I had been aproached by a fellow audiophile who wanted to make a killer TT

without breaking the bank (sub 5000 euro).

He was already using a nice german made turntable (that many would dream of)

but he (and I) thought that his sound was not as it should be.

He had tried many cartridges and three phono stages but he was still unhappy.

After listening to my analog combo he decided to completely alter his set up.

The limit was 5000 euro all included (turntable, arm, cartridge,phono stage).

If you want to make something really good for this kind of money,a nice plan

is paramount!

Since his main part of Lp's were 70's-80's rock, i proposed to him to escape from the belt driven camp and move to the DD one.

For some strange reason DD ones always seem to me to nail down rock/dynamic music better than belt driven turntables.I have some ideas on the subject but i will not discuss them now...

At first he thought that this was a stepback but he changed his mind

when i showed him what i was considering.

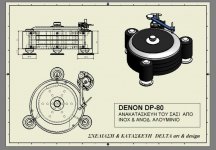

The Denon DP-80 is an 80's workhorse with known good and bad points.

The good ones:bidirectional servo,a 3 phase out motor that can move mountains,a very well damped (two metal part with interdamping layer) platter,easy layout,quality construction.

The bad ones : only 100VAC (Japan only version),hard to find a clean well maintained unit,the underside is prone to sound reverberation...

We had to find the "naked" version that was sold to radio stations

or audiophiles who wanted their own type of plinth because i was going after a design that was going to cure as many as possible of the known flaws.

So our quest for finding such a nice unit started ... and was fruitfull after

3 months or so when a nice specimen was bought through ebay from a german lady whose's late husband had an eye for good things audio

(judging from what else she was selling).

He had quite a collection of turntables and the Denon obviously was sharing duties with other sources which meant that it was a low hours unit.

It arrived at my office nicely packed,totally unscratched,with the Denon manual and the cutout schematic!

Total cost:1000 euro.

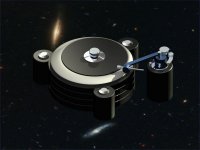

You have to see and hold one of these in your hands to fully appreciate

the quality of construction involved.My friend was stunned with its

flying saucer looks and it's sheer size!

Fot those not familiar please see the pictures:

a)Denon DP 80

b)Denon DP-80 on thevintageknob.org

without breaking the bank (sub 5000 euro).

He was already using a nice german made turntable (that many would dream of)

but he (and I) thought that his sound was not as it should be.

He had tried many cartridges and three phono stages but he was still unhappy.

After listening to my analog combo he decided to completely alter his set up.

The limit was 5000 euro all included (turntable, arm, cartridge,phono stage).

If you want to make something really good for this kind of money,a nice plan

is paramount!

Since his main part of Lp's were 70's-80's rock, i proposed to him to escape from the belt driven camp and move to the DD one.

For some strange reason DD ones always seem to me to nail down rock/dynamic music better than belt driven turntables.I have some ideas on the subject but i will not discuss them now...

At first he thought that this was a stepback but he changed his mind

when i showed him what i was considering.

The Denon DP-80 is an 80's workhorse with known good and bad points.

The good ones:bidirectional servo,a 3 phase out motor that can move mountains,a very well damped (two metal part with interdamping layer) platter,easy layout,quality construction.

The bad ones : only 100VAC (Japan only version),hard to find a clean well maintained unit,the underside is prone to sound reverberation...

We had to find the "naked" version that was sold to radio stations

or audiophiles who wanted their own type of plinth because i was going after a design that was going to cure as many as possible of the known flaws.

So our quest for finding such a nice unit started ... and was fruitfull after

3 months or so when a nice specimen was bought through ebay from a german lady whose's late husband had an eye for good things audio

(judging from what else she was selling).

He had quite a collection of turntables and the Denon obviously was sharing duties with other sources which meant that it was a low hours unit.

It arrived at my office nicely packed,totally unscratched,with the Denon manual and the cutout schematic!

Total cost:1000 euro.

You have to see and hold one of these in your hands to fully appreciate

the quality of construction involved.My friend was stunned with its

flying saucer looks and it's sheer size!

Fot those not familiar please see the pictures:

a)Denon DP 80

b)Denon DP-80 on thevintageknob.org

I had to design a base that would :

a)Add mass to the 10Kgs or the DP-80.

b)Dampen the underplatter constuction

c)Eliminate any other (internal) potential source of vibration.

d)Deal effectively with external vibrations.

I opted for a modular construcion that constituted from four slabs of aluminum, each 3 cms thick.

Those were going to be milled in a circular design (as opposed to the classic Denon "rectangular with lid" wooden chassis).

Each slab was going to be cut according to the "cut out" plan of the underside mechanism with a clearance of 3mm.

Some form of decoupling/damping would have to be implemented between the four slabs of alumimum in order to gradually filter the upward going vibrations from reaching the platter.To be discussed later...

As supporting feet i designed three (10cm in diameter) bronze cylinders that would end on inox steel spikes with cups.

Their connection with the four aluminum slabs that would form the chassis, was to be evaluated...

Another 10 cm bronze cylinder would serve as a tonearm base.

It would sit on a slightly wider inox steel bottom and on the top

i would incorporate a top plate cut to the footprint of the tonearm used.

If a different tonearm was to take service, all that was needed is to CNC a different top plate keeping the costs to a minimum.

a)Add mass to the 10Kgs or the DP-80.

b)Dampen the underplatter constuction

c)Eliminate any other (internal) potential source of vibration.

d)Deal effectively with external vibrations.

I opted for a modular construcion that constituted from four slabs of aluminum, each 3 cms thick.

Those were going to be milled in a circular design (as opposed to the classic Denon "rectangular with lid" wooden chassis).

Each slab was going to be cut according to the "cut out" plan of the underside mechanism with a clearance of 3mm.

Some form of decoupling/damping would have to be implemented between the four slabs of alumimum in order to gradually filter the upward going vibrations from reaching the platter.To be discussed later...

As supporting feet i designed three (10cm in diameter) bronze cylinders that would end on inox steel spikes with cups.

Their connection with the four aluminum slabs that would form the chassis, was to be evaluated...

Another 10 cm bronze cylinder would serve as a tonearm base.

It would sit on a slightly wider inox steel bottom and on the top

i would incorporate a top plate cut to the footprint of the tonearm used.

If a different tonearm was to take service, all that was needed is to CNC a different top plate keeping the costs to a minimum.

For €5000 or a lot less you could have just bought a s/h EMT 950 which already includes phono pre, arm and cartridge.

Not very diy but you won't get a better deck.

Not very diy but you won't get a better deck.

That's great Charles,if you like the vintage look and can stand having an EMT in your living room.

Personally i'm more into a more modern look.

The used market is full today from high priced units of passed years.

That doesn't mean that someone willing to make something really individual

won't make the effort...

Just wait and you'll see what i am talking about!

Personally i'm more into a more modern look.

The used market is full today from high priced units of passed years.

That doesn't mean that someone willing to make something really individual

won't make the effort...

Just wait and you'll see what i am talking about!

As the design of the turntable was advancing, other issues regarding the turntable

had to be addressed.

After discussing with my friend various options about the tonearm that we could use,

we have made a shortlist of arms that we would try buying from ebay.

He had set his sights on the likes of SME,and VPI.

I suggested to look also for a WILSON BENESCH or a DYNAVECTOR.

Our limit was 1000 euro which was a tight margin for such items.

Needless to say that we have bidden on several examples and lost.

After a while i noticed an auction for a Dynavector DV-505 being on sale from a Danish audio store.The auction was running for three weeks with no bids.

He was asking for 1100 euros.

I contacted him, and after a few emails we got it for 1000 euro, including the shipping

and insurance costs.

It was a rare light blue version and arrived in it's original package looking in very good condition.

The cable to phono was replaced with Van den Hul D-501 Hybrid and the short headshell

wires and tonearm wires with the Van den Hul MCS 150-S solid silver cable.

Luckily (in the Dynavector site) we could find for download all the details of the rectangular base of the arm.We decided to keep the other parameters unchanged and make a similar round plate out of solid inox steel.

And that took care of the tonearm part...

had to be addressed.

After discussing with my friend various options about the tonearm that we could use,

we have made a shortlist of arms that we would try buying from ebay.

He had set his sights on the likes of SME,and VPI.

I suggested to look also for a WILSON BENESCH or a DYNAVECTOR.

Our limit was 1000 euro which was a tight margin for such items.

Needless to say that we have bidden on several examples and lost.

After a while i noticed an auction for a Dynavector DV-505 being on sale from a Danish audio store.The auction was running for three weeks with no bids.

He was asking for 1100 euros.

I contacted him, and after a few emails we got it for 1000 euro, including the shipping

and insurance costs.

It was a rare light blue version and arrived in it's original package looking in very good condition.

The cable to phono was replaced with Van den Hul D-501 Hybrid and the short headshell

wires and tonearm wires with the Van den Hul MCS 150-S solid silver cable.

Luckily (in the Dynavector site) we could find for download all the details of the rectangular base of the arm.We decided to keep the other parameters unchanged and make a similar round plate out of solid inox steel.

And that took care of the tonearm part...

The project is complete.I just like to describe the paths taken...

Soon i will post pics.

Be patient.I think that you will be rewarded!

Soon i will post pics.

Be patient.I think that you will be rewarded!

Last edited:

We have decided on a soft type of aluminum for the 3cm thick aluminum slabs.

Each one was CNC cut and milled to accomodate the shape of the turntable

mechanisms plus the supporting legs.

When all main part aluminums where cut we had to decide on the material between them.

After testing sheets of different absorbing/dampening materials and their behaviour after being compressed between the aluminum parts,

we decided to use a sheet of soft pliable silicone that i had also used in other

projects.

That can be found in progressively thicker sheets.

Since my friend wanted to have (for aesthetic reasons) 3mm solid inox rings between the aluminum parts i opted for a slightly thicker 4mm silicone sheet

that would reduce it's thickness to 3mm after being compressed.

This way we had a massive well damped body for the DP-80.

The "feet" were cut from bronze ( i love to mix metals!).

They were 10 cm in diameter drilled hollow about to a 5cm radius so we could

tight the screws that connected them to the main chassis.

They were connected with two screws with the second and fourth aluminum

part of the body so that the first part was decoupled from the feet.

The feet were then going to be filled with sand or lead shot (or both) and close with a screw on tap made from inox steel.

The same "hollow" approach was followed to the tonearm tower.

See some pictures from the construction days...

Each one was CNC cut and milled to accomodate the shape of the turntable

mechanisms plus the supporting legs.

When all main part aluminums where cut we had to decide on the material between them.

After testing sheets of different absorbing/dampening materials and their behaviour after being compressed between the aluminum parts,

we decided to use a sheet of soft pliable silicone that i had also used in other

projects.

That can be found in progressively thicker sheets.

Since my friend wanted to have (for aesthetic reasons) 3mm solid inox rings between the aluminum parts i opted for a slightly thicker 4mm silicone sheet

that would reduce it's thickness to 3mm after being compressed.

This way we had a massive well damped body for the DP-80.

The "feet" were cut from bronze ( i love to mix metals!).

They were 10 cm in diameter drilled hollow about to a 5cm radius so we could

tight the screws that connected them to the main chassis.

They were connected with two screws with the second and fourth aluminum

part of the body so that the first part was decoupled from the feet.

The feet were then going to be filled with sand or lead shot (or both) and close with a screw on tap made from inox steel.

The same "hollow" approach was followed to the tonearm tower.

See some pictures from the construction days...

Attachments

That's great Charles,if you like the vintage look and can stand having an EMT in your living room.

Personally i'm more into a more modern look.

The used market is full today from high priced units of passed years.

That doesn't mean that someone willing to make something really individual

won't make the effort...

Just wait and you'll see what i am talking about!

I know what you mean Mr Void!

As much as I'd love to see a widebody BBC-spec 950 (I love the vintage hi-tech look) in my lounge my wife would not.

Nice work btw! A complete thumbs up from me!

We were always in the look out for a nice phono stage and my friend was very impressed

with the sound he had heard from mine (although i always say that you have to judge an analog system as a whole).

I use a Sonic Frontiers Phono-1SE tubed phono with numerous upgrades that boost it's already excellent sound to a superb level.

Although i warned him that he wasn't going to get exactly the same sound,my friend decided to hunt for such an item.He was intrigued by the fact that although

tubed,this phono stage has a completely uncolored sound, a generous amplification factor with very little noise and a finely judged/balanced character.

The audiogon is the place to look for these items, and after five months search he struck a deal for a black Phono-1 for 1250$.At that time, the exchange rate was in favour of the euro (1.45$) which made the deal a real bargain.It costed him 1200 euros -freight and taxes included.

At the cartridge front, i advised him on finding a FROG cartridge by V.D.HUL.

The one with the OFC copper windings is an excellent all around performer.

I knew that, as i was using one for two years and was extremely happy before upgrading to a more expensive model.

One with very low hours and 0,65mV output was found at the audiomarkt site from a dutch seller for a 1000 euro plus 50 for p&p&insurance.

It arrived safe in it's wooden box.I checked the diamond under the microscope and it was like new.

We had all we wanted!We just had to finish the turntable to let it rip!

Sonic Frontiers Phono-1SE review and photo here:http://www.10audio.com/sf_phono1se.htm

Van den Hul "The Frog" review and photo here:http://www.bluebirdmusic.com/Van den Hul Phono Cartridges.htm

with the sound he had heard from mine (although i always say that you have to judge an analog system as a whole).

I use a Sonic Frontiers Phono-1SE tubed phono with numerous upgrades that boost it's already excellent sound to a superb level.

Although i warned him that he wasn't going to get exactly the same sound,my friend decided to hunt for such an item.He was intrigued by the fact that although

tubed,this phono stage has a completely uncolored sound, a generous amplification factor with very little noise and a finely judged/balanced character.

The audiogon is the place to look for these items, and after five months search he struck a deal for a black Phono-1 for 1250$.At that time, the exchange rate was in favour of the euro (1.45$) which made the deal a real bargain.It costed him 1200 euros -freight and taxes included.

At the cartridge front, i advised him on finding a FROG cartridge by V.D.HUL.

The one with the OFC copper windings is an excellent all around performer.

I knew that, as i was using one for two years and was extremely happy before upgrading to a more expensive model.

One with very low hours and 0,65mV output was found at the audiomarkt site from a dutch seller for a 1000 euro plus 50 for p&p&insurance.

It arrived safe in it's wooden box.I checked the diamond under the microscope and it was like new.

We had all we wanted!We just had to finish the turntable to let it rip!

Sonic Frontiers Phono-1SE review and photo here:http://www.10audio.com/sf_phono1se.htm

Van den Hul "The Frog" review and photo here:http://www.bluebirdmusic.com/Van den Hul Phono Cartridges.htm

Last edited:

I'm enjoying this build 'soundofvoid'-it's not what I thought it would be, which makes it even cooler. Thanks for taking the trouble to post the process.

Hi SoV, I really like he look of he TT and will look forrward to seeing it once complete.

I recently sold my DP75 and 80 but have a couple of SP10's and I think a similar arrangement would look good with one of those de-plinthed.

I recently sold my DP75 and 80 but have a couple of SP10's and I think a similar arrangement would look good with one of those de-plinthed.

Next ,i had to concentrate on the turntable itself.

I unscrewed the bottom chassis and thoroughly examined the internals.

There were three pcbs a "hanging" transformer and the clusters for the stroboscope and control buttons.

The spongy flange on the bottom had deteriorated and was replaced with

a similar one our of three sheets of silicone/neoprene/silicone.

I took out the transformer and and the pcbs that were responsible for

the PS section of the motor.I ordered a toroid replacement with double the clout

of the original,rewired for 230VAC, and beefed up the energy storage with

a larger\bypassed capacitance and new version power transistors.

All the caps were replaced with modern/better equivalents.

All pots were replaced.

The new transformer arrived and was placed with the PS section in an ordinary sheet metal box that we were to "pimp" later.

The motor was taken out and a thin silicone flange (about 0.5mm when pressed)

was placed between its base and the chassis.

The chassis was treated underside with Dynamat heat bonding sheets.

So was the underside "bowl" from the inside.

Then, all was screwed back together.

At the periphery of the underside chassis, are some die cast ribs and holes to strengthen the chassis construction.

All the exposed holes were filled with a sticky tar-like substance that was left to dry at

a little higher level (1-2mm) than the chassis rim.

This was for acting as a press-fit dampening agent when the turntable was to be placed

on its base.

At tests the turntable would start and stop in one (1!) second.

The rotational stability was PERFECT AND PRECISE.

In the mean time the inox parts were constructed and polished.

You can see the innards of a DP-80 here:

denon dp-80

and here:denon dp-80

and a couple more pictures from the CNC work...

I unscrewed the bottom chassis and thoroughly examined the internals.

There were three pcbs a "hanging" transformer and the clusters for the stroboscope and control buttons.

The spongy flange on the bottom had deteriorated and was replaced with

a similar one our of three sheets of silicone/neoprene/silicone.

I took out the transformer and and the pcbs that were responsible for

the PS section of the motor.I ordered a toroid replacement with double the clout

of the original,rewired for 230VAC, and beefed up the energy storage with

a larger\bypassed capacitance and new version power transistors.

All the caps were replaced with modern/better equivalents.

All pots were replaced.

The new transformer arrived and was placed with the PS section in an ordinary sheet metal box that we were to "pimp" later.

The motor was taken out and a thin silicone flange (about 0.5mm when pressed)

was placed between its base and the chassis.

The chassis was treated underside with Dynamat heat bonding sheets.

So was the underside "bowl" from the inside.

Then, all was screwed back together.

At the periphery of the underside chassis, are some die cast ribs and holes to strengthen the chassis construction.

All the exposed holes were filled with a sticky tar-like substance that was left to dry at

a little higher level (1-2mm) than the chassis rim.

This was for acting as a press-fit dampening agent when the turntable was to be placed

on its base.

At tests the turntable would start and stop in one (1!) second.

The rotational stability was PERFECT AND PRECISE.

In the mean time the inox parts were constructed and polished.

You can see the innards of a DP-80 here:

denon dp-80

and here:denon dp-80

and a couple more pictures from the CNC work...

Attachments

I forgot to add that it was a pitty to leave the place of the transformer empty.

So i decided to reposition one of the two remaining boards and place it where the

transformer was.

The original cables where elongated where needed to accomodate the new placing.

I designed two solid weights out of bronze that could be screwed in the empty

places on the underside of the main chassis.

This way i could place them in symmetrical position (with regards to the spindle).

With this reposition and added mass i had a much beefier construction.

Although the transformer plus one "big" and one smaller board were taken out,

the added ballast weight and dampening material have made it to a 15 kilo total.

Not bad!

So i decided to reposition one of the two remaining boards and place it where the

transformer was.

The original cables where elongated where needed to accomodate the new placing.

I designed two solid weights out of bronze that could be screwed in the empty

places on the underside of the main chassis.

This way i could place them in symmetrical position (with regards to the spindle).

With this reposition and added mass i had a much beefier construction.

Although the transformer plus one "big" and one smaller board were taken out,

the added ballast weight and dampening material have made it to a 15 kilo total.

Not bad!

While it's not exactly my piece of cake, I have to say you did a nice job!

Otherwise, I really love those japanese direct drives from the late 70ies and 80ies. Marvelous tables, really.

Is there life after directdrive? 😉

Otherwise, I really love those japanese direct drives from the late 70ies and 80ies. Marvelous tables, really.

Is there life after directdrive? 😉

Well, not all DD turntables were created equal!

People usally say that belt driven ones, are better,more "audiophile".

A usual statement is :"i used to have a japanese DD when i was young/student/poor.When i bought the VPI/Michell/Clearaudio (place your preference) of my dreams,i saw what i was missing..."

Yes but what DD were you using?Has anybody tested a DENON DP-100,or

an Exclusive P3 or a Kenwood L-07 against similarly priced belt driven turntables

to extract a valid substantiated opinion?

And this question comes from someone who uses a belt(s) driven turntable!

My opinion is that a top DD of a couple decades ago lacks usually only

decent plinth/support and a top arm to shine...

At least my experience with THIS one -and some other DPs (59/62/67/72/75)

that i've worked with- make me consider them as unpolished diamonds...

People usally say that belt driven ones, are better,more "audiophile".

A usual statement is :"i used to have a japanese DD when i was young/student/poor.When i bought the VPI/Michell/Clearaudio (place your preference) of my dreams,i saw what i was missing..."

Yes but what DD were you using?Has anybody tested a DENON DP-100,or

an Exclusive P3 or a Kenwood L-07 against similarly priced belt driven turntables

to extract a valid substantiated opinion?

And this question comes from someone who uses a belt(s) driven turntable!

My opinion is that a top DD of a couple decades ago lacks usually only

decent plinth/support and a top arm to shine...

At least my experience with THIS one -and some other DPs (59/62/67/72/75)

that i've worked with- make me consider them as unpolished diamonds...

- Home

- Source & Line

- Analogue Source

- Monsterizing a Denon DP-80