Tremendous. I was hoping it would work. Looks a doddle to cut to size on a hotwire table 🙂

Thanks for the links , plenty to read there 🙂.

Did you have a view on surface treatments for the foam, particularly for horn use where they encounter higher pressures in the throat etc? The resin would appear hard and resilient but a faff to apply maybe. Modge podge instead ? Thanks

Thanks for the links , plenty to read there 🙂.

Did you have a view on surface treatments for the foam, particularly for horn use where they encounter higher pressures in the throat etc? The resin would appear hard and resilient but a faff to apply maybe. Modge podge instead ? Thanks

You might want to use very thin plywood and bond it with resilient (non hardening) adhesive to provide a level of constrained layer damping. In general, it works quite well without treatment. A utility knife and multiple strokes cuts well.

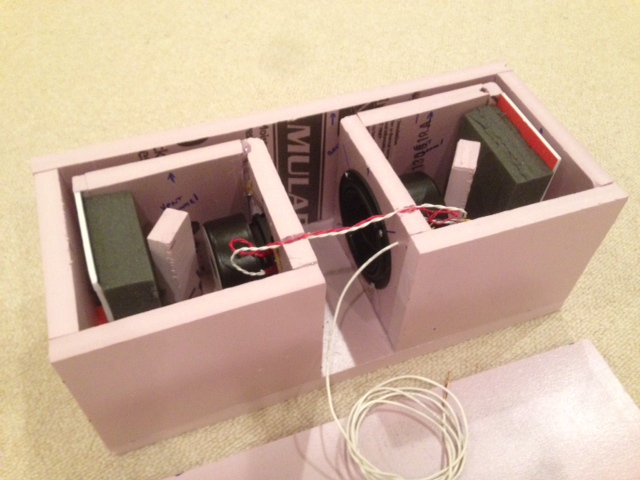

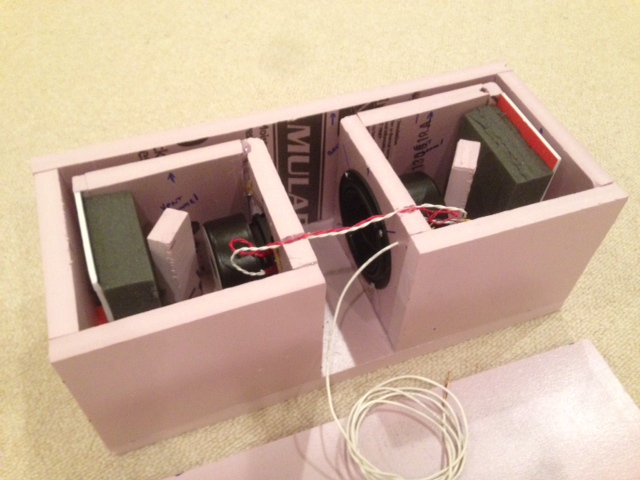

Here is another example:

Light as Air Slot Loaded Band Pass Sub

Here is another example:

Light as Air Slot Loaded Band Pass Sub

And so it begins. Hot wire cutter arrives.

Thanks for the help X , i hope this construction method proves as easy as it appears because I've had my eye on your creative and generous shared designs for a while , including the scaled up karlson k15's you simmed for me a while back ( once ive had my damaged altec 604's repaired :s ) and the Kazba open baffle ( wanting to try it as a sub for dmls and open baffles but still retaining some Karlson kick 🙂 . i have tesla Aro 941's to try in those ) . Thanks 😀

Thanks for the help X , i hope this construction method proves as easy as it appears because I've had my eye on your creative and generous shared designs for a while , including the scaled up karlson k15's you simmed for me a while back ( once ive had my damaged altec 604's repaired :s ) and the Kazba open baffle ( wanting to try it as a sub for dmls and open baffles but still retaining some Karlson kick 🙂 . i have tesla Aro 941's to try in those ) . Thanks 😀

Any luck with hot wire cutter? A sharp utility knife and straight edge work pretty well.

Btw, a very nice aluminum straight edge meter stick is available from Starrett for $7.

Great for foam core projects.

Starrett MS-2 Aluminum Straight... Starrett MS-2 Aluminum Straight Edge Meter Stick, 39.37" Length: Construction Rulers: Amazon.com: Industrial & Scientific

Btw, a very nice aluminum straight edge meter stick is available from Starrett for $7.

Great for foam core projects.

Starrett MS-2 Aluminum Straight... Starrett MS-2 Aluminum Straight Edge Meter Stick, 39.37" Length: Construction Rulers: Amazon.com: Industrial & Scientific

Must admit i haven't started yet. I need to stop buying things and start making things. Acquired three new beta 12lta yesterday for £70.00 all in. Quite pleased with that. For sure ill post follow ups as soon as that hot wire hits the foam.Any luck with hot wire cutter? A sharp utility knife and straight edge work pretty well.

Btw, a very nice aluminum straight edge meter stick is available from Starrett for $7.

Great for foam core projects.

Starrett MS-2 Aluminum Straight... Starrett MS-2 Aluminum Straight Edge Meter Stick, 39.37" Length: Construction Rulers: Amazon.com: Industrial & Scientific

What i lked about the hot wire table was that itll keep cuts fully vertical ( or at a 'chosen' angle ) which freehand might not , depending on the skill of the person holding the knife.

Inviting ideas for templates for curved panels like on a karlson? I guess hardboard wouldn't ignite at the speed a foam cut was made? Thin steel cut with tin snips/jig saw and filed smooth ?

Inviting ideas for templates for curved panels like on a karlson?

That would be neat if it will work sonically. I have a CNC foam cutter that hasn't worked at all since about 2014 when I stopped making model airplane kits. The idea of curved panels, laminated with glass/carbon mat sounds high tech, but should be easy to make. Judging by how well the foam board Karlsonators sound, XPS foam laminate may just work.

Paxolin templates should stand up to the temperature of a hot wire and it can be sanded very smooth.I guess hardboard wouldn't ignite at the speed a foam cut was made? Thin steel cut with tin snips/jig saw and filed smooth ?

I cut my mini Karlsonator’s foam core curves with a sharp utility knife using a template made from plexiglass (perspex). You only need a template for one side of the curve, then flip it around for the other side. I first draw the curve on paper, then glue the paper onto the perspex, then cut the curve with a band saw (or jig saw), then sand it smooth. I guess you can use mdf or plywood too.Inviting ideas for templates for curved panels like on a karlson? I guess hardboard wouldn't ignite at the speed a foam cut was made? Thin steel cut with tin snips/jig saw and filed smooth ?

I cut my mini Karlsonator’s foam core curves with a sharp utility knife using a template made from plexiglass (perspex). You only need a template for one side of the curve, then flip it around for the other side. I first draw the curve on paper, then glue the paper onto the perspex, then cut the curve with a band saw (or jig saw), then sand it smooth. I guess you can use mdf or plywood too.

remember im cutting with a hot wire device ( up to 600 deg f i think ) , perspex might give off nasty smoke below that? im feeling thick card or hardboard might be safer fumes wise?

did read some things suggesting paxolin dust is hazardous?

did read some things suggesting paxolin dust is hazardous?

So is MDF dust. Wear a mask. 😀

I appreciate ppe can be used but im making this stuff in what will be my cinema/listening room, so things i could get away with in a garage might not be desirable for my circumstances.So is MDF dust. Wear a mask. 😀

I appreciate ppe can be used but im making this stuff in what will be my cinema/listening room, so things i could get away with in a garage might not be desirable for my circumstances.

If you're apprehensive about a little Paxolin dust (which is quite heavy and most of it falls straight to the floor when sawing), then maybe you're unaware that fumes from hot wire foam cutting is toxic. This may be worth reading.

I found that a good fan and open doors and windows can take care of the fumes, though. But I wouldn't recommend having children in the same room while cutting.

I have a CNC foam cutter that hasn't worked at all since about 2014 when I stopped making model airplane kits.

It's funny, as I just started this new hobby... RC sailplanes.

Got me a small soaring model to practice around here. Still a beginner, but learning is fun! Also registered at rcgroups.

And I'm reading extensively about DIY foamies... why did you stop making them?

Sorry, a little OT here.... but still about foam! 🙂

It's funny, as I just started this new hobby... RC sailplanes.

Got me a small soaring model to practice around here. Still a beginner, but learning is fun! Also registered at rcgroups.

And I'm reading extensively about DIY foamies... why did you stop making them?

Sorry, a little OT here.... but still about foam! 🙂

RC sailplanes (called gliders in my part of the world) are heaps of fun. Built and flew it for many years. It's quite addictive to search for and "hook" thermals. A lot of the hand-working skills that you learn in aeromodelling can also be used in audio.

I made kits of electric pylon racers that can do speeds of up to 250km/h. Consequently, the market is quite small, because only a small percentage of RC pilots are confident enough to fly such fast models. I only sold locally.

I'm seriously considering cutting some curved panels for a pair of Karlsonators, seeing that I have a CNC foam cutter. Unfortunately I have too many hobbies that require time and money. What can be said for audio, is that it can be enjoyed at all hours of the day and all seasons.

It's taking all my concentration now to fly at about 10 km/h... I can't imagine flying at 250!!! Still, I'm hooked!

I'd love to see a mini-k with curved walls...

A small wire cutter board is about $100 here. I might get one. Could be handy for a number of things. CNC is a bit over my head.

Audio at all hours of the day? Maybe with headphones! 😀

I'd love to see a mini-k with curved walls...

A small wire cutter board is about $100 here. I might get one. Could be handy for a number of things. CNC is a bit over my head.

Audio at all hours of the day? Maybe with headphones! 😀

A small wire cutter board is about $100 here. I might get one. Could be handy for a number of things. CNC is a bit over my head.

A foam cutter can be made very cheaply. You need a transformer and a bow, strung with about 0.01" SS fishing trace. I use a 5A transformer with 2 x 15V taps, connected in series and driven from the mains via a light dimmer.

My CNC foam cutter is made with kitchen drawer slides and 4 stepper motors from old 5.25" floppy disk drives. The cuts are very smooth and need minimum sanding afterwards. The advantage of CNC is that you don't have to make templates. Just draw and cut whatever you want.

Thanks ill give your link a read. I had previously watched a YouTube this bro made which made it sound safe enoughIf you're apprehensive about a little Paxolin dust (which is quite heavy and most of it falls straight to the floor when sawing), then maybe you're unaware that fumes from hot wire foam cutting is toxic. This may be worth reading.

I found that a good fan and open doors and windows can take care of the fumes, though. But I wouldn't recommend having children in the same room while cutting.

YouTube

RC sailplanes (called gliders in my part of the world) are heaps of fun. Built and flew it for many years. It's quite addictive to search for and "hook" thermals. A lot of the hand-working skills that you learn in aeromodelling can also be used in audio.

I made kits of electric pylon racers that can do speeds of up to 250km/h. Consequently, the market is quite small, because only a small percentage of RC pilots are confident enough to fly such fast models. I only sold locally.

I'm seriously considering cutting some curved panels for a pair of Karlsonators, seeing that I have a CNC foam cutter. Unfortunately I have too many hobbies that require time and money. What can be said for audio, is that it can be enjoyed at all hours of the day and all seasons.

Sorry to keep going with the off topic here but I can't resist. Long time RC pilot, tried just about everything over the years but always went back to gliders. In my teens and twenties I could be found most weekends either at the slope or field depending on the wind. These days with little time I sometimes steal an hour on the weekends and fly my discus launch glider at the local park. Slope gliders were mostly foam core covered in balsa, birch or fiberglass. Was always tempted to get a foam cutter but stuck with templates and a long sanding bar. Thermal gliders are all balsa. I just love looking up as the sun shines through the wing. Great fun!

And now here I am thinking about building a pair of Karlsonators to go with my ACA and AKSA Lender preamp. Funny how that works.

So it seems that we have similar hobby backgrounds. I've done it for so long, but now enjoy my new hobby.

For the price it costs to build, the Karlsonators must be the best value ever and perfectly suited to the ACA + AKSA Lender pre for normal home use. You'll also get just about the best soundstage ever. That's something inherent to the Karlsonators that other types of speakers don't necessarily have.

Just be aware that you'll need to use a sub(s) to augment bass. The mini Karlsonators on their own don't have big bass, which is understandable, due to the small size of the drivers.

For the price it costs to build, the Karlsonators must be the best value ever and perfectly suited to the ACA + AKSA Lender pre for normal home use. You'll also get just about the best soundstage ever. That's something inherent to the Karlsonators that other types of speakers don't necessarily have.

Just be aware that you'll need to use a sub(s) to augment bass. The mini Karlsonators on their own don't have big bass, which is understandable, due to the small size of the drivers.

- Home

- Loudspeakers

- Full Range

- Mini Karlsonator (0.53X) with Dual TC9FDs