not over...

dl1000v: perhaps the closest I have seen to my implementation. Nothing fancy, just well put together.

dl1000v: perhaps the closest I have seen to my implementation. Nothing fancy, just well put together.

an armlift solution.

This is what has stopped me from pursuing this as a commercial design. I could buy complete tonearm mounts with an arm lift, but they are a little on the expensive side and would take away from what the arm is. If I could get something made, then maybe not.

I know I could use something as simple as a piece of brass rod bent into a suitable shape. I do like the idea of a good, "proper" lift though.

This is what has stopped me from pursuing this as a commercial design. I could buy complete tonearm mounts with an arm lift, but they are a little on the expensive side and would take away from what the arm is. If I could get something made, then maybe not.

I know I could use something as simple as a piece of brass rod bent into a suitable shape. I do like the idea of a good, "proper" lift though.

Think out of the box

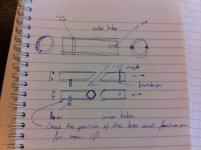

Maybe we should use radial movement to create a steady axial movement to keep it simple....

This can be done with a couple of tubes.

I'll try to work this out this afternoon

Grtz, Mark

Maybe we should use radial movement to create a steady axial movement to keep it simple....

This can be done with a couple of tubes.

I'll try to work this out this afternoon

Grtz, Mark

I like the design. It is clever and simple. I think I'll steal it

Sincerely,

Ralf

Hey Ralf,

Please show me the results when finished.

Succes

Grtz, Mark

Turning te bottom lever delivers a lift of 2,5mm (photo 2).

I hope this will be enough...

Grtz, Mark

Around 2 mm of lift at the lifter translates to a lot of lift at the headshell.

Yours' is a very interesting design. Would you mind sharing the plan? Also, do you use some sort of damping mechanism to slow down the drop?

Plan and damping armlift

Morning JLS,

I'll try to make a drawing of the construction and post it as soon as possible (and request the copyrights ;-) ).

There's is no damping whatsoever. I guess some grease will do the trick, but i have to test that. Gentle movements of the lever defenately works ;-).

Grtz, Mark

Morning JLS,

I'll try to make a drawing of the construction and post it as soon as possible (and request the copyrights ;-) ).

There's is no damping whatsoever. I guess some grease will do the trick, but i have to test that. Gentle movements of the lever defenately works ;-).

Grtz, Mark

Think out of the box III

The POC of the armlift works.

It need some refinements, but the POC has proven that the principle is OK to use. Images will follow...

I love it when a plan.........

Grtz, Mark

The POC of the armlift works.

It need some refinements, but the POC has proven that the principle is OK to use. Images will follow...

I love it when a plan.........

Grtz, Mark

POC...

I tried a version of your arm lift and it does indeed work. With very little effort it van be made to become a proper camshaft lift...

I tried a version of your arm lift and it does indeed work. With very little effort it van be made to become a proper camshaft lift...

Very nice...

... and simple!

I've come up with a camshaft solution tat allows for a twist of a shaft to lift the arm (actually it lifts a ball that lifts a dowel in a tube. Attach a horizontal arm and should be in business! will post as soon as I finish it.

... and simple!

I've come up with a camshaft solution tat allows for a twist of a shaft to lift the arm (actually it lifts a ball that lifts a dowel in a tube. Attach a horizontal arm and should be in business! will post as soon as I finish it.

Whate else?

No not Nespresso, but creating an armlift whith such a tight fit between the tubes that nothing wiggles.

Keep Y'all posted

Grtz, Mark

No not Nespresso, but creating an armlift whith such a tight fit between the tubes that nothing wiggles.

Keep Y'all posted

Grtz, Mark

lifter

nothing new but in the easy way, without any lathe.

May be build with some pieces of plexi (or lexan), 1.5 mm piano wire, a scrapbook screw, and one of 2.5 or 3 mm. The hardest thing is to make the 1.5 mm hole into the scrapbook screw. The 2.5 screw is there to adjust the friction.

Hope this helps - Carlo

nothing new but in the easy way, without any lathe.

May be build with some pieces of plexi (or lexan), 1.5 mm piano wire, a scrapbook screw, and one of 2.5 or 3 mm. The hardest thing is to make the 1.5 mm hole into the scrapbook screw. The 2.5 screw is there to adjust the friction.

Hope this helps - Carlo

Attachments

- Status

- Not open for further replies.

- Home

- Source & Line

- Analogue Source

- my latest iteration of "Nanook's 219 tonearm"..