DMD said:Right-triangle cabinets at 8 1/2 feet apart, since they will aim the drivers at 45 degrees, will place the axis crossing at about 3 feet into the room, maybe a little better in more typical arrangements.

Oops, that should say about 4 feet (half the distance between the speakers). Sorry!

Is that where thay have ballet dancers? The name sounds familar.

Yes, the Royal Ballet is also performing there.

http://www.royalopera.org

Regarding the Royal Albert Hall:

I have never been there personally (apart from driving by) but a recent article in a German audio mag counted it to the top 12 venues in the world (after the installation of ceiling diffusors to tame the characteristics of the reverb).

Regards

Charles

Hi DMD - Thanks for the ahoy. No one mentioned the pics earlier so I hadn't got round to it. Later today.

>Sounds like a project just suited to JX53 satellites with a sub

Worth holding off on that for a month or so. There is a replacement for the JX53 along in late September which has a much lower resonance (70Hz) and is ideal for sat/sub use. I've heard it (briefly) in a 1 litre box and it sounded remarkable.

Colin

>Sounds like a project just suited to JX53 satellites with a sub

Worth holding off on that for a month or so. There is a replacement for the JX53 along in late September which has a much lower resonance (70Hz) and is ideal for sat/sub use. I've heard it (briefly) in a 1 litre box and it sounded remarkable.

Colin

The triangles in question ... The speaker on the left is a JX53/125 system, a 33 litre sealed bass enclosure and a 3 litre sealed enclosure for the 53. GM's MLTL design goes deeper and is actually less resonant on male vocals - either because of the tuning or due to the triangular cross-section of the cabinet.

As you can see, the triangular cabs are not finished yet - I put them in place to test them and haven't wanted to dismantle them since.

Someone is bound to ask, so ... the JX92 is slightly more brash-sounding than the JX53 system but somehow seems more organic. It's not something I mind because the end result is so enjoyable. The stereo image is much deeper. The JX53 has a little more air and delicacy in the HF.

GM's design seems to bring out the best in the JX92s and the system is one of the most enjoyable I've heard. There are a couple of electrostatics I could live with as replacements but that's about it.

As you can see, the triangular cabs are not finished yet - I put them in place to test them and haven't wanted to dismantle them since.

Someone is bound to ask, so ... the JX92 is slightly more brash-sounding than the JX53 system but somehow seems more organic. It's not something I mind because the end result is so enjoyable. The stereo image is much deeper. The JX53 has a little more air and delicacy in the HF.

GM's design seems to bring out the best in the JX92s and the system is one of the most enjoyable I've heard. There are a couple of electrostatics I could live with as replacements but that's about it.

Attachments

Another pic, showing the shape a little better.

The walls are 1" thick so the internal shape is triangular, even though externally they are six-sided. I thought this would make them easier to construct but if anything it may have made them trickier. The next version will be three-sided with the corners rounded and I'll get access to a proper workbench to assemble them on. (I do woodwork to build speakers, not the other way round. All constructional suggestions welcome.)

Incidentally, the walls show very little vibration but there is some in the top panel, which I guess fits with the column resonance aspect of the design. The enclosures are braced just below the driver (you can see the screw hole filler) and the entire top section lightly filled with BAF wadding. I seem to have been lucky in that I've not felt the need to adjust the filling. I may reduce it to see what happens.

The walls are 1" thick so the internal shape is triangular, even though externally they are six-sided. I thought this would make them easier to construct but if anything it may have made them trickier. The next version will be three-sided with the corners rounded and I'll get access to a proper workbench to assemble them on. (I do woodwork to build speakers, not the other way round. All constructional suggestions welcome.)

Incidentally, the walls show very little vibration but there is some in the top panel, which I guess fits with the column resonance aspect of the design. The enclosures are braced just below the driver (you can see the screw hole filler) and the entire top section lightly filled with BAF wadding. I seem to have been lucky in that I've not felt the need to adjust the filling. I may reduce it to see what happens.

Attachments

>BTW the toe-in suggested for the JX53 array system at the Jordan site is 60 degrees

Catching up with this - all the Jordan drivers are designed to cross at the same angle - so that 60 degrees is probably from the side wall. (Needs a picture, I think.) The JX92Ss rising HF response is designed to mimic the effect of the linear array, giving a stable image wherever you move.

Moving the JX92Ss so that they are at a more traditional 45 degrees causes the image to flatten and focus more on the speakers, in my experience.

Catching up with this - all the Jordan drivers are designed to cross at the same angle - so that 60 degrees is probably from the side wall. (Needs a picture, I think.) The JX92Ss rising HF response is designed to mimic the effect of the linear array, giving a stable image wherever you move.

Moving the JX92Ss so that they are at a more traditional 45 degrees causes the image to flatten and focus more on the speakers, in my experience.

Bracing in the MLTLs?

One aspect of the MLTL columns seems to escape my attention: bracing. If I were to build triangular x-section columns, I'd add triangles inside the column as horizontal braces, and cut holes in them. This would make sense for vented enclosures. However, these braces may give rise to short standing waves between adjacent braces in a TL. Does this cause problems?

What bracing methods do all of you use for the TL columns?

One aspect of the MLTL columns seems to escape my attention: bracing. If I were to build triangular x-section columns, I'd add triangles inside the column as horizontal braces, and cut holes in them. This would make sense for vented enclosures. However, these braces may give rise to short standing waves between adjacent braces in a TL. Does this cause problems?

What bracing methods do all of you use for the TL columns?

Re: Bracing in the MLTLs?

I'm the novice in the group, and this is as much an echoing of the question as it is an answer, but the geometry of the triangular MLTL cabinet gives it such intrinsic stability, perhaps no such bracing is called for. I'd venture that none of the people we've heard from here who have built these cabs have added bracing to them, but of course they'll need to verify that.

OTOH, if you go to page 9 of the 1st main GM JX92S MLTL thread, you'll see a brief discussion of some braces that one person put into the rectangular design. GM suggested wrapping the braces, (you can see the inside of his cab with wrapped braces in this photo that he posted). Everyone seemed to think that airflow would be fine in that arrangement.

Again, you'll need to hear from those with more expertise.

Greetings from the other side of the world, BTW. Where is Mumbal, Dilli ke nazdik? - or am I a thousand miles and about a hundred languages off the mark?

Best of success,

Don

tcpip said:One aspect of the MLTL columns seems to escape my attention: bracing. If I were to build triangular x-section columns, I'd add triangles inside the column as horizontal braces, and cut holes in them. This would make sense for vented enclosures. However, these braces may give rise to short standing waves between adjacent braces in a TL. Does this cause problems?

What bracing methods do all of you use for the TL columns?

I'm the novice in the group, and this is as much an echoing of the question as it is an answer, but the geometry of the triangular MLTL cabinet gives it such intrinsic stability, perhaps no such bracing is called for. I'd venture that none of the people we've heard from here who have built these cabs have added bracing to them, but of course they'll need to verify that.

OTOH, if you go to page 9 of the 1st main GM JX92S MLTL thread, you'll see a brief discussion of some braces that one person put into the rectangular design. GM suggested wrapping the braces, (you can see the inside of his cab with wrapped braces in this photo that he posted). Everyone seemed to think that airflow would be fine in that arrangement.

Again, you'll need to hear from those with more expertise.

Greetings from the other side of the world, BTW. Where is Mumbal, Dilli ke nazdik? - or am I a thousand miles and about a hundred languages off the mark?

Best of success,

Don

I recall reading that the walls of a TL don't really experience much pressure, it is the two ends where structural integrity is really required.tcpip said:What bracing methods do all of you use for the TL columns?

The structure itself (long and narrow) makes for panels that aren't likely to vibrate much.

People use cardboard Sonotube for subwoofer TLs, and I haven't read any complaints about panel resonance or what.

Colin, those new TLs looks great. That hexagonal shape is very elegant, and I'm sure once you sand and finish them, very nice looking.

Excuse mem Tcpip, I forgot that Colin mentioned that his cabinets were braced just below the drivers (see about 5 posts back). He also mentioned the horizontal-vertical-resonance point brought up in the previous post.

Re: Re: Bracing in the MLTLs?

Thanks a lot for this pointer.

Mumbai is the new politically correct name for Bombay. It's on the Western seaboard of India, in Maharashtra state, and is the biggest centre of economic activity in India. It contributes about 40% of the country's income tax, for instance. 😀

I almost suspect that Bombay is more well-known than Delhi, sort of like NYC is better known than WDC. 🙂

So, yes, you are about thirteen hundred miles off the mark when you mentioned "Dilli ke nazdik", but the language was spot on. 😀

I too thought an equilateral triangle prism of a tall and narrow design may be rigid enough by itself.DMD said:... the geometry of the triangular MLTL cabinet gives it such intrinsic stability, perhaps no such bracing is called for.

This was really helpful. Makes me think now...GM suggested wrapping the braces, (you can see the inside of his cab with wrapped braces

Thanks a lot for this pointer.

How did you learn Hindi? 😀 Have you visited here?Greetings from the other side of the world, BTW. Where is Mumbal, Dilli ke nazdik? - or am I a thousand miles and about a hundred languages off the mark?

Mumbai is the new politically correct name for Bombay. It's on the Western seaboard of India, in Maharashtra state, and is the biggest centre of economic activity in India. It contributes about 40% of the country's income tax, for instance. 😀

I almost suspect that Bombay is more well-known than Delhi, sort of like NYC is better known than WDC. 🙂

So, yes, you are about thirteen hundred miles off the mark when you mentioned "Dilli ke nazdik", but the language was spot on. 😀

All your comments are making sense. I think I'll just go ahead and make a pair of the long thin ones in the shape of equilateral triangles. I have the drivers with me for two years now, sitting in little 18L vented boxes, and this shift of box can only be an improvement.Dumbass said:The structure itself (long and narrow) makes for panels that aren't likely to vibrate much.

People use cardboard Sonotube for subwoofer TLs, and I haven't read any complaints about panel resonance or what.

Thanks. 🙂

tcpip said:

All your comments are making sense. I think I'll just go ahead and make a pair of the long thin ones in the shape of equilateral triangles. I have the drivers with me for two years now, sitting in little 18L vented boxes, and this shift of box can only be an improvement.

Thanks. 🙂

Don't underestimate your 18L boxes, I have some JX125's still in something like that, and they work pretty good in the base if you vent them thr right way.

Colin said:Another pic, showing the shape a little better.

The walls are 1" thick so the internal shape is triangular, even though externally they are six-sided. I thought this would make them easier to construct but if anything it may have made them trickier. The next version will be three-sided with the corners rounded and I'll get access to a proper workbench to assemble them on. (I do woodwork to build speakers, not the other way round. All constructional suggestions welcome.)

If you can make "Lock Miter Bit Joints" for thos angles, it might make assembly easier.

tcpip said:How did you learn Hindi? 😀 Have you visited here?

Mumbai is the new politically correct name for Bombay. It's on the Western seaboard of India, in Maharashtra state, and is the biggest centre of economic activity in India. It contributes about 40% of the country's income tax, for instance. 😀

Yikes! I feel like the Old Man in the Mountain, not knowing the new politically correct name for Bombay. My former collegues at the Center for South Asian Studies will think I've left Bhurloka to be that out of touch! Thank you for the update.

When I studied Sanskrit (in Berkely, California—alas not Poona, Maharashtra!), I also studied a little Hindi. After that, when I was a vegetarian chef for several years, I sometimes shared a kitchen with Indian cooks who knew about as much English as I did Hindi. I think I learned more Hindi in the Kitchen than I did at the university!

I'm sure you'll be pleased with the triangular MLTL's—I'm sure I will be, too. 😉

Namaskar,

Don

soongsc said:

If you can make "Lock Miter Bit Joints" for thos angles, it might make assembly easier.

Could you elaborate a little on that, Soongsc? I should confess that I'm almost as much a novice at woodworking as I am at speakerbuilding.

Colin said:Another pic, showing the shape a little better.

The walls are 1" thick so the internal shape is triangular, even though externally they are six-sided. I thought this would make them easier to construct but if anything it may have made them trickier. The next version will be three-sided with the corners rounded and I'll get access to a proper workbench to assemble them on. (I do woodwork to build speakers, not the other way round. All constructional suggestions welcome.)

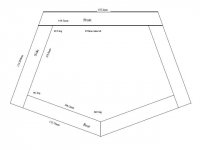

I like the hexagonal shape Colin - an elegant solution. I made mine pentagonal with internal side dimensions of rear panels 106mm, sides 102mm and front 130mm. Angles are 110 (2), 90 (2) and 140. I did an Excel spreadsheet to calculate the internal and external face dimensions of the panels.The angled cuts all come off a table saw set at 20 degrees from the vertical, so once it's set and checked you don't need to keep altering it. The side and rear panels are produced from a larger piece by a single cut.

The narrowness of the panels cuts down resonances, but I think I may put in a couple of bracing rods from front to back. The narrow front makes for great imaging.

I'm attaching a sectional plan. In the event I added corner bracing in the angles which meant the dimensions had to be changed a bit to keep GM's cross sectional area. I have the final plan on another computer which I can't get at for a while.

I used 18mm MDF. Assembly was trial and error, but I've learned enough from it to do it properly next time out of a better material. I've been promised some iroko (teak) recycled from old school laboratory workbenches and planed to 20mm. It will be interesting to hear how it sounds, as it's much denser than ply or MDF. Anyone have experience of using it or similar?

Attachments

DMD said:

Could you elaborate a little on that, Soongsc? I should confess that I'm almost as much a novice at woodworking as I am at speakerbuilding.

It basically uses a different bit to do the edges. 45degrees is the basic agle, but some might allow custom angles. See this site to get a better understanding.

http://www.oldham-usa.com/Products/BitsMain/Tip and tricks/Sect13/LockMiterJoints.htm

The joints will allow the edges to lot together naturally, then you only need some strong rubber bands to hold the sides together.

Thanks for the comments and the mitre-joint link.

BTW, Soongsc, I'd be interested in more details of your vented enclosure for the JX125. My sealed enclosure was calculated to give a Q are 0.74 but rolls off a little higher than I'd prefer.

Colin

BTW, Soongsc, I'd be interested in more details of your vented enclosure for the JX125. My sealed enclosure was calculated to give a Q are 0.74 but rolls off a little higher than I'd prefer.

Colin

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Full Range

- Most appropriate driver/enclosure/design for full orchestra source material?