well other than in flights of fantasy, I'm not a scientist, engineer or artist - I leave that to the truly talented, but we certainly look forward to your progress reports and listening impressions

Ha ha to me too, I may end up having pie on my face. The drivers are too small for the volume in this enclosure if I follow the general rule of 8" to 0.7 to 1 cubic foot...

So it's been a little while since my last update.

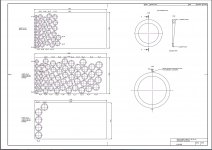

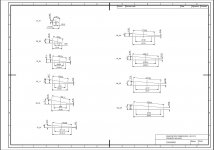

Due to the nature of the design, I had no intensions on shaping every individual section by hand, (theirs 102 on one cabinet), but I wanted to use a CNC Router.

This has been just as slow which was a surprise. I have been approaching many companies in both the UK and France, but everyone wants crazy money for the use of their machines.

I have now made a router jig to be able to get the angles, though this is a backup plan.

I have been bogging on my progress to date on - https://www.facebook.com/SparrowLegsSpeakerDesign

Due to the nature of the design, I had no intensions on shaping every individual section by hand, (theirs 102 on one cabinet), but I wanted to use a CNC Router.

This has been just as slow which was a surprise. I have been approaching many companies in both the UK and France, but everyone wants crazy money for the use of their machines.

I have now made a router jig to be able to get the angles, though this is a backup plan.

I have been bogging on my progress to date on - https://www.facebook.com/SparrowLegsSpeakerDesign

Attachments

Oh, last week there was a point when I was getting the quotes for the CNC Routing coming in at a ridicules prices. So I made a video. If you want a laugh, have a look at - Invest in Sparrow Legs Speaker Design - YouTube

My project has 126 layers in each tower and I did it with a hand router 😀. You'll need time, lots of it!!! The angle part would take even longer!

I did pre-cuts with a jig saw. That's not something I'd like to do again!

I did pre-cuts with a jig saw. That's not something I'd like to do again!

Oh, last week there was a point when I was getting the quotes for the CNC Routing coming in at a ridicules prices.

Are you sure you just don't have unreasonable expectations?

CNCs are not cheap, require significant space to house,maintenance, skilled operator ...

dave

3 months of daily routing/sawing about 6 hours a day 😱.How long did it take?

Give or take a few days off to keep my sanity 🙄.

The use of a template was very helpful for me. You have ever changing shapes and only 2 of the same shape, one for each speakers. So basically 105 different shapes! I had only 4 different shapes.

Last edited:

Are you sure you just don't have unreasonable expectations?

CNCs are not cheap, require significant space to house,maintenance, skilled operator ...

dave

Dave, When I say ridicules, I'm not joking - remember, I'm in the south of France, so when asking for 3400Euros for the pair, this is a mad price. It would be no more than 1000 in the uk...

I had a thought of doing this a while ago.

I never really experimented but planned to get some flexible hose as used for machine extraction, 100 diameter, make a cut along its length and glue it back tighter, so it forms a tapering tube (like when your roll a newspaper up)

I had planned to put it in a box and fill the void with expanding foam or similar to dampen it down.

I have access to a CNC, pm your details and Ill try and work out a price.

Louis

I never really experimented but planned to get some flexible hose as used for machine extraction, 100 diameter, make a cut along its length and glue it back tighter, so it forms a tapering tube (like when your roll a newspaper up)

I had planned to put it in a box and fill the void with expanding foam or similar to dampen it down.

I have access to a CNC, pm your details and Ill try and work out a price.

Louis

Those prices sound in the ballpark. Routing the wedge shape on each piece probably rtiples (at least) the cost over flat pieces.

dave

dave

hmmm, could any of that have been predicted? 🙄

Not to belittle his work in the least, but wesayso's monumental project was at least somewhat simpler than the proposed spirals in that there were "only" a couple or maybe 4(?) discrete patterns to be executed, albeit with dozens of copies of each

Still, its a far more ambitious project than many of us would want to undertake, and I must admit that while not being a fan of any of the line arrays (or for that matter full size planars) that I've yet heard, there's an ineffable appeal to his work.

Certainly props need be given for the effort and the results - once the system is dialed in, maybe he could post a YouTube video with MP3 sound recording 😉 - sorry, now that's a cheap shot - not at WSS , but at other such posts 🙂

Not to belittle his work in the least, but wesayso's monumental project was at least somewhat simpler than the proposed spirals in that there were "only" a couple or maybe 4(?) discrete patterns to be executed, albeit with dozens of copies of each

Still, its a far more ambitious project than many of us would want to undertake, and I must admit that while not being a fan of any of the line arrays (or for that matter full size planars) that I've yet heard, there's an ineffable appeal to his work.

Certainly props need be given for the effort and the results - once the system is dialed in, maybe he could post a YouTube video with MP3 sound recording 😉 - sorry, now that's a cheap shot - not at WSS , but at other such posts 🙂

Those prices sound in the ballpark.

dave

Which price, UK or French?

Dave, When I say ridicules, I'm not joking - remember, I'm in the south of France, so when asking for 3400Euros for the pair, this is a mad price. It would be no more than 1000 in the uk...

You've confirmed the latter figure, and does that include all the material (which even with tightly nested planning can still have a very low yield when descending radii are involved) as well as machining /programming time? Being in the commercial trade or over 20yrs, I can suggest that it'd be risky to blindly accept CAD files not produced or recompiled in house for the specific machine's OS (yes, they're not all the same) , and there's a lot to be vetted in a design such as this.

Don't take this as dismissive of the concept, but a dose of reality is in order.

Chrisb, Yep you are right on all counts.

I like a challenge and as with everything I have done, if it's not a challenge I seem to lose interest.

This project has become more challenging than first thought, but I have spoken to many interesting people along the way, as well as received much interest.

I would like to say "watch this space", but as I'm learning, this may be a while!

I like a challenge and as with everything I have done, if it's not a challenge I seem to lose interest.

This project has become more challenging than first thought, but I have spoken to many interesting people along the way, as well as received much interest.

I would like to say "watch this space", but as I'm learning, this may be a while!

Forgive me, haven't read all this, but in regards to fabricating a spiralesque design:

Could cutting flat panel rings as ribs and wrapping them in fiberglass not provide a cheap/rigid enclosure than ca be filled and sanded smooth? Probably not very expensive but could cause turbulence issues? I'm new.

Could cutting flat panel rings as ribs and wrapping them in fiberglass not provide a cheap/rigid enclosure than ca be filled and sanded smooth? Probably not very expensive but could cause turbulence issues? I'm new.

Even doing it by hand can add up. I've used up 7 router bits of good quality. 10 saw blades, two routers (my first cheap router failed after only a week) 🙂.

The design has been done, as well as been tested. I've had 10 sections cut already with little issues. That was the easy part.

With regards to nesting, I have managed to get the pair nested on 3 sheets of ply, 2x 38mm and 1x 22mm.

The UK price was including materials, but I would rather have this done locally.

With regards to nesting, I have managed to get the pair nested on 3 sheets of ply, 2x 38mm and 1x 22mm.

The UK price was including materials, but I would rather have this done locally.

Last edited:

Forgive me, haven't read all this, but in regards to fabricating a spiralesque design:

Could cutting flat panel rings as ribs and wrapping them in fiberglass not provide a cheap/rigid enclosure than ca be filled and sanded smooth? Probably not very expensive but could cause turbulence issues? I'm new.

This has been done already. I have no interest in doing something which already exists.

Also, from my research, these may be the first logarithmic spiral speaker made purely from wood ever made 🙂😀

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Full Range

- My first build - Affordable Transmission Line spiralled Loud Speaker