Tinitus, that's very cool! 🙂

I'd be interested to try it...what data would you need in order to make it appropriate for the Alpha 8?

I'd be interested to try it...what data would you need in order to make it appropriate for the Alpha 8?

unaHm:

For experimental purposes hardboard will be ok.

For a permanent solution I used " wiggle board " also known as bendable plywood that come in 3/8" thickness ( only size I found ) and will easily bend to any horn profile. For my mid bass horn I used 4 layers per side with epoxy glue between each layer. Regular wood glue tends to shift and delaminate over time. the epoxy glue is much more rigid. I finished my horns by using oak veneer on the inside and oak wainscot on the exterior to give a finished look.

For experimental purposes hardboard will be ok.

For a permanent solution I used " wiggle board " also known as bendable plywood that come in 3/8" thickness ( only size I found ) and will easily bend to any horn profile. For my mid bass horn I used 4 layers per side with epoxy glue between each layer. Regular wood glue tends to shift and delaminate over time. the epoxy glue is much more rigid. I finished my horns by using oak veneer on the inside and oak wainscot on the exterior to give a finished look.

...what data would you need in order to make it appropriate for the Alpha 8?

I don't know about data, or how to use them 😛 ... but it would surely need more 'refinement'

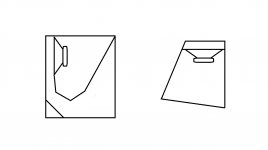

here is another 'teaser' 😀

first is seen from above, and could be in a corner

second is turned around, and seen from the side

Attachments

unaHm:

For experimental purposes hardboard will be ok.

For a permanent solution I used " wiggle board " also known as bendable plywood that come in 3/8" thickness ( only size I found ) and will easily bend to any horn profile. For my mid bass horn I used 4 layers per side with epoxy glue between each layer. Regular wood glue tends to shift and delaminate over time. the epoxy glue is much more rigid. I finished my horns by using oak veneer on the inside and oak wainscot on the exterior to give a finished look.

I agree on the glue front. The only time I use 'standard' wood glue is when I'm making instruments, which I'd imagine to be considerably stiffer than the thinner and more flexible horn walls.

Thanks for those tips, I'll bear that in mind!

For speaker building I'll usually use something like construction adhesive.

I don't know about data, or how to use them 😛 ... but it would surely need more 'refinement'

here is another 'teaser' 😀

first is seen from above, and could be in a corner

second is turned around, and seen from the side

Thanks for the teaser, it looks nice! 🙂 Are you using a particular horn design, or are you just playing 'graphically' for now?

Based on that design, my goal would be to fit that 25" horn on the previous page into an 18x18" (45.72x45.72cm) footprint.

With the offset driver design, I noticed in HornResp that the response has quite a few resonant peaks. Would the same happen in that curved design?

Last edited:

... 18x18" (45.72x45.72cm) footprint.

... quite a few resonant peaks. Would the same happen in that curved design?

small, but maybe if taller

maybe the first could make high sound pressure

but yes, I expect the curved one would be better

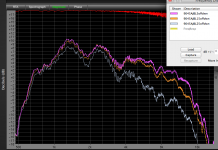

We can certainly hear reflections from floor and ceiling, and those reflections being a longer path length than the direct path cause peaks and dips in the response.Would anybody like to comment on pattern flip? How bad is this? Just as bad as the "horrible" directivity issues a 7 inch woofer + 1 inch dome speaker suffers? or really, really bad? Our hearing is not that sensitive vertical.

Horns, if made large enough, can control the pattern so reflections from floor and ceiling can be minimized without resorting to acoustical treatment.

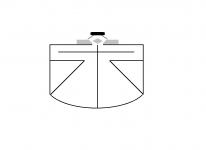

"Pattern flip" is simply a widening in the pattern at lower frequencies when the mouth is too small vertically to control the pattern.

As you can see below, the 90 x 45 degree horn starts to loose control below 4000 Hz (about the wavelength of the vertical horn dimension) so below that point more energy will be directed outside the nominal pattern, progressively increasing floor and ceiling reflections.

It is not a "horrible" transition, but if making or choosing a horn, unless vertical size (and the depth required for it) is a big concern, no reason to go for one that has compromised vertical control.

Attachments

Yes.With the offset driver design, I noticed in HornResp that the response has quite a few resonant peaks. Would the same happen in that curved design?

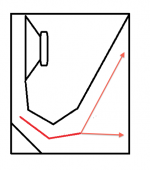

you could achieve smaller footprint this way

actually, that last bit of 'sides' could be 'attached', and removed when not needed

how long was your original straight horn design ?

I think the original design (that I'd made in cardboard) was 88.22cm.

Thanks Art,

Very clear. Round horns "mess up" driver to driver spacing...a 90 x 40 horn has patternflip.

Very clear. Round horns "mess up" driver to driver spacing...a 90 x 40 horn has patternflip.

Must not be too clear, a 90 x 40 with the vertical dimension the same as the horizontal won't flip in pattern.Thanks Art,

Very clear. Round horns "mess up" driver to driver spacing...a 90 x 40 horn has patternflip.

However, to make that type of horn requires a diffraction slot.

What do you mean by "round horns mess up driver to driver spacing"?

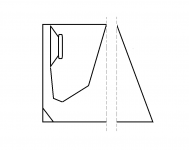

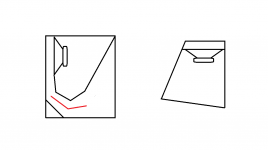

Yes, getting the bends right is tricky 🙂.be aware that when constructing/drawing it, the trick is to get the bend right, marked with red

The one you show results in two different path lengths, which will result in nasty peaks and dips, as well as an erratic polar response.

Attachments

Hi Art,

You are right, somehow combined 90 x 40 horns with wide bi-radials. My bad, to many hours behind the screen. An 18w x 9h inch biradial would allow closer driver to driver placement as an 14 -15 inch round horn with the same mouth area.

You are right, somehow combined 90 x 40 horns with wide bi-radials. My bad, to many hours behind the screen. An 18w x 9h inch biradial would allow closer driver to driver placement as an 14 -15 inch round horn with the same mouth area.

I know that this isn't to any particular scale, and the expansion probably isn't that great, but what about something like this?

Note - the right-hand side of the box is closed, and the horn now exits at the top of the picture.

Note - the right-hand side of the box is closed, and the horn now exits at the top of the picture.

Last edited:

The one you show results in two different path lengths, which will ...

nothing special about that one

just a simple generic fold or bend

well, yeah, one side is straight for easier construction

maybe that could be a problem

hey Art, I understand you use lots of paralines 😀

Attachments

I am amazed there is not a thread about folding horns @Diyaudio, with al the crazy examples together. I am a bit hesitant to empty out my complete "hornfold" directerory here. As recent convert to the "thou shall not fold a frontloaded horn" church. Wasn't the gist of the thread some page's ago, that only a Sato horn fold or a Western Electric 1 fold horn would not be detrimental to the midrange 🙂

... detrimental to the midrange

or move the goalposts

Right, for widest BW, a fibonacci spiral is the ideal ...

because it is very long, and thus no abrupt changes ?

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Multi-Way

- Midbass horn