thank you guys, I build them in 4-5 weeks actually, but it took me over 2 years to start working on them after I got recommendation from XRK and when I completed all the materials, speakers etc.. Definatelly I am very pleased with the sound they produce.

Gluing with Titebond Original takes 24h before stressing, so gluing all the elements took me 1.5-2 weeks, but most of the time spent making them looking subjectively good 🙂

Gluing with Titebond Original takes 24h before stressing, so gluing all the elements took me 1.5-2 weeks, but most of the time spent making them looking subjectively good 🙂

Additionally I did one crazy thing, the grilles for the Karlsonator. I used 3x6mm neodymium magnets to mount them, on the front of the grille I glued 2mm EPDM rubber to reduce vibrations. BTW I used the same material to mount the front aperture.

I'm not sure if I'm going to use them as the front aperture doesn't look bad after all 🙂

So far I can't hear the difference, but I have to make sure they do not vibrate when listening louder.

I'm not sure if I'm going to use them as the front aperture doesn't look bad after all 🙂

So far I can't hear the difference, but I have to make sure they do not vibrate when listening louder.

Hey, Ripson. Amazing work. Congrats on a superb looking pair of speakers.

Would you mind elaborating on how you made them, please? Material, thickness, stuffing, veneer/vinyl, etc. I'm still listening to mine built from 5mm foam board, but have been threatening to build wood cabinets.

.

.

Would you mind elaborating on how you made them, please? Material, thickness, stuffing, veneer/vinyl, etc. I'm still listening to mine built from 5mm foam board, but have been threatening to build wood cabinets.

.

.

Hi Skylar, I'm glad you like them because I build them based on your sketches from 2017 🙂 According to your project, I made them from 12mm plywood, I used Monacor MDM-4 (60% cotton + 40% polyester) for stuffing, on the back the drivers there is 20mm melamine foam, and the walls (lower part) are covered with Poroso 12mm.

At the back of the aperture, I glued BASF Basotect 10mm melamine foam. But I added it all over the area, it reduced the high frequency harshness, but it might be related to a speaker burning-in / breaking-in process.

Karlsonator 0.53 FaitalPRO 3FE25-16 - YouTube

I haven't added any internal bracing, but adding 10mm pieces of decorating wood reduced vibration. I didn't measure their SPL as a function of f, but I have to wait for the pandemic to end.

I don't know how perform the speakers made of the foam core, but definitely I am very happy with mine. 🙂

Thanks a lot for sharing the plans Skylar!

At the back of the aperture, I glued BASF Basotect 10mm melamine foam. But I added it all over the area, it reduced the high frequency harshness, but it might be related to a speaker burning-in / breaking-in process.

Karlsonator 0.53 FaitalPRO 3FE25-16 - YouTube

I haven't added any internal bracing, but adding 10mm pieces of decorating wood reduced vibration. I didn't measure their SPL as a function of f, but I have to wait for the pandemic to end.

I don't know how perform the speakers made of the foam core, but definitely I am very happy with mine. 🙂

Thanks a lot for sharing the plans Skylar!

Last edited:

Hi Ripson

Glad that you found the plans useful and that you "test built" it. It should be safe for me to go ahead and build my own wood set now. 😀

How did you finish the cabinets on the outside? Veneer?

.

.

Glad that you found the plans useful and that you "test built" it. It should be safe for me to go ahead and build my own wood set now. 😀

How did you finish the cabinets on the outside? Veneer?

.

.

It's not a veneer. I have some furnitures made of old/vintage pine. So I thought it might be good idea to make the speakers in the same style. So I purchased old pine/spruce 10mm pieces taken from some 50-80 year old barn. When the cabinets were done I took them to a carpetner who cut the edges of the old wood under 45 degrees so I could glue them to the cabinets. The wood glue was on the entire area so there is no wood to wood contact that might make rattle noise.

PS. I didn't know I was the first who made dual 3FE25-16 of 12mm plywood. The only thing I am not certain/happy is the sensitivity, I don't think they are 96dB 2.83V 1m

PS. I didn't know I was the first who made dual 3FE25-16 of 12mm plywood. The only thing I am not certain/happy is the sensitivity, I don't think they are 96dB 2.83V 1m

Fantastic work and care in the construction, Ripson. You really put some thought and time into these.

Jhofland built me a pair in BB plywood. I think it’s 12mm back in December 2018. Plans in Sketchup are here:

Mini Karlsonator (0.53X) with Dual TC9FDs

Jhofland built me a pair in BB plywood. I think it’s 12mm back in December 2018. Plans in Sketchup are here:

Mini Karlsonator (0.53X) with Dual TC9FDs

Attachments

The only thing I am not certain/happy is the sensitivity, I don't think they are 96dB 2.83V 1m

If you're using BSC to tame the highs, it might influence your perception of the sensitivity. I chucked the BSCs and now use software EQ in my media player.

.

.

.

I think it’s the 90dB spec is at 1W according to datasheet, and incorrectly, at 2.83v according to Parts Express website.

A Speaker that Kicks Butt in Large Spaces

A Speaker that Kicks Butt in Large Spaces

Hi X, I think you once calculated, or guestimated, 94dB or was it 96dB? for parallel 16Ohm 3FE25's.

.

.

.

.

.

.

.

.

Thanks for posting those.

They look wonderful.

Inspiring.

I just received my delivery of foam board for my first crack in a couple of weeks time.

They look wonderful.

Inspiring.

I just received my delivery of foam board for my first crack in a couple of weeks time.

I calculated 96dB based on 90dB at 2.83v. But it seems the spec I used was misquoted by Parts Express. Sorry about that, I should have been more careful and looked at the factory data sheet.

1W into 16ohms requires 4v as power is V^2/R. So the spec is 90dB at 4V and 1m.

Two in parallel is +6dB and 2.83v is -3dB from 4v. So net gain is 3dB for dual 3FE25-16 in parallel.

Or 93dB at 2.83v and 1m and 8ohms.

1W into 16ohms requires 4v as power is V^2/R. So the spec is 90dB at 4V and 1m.

Two in parallel is +6dB and 2.83v is -3dB from 4v. So net gain is 3dB for dual 3FE25-16 in parallel.

Or 93dB at 2.83v and 1m and 8ohms.

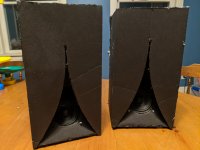

Back in June 2019 I planned to get a pair of these finished. Today I finally had the chance!

They're a bit rough around the edges in terms of assembly, but I'll clean them up a bit 🙂

As bookshelf speakers they work very well - a nice, even sound, and they don't need to be driven hard to get clarity. If you have a pair of FaitalPRO 3FE25s and you want to do something good with them without delving into a complicated design, I'd certainly recommend this one!

This foam build definitely pales in comparison to a lot of the other builds here (which are frankly amazing to see)! I've been wanting to finish this project for a long time, and quickly assembling them in an afternoon with the audible results I experienced is testament to the design!

They're a bit rough around the edges in terms of assembly, but I'll clean them up a bit 🙂

As bookshelf speakers they work very well - a nice, even sound, and they don't need to be driven hard to get clarity. If you have a pair of FaitalPRO 3FE25s and you want to do something good with them without delving into a complicated design, I'd certainly recommend this one!

An externally hosted image should be here but it was not working when we last tested it.

This foam build definitely pales in comparison to a lot of the other builds here (which are frankly amazing to see)! I've been wanting to finish this project for a long time, and quickly assembling them in an afternoon with the audible results I experienced is testament to the design!

Last edited:

Thanks for reposting. Black foam core has a nice stealth look!

I think at the time the black foam core was cheaper from wherever I bought it from 🙂

Unfortunately, the creases in the Karlsonator shaped panels were because they were stored for 18 months in a less than ideal location. I'll see what I can do to clean them up, and if I can, I'll post the results of my rescue mission!

You can always glue another layer on the front. It helps to stiffen that part. I usually use at least double layer there. A thin 1/8in to 3/16in plywood is really good too. That will really make it a presentable “wood-like” speaker.

- Home

- Loudspeakers

- Full Range

- Mini Karlsonator (0.53X) with Dual TC9FDs

.

.