Plus a couple more...

One is a close up of the PS box and the other is with a stylish lamp ,matched to the turntable colors ...

I have to thank of course the "Delta art & design" team for transforming

my designs into CNC executable files and for their contribution into metal selection,raw metals preparation and cutting and help into making this

(and other crazy designs of me) come to reality...

One is a close up of the PS box and the other is with a stylish lamp ,matched to the turntable colors ...

I have to thank of course the "Delta art & design" team for transforming

my designs into CNC executable files and for their contribution into metal selection,raw metals preparation and cutting and help into making this

(and other crazy designs of me) come to reality...

Attachments

Fabulous project, and a real inspiration! I have two Victor TT-101's and a SP10 sitting here, waiting for my lazy bum to get startet on some plinths... hopefully this autumn!

I have been toying around with the sandwich concept myself, as a way to cope with vibrations etc.. Alu, Corian, rubber, stainless steel.... all of it is being considered (and researched) as we speak. As I am no great fan of free-standing armboards I will have to find a way of incorporating a flexible and adjustable system that can take 9" - 12" arms of different types and makes, without any (possible) vibrations from the motor entering the arm base. Luckily the summer never happened this year, so there is no risk of overheating the brain cell!

I have been toying around with the sandwich concept myself, as a way to cope with vibrations etc.. Alu, Corian, rubber, stainless steel.... all of it is being considered (and researched) as we speak. As I am no great fan of free-standing armboards I will have to find a way of incorporating a flexible and adjustable system that can take 9" - 12" arms of different types and makes, without any (possible) vibrations from the motor entering the arm base. Luckily the summer never happened this year, so there is no risk of overheating the brain cell!

Thanks for the good words!

The possibilities with the mix and match of different chassis materials

and dampening/absorbing solutions are endless.

I prefer to use different metals with strategically placed dampening materials.

I think suspension is uselles if you are over 35-40 Kilos.

As for the free standing armboard...i totally agree.

You can follow a solution like the one i used or ...

you can incorporate a round free standing block inside a cutout in

the -presumably- rectangular chassis.

There is a way to be able to use the same block for 9 and 12 inch armboards

by making this cylinder around 10 cm in diameter and drilling just one offcenter armboard hole in it.

By rotating the round block the offcenter hole either comes near the spindle

(9" tonearm) or pulls away (12" tonearm).

This is a very neat solution to your problem.

The block itself could be all one mass,different metals or make it hollow (bowl like) use a separate -scew on- top layer for attaching the tonearms and experiment with different fillings,eg lead shot,liquid silicone,sand etc etc.

The most damping i have achieved (completely DEAD) is sand saturated with motor oil or lead shot with motor oil...

But most damping doesn't always produce the best or more "likeable" sound...

The possibilities with the mix and match of different chassis materials

and dampening/absorbing solutions are endless.

I prefer to use different metals with strategically placed dampening materials.

I think suspension is uselles if you are over 35-40 Kilos.

As for the free standing armboard...i totally agree.

You can follow a solution like the one i used or ...

you can incorporate a round free standing block inside a cutout in

the -presumably- rectangular chassis.

There is a way to be able to use the same block for 9 and 12 inch armboards

by making this cylinder around 10 cm in diameter and drilling just one offcenter armboard hole in it.

By rotating the round block the offcenter hole either comes near the spindle

(9" tonearm) or pulls away (12" tonearm).

This is a very neat solution to your problem.

The block itself could be all one mass,different metals or make it hollow (bowl like) use a separate -scew on- top layer for attaching the tonearms and experiment with different fillings,eg lead shot,liquid silicone,sand etc etc.

The most damping i have achieved (completely DEAD) is sand saturated with motor oil or lead shot with motor oil...

But most damping doesn't always produce the best or more "likeable" sound...

Beautiful work Ionannis, I have a lead on a DP-80 with a damaged arm. I'm hoping to make an offer. My plans include making a DIY arm of extended length for it, and a custom wood plinth of artistic shape.

It's a great basis for a top turntable George.I wish you all the luck!

I have just acquired from Japan a Pioneer PL-L1 whose parallel tracking arm

i consider a masterpiece but the platter itself i consider of a lesser quality.

I am thinking of mating one of my DP-80s with that arm in a custom heavy construction and put it side by side to my LT-5V based turntable.

Two diy parallel trackers, one vertical, one horizontal...what more to ask?

I have just acquired from Japan a Pioneer PL-L1 whose parallel tracking arm

i consider a masterpiece but the platter itself i consider of a lesser quality.

I am thinking of mating one of my DP-80s with that arm in a custom heavy construction and put it side by side to my LT-5V based turntable.

Two diy parallel trackers, one vertical, one horizontal...what more to ask?

really nice player you've got there. You ought to try to bolt the platter solid, and add even more mass to the platter. My experience doing this resulted in even more dynamics and response. The downside doing this is imo you need a horn system to really hear the full potensial of the player.

Turned out to be a DP-60, and the store was able to fix the arm.It's a great basis for a top turntable George.I wish you all the luck!

Still looking.🙂

Ha...imitation - really exact! - is the sincerest form of flattery...

I just wish people had the decency to tell me about it...and not take credit of their "new ideas"...lol.

https://www.vinylengine.com/turntable_forum/viewtopic.php?f=18&t=80387

I just wish people had the decency to tell me about it...and not take credit of their "new ideas"...lol.

https://www.vinylengine.com/turntable_forum/viewtopic.php?f=18&t=80387

Attachments

Ha...imitation - really exact! - is the sincerest form of flattery...

I just wish people had the decency to tell me about it...and not take credit of their "new ideas"...lol.

https://www.vinylengine.com/turntable_forum/viewtopic.php?f=18&t=80387

Wow. That's ridiculous.

im a bit confused by your comment. I know Jeff and he bought his plinth from the guy who machined your original and your other " attempt " Jeff gave me the guys email and I contacted him for a price that was way over my budget. So I built my own plinth from rosewood and posted on your other thread. How are you these days, any more amazing projects on the go?Ha...imitation - really exact! - is the sincerest form of flattery...

I just wish people had the decency to tell me about it...and not take credit of their "new ideas"...lol.

https://www.vinylengine.com/turntable_forum/viewtopic.php?f=18&t=80387

I see...i didn't know that he bought it from the same guy...by the way ...that CNC shop has been closed the last two years...and he sold all the machinery. We didn't part well! He insisted that HE designed it although me/the owner/everybody else who knows anything about it, know that he was just executing my sketches in CNC files...although he was payed he never returned these files. The second more complex design has nothing to do with him. I learned my lesson well and called a guy, payed for the CNC files and kept them. Then offered them to ANOTHER CNC shop that created the green/black monster. If he has told you that he made the second attempt too...i don't know, there is no end to what a man can do...You were contacting the scammer and not the original designer...I do the usual reconditioning to new status of the DP-80's that i sell or people send me theirs and ask for that bit more...like the new ball/thrust plate/subweight that makes it even more quiet, or the extra mat/periphery ring/record weight, or taking out some of the electronics...

Attachments

-

Photo0658-Optimized.jpg65.4 KB · Views: 275

Photo0658-Optimized.jpg65.4 KB · Views: 275 -

Photo0389-Optimized.jpg71 KB · Views: 457

Photo0389-Optimized.jpg71 KB · Views: 457 -

Photo0484-Optimized.jpg60.3 KB · Views: 461

Photo0484-Optimized.jpg60.3 KB · Views: 461 -

20170222_140423 (FILEminimizer).jpg593.6 KB · Views: 466

20170222_140423 (FILEminimizer).jpg593.6 KB · Views: 466 -

20170217_174913 (FILEminimizer).jpg115.7 KB · Views: 480

20170217_174913 (FILEminimizer).jpg115.7 KB · Views: 480 -

20170302_133557 (FILEminimizer).jpg140.2 KB · Views: 551

20170302_133557 (FILEminimizer).jpg140.2 KB · Views: 551

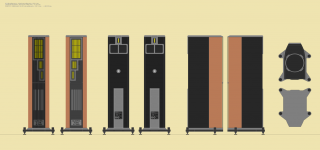

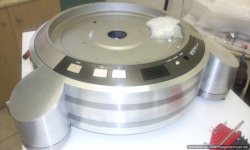

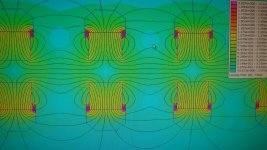

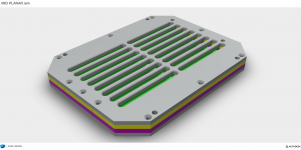

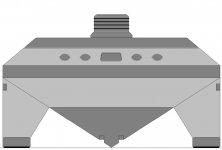

As for what my new plans are ... these days i am in the process of producing a medium size, very high quality, high-efficiency planar driver able to play from 250 Hz to 10Khz with a novel way to "tune" the foil. I am also in the process of making my own direct drive motors, one about the size of the DP-80 but slightly wider, one that is 1.5X and one that 2X that size (about the size of the DP-100 motor). The plan is to be able to make my completely own line of DD turntables (probably three models) with my own motors and electronics with progressively heavier construction and heavier platters with magnetic levitation...see example of entry model.

Ah...and i bought THESE and i am preparing them for heavy modifications too.

Ah...and i bought THESE and i am preparing them for heavy modifications too.

Attachments

-

20151121_121651 (FILEminimizer).jpg141.4 KB · Views: 188

20151121_121651 (FILEminimizer).jpg141.4 KB · Views: 188 -

20151121_102912 (FILEminimizer).jpg88.4 KB · Views: 190

20151121_102912 (FILEminimizer).jpg88.4 KB · Views: 190 -

20150729_182326-Optimized.jpg98.7 KB · Views: 203

20150729_182326-Optimized.jpg98.7 KB · Views: 203 -

Screenshot(6).png593.1 KB · Views: 198

Screenshot(6).png593.1 KB · Views: 198 -

20170209_115359 (FILEminimizer).jpg115.9 KB · Views: 218

20170209_115359 (FILEminimizer).jpg115.9 KB · Views: 218 -

20170209_115428 (FILEminimizer).jpg133.2 KB · Views: 236

20170209_115428 (FILEminimizer).jpg133.2 KB · Views: 236 -

entry level spaceship II (FILEminimizer).jpg28.7 KB · Views: 183

entry level spaceship II (FILEminimizer).jpg28.7 KB · Views: 183 -

titan_1.jpg84.9 KB · Views: 234

titan_1.jpg84.9 KB · Views: 234

He didn't claim to have designed the green monster or offer it for sale. In fact I didn't even know about you at the time. He didn't claim to have designed it as far as I remember, but said he had permission to make and sell them. I look forward to hearing your progress on the speaker, I wish you the very best.

The plan is to be able to make my completely own line of DD turntables (probably three models) with my own motors and electronics with progressively heavier construction and heavier platters with magnetic levitation...

What amazing resourcefulness and unique designer's mind! I'm glad someone is making new direct-drive turntables these days.

Will the electronics separate from the motor unit? I think the way Japanese made those DD tables in the 70's and 80's contributed to some of misconceptions of DD tables by shrouding them with all the buttons outside that made them look more like an electronic box than a turntable. Visually, I much prefer belt drive turntable's aesthetic that it exhibits the mechanical simplicity and elegance of individual components: platter, bearing, plinth, and motor. Therefore I am fond of a DD table that tugs all the complicated electronics inside a separate box and runs umbilical cord to the motor unit a la Monaco, Brinkman, Micro-Seiki DQX series, et al. Their demystification of the DD system is satisfying to me.

I have rather smart friend who didn't even know a DD motor runs at 33rpm! Duh! I think years of brainwashing by Linn (and mainstream publications) that consumers think belt-drive is superior over direct-drive because it provides better motor isolation, hence quieter, when in fact a DD motor runs at about half hertz! DD is quiet because because you don't even need motor isolation! Brinkmann's marketing has to change the name of the drive system as "magnetic drive" to avoid the stigma of DD!

Best of luck to you and I look forward to seeing your future projects!

Thank God he didn't...because he wouldn't know where to start! And he had no permission for the first shape at all! He did this behind my back...When i found this guy he had no CNC machines and was making inox steel railings for balconies...Then after a few projects, he suddenly became a turntable designer...Oh well.He didn't claim to have designed the green monster or offer it for sale. In fact, I didn't even know about you at the time. He didn't claim to have designed it as far as I remember, but said he had permission to make and sell them. I look forward to hearing your progress on the speaker, I wish you the very best.

Regarding the speaker: the front facing woofer will be replaced by a larger planar element -so large that the mid/tweeter combo will have to be lowered about 10 cm- leaving the active top mounted -transmission line loaded- 30cm woofer to act as a subwoofer from 150 Hz downwards. The order for the new larger foils has been made and i am waiting for them maybe within the week.

The ribbon tweeter will be re-located in the back to enhance the "ambiance" of the recordings and its place will be taken by another larger unit custom made for me by a friend who works in the business. Also, other work will be done...reinforcing the woodwork, on the crossover and the general aesthetics. Hoping to make it have planar sound in all but the subwoofer and look like this:

Thank you all for your good words and wishes!

Attachments

Last edited:

I carefully read all these steps, and the description. You have built a beautiful product, and I believe it is also very good for acoustic insulation. You're making me dream, I'm excited. I have to think carefully about my next moves. Thank you

I just discover this very interesting post! Congratulation for the beautiful job!

I Have the project of buiding a table, but neither my knowledge, nor my ressources allow me to lokk forward such an elaborate project. I just plan for a more conventional plinth.

I read in the very first lines that you got the DP-80 with a cutout schematic. Would you be kind enough to post it under the format which is most convenient for you? That would be a great help for many people.

Thanks in advance.

I Have the project of buiding a table, but neither my knowledge, nor my ressources allow me to lokk forward such an elaborate project. I just plan for a more conventional plinth.

I read in the very first lines that you got the DP-80 with a cutout schematic. Would you be kind enough to post it under the format which is most convenient for you? That would be a great help for many people.

Thanks in advance.

- Home

- Source & Line

- Analogue Source

- Monsterizing a Denon DP-80