Reply to post

I've used STP in the arm pot on my WTT with LP Lab carbon fiber arm mod for well over a decade. Thinner than the recommended silicone viscosity. Tracks beautifully.

I've used STP in the arm pot on my WTT with LP Lab carbon fiber arm mod for well over a decade. Thinner than the recommended silicone viscosity. Tracks beautifully.

Thanks bcc1955, I have reviewed WTL manuals and see the doughnut counterbalance weight on the tone arm tube. Easy enough to turn another though I will need to source some large diameter material first.

Regarding stability, bgruhn suggested adding a magnet. I find that rotation (Tracking record) and raise/lower of tonearm, the fluid is in shear and (hopefully) not too difficult to move; while the fluid must flow from one side of the pot to the other in order to move off centre and this is much more difficult. So location should not be an issue with ~ 1/3rd ball depth.

Regarding stability, bgruhn suggested adding a magnet. I find that rotation (Tracking record) and raise/lower of tonearm, the fluid is in shear and (hopefully) not too difficult to move; while the fluid must flow from one side of the pot to the other in order to move off centre and this is much more difficult. So location should not be an issue with ~ 1/3rd ball depth.

Sorry for the late reply as the diyaudio.com site was down yesterday. I have considered a magnet as well but am not convinced it is desirable. It would fight against vertical pivoting of the tonearm which is already slowed by the dampening fluid. I have yet to read a single review that detects any audible effect from the small movement you would expect from variable drag at the stylus. I plan on doing a lot of listening before thinking about adding that feature. As they they say KIS!

Last edited:

russc,

IMO unipivot tonearms are garbage!! Since you have lowered your counterbalance CG and essentially recreated the worst feature of this tonearm you can do the same experiment I have done. Get your gram scale out. Place your tonearm on it with the arm parallel to earth at 2 grams VTF or whatever you use. Next lower the cartridge/tonearm end a bit and reweigh the VTF again. Yow, what do you see! A lower VTF when you really need a higher VTF to overcome the dip in the record! This is why unipivots are CRAP! and why the WT LTD overcomes their limitation. So keep your CG over your hinge point and you will be rewarded.

IMO unipivot tonearms are garbage!! Since you have lowered your counterbalance CG and essentially recreated the worst feature of this tonearm you can do the same experiment I have done. Get your gram scale out. Place your tonearm on it with the arm parallel to earth at 2 grams VTF or whatever you use. Next lower the cartridge/tonearm end a bit and reweigh the VTF again. Yow, what do you see! A lower VTF when you really need a higher VTF to overcome the dip in the record! This is why unipivots are CRAP! and why the WT LTD overcomes their limitation. So keep your CG over your hinge point and you will be rewarded.

Counterweight

Hi Everyone

The issue regarding the counterweight and centre of gravity hadn't occurred to me as the arm performed so well with the 'dropped' counterweight. I'd merely used this design as I had used this type of counterweight on my unipivots as they were easy to source (drawer handles), were easy to adjust and looked good.

After reading the recent inputs, I've made another counterweight which keeps cog above pivot. Initial impressions don't immediately seem different to the other arrangement. Watch this space. Pictures included.

Hi Everyone

The issue regarding the counterweight and centre of gravity hadn't occurred to me as the arm performed so well with the 'dropped' counterweight. I'd merely used this design as I had used this type of counterweight on my unipivots as they were easy to source (drawer handles), were easy to adjust and looked good.

After reading the recent inputs, I've made another counterweight which keeps cog above pivot. Initial impressions don't immediately seem different to the other arrangement. Watch this space. Pictures included.

Attachments

In theory it should be better on your least flat records. It should also allow equal tracking at slightly lower VTF. So you have some playing around to do to detect a sonic difference. I am just going with theory. For fun put the end of the tonearm on a scale when flat, when tilted down, and when tilted up. Do it with both your counterweight configurations. You should be able to measure what I noted.

Have fun!

Have fun!

Hey-there's something going on here!! I believe that the revised counterweight arrangement is having a significant effect on the performance of the arm. For the better I might add. I'll report further after a bit more listening.

Chris

Chris

Nice counterweight. Did you turn it on a lathe yourself? I am just getting a lathe together and will hopefully post some pics in due time. When I went about making my own tonearms I found unipivot configurations with their CG well below the hinge point perversely caused the opposite of the tracking dynamics that I sought. As always the CG is forward of the hinge point to give the cartridge a couple grams of down force. If the hinge point is above the CG downward movement of the cartridge reduces the lever arm of gravity's force. If the hinge point is instead below the CG downward movement of the cartridge increases the lever arm of gravity's force. Best to sketch it out yourself to get a firm grasp on it all. So without listening to the effect I have concluded that getting heavier for dips and lighter for hills is a better dynamic for cartridge VTF. This is impossible to achieve with a unipivot as it becomes unstable. However, the WT tonearm with its V-string pivot stabilizes the tonearm and allows this configuration as does your typical physically hinged tonearms. Hopefully, someone will chime in here and offer a defense for unipivot tonearms. Other than having cheaper manufacturing expenses I see zero benefit to the design. Particularly with the even cheaper to manufacture WT style tonearms that overcome its deficiency and others.

Last edited:

As I'm looking to test one of these out, does anyone know if this arm should work well with my current cartridge, an AT150MLX?

Arm length would be 12" eff, full golf ball style at first.

Arm length would be 12" eff, full golf ball style at first.

AT Cartridge

Hi

I've used my arms with both MC's (AT OC5/OC9/Ortofon MC15 Super) and MM's (Goldring 1042 and a selection of others). Always brought the best out in any cartridge I was using.

Regards

Chris

Hi

I've used my arms with both MC's (AT OC5/OC9/Ortofon MC15 Super) and MM's (Goldring 1042 and a selection of others). Always brought the best out in any cartridge I was using.

Regards

Chris

Thanks, I remembered seeing something along those lines in the iirc Fremer review, but I tend to take those reviews with a grain of salt, and was curious what others had experienced.

My main reason for trying it is to see if my current tt is more limited by the arm or tt itself. Despite aligning the at150mlx as well as I can on the current tt (debut carbon) I'm still getting sibilance on a few records, to the point it actually sounds like static. For comparison, the closest place with actual turntables set up has a poorly set up project xtension 9 super pack, and even with the table not leveled correctly, it got rid of the sibilance on those records.

My main reason for trying it is to see if my current tt is more limited by the arm or tt itself. Despite aligning the at150mlx as well as I can on the current tt (debut carbon) I'm still getting sibilance on a few records, to the point it actually sounds like static. For comparison, the closest place with actual turntables set up has a poorly set up project xtension 9 super pack, and even with the table not leveled correctly, it got rid of the sibilance on those records.

Hi Chris,

There is a great obscure article from 2004 that is well worth the read and I think nails the situation. Its long and if you are impatient skip to the end of it. He basically goes through and explains that the importance of VTA, in and of itself, is hype and the press is confused due to designs such as unipivots that result produce inordinately high VTF effects from small VTA changes. Which given that VTA is nearly impossible to tightly control (given record height and flatness variability) would make that tonearm design poor.

See Exposing the VTA myth? [English]

There is a great obscure article from 2004 that is well worth the read and I think nails the situation. Its long and if you are impatient skip to the end of it. He basically goes through and explains that the importance of VTA, in and of itself, is hype and the press is confused due to designs such as unipivots that result produce inordinately high VTF effects from small VTA changes. Which given that VTA is nearly impossible to tightly control (given record height and flatness variability) would make that tonearm design poor.

See Exposing the VTA myth? [English]

Last edited:

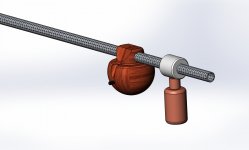

Not wired yet but soon come.

I have mixed 10k cs silicone with 125k to get a reasonable value.

I think the fluid should be light enough to cover more than 1/4 of the

damping ball. this way I should not get so much fore/aft movement.

arm is 12" and made of Western Red Cedar.

I think it is going to work well judging by how the arm moves!

I have mixed 10k cs silicone with 125k to get a reasonable value.

I think the fluid should be light enough to cover more than 1/4 of the

damping ball. this way I should not get so much fore/aft movement.

arm is 12" and made of Western Red Cedar.

I think it is going to work well judging by how the arm moves!

An externally hosted image should be here but it was not working when we last tested it.

That's great work, yours is working.

Mine has come to a grinding halt.

Gosh I need to get it finished and running

Mine has come to a grinding halt.

Gosh I need to get it finished and running

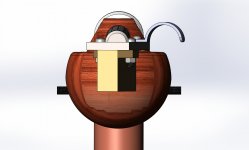

I tried STP; way too light the way I see it. I tried to kee the arm light. The headshell was hacksawed and filed from 1/8" al. the wires will be teflon coated (28 ga.?) from an HP mouse. What a job it was to get those out.

The damping ball was originally routered out with a slot such as on the armrest. This resulted in too low of an arm to work with the bowl/bath/cup.

Worse it did not allow for low enough pins on the ball for the string. A second arm was made and the arm was glued directly on the top of the flat on the ball. Much better.

I did not realize that azimuth was changed by rotating the rubber grommet.

Very slick.

I am getting some rubbing/clicking of the nylon line as it unwinds. I will see if it does it in the final setup. If it does I will not use a half twist in the string, but rather setup the arm wires in a half loop to the inside of the back of the arm to resist inward movement of the arm.

I took care that the stylus would be centered on the axis of the arm.

the headshell was cut at 17 degrees.

The damping ball was originally routered out with a slot such as on the armrest. This resulted in too low of an arm to work with the bowl/bath/cup.

Worse it did not allow for low enough pins on the ball for the string. A second arm was made and the arm was glued directly on the top of the flat on the ball. Much better.

I did not realize that azimuth was changed by rotating the rubber grommet.

Very slick.

I am getting some rubbing/clicking of the nylon line as it unwinds. I will see if it does it in the final setup. If it does I will not use a half twist in the string, but rather setup the arm wires in a half loop to the inside of the back of the arm to resist inward movement of the arm.

I took care that the stylus would be centered on the axis of the arm.

the headshell was cut at 17 degrees.

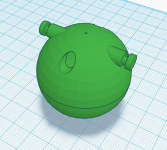

Maybe something like this?

Would come in at about 4grm lighter than the original golf ball.

Small hole at top to align pivot point marked on shaft (if you wish to do so)

External tie points so you don't have to thread through ball and everything is squared off perpendicular. Total volume about 24.4cm, so I think compacted sand would come in at about 4-5 grams light than standard.

This would take an Easton Arrows Jazz 1516 or is it 1615? anyway its 6mm diameter.

Would come in at about 4grm lighter than the original golf ball.

Small hole at top to align pivot point marked on shaft (if you wish to do so)

External tie points so you don't have to thread through ball and everything is squared off perpendicular. Total volume about 24.4cm, so I think compacted sand would come in at about 4-5 grams light than standard.

This would take an Easton Arrows Jazz 1516 or is it 1615? anyway its 6mm diameter.

Attachments

Last edited:

If you move the center of mass of the needle area will be a very good effect.

I have read the opposite. What has been your experience as to the good effects? thank you.

Centre of mass and pivot point.If you move the center of mass of the needle area will be a very good effect.

Attachments

- Status

- Not open for further replies.

- Home

- Source & Line

- Analogue Source

- My DIY WTL Tonearm