One of the main benefits of a DIY amplifier is you get to choose if you want to use powercons and Speakons instead of IEC power modules and binding posts. That is what I am using.

Yep. Absolutely nothing prevents you from downloading the chassis CAD drawings and modifying them to suit your needs before you have ModuShop manufacture them (or before you cut the holes yourself). That's all part of DIY.

QCAD Pro is only $40 and you can use it for 15 minutes at a time without ever paying a dime.

Tom

QCAD Pro is only $40 and you can use it for 15 minutes at a time without ever paying a dime.

Tom

So you always have to compromise with engineering. What is then right?

Building a consumer product is not only getting the best specs, but also building a safe product.

When you do not take that in account you are inresponsible.

Because other producers sells equipment without compliance and buyers buy it, makes it still illegal.

Building a consumer product is not only getting the best specs, but also building a safe product.

When you do not take that in account you are inresponsible.

Because other producers sells equipment without compliance and buyers buy it, makes it still illegal.

Last edited:

Funny how the goal posts keep moving. For those keeping track at home, here're the movements so far:

@Koifarm would you care to share an example of a design that you have been solely responsible for from start to finish? Please make sure to share the performance measurements and the reports from the compliance labs.

Anybody can be a keyboard warrior and spread fear, uncertainty, and doubt. It takes skills and persistence to actually accomplish something. What skills do you have? I'm curious.

I have spoken with lawyers in the past regarding my business setup, product liability, and such. None of them have expressed any reservations regarding the legality of what I'm doing. Would you care to share the specific US or Canadian laws that you believe I'm in violation of. Please be specific and keep in mind that defamation is illegal too.

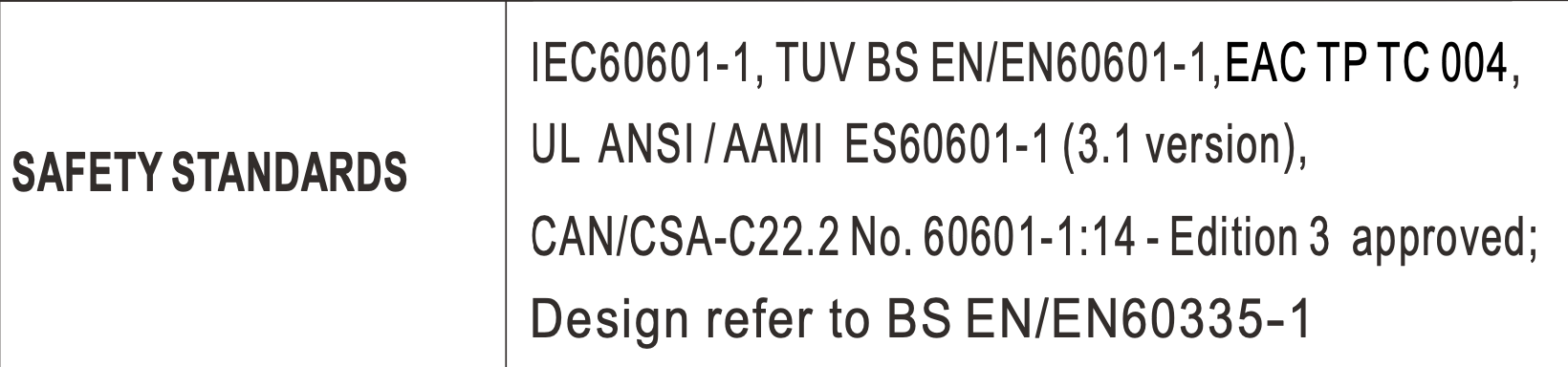

Naturally, I take electrical safety seriously. That's another one of my design constraints: Do not kill the end user. That's in part why I use the Mean Well supplies. Here are the safety standards they comply with:

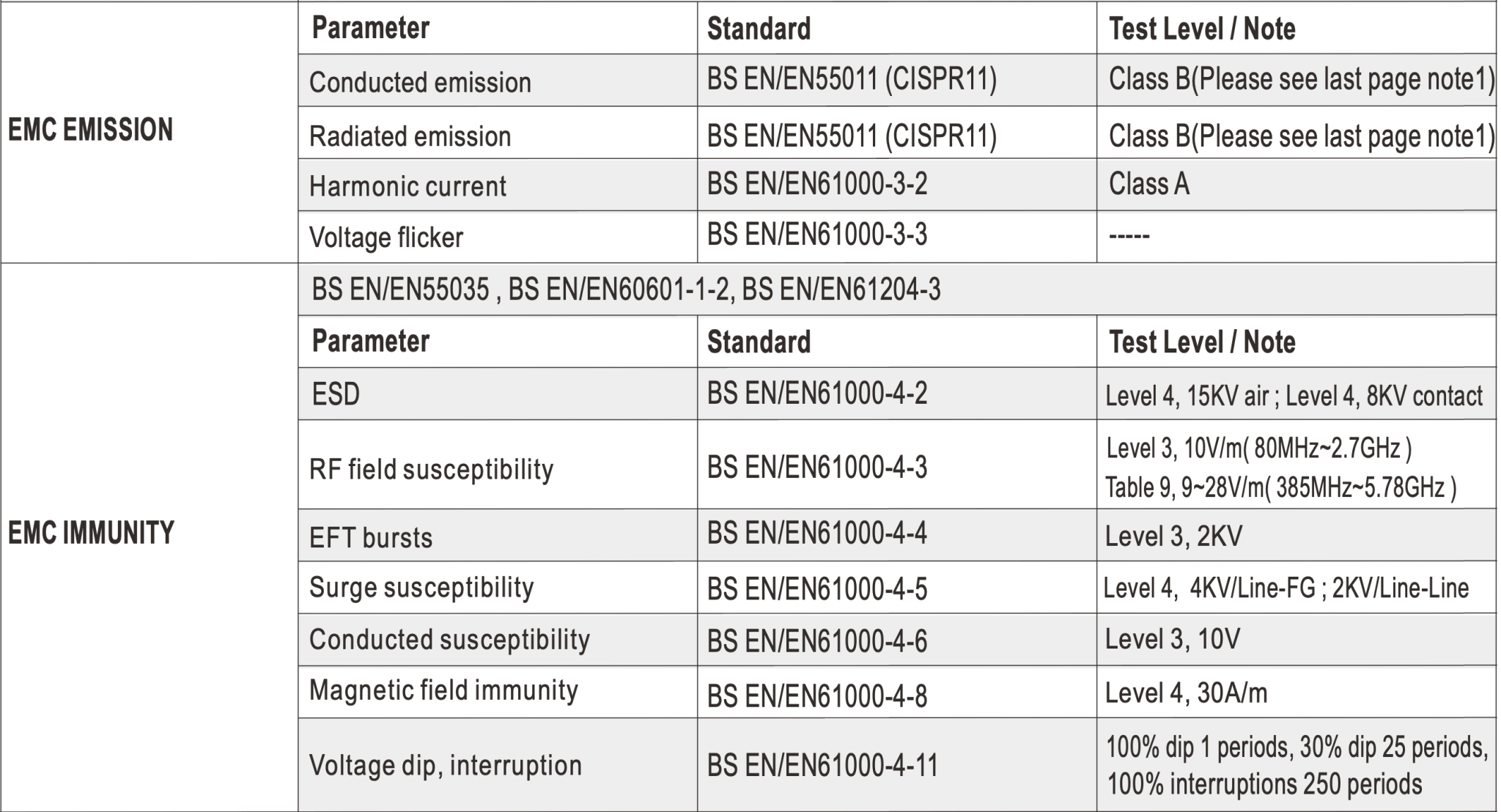

It is also important to me that my equipment plays well with others. That is in part why I include EMI/RFI filtering on the input of the amp. As for emissions out of the amp, the creator of that would be the Mean Well supplies again. Here are the standards they comply with:

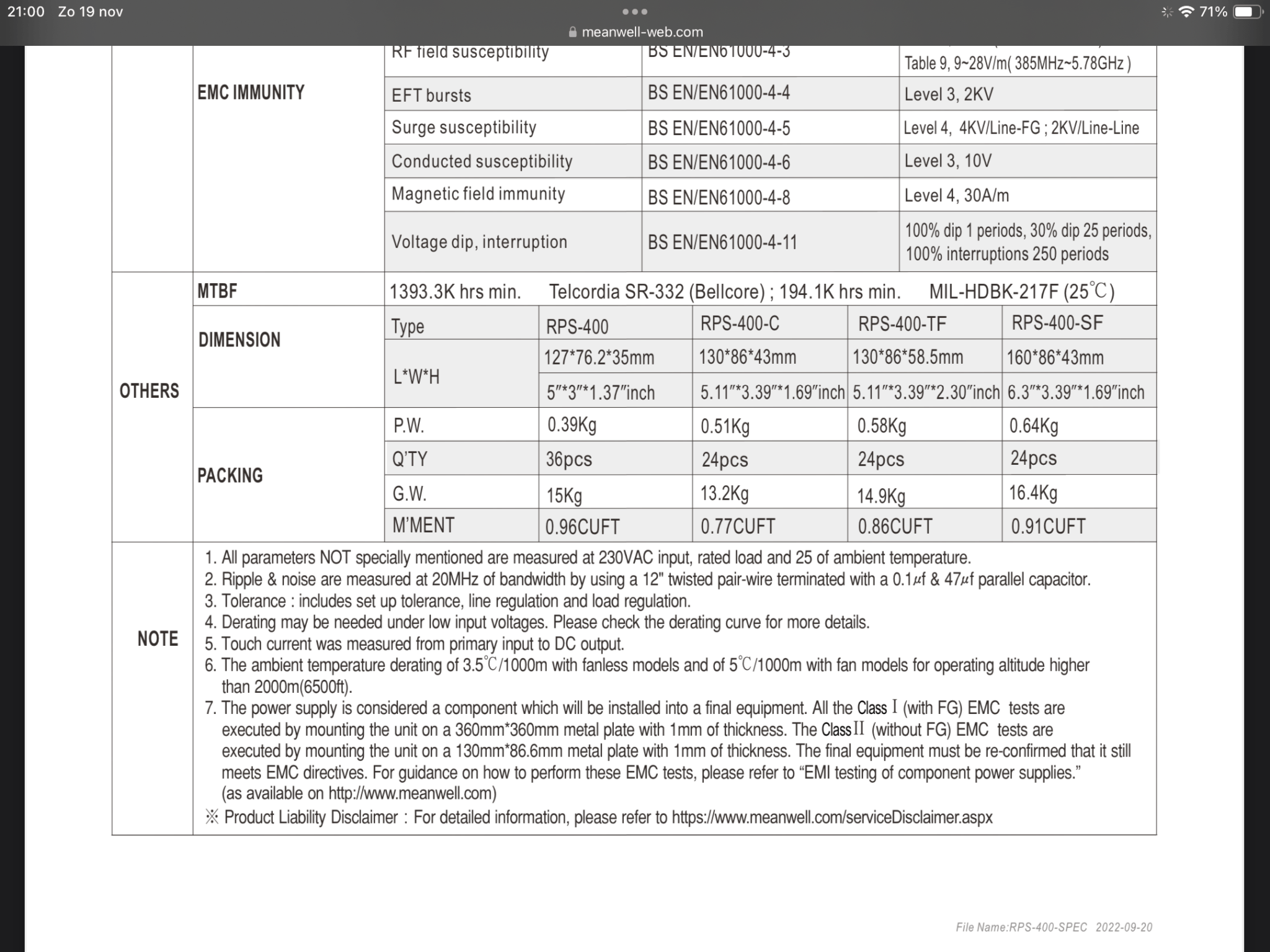

You can find the test reports at the bottom of this page: https://www.meanwell-web.com/en-gb/...cal-power-supply-output-27vdc-rps--400--27--c

Naturally, that doesn't prove that the finished product will pass compliance testing but I certainly give myself the best chance of passing both on electrical safety and on EMC compliance.

Tom

- Power connector

- Heat sink insulation

- Electrolytic capacitors

- And now apparently what is right, safety, and legality

@Koifarm would you care to share an example of a design that you have been solely responsible for from start to finish? Please make sure to share the performance measurements and the reports from the compliance labs.

Anybody can be a keyboard warrior and spread fear, uncertainty, and doubt. It takes skills and persistence to actually accomplish something. What skills do you have? I'm curious.

I have spoken with lawyers in the past regarding my business setup, product liability, and such. None of them have expressed any reservations regarding the legality of what I'm doing. Would you care to share the specific US or Canadian laws that you believe I'm in violation of. Please be specific and keep in mind that defamation is illegal too.

Naturally, I take electrical safety seriously. That's another one of my design constraints: Do not kill the end user. That's in part why I use the Mean Well supplies. Here are the safety standards they comply with:

It is also important to me that my equipment plays well with others. That is in part why I include EMI/RFI filtering on the input of the amp. As for emissions out of the amp, the creator of that would be the Mean Well supplies again. Here are the standards they comply with:

You can find the test reports at the bottom of this page: https://www.meanwell-web.com/en-gb/...cal-power-supply-output-27vdc-rps--400--27--c

Naturally, that doesn't prove that the finished product will pass compliance testing but I certainly give myself the best chance of passing both on electrical safety and on EMC compliance.

Tom

I'm not going to get into a mains connector debate - because I build my own stuff I use Powercon connectors. But that is only because nothing hacks me off more that to power something up and it doesn't because the IEC plug came out the socket. Or enough out of the socket to not make contact. So there is a plus to using a locking connector.

And because I am using Linkwitz LX521's I have 5 power amps per side (two chassis with four amps each, and a third chassis with two) - so I use Speakons too because the consequence of miswiring binding posts and shoving the woofer signal up the tweeter is just too awful to contemplate. And the signal connections (balanced XLR, so again locking) from the active crossover to the power amps are colour coded - for the same reason. Blue to blue, yellow to yellow etc. The arrangement is as foolproof as I can make it.

I'm most certainly not knocking Toms choice of using IEC mains input sockets - he's running a business and has to put socketry in place so that Joe Punter can wire it up easily. Let's not forget that Mark Levinson gear and Cello gear too used Camac signal connectors - which meant they had to supply Camac to XLR adaptors and cables. There is a major consequence to not using standard connections.

Those amps of the LX521 of mine are Douglas Self blameless class B. I built them well over 10 years ago. But given my time again it'd be a close run thing between Tom's Modulus amps, and class D.

Craig

And because I am using Linkwitz LX521's I have 5 power amps per side (two chassis with four amps each, and a third chassis with two) - so I use Speakons too because the consequence of miswiring binding posts and shoving the woofer signal up the tweeter is just too awful to contemplate. And the signal connections (balanced XLR, so again locking) from the active crossover to the power amps are colour coded - for the same reason. Blue to blue, yellow to yellow etc. The arrangement is as foolproof as I can make it.

I'm most certainly not knocking Toms choice of using IEC mains input sockets - he's running a business and has to put socketry in place so that Joe Punter can wire it up easily. Let's not forget that Mark Levinson gear and Cello gear too used Camac signal connectors - which meant they had to supply Camac to XLR adaptors and cables. There is a major consequence to not using standard connections.

Those amps of the LX521 of mine are Douglas Self blameless class B. I built them well over 10 years ago. But given my time again it'd be a close run thing between Tom's Modulus amps, and class D.

Craig

Last edited:

No doubt the PowerCon are awesome connectors. Just as the speakON connectors are. As pointed out above, it would be a simple modification to the chassis to change to the PowerCon. The speakON and XLRs gives you the hole pattern already. Copy, paste. Done. DIY at its finest. 🙂

Funny that you mention the Blameless design. Me and a friend of mine in college went with the Trimodal amp from Self's Wireless World article series that later became his power amp design book. Great amp. We made it far enough in the design to have a working prototype but I don't think any of us completed the project. He had kids and ran out of time. I moved across the Atlantic Ocean and started a new life.

Those Doug Self articles took some time to sink in. I really admired his thorough, methodical approach and desire for precision.

Tom

Funny that you mention the Blameless design. Me and a friend of mine in college went with the Trimodal amp from Self's Wireless World article series that later became his power amp design book. Great amp. We made it far enough in the design to have a working prototype but I don't think any of us completed the project. He had kids and ran out of time. I moved across the Atlantic Ocean and started a new life.

Those Doug Self articles took some time to sink in. I really admired his thorough, methodical approach and desire for precision.

Tom

Tom, just using a power supply which is in compliance makes not the complete amplifier legal and in compliance.

I doubt if leaving the cage of the powersupply make them still safe for consumers.

My point is try apply in the future the right safety and compliance certificates. You will see for export every continent/country has his own rules.

I build/sold(>10k pcs) Filmnet decoders in the 80's. And was not convicted for illegal using Filmnet but for selling consumer equipment which was not in compliance with safety rules.

And dont trust your lawyers they live from your faults. Ask the notified bodies in your country.

I doubt if leaving the cage of the powersupply make them still safe for consumers.

My point is try apply in the future the right safety and compliance certificates. You will see for export every continent/country has his own rules.

I build/sold(>10k pcs) Filmnet decoders in the 80's. And was not convicted for illegal using Filmnet but for selling consumer equipment which was not in compliance with safety rules.

And dont trust your lawyers they live from your faults. Ask the notified bodies in your country.

I also like Self's detailed and no-audio-******** approach. I have all his books, and his treatment of the details of the causes of distortion in audio electronics needs reading and re-reading.

I built my Blameless amps using circuit boards from http://www.signaltransfer.freeuk.com/ , which is actually Self's site to sell his boards.

My 10 channels of it have been running without missing a beat for a decade. I used to leave them permanently on when energy was cheap. Now that it isn't I turn the off when not being listened too.

Craig

I built my Blameless amps using circuit boards from http://www.signaltransfer.freeuk.com/ , which is actually Self's site to sell his boards.

My 10 channels of it have been running without missing a beat for a decade. I used to leave them permanently on when energy was cheap. Now that it isn't I turn the off when not being listened too.

Craig

In response to compliance testing - if you go that route, the compliance applies to a "build file". You cannot change anything in the design afterwards without notifying the approving authority. If they judge the change to be minor, they might just approve it. If they think that it warrants re-approval you end up back in their test lab with more money.

Been there done that, got the badge. With everything from pollution monitors to space electronics.

Been there done that, got the badge. With everything from pollution monitors to space electronics.

Tom, I will not buy your product so from me yo do not have to expect any liability issues.

Also I wont buy products from Nord, Emerald physics and Minidsp.

Also I wont buy products from Nord, Emerald physics and Minidsp.

The other compliance headache I had was ATEX approval https://www.hse.gov.uk/fireandexplosion/atex.htm - so safe in an explosive environment. Think oil rig, oil refinery, re-fuelling aircraft, flour mill - even a forecourt filling station. ATEX approvers have absolutely no sense of humour, and apart from going on courses to learn, the only way to really learn is to design what you think will meet the code, submit it and weep when you get chapter and verse why you don't remotely comply.

Craig

Craig

I got it,Craig.

Build one of the biggest digester( biogas plant) in europe. Atex, CE and environmental and labour laws.

Before that Polyester chip, Methanol and biodiesel plant. You have to do it by the rules but it is not the most pleasant part of engineering. At the moment having a headache to get CE certification on my newly build production line for enternal nutricion

So Tom, try to do It right. If you not can do it alone seek a partner.

Then your products earn “engineering done right”

Build one of the biggest digester( biogas plant) in europe. Atex, CE and environmental and labour laws.

Before that Polyester chip, Methanol and biodiesel plant. You have to do it by the rules but it is not the most pleasant part of engineering. At the moment having a headache to get CE certification on my newly build production line for enternal nutricion

So Tom, try to do It right. If you not can do it alone seek a partner.

Then your products earn “engineering done right”

There is a whole world of difference between the sort of things we have got involved with, which are major high ticket systems, and Tom's company, which like most audio companies, a cottage industry run by either a sole trader or two or three people.

To put a product through approvals takes time - book a slot - perhaps three months out and maybe more. And which approvals? In the UK the Low Voltage Directive at least. And because there is a switched mode supply in there, conducted and radiated RFI, and possibly RTTE too. Two to three weeks of testing. Then suppose it fails. Rework and test again.

And given that you cannot sell a product if you are going through this approvals process - how you you eat and pay the mortgage?

Plus Tom sells kits of bits to the DIY community. How do you suggest he handles that?

To put a product through approvals takes time - book a slot - perhaps three months out and maybe more. And which approvals? In the UK the Low Voltage Directive at least. And because there is a switched mode supply in there, conducted and radiated RFI, and possibly RTTE too. Two to three weeks of testing. Then suppose it fails. Rework and test again.

And given that you cannot sell a product if you are going through this approvals process - how you you eat and pay the mortgage?

Plus Tom sells kits of bits to the DIY community. How do you suggest he handles that?

Folks, let's just ignore this Koifarm guy and maybe he'll go away back to caring for his fish pond.

Kiofarm, you appear to have some serious holes in your understanding of 'compliance'. How do I know -- well, I've spent 39+ of my 45+ years of engineering employment in new product development and product support for major automotive/instrumentation/electronics companies. We followed the rules (including all the national variants) and were 'self-certifying'. The point is to follow the rules, not the sending-off of equipment to certifiers. Additionally, your comments are all over the map -- latest about biogas have no relation to Tom's amplifier products.

So, perhaps just cease and desist from your trolling and go away.

Kiofarm, you appear to have some serious holes in your understanding of 'compliance'. How do I know -- well, I've spent 39+ of my 45+ years of engineering employment in new product development and product support for major automotive/instrumentation/electronics companies. We followed the rules (including all the national variants) and were 'self-certifying'. The point is to follow the rules, not the sending-off of equipment to certifiers. Additionally, your comments are all over the map -- latest about biogas have no relation to Tom's amplifier products.

So, perhaps just cease and desist from your trolling and go away.

As I mentioned in Post #1567, I used the power supply exactly how it was provided to me by Mean Well. I made NO modifications to it of any kind. The end user will never come into contact with the power supply.

I think the troll is well fed.

Tom

Exactly.The point is to follow the rules, not the sending-off of equipment to certifiers.

I think the troll is well fed.

Tom

@poseidonsvoice Could you please provide a bit more detail about the measurements you're showing? (I'm almost completely uneducated on this stuff, trying to learn more.)Some more pics and measurements attached. Don’t worry, me and my alter ego are arguing about the pin 1 issue. It will be resolved 😉.

Best,

Anand.

I'm guessing you're feeding a sine wave to the amp with a signal generator (built into the scope?) and it's the middle waveform on the photos? The sine wave gets fed to the amp input, then measured at the output, showing the + and - waveforms, for a single channel because the Mod-686 outputs a balanced signal?

What is the purpose of such measurements? Just verifying if the behavior of the amp is in the right direction? The equipment used is probably not "sensitive" enough (hope I'm using a sensible term) to truly show the level of the amps performance right?

So how would you determine you're measuring exactly 1 or 60 watts? By the amount of input voltage? Does the signal generator set that? And do you need to connect a load to the amps output for these measurements?

Apologies in advance if I'm asking too many questions. My curiosity can be too much at times.

Usually the amp is loaded by a resistive load of 4 Ω or 8 Ω. The power dissipated in the load is then simply calculated from P = E^2/R. So with an 8 Ω load you turn the input voltage up until you have a 2.82 V RMS sine wave on the output. This results in 1 watt delivered to the load resistor.So how would you determine you're measuring exactly 1 or 60 watts? By the amount of input voltage? Does the signal generator set that? And do you need to connect a load to the amps output for these measurements?

There's nothing magic about 1 W. It's just the power that folks in the audio industry have accepted as representative of normal listening volume, so it's a good measure for how the amp will behave in actual use.

You'll notice that Amir at ASR has chosen 5 W as his magic number. He claims modern speakers are inefficient and that normal listening power is therefore higher. So he measures at 5 W. Everybody else measures at 1 W. Some argue we should measure at even lower power levels.

Tom

Read note 7 from the meanwell manual and study class 1 and/or class 2 insulation directive.

It,s always in the small letters.

It,s always in the small letters.

- Home

- Vendor's Bazaar

- Modulus-686: 380W (4Ω); 220W (8Ω) Balanced Composite Power Amp with extremely low THD