Headshell

Hi Stu

Been a little preoccupied with other things recently but the brain is now back in gear! I was on EBay earlier and saw a mod for an SME 12" with a straight wand. I was intrigued that the headshell followed my design but the mounting was 'over to one side' to ensure the stylus was exactly in line with the pivot-as you keep advocating and I keep missing the point-until now. I'll do the mod on my 12" version and see what the results are like.

I'll post pictures of the results in a few days.

Regards

Chris

Hi Stu

Been a little preoccupied with other things recently but the brain is now back in gear! I was on EBay earlier and saw a mod for an SME 12" with a straight wand. I was intrigued that the headshell followed my design but the mounting was 'over to one side' to ensure the stylus was exactly in line with the pivot-as you keep advocating and I keep missing the point-until now. I'll do the mod on my 12" version and see what the results are like.

I'll post pictures of the results in a few days.

Regards

Chris

send a link...

chris: either PM or post here. I've thought about this some more and have come to the conclusion that my intuition is correct and for the correct reasons. I guess I could call it "the 219" difference 😉.

dv1000v: If wanting a dual pivot arm, I would strongly suggest looking at a DIY version of the Garrard "zero" arm. Just use much better bearings, or modify one of the old Garrards.

Hi Stu

Been a little preoccupied with other things recently but the brain is now back in gear! I was on EBay earlier and saw a mod for an SME 12" with a straight wand. I was intrigued that the headshell followed my design but the mounting was 'over to one side' to ensure the stylus was exactly in line with the pivot-as you keep advocating and I keep missing the point-until now. I'll do the mod on my 12" version and see what the results are like.

I'll post pictures of the results in a few days.

Regards

Chris

chris: either PM or post here. I've thought about this some more and have come to the conclusion that my intuition is correct and for the correct reasons. I guess I could call it "the 219" difference 😉.

dv1000v: If wanting a dual pivot arm, I would strongly suggest looking at a DIY version of the Garrard "zero" arm. Just use much better bearings, or modify one of the old Garrards.

Last edited:

Hi Stu et al

I finally understood the need for the stylus to be in line with the arm tube and pivot and carried out the mod to the headshell this morning-around a 15 minute job. This is not the final product as it was a piece of oak I had lying around and roughly the right dimensions.

Incidentally, the arm is now closer to 14" than the original 12".

Plugged in the Goldring 1042 and you know what-sound quality had gone up several notches in every respect.

The headshell is till very easy to make but will be used on my other designs in future-should have listened around a year ago!

Thank Stu!!

Chris

I finally understood the need for the stylus to be in line with the arm tube and pivot and carried out the mod to the headshell this morning-around a 15 minute job. This is not the final product as it was a piece of oak I had lying around and roughly the right dimensions.

Incidentally, the arm is now closer to 14" than the original 12".

Plugged in the Goldring 1042 and you know what-sound quality had gone up several notches in every respect.

The headshell is till very easy to make but will be used on my other designs in future-should have listened around a year ago!

Thank Stu!!

Chris

Attachments

Stew,

Your comments regarding keeping the stylus in line with the pivot interest me. If I am planning to make a fixed mounting distance arm, would I be wanting to make a straight slotted headshell like your original, or would I be better to make an angled one with an offset headshell?

I see you're able to move your base, and that makes alignment much easier to achieve with your headshell. I intend to copy most of an existing 12" arms geometry such as an SME V12, but a unipivot of course. The headshell has about an 18 degree or so angle to it, so would I just make my slots the same angle to allow my headshell to move for and aft to get the stylus in line? This is the arm I was using as a visual, hence my using it as an example:

SME - Series V-12

I am still confused on the level of the pivot. Is the pivot at stylus level preferable to a pivot above the stylus? I get the center of gravity principle, but the actual location interests me.

Thanks in advance.

Your comments regarding keeping the stylus in line with the pivot interest me. If I am planning to make a fixed mounting distance arm, would I be wanting to make a straight slotted headshell like your original, or would I be better to make an angled one with an offset headshell?

I see you're able to move your base, and that makes alignment much easier to achieve with your headshell. I intend to copy most of an existing 12" arms geometry such as an SME V12, but a unipivot of course. The headshell has about an 18 degree or so angle to it, so would I just make my slots the same angle to allow my headshell to move for and aft to get the stylus in line? This is the arm I was using as a visual, hence my using it as an example:

SME - Series V-12

I am still confused on the level of the pivot. Is the pivot at stylus level preferable to a pivot above the stylus? I get the center of gravity principle, but the actual location interests me.

Thanks in advance.

Hi Stew

Mind must have been wandering again!

Regards

Chris

Chris,

even my (biological) brothers screw that one up. I just "shorten to "stu" when in a hurry or not paying attention, too.

Stew,

Your comments regarding keeping the stylus in line with the pivot interest me. If I am planning to make a fixed mounting distance arm, would I be wanting to make a straight slotted headshell like your original, or would I be better to make an angled one with an offset headshell?

I see you're able to move your base, and that makes alignment much easier to achieve with your headshell. I intend to copy most of an existing 12" arms geometry such as an SME V12, but a unipivot of course. The headshell has about an 18 degree or so angle to it, so would I just make my slots the same angle to allow my headshell to move for and aft to get the stylus in line? This is the arm I was using as a visual, hence my using it as an example:

SME - Series V-12

I am still confused on the level of the pivot. Is the pivot at stylus level preferable to a pivot above the stylus? I get the center of gravity principle, but the actual location interests me.

Thanks in advance.

Morton:

I'm very familiar with the SME tonearms (I own one of the newest 309's, with magnesium armtube). Not a 12", but it fit the existing arm board (sort of) on my old Oracle Alexandria tt.

An aside: Anybody that has complained regarding the Alex's sound most certainly has not heard one properly set up with a decent or good arm on it---the Oracle Prelude arm is such a POS, it actually hurts the performance of the Alex.

and now back to the question at hand... The location for the pivot (vertically) is typically about half way through the arm tube. This helps to stabilize the arm. Think like the broom on a finger, or broom held by your index finger and thumb being hung below . Which is more stable? Ideally the pivot would be in the exact plane as the stylus, but this is not practical. So I use a vertical pivot approximately 4.5 mm inside the arm tube (when using an arm tube with an OD of 23/64" or 9.12812 5mm).

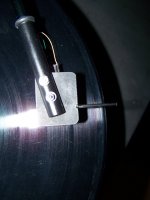

Headshell

Hi Everyone

Close ups of new headshell-a real success now I've cottoned on to the fact that the stylus needs to be aligned to the pivot down the centre line of the arm tube.! Put a second bolt on to ensure a snug, secure mounting-again, it worked superbly!

I'll be making one out of perspex-it'll look prettier.

Chris

Hi Everyone

Close ups of new headshell-a real success now I've cottoned on to the fact that the stylus needs to be aligned to the pivot down the centre line of the arm tube.! Put a second bolt on to ensure a snug, secure mounting-again, it worked superbly!

I'll be making one out of perspex-it'll look prettier.

Chris

Attachments

Latest Perspex headshell

Hi Folks

This is the latest version of the headshell and it looks like this is the one I'll use from now on. The mounting plate is perspex and it looks a whole lot neater than the previous one-and is probably sonically better as it's more rigid.

Chris

Hi Folks

This is the latest version of the headshell and it looks like this is the one I'll use from now on. The mounting plate is perspex and it looks a whole lot neater than the previous one-and is probably sonically better as it's more rigid.

Chris

Attachments

Looking clean Chris.

Are you using a different arm tube now? I guess to move the cartridge and get alignment perfected that you need to move the base/pivot point?

Are you using a different arm tube now? I guess to move the cartridge and get alignment perfected that you need to move the base/pivot point?

Headshell

Hi Mortron

No-that's just a kebab stick used for holding it while I spray it! Still using Easton Gamegetters-had to buy a dozen-get two arms per shaft so plenty left.

I've been experimenting with another configuration-watch this space-it looks mighty interesting.

Regards

Chris

Hi Mortron

No-that's just a kebab stick used for holding it while I spray it! Still using Easton Gamegetters-had to buy a dozen-get two arms per shaft so plenty left.

I've been experimenting with another configuration-watch this space-it looks mighty interesting.

Regards

Chris

New Headshell in Action

Hi Folks

New headshell in action-very pleased with it. However-the 'business-end ' on this is not a unipivot-I've been playing around with this a while and decided to get it up and running this morning-it's super!! Can anyone guess what I've done?

Regards to All

Chris

Hi Folks

New headshell in action-very pleased with it. However-the 'business-end ' on this is not a unipivot-I've been playing around with this a while and decided to get it up and running this morning-it's super!! Can anyone guess what I've done?

Regards to All

Chris

Attachments

Het Stew,

Regarding the multipvot, I ment two unipivot arms, parallel working with (very) small ball bearings in the headshell mounting. Something like the Thales Simplicity.

OK, it's more complex than a kebab stick as tone arm ( ;- Chris), but it should me doable...

GRTZ,

Mark

Regarding the multipvot, I ment two unipivot arms, parallel working with (very) small ball bearings in the headshell mounting. Something like the Thales Simplicity.

OK, it's more complex than a kebab stick as tone arm ( ;- Chris), but it should me doable...

GRTZ,

Mark

Hi guys.

Mark: Which is very similar to the Garrard Zero tonearms. Look here and see what I mean. If good low friction bearings are used it should work very well and provide near linear tracking levels of racking error.

Chris: You're getting closer, but there is still one point that all have missed (and dare I say almost every tonearm manufacturer as well). I'm not saying I smarter than everybody else ever associated in making tonearms (whether as a hobby or as a manufacturer), I just see things "differently. This has allowed me to make changes that I may not be able to articulate, but to me they are just intuitive. When you get it absolutely correct, I might let you know😉

Mark: Which is very similar to the Garrard Zero tonearms. Look here and see what I mean. If good low friction bearings are used it should work very well and provide near linear tracking levels of racking error.

Chris: You're getting closer, but there is still one point that all have missed (and dare I say almost every tonearm manufacturer as well). I'm not saying I smarter than everybody else ever associated in making tonearms (whether as a hobby or as a manufacturer), I just see things "differently. This has allowed me to make changes that I may not be able to articulate, but to me they are just intuitive. When you get it absolutely correct, I might let you know😉

Last edited:

Hey guys,

Stew: I hope to combine the advantages (and simplicity) of the unipivot design with a semi lineair tracking arm.

Chris; you lost AFAICS the unipivot completely with this arm, but I guess you're clever enough to make it great sounding tonearm

In my opinion the fixing and pivoting point of the "cartridge plate" should be the exact location where the stylus tip must be, at the centre of te tonearm. Then it is allways exactly in line with the arm and the pivot.

Stew: I hope to combine the advantages (and simplicity) of the unipivot design with a semi lineair tracking arm.

Chris; you lost AFAICS the unipivot completely with this arm, but I guess you're clever enough to make it great sounding tonearm

In my opinion the fixing and pivoting point of the "cartridge plate" should be the exact location where the stylus tip must be, at the centre of te tonearm. Then it is allways exactly in line with the arm and the pivot.

Hi All

No-I'm not going to abandon the unipivot principle-it's just that I had these bits lying around and I wanted to experiment with the headshell which will now be used in future. The arm pillar and horizontal bearings are from an SME 3009 and I have dispensed with the the knife edge and replaced with two ABEC 9 ball races. It works exceptionally well. The plate and its configuration on the headshell ensures that the stylus tip is always in line with the pivot. Neat eh?

Regards

Chris

No-I'm not going to abandon the unipivot principle-it's just that I had these bits lying around and I wanted to experiment with the headshell which will now be used in future. The arm pillar and horizontal bearings are from an SME 3009 and I have dispensed with the the knife edge and replaced with two ABEC 9 ball races. It works exceptionally well. The plate and its configuration on the headshell ensures that the stylus tip is always in line with the pivot. Neat eh?

Regards

Chris

I would be very grateful if you could share how you fitted the ball race bearings. I have a pillar and yolk from a SME also but have stalled using it because of the knife bearings.

Sorry to go OT

Sorry to go OT

SME Pillar and Pivot

Hi

As promised. This will be the last post on this as it isn't a good unipivot design!

It is ,however, an excellent performer! You need a round file to file down the 'v' on either side to ensure a snug fit with your chosen bearings. Then use industrial strength superglue and there you have it!

Regards

Chris

Hi

As promised. This will be the last post on this as it isn't a good unipivot design!

It is ,however, an excellent performer! You need a round file to file down the 'v' on either side to ensure a snug fit with your chosen bearings. Then use industrial strength superglue and there you have it!

Regards

Chris

Attachments

- Status

- Not open for further replies.

- Home

- Source & Line

- Analogue Source

- my latest iteration of "Nanook's 219 tonearm"..