Well,the time arrived when everything was ready for paint.

We decided on a semi-flat black on aluminum parts ,so the inox ones would stand out.

I would really like to have the DP and the Dynavector painted also in black and silver but my friend thought that this would be too much (is there such a thing in modding?).

Anyway,it was HIS turntable and so he took only the aluminum pieces to an auto-body shop

for painting.

And they messed up big time!I had never seen such a bad paint job!

My friend was furious and asked for a repaint.

And again, they did a marginally better job!

So we decided to take the parts from them, and sent them to a another painter

specialized in painting gas tanks for bikes!

And he delivered!Everything looked great/professional.

We took the parts and with great care we layed the "layers" of aluminum/silicone/inox one on top of the other.

The big screws were tightened with the same torque untill the silicone

flanges were compressed to the point that the inox rings were secured.

Then it was time to add the three "legs",each with two screws as explained.

The lower inox parts/spikes were bolted on to produce a stunning effect.

The PS box and tonearm "tower" had the same treatment.

A mixed sand/leadshot filling was used in the hollow parts of the legs and the tonearm base.

They were filled up to the brim and then the top inox parts were screwed on tight.

All this construction had a weight of 35 kilos.

The PS box was another 7.5 Kg and the tonearm base another 8.5 Kg.

A true heavyweight before even placing the DP-80 inside!

We decided on a semi-flat black on aluminum parts ,so the inox ones would stand out.

I would really like to have the DP and the Dynavector painted also in black and silver but my friend thought that this would be too much (is there such a thing in modding?).

Anyway,it was HIS turntable and so he took only the aluminum pieces to an auto-body shop

for painting.

And they messed up big time!I had never seen such a bad paint job!

My friend was furious and asked for a repaint.

And again, they did a marginally better job!

So we decided to take the parts from them, and sent them to a another painter

specialized in painting gas tanks for bikes!

And he delivered!Everything looked great/professional.

We took the parts and with great care we layed the "layers" of aluminum/silicone/inox one on top of the other.

The big screws were tightened with the same torque untill the silicone

flanges were compressed to the point that the inox rings were secured.

Then it was time to add the three "legs",each with two screws as explained.

The lower inox parts/spikes were bolted on to produce a stunning effect.

The PS box and tonearm "tower" had the same treatment.

A mixed sand/leadshot filling was used in the hollow parts of the legs and the tonearm base.

They were filled up to the brim and then the top inox parts were screwed on tight.

All this construction had a weight of 35 kilos.

The PS box was another 7.5 Kg and the tonearm base another 8.5 Kg.

A true heavyweight before even placing the DP-80 inside!

People usally say that belt driven ones, are better,more "audiophile".

Well, everybody got an opinion.

I have certain experiences, like that people loved (and still love) a certain british belt driven turntable (no longer in production for a long time) that audibly rumbled...I mean what is a dynamic range of 100dB good for if you listen to rumble in high definition 😉

I cannot agree more!

Belts are by definition elastic and by nature induce speed irregularities.

That's why heavy platters (and multiple belts?) are used.

Designers count on big rotating masses to smoothen out these problems.

Hence, the "new" rim drive trend!

Belts are by definition elastic and by nature induce speed irregularities.

That's why heavy platters (and multiple belts?) are used.

Designers count on big rotating masses to smoothen out these problems.

Hence, the "new" rim drive trend!

Last edited:

As i have desribed before,a 3mm free space was calculated around the DP-80's

lower part chassis (not for ventilation/heat reasons-the bottom aluminum part was drilled for this reason).

The initial thought was to find a material that we could wrap around the chassis

that would have a contact with the heavy aluminum base to prevent any ringing.

After some searching we found a self adhensive neoprene strip (about 3,5mm

thick and 5 cm wide) that we could use.

These were placed on the inside of the aluminum base in a vertical manner,

roughly leaving 5 cms of free space from each other.

The bottom of the DP-80's chassis would have a free space of 5mm from the

aluminum base, thus we added two round cut pieces (5cm diameter)

of the same neoprene foam, one on top of the other (7mm high) that would be compressed to 5mm when the two would mate.

A little K-Y gell was used to help the "insertion"!

It was a very tight fit and i had to push down while my friend was securing the turntable chassis tightening the bolts.

Then the platter with the thick rubber mat was placed.

After connecting with the PS and pushing "start" we could judge the outcome of our efforts.

The turntable would spin but we could here NOTHING!

It was almost spooky!

We would place our ears next to the rotating platter in an effort to sense something but there was nothing to be felt!

I placed my hand on the chassis and felt a complete absense of vibration.

In my book that was total success.

Quicly we set up the tonearm to have a complete picture of the visual

impact.My friend was so over the moon that he kissed me!

The next day we set the turntable/arm/cartridge/phono in his system.

TOTAL SUCCESS!For a total of 5500 euro (and some personal work...)

he had in his possesion an outstanding analog combo.

Just for the sake of argument we put his old turntable (7000 euro cost turntable/arm only) against our DP.

It was laughable...and my friend put it for sale the next day.

He sold it with his old (2000 euro) cartridge for a cool 4500 euro.

He has still his old phono stage to sell,so we can say that he hasn't lost any money at all!

See some pictures before tonearm...

lower part chassis (not for ventilation/heat reasons-the bottom aluminum part was drilled for this reason).

The initial thought was to find a material that we could wrap around the chassis

that would have a contact with the heavy aluminum base to prevent any ringing.

After some searching we found a self adhensive neoprene strip (about 3,5mm

thick and 5 cm wide) that we could use.

These were placed on the inside of the aluminum base in a vertical manner,

roughly leaving 5 cms of free space from each other.

The bottom of the DP-80's chassis would have a free space of 5mm from the

aluminum base, thus we added two round cut pieces (5cm diameter)

of the same neoprene foam, one on top of the other (7mm high) that would be compressed to 5mm when the two would mate.

A little K-Y gell was used to help the "insertion"!

It was a very tight fit and i had to push down while my friend was securing the turntable chassis tightening the bolts.

Then the platter with the thick rubber mat was placed.

After connecting with the PS and pushing "start" we could judge the outcome of our efforts.

The turntable would spin but we could here NOTHING!

It was almost spooky!

We would place our ears next to the rotating platter in an effort to sense something but there was nothing to be felt!

I placed my hand on the chassis and felt a complete absense of vibration.

In my book that was total success.

Quicly we set up the tonearm to have a complete picture of the visual

impact.My friend was so over the moon that he kissed me!

The next day we set the turntable/arm/cartridge/phono in his system.

TOTAL SUCCESS!For a total of 5500 euro (and some personal work...)

he had in his possesion an outstanding analog combo.

Just for the sake of argument we put his old turntable (7000 euro cost turntable/arm only) against our DP.

It was laughable...and my friend put it for sale the next day.

He sold it with his old (2000 euro) cartridge for a cool 4500 euro.

He has still his old phono stage to sell,so we can say that he hasn't lost any money at all!

See some pictures before tonearm...

Attachments

That looks absolutely STUNNING! I am EXTREMELY envious! I've wanted a DP-80 for a while now but never have the money whenever they rarely show up on Ebay. Patience... patience.....

That's one of the nicest looking decks I have ever seen - truly a work of art!

- John

That's one of the nicest looking decks I have ever seen - truly a work of art!

- John

Thank you for your kind words.

That was my goal:a) to make it in a totally professional way.

b) address the problems of the original design.

c) make it look like true eye candy-in a Darth Vader way!

That was my goal:a) to make it in a totally professional way.

b) address the problems of the original design.

c) make it look like true eye candy-in a Darth Vader way!

As a last part regarding the construction,i had cut circular flanges out of a sheet of hard

silicone for the cups under the spikes and the tonearm base.

I tried for a softer grade but the 50 kilos weight compressed them to nothing...

As a final touch, a record weight (450gr) was cut and polished

from a solid block of inox steel.

Under it, a similar (soft) silicone flange was glued.

As soon as my friend sells his phonostage,and has the ability to finance this last stage,i will design a 5mm hard aluminum"platter" that will go

under the rubber turntable mat with a thin sheet of decoupling material under it.

This way a)i will add approx 1.1Kg of rotating mass

b) i will add another decoupling layer from motor vibrations and

c)i will be able to design a periphery ring.

It will be out of inox steel (1.1Kg) and will look as an integral part of the design.

When all this will be over,i have great expectations from this set up.

And some more pictures...this time with the Dynavector in place.

silicone for the cups under the spikes and the tonearm base.

I tried for a softer grade but the 50 kilos weight compressed them to nothing...

As a final touch, a record weight (450gr) was cut and polished

from a solid block of inox steel.

Under it, a similar (soft) silicone flange was glued.

As soon as my friend sells his phonostage,and has the ability to finance this last stage,i will design a 5mm hard aluminum"platter" that will go

under the rubber turntable mat with a thin sheet of decoupling material under it.

This way a)i will add approx 1.1Kg of rotating mass

b) i will add another decoupling layer from motor vibrations and

c)i will be able to design a periphery ring.

It will be out of inox steel (1.1Kg) and will look as an integral part of the design.

When all this will be over,i have great expectations from this set up.

And some more pictures...this time with the Dynavector in place.

Attachments

Last edited:

Thanks!In this case, it is just "form follows function".

Come to think of it,it's round shape leads to a design like this.

I just followed through my initial thought of how it should look...

I know that many will resent the "modernization" of this turntable

but i was not into "restoring" anything to it's "vintage glory".

My goal was merely to make it the best that it could be...

Come to think of it,it's round shape leads to a design like this.

I just followed through my initial thought of how it should look...

I know that many will resent the "modernization" of this turntable

but i was not into "restoring" anything to it's "vintage glory".

My goal was merely to make it the best that it could be...

???

The sound from a audio system is a combination of sound from preamp(not to mention tube), amp, cables, speakers, speaker's placement, vibration control on equipments , TT, arm, cartridge, the room treatment or even the room itself. I'm not sure how he can precisely single out that so-called 'great sound' was directly from from the TT/phono stage only. I really not sure how he do it. 😕

My the way, the new DP-80 + the blue Dynavector tonearm look really sexy ! Great job on the new reborn DP-80. 😀😀😀

The sound from a audio system is a combination of sound from preamp(not to mention tube), amp, cables, speakers, speaker's placement, vibration control on equipments , TT, arm, cartridge, the room treatment or even the room itself. I'm not sure how he can precisely single out that so-called 'great sound' was directly from from the TT/phono stage only. I really not sure how he do it. 😕

My the way, the new DP-80 + the blue Dynavector tonearm look really sexy ! Great job on the new reborn DP-80. 😀😀😀

Last edited:

Dear fxb,thanks for your kind words!

As you have probably read in my relative post,i agree with your remarks and i always urge people to judge a system as a whole.

But,there were some similarities in our systems that provoked his reaction...

We both use tube preamps and biamplify with SS amps for the bass and tube ones (the same!) for the mid+tremble.We even use the same Sacd/Cd players and use tubed dacs.

We use the same brand of cables...

Our speakers are similar too (magneto-planars with bass cones).

As i said,i warned him that he wasn't going to get the exact sound but a pretty good approximation.

That is because i use a diy, vertical standing, linear tracking turntable (made without cost limits) that is belt or i should say tape driven,i use a more expensive cartridge and a very modified phono stage with custom made step-up transformers.

The good thing is that our efforts and costs delivered.

We both (and many others who are showing interest in the same solution)

heard a sound of different magnitude from the one he already had from his

past (very well regarded) set-up.

He is now a happy man!

As you have probably read in my relative post,i agree with your remarks and i always urge people to judge a system as a whole.

But,there were some similarities in our systems that provoked his reaction...

We both use tube preamps and biamplify with SS amps for the bass and tube ones (the same!) for the mid+tremble.We even use the same Sacd/Cd players and use tubed dacs.

We use the same brand of cables...

Our speakers are similar too (magneto-planars with bass cones).

As i said,i warned him that he wasn't going to get the exact sound but a pretty good approximation.

That is because i use a diy, vertical standing, linear tracking turntable (made without cost limits) that is belt or i should say tape driven,i use a more expensive cartridge and a very modified phono stage with custom made step-up transformers.

The good thing is that our efforts and costs delivered.

We both (and many others who are showing interest in the same solution)

heard a sound of different magnitude from the one he already had from his

past (very well regarded) set-up.

He is now a happy man!

Last edited:

I have posted about this, about 3 months earlier...

Prepare yourself for a long read-it's about 14 constuctional episodes in it!

Please post any critisism or observation in that thread and leave this one for the DP-80 only...

The link: http://www.diyaudio.com/forums/analogue-source/173341-my-last-turntable.html

Prepare yourself for a long read-it's about 14 constuctional episodes in it!

Please post any critisism or observation in that thread and leave this one for the DP-80 only...

The link: http://www.diyaudio.com/forums/analogue-source/173341-my-last-turntable.html

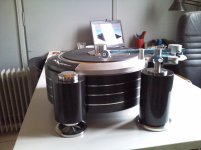

Finally my friend has sent me some more photos with the turntable in action...

Here they are...tinted because of the lights used in his audio room...

The separate power supply box is located lower in his rack.

The "spotted white" granite plate that it is placed on, doesn't match (in my opinion), plus it's only 2 cm thick.

I have advised him to get a second layer of granit with another vibration absorbing sheet under it...

I am waiting for two more DP-80s to arrive and get the same treatment.

At least one of the owners is going for the "full monty" upgrade with the

added metal mat and periphery ring...

I can't wait to see how high the limit is!

Here they are...tinted because of the lights used in his audio room...

The separate power supply box is located lower in his rack.

The "spotted white" granite plate that it is placed on, doesn't match (in my opinion), plus it's only 2 cm thick.

I have advised him to get a second layer of granit with another vibration absorbing sheet under it...

I am waiting for two more DP-80s to arrive and get the same treatment.

At least one of the owners is going for the "full monty" upgrade with the

added metal mat and periphery ring...

I can't wait to see how high the limit is!

Attachments

-

DSC_0681-Optimized.jpg133.9 KB · Views: 514

DSC_0681-Optimized.jpg133.9 KB · Views: 514 -

DSC_0669-Optimized.jpg107.6 KB · Views: 411

DSC_0669-Optimized.jpg107.6 KB · Views: 411 -

DSC_0674-Optimized.jpg133.1 KB · Views: 359

DSC_0674-Optimized.jpg133.1 KB · Views: 359 -

DSC_0680-Optimized.jpg113.8 KB · Views: 342

DSC_0680-Optimized.jpg113.8 KB · Views: 342 -

DSC_0677-Optimized.jpg90.5 KB · Views: 342

DSC_0677-Optimized.jpg90.5 KB · Views: 342 -

DSC_0670-Optimized.jpg136.8 KB · Views: 363

DSC_0670-Optimized.jpg136.8 KB · Views: 363 -

DSC_0686-Optimized.jpg106.7 KB · Views: 314

DSC_0686-Optimized.jpg106.7 KB · Views: 314 -

DSC_0684-Optimized.jpg95.3 KB · Views: 280

DSC_0684-Optimized.jpg95.3 KB · Views: 280 -

DSC_0687-Optimized.jpg96.9 KB · Views: 282

DSC_0687-Optimized.jpg96.9 KB · Views: 282 -

DSC_0675-Optimized.jpg124 KB · Views: 420

DSC_0675-Optimized.jpg124 KB · Views: 420

- Home

- Source & Line

- Analogue Source

- Monsterizing a Denon DP-80