Hi Jwjarch,

Thanks for the update on the listening impressions! Sounds like these little foam core boxes did ok if they stood their own vs the Paradigms! Yes, adding some damping can help. Certainly with wooden cabinets, damping is critical to get the Karlasonators to sound good. They do contribute some pass through sympathetic vibrations. Bracing can help reduce the large panel vibrations.

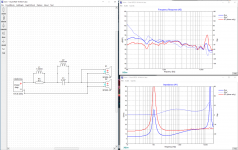

Hey X. I did add some bracing during my initial glueup of the boxes. I’m sure that helped some. What seems to help more is my experiment with BSC and a small notch filter to ever so slightly knock down the highs. Here’s my XSim showing a single driver in Red and the dual 3fe25’s in the Blue trace. And then I put it into real components. The sound is fantastic. The foam core sound has diminished from what I can hear. I think it may have been accentuated by the FR imbalance before BSC. My only question is regarding the impedance shown in XSim after my adjustments. Should I be concerned about the huge spike in the high frequency impedance or does this just make the amp work a little less? Also, is there an associated phase shift?

Attachments

That looks great Jwjarch! You can flatten the impedance peak with a cap and resistor in series and this is then strapped across the driver +/- . Try 2.2uF and 10R and go from there. There is a formula for calculating the exact frequency and that might be good to look up.

Are any of the curves from measurements or just factory data?

Are any of the curves from measurements or just factory data?

Thanks for the tip X. The data is just factory at this point. I haven’t learned how to use my UMIK yet. I’m interested in measuring these speakers to see what they look like. One of these days...

Hello everybody,

could someone post the last PDF plan for dual 3FE25 Karlsonator?

Thank you,

JP

could someone post the last PDF plan for dual 3FE25 Karlsonator?

Thank you,

JP

could someone post the last PDF plan for dual 3FE25 Karlsonator?

You don't say if it's for foam core or plywood/MDF construction.

Here is a plan for 12mm wood:

www.diyaudio.com/forums/attac...onator-053-pdf

Glad to see you're jumping on the bandwagon of the dual 3FE25, JPS! Here's a link to the foam core plans I used from Muddjester.

Mini Karlsonator (0.53X) with Dual TC9FD's

The holes for the drivers are a little low on the front plate. I think I moved them up about 1 cm so the magnet from the lower driver doesn't hit the bottom of the enclosure.

Good luck with your build!

Mini Karlsonator (0.53X) with Dual TC9FD's

The holes for the drivers are a little low on the front plate. I think I moved them up about 1 cm so the magnet from the lower driver doesn't hit the bottom of the enclosure.

Good luck with your build!

Is there an error with the drawing regarding frontplatte?

What kind of error are you referring to? As jwjarch suggested, move the drivers up if they touch the bottom.

Thank you @Skylar88

Neither plywood/MDF or foam.

JP

What material then? Solid wood? Please note that when building out of something other thanfoam core, extensive internal foam (melamine reticulated - aka miracle cleaning pads/BASF Basotect) padding needs to be applied to surfaces adjacent to back of drivers and on front chamber side walls and foam core and felt on front aperture on the inside. The foam core box sounds excellent actually and is a nice "kitchen table" project with a child. About 4hrs each should be enbough time or two nights in the kitchen or shop.

Melamine pads are on eBay from China for $7 to $10 a bag of 100 shipping included.

Has anyone had a go at building a dual 3fe22 MK with a shallow depth for wall mounting? Assuming that I preserve the proportions and volume, could the design be "stretched" vertically? If so, I'm assuming the front aperture slot would need to remain the same proportion in relation to the drivers.

Dumb idea?

Dumb idea?

No, never thought of doing that. You can try the flat wall mounted MLTL designs I have posted in the foam core thread.

Cheers X. I had a quick go at cut and paste of the designs in photoshop and it seems more effort than starting from scratch (or trying one of your previous designs)!

Plans are best used for dimensions of key locations which can be transcribed to a panel of foam core using a ruler. Then sketch the design on the panel and glue the pieces to the sketch. That’s how I make them. The only time I use a printed plan is the Cornu.

I was a skeptic but I really like my double 3FE25 Karlsonators.

How much lower bass could we expect with a 4X 3FE25?

Has someone already done a sim for that configuration?

Greets,

Klaus

How much lower bass could we expect with a 4X 3FE25?

Has someone already done a sim for that configuration?

Greets,

Klaus

hi Balaji - IF that 6 inch speaker meets its published spec then its not far off from the L CAO F6 which I have in the old Karlsonator 6 prototype

http://i.imgur.com/xp0P8go.png

With regards to that 12 inch speaker, I had Fane's 12-250TC in the stock Karlsonator 12 and fwiw, it sounded pretty good. I'm not sure how much peaking it would exhibit on the low end as did not test.

Hi Freddy,

my brother has two of those Fanes and he struggles to get any meaningful bass out of them.

Do you care to share the Karlson plans for this speaker?

Klaus

Drivers and amp parts have arrived so time to start the .4 sized karlsonators.Do you think its possible to bump the corners off the back of the cabinet off,old style corner cabinet style, increasing depth to keep the volume the same ?

I was a skeptic but I really like my double 3FE25 Karlsonators.

How much lower bass could we expect with a 4X 3FE25?

Has someone already done a sim for that configuration?

Greets,

Klaus

You don't get more bass by adding the same driver.

You get more output of what is already there.

If you want more bass, you'll need a different driver or EQ.

- Home

- Loudspeakers

- Full Range

- Mini Karlsonator (0.53X) with Dual TC9FDs