Apologies Dene i mistook you to be in Yorkshire....

The silicon fluid most of us use is 100,000 ct very thick.

It's said that when you let go of the finger lift that the cartridge should take a few seconds to reach the record.

Looking at your arm you have fitted the arm tube low in the ball, Most of us have fitted it much higher near to the top or on top of the ball.

How is the cartridge mount fitted to the tube? It looks as though the cartridge mount is 'only just touching' the tube with a very small contact area, this could restrict 'energy flow' through the tube.

The silicon fluid most of us use is 100,000 ct very thick.

It's said that when you let go of the finger lift that the cartridge should take a few seconds to reach the record.

Looking at your arm you have fitted the arm tube low in the ball, Most of us have fitted it much higher near to the top or on top of the ball.

How is the cartridge mount fitted to the tube? It looks as though the cartridge mount is 'only just touching' the tube with a very small contact area, this could restrict 'energy flow' through the tube.

Its hard to see how much fluid you have in the ball reservoir. If you make the cup adjustable height, you could tune the sound quite a bit. If you have the ball too deep in the silicon, the sound could get very dull.

As to your wire, Bill Firebaugh highly recommends litz wire.

As to your wire, Bill Firebaugh highly recommends litz wire.

I agree with ponger about depth of fluid. You can use a biggish syringe to extract fluid if you put in to much. & litz wire is cheep & very good

Guys, thank you for the good advice. I will go in steps, first playing with the depth of the silicon oil. I use 100,000 cSt and can adjust the depth of the ball in the oil bath with the top screw within a 10mm range. Modifying the inner cable would be the next step.

001

My take on the sand filled tube is it is possible to over damp the tube and (possibly) contribute a mechanism that would compete with a high frequency resonance created by the cartridge leading to a dulling of what your hearing.

If it were me I would loose the carbon fiber somewhere in the trash can and put a titanium tube in its place with sand mixed with chalk so all spaces are filled to limit any movement to an absolute miniscule level.

Its easier to damp a high frequency tube (ti) than a lower resonant tube ( carbon fiber)

Never heard a carbon fiber tonearm sound good unless it was a trilaminate mixture.

Had a chat once with Graham tonearm maker and his arms are as stiff as possible and way high in natural frequency to keep the cartridge further away from self resonance with the tonearm.

Seems to work and his reviews are stellar.

Regards

David

My take on the sand filled tube is it is possible to over damp the tube and (possibly) contribute a mechanism that would compete with a high frequency resonance created by the cartridge leading to a dulling of what your hearing.

If it were me I would loose the carbon fiber somewhere in the trash can and put a titanium tube in its place with sand mixed with chalk so all spaces are filled to limit any movement to an absolute miniscule level.

Its easier to damp a high frequency tube (ti) than a lower resonant tube ( carbon fiber)

Never heard a carbon fiber tonearm sound good unless it was a trilaminate mixture.

Had a chat once with Graham tonearm maker and his arms are as stiff as possible and way high in natural frequency to keep the cartridge further away from self resonance with the tonearm.

Seems to work and his reviews are stellar.

Regards

David

Last edited:

How long does it take for the arm to drop?

what is the effective mass of the tonearm?

I don't think the sure is that great for detail.... great bass with the wtl arm for sure.

I now use a at 95vl and love it but have not tried it on my wtl arm.

best of luck

what is the effective mass of the tonearm?

I don't think the sure is that great for detail.... great bass with the wtl arm for sure.

I now use a at 95vl and love it but have not tried it on my wtl arm.

best of luck

Drop time is about 2 sec, but that's for about 3cm. To my eyes the silicon oil does its job in damping, you can also feel it when trying to move the arm sideways.

Whatever the cartridge, there's a difference between the WTL and another arm.

Would you try your AT95 on your WTL and tell me how does it sound compared to your other arm?

Whatever the cartridge, there's a difference between the WTL and another arm.

Would you try your AT95 on your WTL and tell me how does it sound compared to your other arm?

Balls

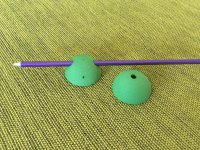

I haven’t been on this forum for a long time, but found some pieces i was working on.

I made these balls up via tinkercad, and printed them out. Pretty much the same size as a standard golf ball.

I did the first one in a two piece, but wasn’t too keen on it.

Some pics of the printed version below.

I haven’t been on this forum for a long time, but found some pieces i was working on.

I made these balls up via tinkercad, and printed them out. Pretty much the same size as a standard golf ball.

I did the first one in a two piece, but wasn’t too keen on it.

Some pics of the printed version below.

Attachments

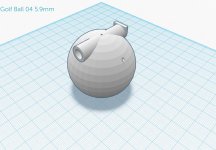

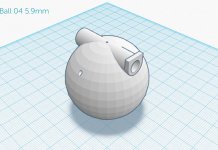

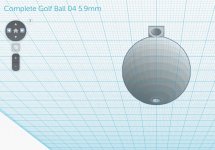

I was going to print out my next version but never got around to it.

Shapeways will print it out for about $15USDea.

If you do print, dont print it off in colour as all they do is a crappy spray job and it really does suck.

This one was designed to be able to flick upside down allowing you to put a tack or pin through a board and sit the ball on it to accurately measure off your effective length and also make sure your cartridge is aligned with the ball properly. All the holes are lined up and level/perpendicular/straight.

You fill the ball with sand, and it will take a 5.9mm arrow shaft and also some small brass tubing for the tread to go through. Then just fill with sand and seal with silicon.

I have not printed this one off.

I’m trying to work out how to put up the info on tinkercad or shapeways so you can have it for free, you know, the files. So you can print your own off if you can.

Anyway here are some pics of the ball in question below..

Shapeways will print it out for about $15USDea.

If you do print, dont print it off in colour as all they do is a crappy spray job and it really does suck.

This one was designed to be able to flick upside down allowing you to put a tack or pin through a board and sit the ball on it to accurately measure off your effective length and also make sure your cartridge is aligned with the ball properly. All the holes are lined up and level/perpendicular/straight.

You fill the ball with sand, and it will take a 5.9mm arrow shaft and also some small brass tubing for the tread to go through. Then just fill with sand and seal with silicon.

I have not printed this one off.

I’m trying to work out how to put up the info on tinkercad or shapeways so you can have it for free, you know, the files. So you can print your own off if you can.

Anyway here are some pics of the ball in question below..

Attachments

I just downloaded the files, they are as follows:

.STL

.OBJ

.X3D COLORS

.VRML COLORS

They are in a folder on my old desk top so if someone wants to give the new one a go PM me and ill email you the folder with all the files in. Hopefully that’ll work?

.STL

.OBJ

.X3D COLORS

.VRML COLORS

They are in a folder on my old desk top so if someone wants to give the new one a go PM me and ill email you the folder with all the files in. Hopefully that’ll work?

Ok sorry, I think I just managed to upload the files to the public tinkercad site.

So you should visit www.tinkercad.com

Sign up and log in. Then do a search under WTL Tonearm Gulf Ball.

It should come up, its all free. If you do that, you can then just choose where to send it to get printed off. Just don’t get it coloured.

Anyway sorry I’m not up with all this tech stuff.

So you should visit www.tinkercad.com

Sign up and log in. Then do a search under WTL Tonearm Gulf Ball.

It should come up, its all free. If you do that, you can then just choose where to send it to get printed off. Just don’t get it coloured.

Anyway sorry I’m not up with all this tech stuff.

Head Shells

I also printed off some head shells at 12 and 13 degrees, the paint is a shocker and I had to be very careful when trying to remove it. In the end I gave up, but here they are and up on the tinkercad site as well if anyone wants to have a go.

This will give you the ability to make quite a long arm if you want to.

I also printed off some head shells at 12 and 13 degrees, the paint is a shocker and I had to be very careful when trying to remove it. In the end I gave up, but here they are and up on the tinkercad site as well if anyone wants to have a go.

This will give you the ability to make quite a long arm if you want to.

Attachments

Hi All

I've been using this 16" Royale clone for a number of months now and have to report how great it is. It's so good that my other developments have taken a back seat- for now. You will notice that the cartridge is a humble AT 95E. I am currently breaking it in for my son- a new devotee to vinyl!!!

I remember Linn stating that a more modest cartridge in a superior arm would perform much better than vice versa. They were absolutely correct. I'm used to the high end Ortofons and the ATOC9 and have been knocked out by the performance of this £20.00 (approx) cartridge. Also, because of the length of the arm, the offset is almost negligible.

Here are some pictures:

I've been using this 16" Royale clone for a number of months now and have to report how great it is. It's so good that my other developments have taken a back seat- for now. You will notice that the cartridge is a humble AT 95E. I am currently breaking it in for my son- a new devotee to vinyl!!!

I remember Linn stating that a more modest cartridge in a superior arm would perform much better than vice versa. They were absolutely correct. I'm used to the high end Ortofons and the ATOC9 and have been knocked out by the performance of this £20.00 (approx) cartridge. Also, because of the length of the arm, the offset is almost negligible.

Here are some pictures:

Attachments

Your table is beautiful!

I agree with the modest cart/good arm combo - I've been using a cheap and cheerful OM10 on my Graham 2.2/Technics rig for some time now, and although it has the sonic flavor of an inexpensive cartridge, it plays the music as well or better than anything else I've tried.

I agree with the modest cart/good arm combo - I've been using a cheap and cheerful OM10 on my Graham 2.2/Technics rig for some time now, and although it has the sonic flavor of an inexpensive cartridge, it plays the music as well or better than anything else I've tried.

Last edited:

Hi All

I've been using this 16" Royale clone for a number of months now and have to report how great it is.

Hi Chris,

what material is your armtube made from?

- Status

- Not open for further replies.

- Home

- Source & Line

- Analogue Source

- My DIY WTL Tonearm