it to the esl in full range mode and the Peerless woofer. Compared to the esl in full range mode the sound is a little "fuller", I guess it adds a few Hz of low range. Compared to the Peerless woofer it sounds cleaner.

I didn't use a proper way of measurements to reach the current stuffing, although I did some measurements of phase and frequency response close to the front of the baffle and in the rear opening and compared these measurements with and without stuffing.

I'm just wondering if sheep wool is the right material for damping these frequencies? Or should I try something different?

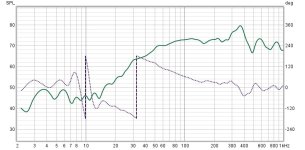

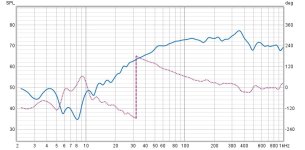

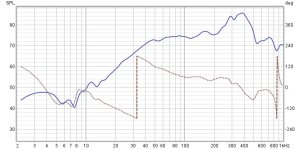

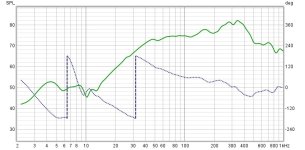

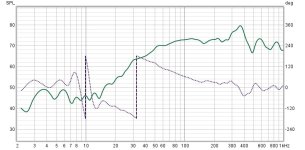

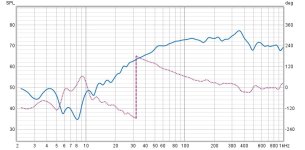

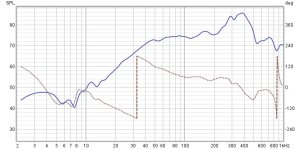

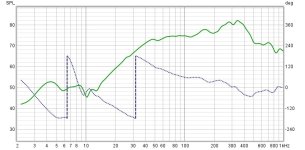

Here are some images of the measurements of the tapered u frame baffle:

front without stuffing

front with stuffing

rear whithout stuffing, phase inverted

rear whith stuffing, phase inverted

it has been a while since I posted in this topic. for about 6 months ago I built a tapered u-frame line array woofer suggested by Calvin using the RS180-4 driver, 6 drivers per channel.

I just made them from rest-sheets of mutilayered wood, about 15mm thickness. Just routed the driver holes and cut them under an angle to get the wings taper-in. (hope my English is ok...)

As I am very busy with restoring my old house, I forgot to add damping materials to the woofers. So I connected them and started experimenting with DSP crossovers and PEQ, without considering the damping materials. A bit stupid mistake...

I compared the new woofer to my esl's in full-range mode and to the Peerless SLS 12 dipole line array woofer, using 4 drivers, just a plain baffle, no u-frame.

I concluded, just as my girlfriend, that both woofers don't add anything audibly positive: the Peerless woofer baffle sounded maybe a little bit better than the u-frame woofer, but still less "clean" compared to the esl in full range mode. The lf extension was negligible.

So I decided to listen to just the esl's in full range mode. Then last week I read a thread on the audiosciencereview forum about mistakes in open baffle desings. It compared H to U frame and flat baffles and I read some intersting articles about stuffing U frame baffles to overcome problems because of the assymetrical baffle shape and inherent unwanted radiaton patterns:

https://www.audiosciencereview.com/forum/index.php?threads/open-baffle-speaker-pitfalls.39216/

http://musicanddesign.speakerdesign.net/NaO-II-U-frame.html

Then I decided to just try to add some acoustical damping material to 1 channel. I only had sheep wool, so I added this to one channel and made measurements and did some listening tests.

After some testing I can conclude that I prefer the sound of the new U frame woofer with stuffing to the unstuffed one. I also prefer it to the esl in full range mode and the Peerless woofer. Compared to the esl in full range mode the sound is a little "fuller", I guess it adds a few Hz of low range. Compared to the Peerless woofer it sounds cleaner.

I didn't use a proper way of measurements to reach the current stuffing, although I did some measurements of phase and frequency response close to the front of the baffle and in the rear opening and compared these measurements with and without stuffing.

I'm just wondering if sheep wool is the right material for damping these frequencies? Or should I try something different?

Here are some images of the measurements of the tapered u frame baffle:

front without stuffing

front with stuffing

rear whithout stuffing, phase inverted

rear whith stuffing, phase inverted

Last edited:

Hi,

the measurements (nice job btw) prove the effectivenes of the damping where it´s required .... to get rid of the chamber resonance peak in the upper range between 200-400Hz.

Amplitude as well as phase response clearly profit from the appliance of the damping material.

Below 200Hz almost no damping material will have an considerable effect ... the mecanical dimensions are just too small.

So the useable upper bandwidth limit should not surpass 200Hz too far.

Regarding the author of the first link, I´d like to say, that his talking so negatively about the U-Frame and similars seems a very restricted view .... seemingly just a theoretical one without due consideration of surrounding parameters.

- U-Frames and similars, as V- and A-types, are very small sized variants of the classic OB-Theme.

Please keep in mind that the footprint of the tower utilizing 6.5" woofer drivers can be as small as a DIN-A5 sheet of paper!

And not every DIYer is willing to sacrifice on looks, haptics and build quality in praxis for an possibly only academically relevant technical improvement .... which might not even appear as a sonic improvement to the ear.

With my woofer towers I eq down to 50Hz (i.e. almost nothing) if a dedicated CB subwoofer is used, or down to 35Hz in solitary use (about +6dB iIrc).

This is a rather mild correction which the array of 6 or 8 drivers can easily take without running into dynamic limitations.

What I like most about the tower besides its tiny footprint is its seamless blending with the ESLs.

It just adds a a couple of Hz down there, with the exact same clean and lightfooted sound character of the ESL, but without the tendency towards a soft, boomy onenote bass so typical for all(!) FR-ESLs.

It increases the dynamic range considerably and performs with a increadibly ´fast´ and punchy kickbass.

jauu

Calvin

the measurements (nice job btw) prove the effectivenes of the damping where it´s required .... to get rid of the chamber resonance peak in the upper range between 200-400Hz.

Amplitude as well as phase response clearly profit from the appliance of the damping material.

Below 200Hz almost no damping material will have an considerable effect ... the mecanical dimensions are just too small.

So the useable upper bandwidth limit should not surpass 200Hz too far.

Regarding the author of the first link, I´d like to say, that his talking so negatively about the U-Frame and similars seems a very restricted view .... seemingly just a theoretical one without due consideration of surrounding parameters.

- U-Frames and similars, as V- and A-types, are very small sized variants of the classic OB-Theme.

Please keep in mind that the footprint of the tower utilizing 6.5" woofer drivers can be as small as a DIN-A5 sheet of paper!

- it is common knowledge, that reducing dimensions comes at a price ... in this case, it´s the reduction in useable upper bandwidth.

- to ´condemn´ the principle all in all by ignoring this simple fact alone is a theoretical, non-practical view.

- used in a sensitive way within a matching overall system concept, the ´flaws´ of the folded baffles may become irrelevant, and the considerable advantage of smaller dimensions outweighs, like wasting less real estate, better looks, and hence higher acceptance factor, etc.

And not every DIYer is willing to sacrifice on looks, haptics and build quality in praxis for an possibly only academically relevant technical improvement .... which might not even appear as a sonic improvement to the ear.

With my woofer towers I eq down to 50Hz (i.e. almost nothing) if a dedicated CB subwoofer is used, or down to 35Hz in solitary use (about +6dB iIrc).

This is a rather mild correction which the array of 6 or 8 drivers can easily take without running into dynamic limitations.

What I like most about the tower besides its tiny footprint is its seamless blending with the ESLs.

It just adds a a couple of Hz down there, with the exact same clean and lightfooted sound character of the ESL, but without the tendency towards a soft, boomy onenote bass so typical for all(!) FR-ESLs.

It increases the dynamic range considerably and performs with a increadibly ´fast´ and punchy kickbass.

jauu

Calvin

Hi all,

about 2 - 3 months ago, one channel of my stats got much lower sensitivity... I was unable to compensate with my DSP. So I built a pair of simple OB speakers, which sounds fine, but I miss the sound quality of my stats.

I ruled out the high voltage supply and the external resistor network. So it must be in the panel itself. Fortunately, I made everything dismountable / removable.

There are no hissing noises like my previous stats, since I use meshes on both front and rear of the panels. I would expect the cause beiing some leakage of hv, but not sure. I have to investigate...

I talked to a former Quad ESL owner, who told me he had to replace his diaphragms after only 2 years. I heard many more similar stories about stats losing their sensitivity. I'm wondering: are these examples of design errors, or is it something inherent to stats running on hv?

about 2 - 3 months ago, one channel of my stats got much lower sensitivity... I was unable to compensate with my DSP. So I built a pair of simple OB speakers, which sounds fine, but I miss the sound quality of my stats.

I ruled out the high voltage supply and the external resistor network. So it must be in the panel itself. Fortunately, I made everything dismountable / removable.

There are no hissing noises like my previous stats, since I use meshes on both front and rear of the panels. I would expect the cause beiing some leakage of hv, but not sure. I have to investigate...

I talked to a former Quad ESL owner, who told me he had to replace his diaphragms after only 2 years. I heard many more similar stories about stats losing their sensitivity. I'm wondering: are these examples of design errors, or is it something inherent to stats running on hv?

Use a simple neon oscillator to check the current draw of both panels. That will tell you if they are leaky.

What coating did you use? It is not uncommon that the coating looses conductivity over time. Try breathing on the membrame while it's playing. The moisture in your breath will temporarely increase conductivity. If this results in increase in volume your coating is eol.

What coating did you use? It is not uncommon that the coating looses conductivity over time. Try breathing on the membrame while it's playing. The moisture in your breath will temporarely increase conductivity. If this results in increase in volume your coating is eol.

Hi, first of all, thanks for the good suggestions! I just opened the stators this morning, and I was surprised how good they stil look after 2 years of use: optically they look clean and like new!

I just cleaned some spots with alcohol, just to be sure. But I didn't see any strange things. I have an external pcb with resisors for electrical segmentation. About 1,5 years ago, I put some super glue on 1 spot because it arced, creating noise / flashes. Since then, it functioned correctly. I detected a lot of dust on the pcb, so I cleaned it, together with everyting in the electronics box. Unfortunately the panel plays still way too soft.

I will try the moisture / diaphragm / coating test! I use a proprietary caoting by M.J. Dijkstra. If the coating would be the cause, I would expect the other, well functioning panel, to have the same issue?

I have neon oscillators on the HV pcb's, and it does't have a higher blinking frequency, so this gives me the impression it could be the segmentation resistor pcb. I will short all segments, bypassing the resistors, to see if there are connection errors here. (I already measured all resistors which measure ok).

I just cleaned some spots with alcohol, just to be sure. But I didn't see any strange things. I have an external pcb with resisors for electrical segmentation. About 1,5 years ago, I put some super glue on 1 spot because it arced, creating noise / flashes. Since then, it functioned correctly. I detected a lot of dust on the pcb, so I cleaned it, together with everyting in the electronics box. Unfortunately the panel plays still way too soft.

I will try the moisture / diaphragm / coating test! I use a proprietary caoting by M.J. Dijkstra. If the coating would be the cause, I would expect the other, well functioning panel, to have the same issue?

I have neon oscillators on the HV pcb's, and it does't have a higher blinking frequency, so this gives me the impression it could be the segmentation resistor pcb. I will short all segments, bypassing the resistors, to see if there are connection errors here. (I already measured all resistors which measure ok).

I don't remember how you did your diaphragm contact. Was it a single connection point, a fully conductive line running up one side, a charge ring (like Sound Lab), tape with conductive adhesive, plain copper foil with pressure contact, conductive paint, etc.?

I also don't remember if you have a high voltage probe. If you do, you can connect your bias to the open panel and probe around the diaphragm to see if it has the proper voltage on it all around. Be careful, obviously, since it's easy to poke a hole in the diaphragm if you get carried away.

I also don't remember if you have a high voltage probe. If you do, you can connect your bias to the open panel and probe around the diaphragm to see if it has the proper voltage on it all around. Be careful, obviously, since it's easy to poke a hole in the diaphragm if you get carried away.

If the contact is poor of the membrane-coating and HV supply or the coating is defective, can be the blinking frequency lower. If the freq. is normal (same as other side), likely there is stator driving problem, as you mean it.I have neon oscillators on the HV pcb's, and it does't have a higher blinking frequency

I'm waiting for your news and good luck!

The EC-coating as well as the slightly improved version HTEC coating work independent from air humidity. They both are insensitive to UV and ozone. If you can see the very slightly opaque coating sitting on the Mylar you can be sure it is conductive. What may respond to your breathing is dirt sitting on the mylar. That can be hygroscopic.I will try the moisture / diaphragm / coating test! I use a proprietary caoting by M.J. Dijkstra. If the coating would be the cause, I would expect the other, well functioning panel, to have the same issue?

The breathing trick tends to work regardless of the coating so yes, it must be dirt ont the membrame that gets conductive with the moisture. I even managed to get output from an uncoated membrame this way, albeit low and just for a few seconds. A fine mist from a spraying bottle such as used for plants works even better, but it can be too much and cause isolation breakdowns.

After say 10 years most audiostatics are pretty dirty inside. Certainly when connected continuously to the mains. Automatic on/off switching is highly recommended. I simply use a switched socket to manually switch on and off.

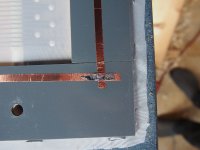

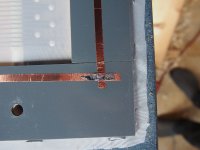

@mattstat: my stats are built als follows: both stators are MDF frames, and on both inner sides there is a pvc sheet around the perimeter for electrical insulation from the MDF framing. One stator has a mylar diapgragm glued to it, using double sided floor tape. Although this doesn't sound high-end, it functions very well! It was a bit of a risk to try this, but it still works well after > 2 years of use.

On the mylar film is the propriety coating by M.J. Dijkstra, pointing towards the copper strip on the other stator. The other stator has a 5mm (?) wide, thin, copper strip, which is thin. It consists of several seperate parts, taped over each other(overlapping), in order to make eletrical contact. It makes pressure contact with the mylar.

Yesterday I managed to solve the problem, which is something I didn't expect! I started measuring the copper ring by connecting the digital multimeter on the connection wire which is soldered at 1 point on the copper ring. I put the other DMM wire on several other points of the ring. At about 60-70% of the measured points I measured a infinite resistance. So I cleaned it with vinegar, as this should remove copper oxidation, if I understand correctly. I also soldered all overlapping copper tape strips, and made the solder also as thin as possible, which was not difficult as it spreads easily across the copper surface.

I assembled the stats again - I made everything removable / detachable, so in about 10 minutes I can (dis) assemble one stat, which is very nice and practical!

Unfortunately there was no noticable difference in sound pressure (sensitivity).

Then I decided to re-apply a new layer of coating on the diaphragm. This made a big difference: the panel plays as loud as the other panel again!

I didn't made sensitivity measurements, unfortunately.

This leads to the question what would have been the cause of this error? Was it only the coating near the small copper strip, or the whole diaphragm area which was affected? Was it only a mechanical problem (both stators not making good physical contact), or something else, like interaction of copper oxide with the diaphragm coating?

@neodymium: unfortunately not at the moment, as I don't own a HV probe. But maybe I can make a HV probe? I do see an increase in neon flash light flickering frequency after applying the new layer of coating.

@MJDijkstra: thanks for the explanation!

I made some pictures during the debugging process:

On the mylar film is the propriety coating by M.J. Dijkstra, pointing towards the copper strip on the other stator. The other stator has a 5mm (?) wide, thin, copper strip, which is thin. It consists of several seperate parts, taped over each other(overlapping), in order to make eletrical contact. It makes pressure contact with the mylar.

Yesterday I managed to solve the problem, which is something I didn't expect! I started measuring the copper ring by connecting the digital multimeter on the connection wire which is soldered at 1 point on the copper ring. I put the other DMM wire on several other points of the ring. At about 60-70% of the measured points I measured a infinite resistance. So I cleaned it with vinegar, as this should remove copper oxidation, if I understand correctly. I also soldered all overlapping copper tape strips, and made the solder also as thin as possible, which was not difficult as it spreads easily across the copper surface.

I assembled the stats again - I made everything removable / detachable, so in about 10 minutes I can (dis) assemble one stat, which is very nice and practical!

Unfortunately there was no noticable difference in sound pressure (sensitivity).

Then I decided to re-apply a new layer of coating on the diaphragm. This made a big difference: the panel plays as loud as the other panel again!

I didn't made sensitivity measurements, unfortunately.

This leads to the question what would have been the cause of this error? Was it only the coating near the small copper strip, or the whole diaphragm area which was affected? Was it only a mechanical problem (both stators not making good physical contact), or something else, like interaction of copper oxide with the diaphragm coating?

@neodymium: unfortunately not at the moment, as I don't own a HV probe. But maybe I can make a HV probe? I do see an increase in neon flash light flickering frequency after applying the new layer of coating.

@MJDijkstra: thanks for the explanation!

I made some pictures during the debugging process:

The coating comes with an instruction guide. This guide also recommends how to make the contact between copper and coating. My advice is to use the described method instead of the current one. By the way my guess is your coating fluid must have been expired for quite a while. It expires within 6 months after ptoduction (see bottle) while I havent distributed it for some time.

@MJ Dijkstra: thanks for your response.

@2tec: they sound very fine, at least, in my subjective opinion. When one channel lost sensitivity, I decided to create a simple open baffle loudspeaker. But it lacked the definition and spacious sound of my stats. It's a big releave to have them in good order again! Way better sound - to my taste - than dynamic drivers, at least, the ones I used.

@2tec: they sound very fine, at least, in my subjective opinion. When one channel lost sensitivity, I decided to create a simple open baffle loudspeaker. But it lacked the definition and spacious sound of my stats. It's a big releave to have them in good order again! Way better sound - to my taste - than dynamic drivers, at least, the ones I used.

They look great, I own some Quad 57s and I've always wanted to build a set of panels.

I also prefer the sound of electrostats.

I also prefer the sound of electrostats.

Hi,

dipole character is not the only reason.

As headphones show, even the best dynamic, iso-dynamic and whatsoever-dynamic HPs just come close to an esl-HP ... and not just when it comes to clarity, fine detail and resolution.

jauu

Calvin

dipole character is not the only reason.

As headphones show, even the best dynamic, iso-dynamic and whatsoever-dynamic HPs just come close to an esl-HP ... and not just when it comes to clarity, fine detail and resolution.

jauu

Calvin

- Home

- Loudspeakers

- Planars & Exotics

- My newest pair of DIY electrostatic panels, advice needed