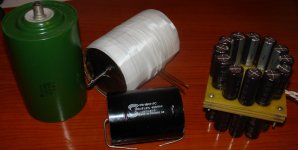

These are my toys that I am playing with now. On the left side - 4,7uFx125V teflon capacitor, it is manufactured for power industry, for passing very large high-frequency currents through it. I have taken them out from the metal case, and even without it, the weight of teflon cap maybe 5...7 times more than 100uF polypropylene one. I wrapped it in natural leather (good vibrations damping material), then in teflon tape. It measures excellently, but when I used it as a shunt cap, the effect was very small, 100uF polypropylene gives much more noticable sound improvement.

Attachments

Jay,

the dielectric loss factor for paper is relatively large at high frequencies.

In case of my speakers' crossovers...

My lowly electronics knowledge tells me that a dielectric loss should not create a problem in tweeter frequency signal. The voltage amplitude (across the caps) is relatively small. But I have been 100% relying on my ears. My ears said "no problem, it sounds good". And I have always paralleled them with other MKPs (Note that these caps comprises of 2x 2uF in one can).

In case of small size paper caps...

What I mean here is actually a POLYSTYRENE. I'm not sure whether polystyrene is the same with paper cap. Since childhood I have been told (by sellers) that it was a paper cap. I know that they have problems. But if it is this problem that gives the enjoyable sound, I can accept the problem.

...Use tinfoil/film capacitors...they are magnificent in crossovers.. and may also be good in electronics (just a gut feel)

I know there are 2 types of Solen caps. The black one is MKP, the white one I think is foil. The white Solen is bigger in size and much more expensive than the black one. But I don't like the sound of the white Solen (I have them unused, or just use them for supply bypass to make them useful). I think nobody would like their sound (in crossover)?

One reason why polypropylene is good for capacitors is the fact that it is stretched before the metalization...then after winding they can be baked and thus form a mechanically solid body....this is not possible with teflon and thus they are more loose in the winding...And also bigger as teflon is no so thin...so the plates can't be as close together...and thus they have to be larger...Tinfoil is the only foil that can be cut without edgeburs..so that is good with polypropylene film...copper foil can be sharp so it needs some thicker material..and thus grows bigger....bigger means also more inductance and less high frequency performance...

The drawback with metalized polypropylene is that the plates are so thin that they don't conduct very well...typical less than 1 um thick and not very even..This is tha same also when the metalization contains copper silver or gold.. The layer is much too thin for my liking...A reason why its kept so thin is the self healing aspect... which means that the film pores that causes DC leaks can be burnt away with a high voltage chock...

To me the best compromise for audio is the tinfoil/polypropylene caps...as plates conduct better and the foil is still thin..Some may think different...and my preference is from making loudspeakers..so I may be wrong when it comes to electronics...though the cap here in question is for loudspeaker....🙂

I can't say about Solen...I use the Mundorf tin/foil in my loudspeakers. And for my application I still haven't found any better...regardless of price...

The drawback with metalized polypropylene is that the plates are so thin that they don't conduct very well...typical less than 1 um thick and not very even..This is tha same also when the metalization contains copper silver or gold.. The layer is much too thin for my liking...A reason why its kept so thin is the self healing aspect... which means that the film pores that causes DC leaks can be burnt away with a high voltage chock...

To me the best compromise for audio is the tinfoil/polypropylene caps...as plates conduct better and the foil is still thin..Some may think different...and my preference is from making loudspeakers..so I may be wrong when it comes to electronics...though the cap here in question is for loudspeaker....🙂

I can't say about Solen...I use the Mundorf tin/foil in my loudspeakers. And for my application I still haven't found any better...regardless of price...

Last edited:

In case of small size paper caps...

What I mean here is actually a POLYSTYRENE. I'm not sure whether polystyrene is the same with paper cap. Since childhood I have been told (by sellers) that it was a paper cap. I know that they have problems. But if it is this problem that gives the enjoyable sound, I can accept the problem.

Polystyrene caps have absolutely nothing in common with paper caps, and polystyrene film caps is generally recognized as being superiour to polypropylene. The only problem with them, similar to teflon, there is no big enough uF with polystyrene, usually less than 1uF.

Referring to what MiiB has pointed out, it seems that polypropylene has no alternatives in Solid State designs, for PS and output caps, since somthing less than 20uF has almost no effect on sound. Those 0,1uF put on PCB power traces, I think they only help to make circuit more stable.

Last edited:

Polystyrene caps have absolutely nothing in common with paper caps, and polystyrene film caps is generally recognized as being superiour to polypropylene. The only problem with them, similar to teflon, there is no big enough uF with polystyrene, usually less than 1uF.

My ears told me that the polystyrene is superior, but only a few who consistently uses it. Also, I cannot find situation where FKP has been useful. Even the famous silver mica has never had an audible effect to my ears.

Referring to what MiiB has pointed out, it seems that polypropylene has no alternatives in Solid State designs, for PS and output caps, since somthing less than 20uF has almost no effect on sound. Those 0,1uF put on PCB power traces, I think they only help to make circuit more stable.

Not to my ears (if I get you right). Even below 1uF, supply bypass caps are perfectly audible.

- Status

- Not open for further replies.