You can tweak this by letting more of the expansion happen with the side walls/ top and bottom walls, and considering that a bend may be less than perfect to begin with, making it smooth (and therefore easier to build) may/may not necessarily be a bad thing.

it appears you are making big compromises, yet maintains complicated construction 😕

the sharp inner bend may do ok for bass horns

but I doubt it works well with midrange

the sharp inner bend may do ok for bass horns

but I doubt it works well with midrange

Since the inside wall of the horn is shortened through the curve, it effectively expands much more quickly. Where that rapid expansion meets the normal expansion of the straight section, there is a little kink. I adjusted the inside wall to straighten that bit out. This means the horn doesn't expand at the original rate. I have no idea what that will do to the frequency response, but I expect it does less than bending the horn in the first place.

I think the horns I have will work for now, though that's not to say I wouldn't look into other avenues. I would eventually like to have a wider dispersion angle, but for now the narrow one would be Ok.

I had a quick attempt at bending the original tractrix horn (the one I'd made in cardboard that is longer, and has a smaller throat):

The mouth and throat dimensions are correct, but that bend on the inside of the curve is a bit wonky! I've not done anything to it, besides to bend it and check those measurements, so this may not work at all, or may be plausible.

For anyone who wants to play with this image, I'd set the dpi to 25.4, so that one dot represents a millimetre...

Edit: David, thanks for the info - that gives me something to play with!

If you're going to bend a horn, bend it at a right angle:

http://volvotreter.de/downloads/Edgar-Show-Horn.pdf

^^ read page four in particular

Or don't.If you're going to bend a horn, bend it at a right angle:

^^ read page four in particular

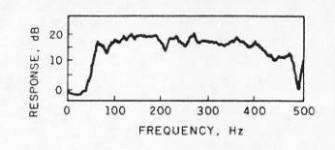

The Show Horn response is ragged, and has a hole around -20 dB at 475 Hz, right in the middle of voice fundamentals.

Bruce Edgar gives no technical reasons behind his folding, other than a cursory unvalidated dismissal of 180 degree bends.

I would not consider the Show Horn to be a good example of folding to emulate for smooth upper response.

Low frequencies are indifferent to horn bends, LF waves round corners similar to laminar flow, but higher frequencies react to bends similar to rays of light, reflecting at the same angle of incidence as they arrive.

To get a horn bend to work properly (result in equal path length) requires a parabolic or hyperbolic curved reflector, the parabola or hyperbola needs to be correct for the particular entrance and exit angle.

Because of the potential for large path length differences, placing bends in the latter part of the horn is more problematic than the towards the throat.

Good re-entrant (old school name for folded) horns may use multiple near 180 degree bends, but because of careful attention to the transition reflectors can have much smoother response than the Show Horn.

The two examples below have two near 180 degree bends.

Getting folded mid/HF horns right is difficult, and the higher in frequency the more damage a simple 45 degree reflector will impart.

Art

Attachments

Last edited:

Art and Patrick, once again thanks for your inputs!

This may or may not sound strange, but I had thought about the notion of using the re-entrant design like in the usual PA-style 'megaphones'.

I had also wondered about where to bend the horn too, and just in terms of 'feel', it seemed more likely that bending the horn at the throat end would be easier - given the shape, and rate of expansion.

It might be impossible, but I did briefly wonder about scouting for some of those horn shapes on eBay, and applying the driver I have to it. Then again, I'm sure that most of those (at least from what I've seen) are designed for compression drivers, and so being able to adapt them is unlikely.

I didn't really intend to cause a large amount of debate...but I made the drawing yesterday as a starting point, something to get wrong, and eventually correct 🙂

Thanks for the reading material!

This may or may not sound strange, but I had thought about the notion of using the re-entrant design like in the usual PA-style 'megaphones'.

I had also wondered about where to bend the horn too, and just in terms of 'feel', it seemed more likely that bending the horn at the throat end would be easier - given the shape, and rate of expansion.

It might be impossible, but I did briefly wonder about scouting for some of those horn shapes on eBay, and applying the driver I have to it. Then again, I'm sure that most of those (at least from what I've seen) are designed for compression drivers, and so being able to adapt them is unlikely.

I didn't really intend to cause a large amount of debate...but I made the drawing yesterday as a starting point, something to get wrong, and eventually correct 🙂

Thanks for the reading material!

A loudspeaker with a compression chamber is a compression driver.It might be impossible, but I did briefly wonder about scouting for some of those horn shapes on eBay, and applying the driver I have to it. Then again, I'm sure that most of those (at least from what I've seen) are designed for compression drivers, and so being able to adapt them is unlikely.

There are many old thread on compression drivers with no phase plug.

Proper phase plugs can make the upper response of loudspeakers more usable as compression drivers.

It is very possible to get a decade (100-1000, 250-2500) of smooth response from a cone driven horn.

Curt Graber getting 250-8000 Hz relatively smooth response with a pair of his compression drivers at 150 dBC output from a 14.9" x 20.5" x 18.2" 20 pound unit is phenomenal.

Art

Jean-Michel LeCleach studied the Western Electric big snail horns a lot. They are the champions of extended range. He pointed out that the initial expansion in the first sections of the horns are mostly in one plane. The other plane stays narrow. When going around a corner, the pathway differences stay small between outer and inner wall, so there is less trouble for treble (pun intended!). Also, the bends are quite wide (these are seriously big horns!), which also reduces problems.

I think it probably doesn't meet your design constraints, but it shows the best approach to wide range and folding in the midrange. Maybe gives some direction for thought.

An externally hosted image should be here but it was not working when we last tested it.

I think it probably doesn't meet your design constraints, but it shows the best approach to wide range and folding in the midrange. Maybe gives some direction for thought.

I can't figure out why you don't just build a straight horn with a 12 or 15 to cover your original 200 to 1000 cycle range and enjoy it. Why fold the horn when you don't have to to? a straight horn going to give you the best performance 😱

I agree that a straight horn has better midrange performance than most folded, but the OP has already purchased Alpha 8", and is on a budget.I can't figure out why you don't just build a straight horn with a 12 or 15 to cover your original 200 to 1000 cycle range and enjoy it. Why fold the horn when you don't have to to? a straight horn going to give you the best performance 😱

don't know about that 'flipping' polar stuff 😀

ehh, when polar response 'flips' around, what listening distance would we be talking about ?

Would anybody like to comment on pattern flip? How bad is this? Just as bad as the "horrible" directivity issues a 7 inch woofer + 1 inch dome speaker suffers? or really, really bad? Our hearing is not that sensitive vertical.

Last edited:

That's Ok, in terms of bending the horn. I wanted to try it out to see how the curves looked, and the general opinion on them. While some people have been very successful with bending the horns, it does look like there's a straight horn in my midst 🙂

One of the designs I have came to just under 25" in length, so it'll be close to 30" overall.

I don't know how well this will appear, but here's the 'code' for that design:

I think I'd posted another one after that which might have been shorter. It's interesting to see how the low frequency response of a Tractrix curve rolls off in a pattern; from some fiddling I'd found that half the distance would give a similar value, even though the bandwidth response was not as smooth.

One of the designs I have came to just under 25" in length, so it'll be close to 30" overall.

I don't know how well this will appear, but here's the 'code' for that design:

Code:

Length (cm) Area (sq cm) Radius (cm) Angle (deg) Side Len (cm) Height/2 (cm) Top Len (cm) Width/2 (cm) Width Flare

0.000000 105.000000 5.781223 7.580000 0.000000 5.126953 0.000000 5.120000 Uni

10.000000 166.622171 7.282684 9.571222 10.209830 6.457930 10.209465 6.450293 Uni

20.000000 265.233734 9.188390 12.109656 20.435712 8.147111 20.435155 8.138890 Uni

30.000000 424.383038 11.622621 15.388351 30.698759 10.304585 30.698207 10.295976 Uni

40.000000 684.991542 14.766163 19.702200 41.095306 13.090505 41.094743 13.081840 Uni

50.000000 1123.113483 18.907621 25.574635 51.756677 16.760536 51.755938 16.752351 Uni

60.000000 1899.986837 24.592369 34.157998 62.964915 21.797850 62.963580 21.790989 Uni

61.710000 2090.000000 25.792783 36.080000 64.978999 22.861518 64.977483 22.855000 UniI think I'd posted another one after that which might have been shorter. It's interesting to see how the low frequency response of a Tractrix curve rolls off in a pattern; from some fiddling I'd found that half the distance would give a similar value, even though the bandwidth response was not as smooth.

So here was the last horn I'd put into HornResp. The following picture shows the same design, but exported in three different ways:

Black line = 2 divisions (8 panels in total)

Red line = 6 divisions, one per 10cm (24 panels in total)

Green line = 4 divisions, one per 15cm (16 panels in total)

I think it's really clever that HornResp adjusts the panel dimensions based on the number of divisions/increments we specify 🙂

Given that HornResp can do that, would I lose anything if I made the profile based on two panels per side, or is it still advisable to be more detailed?

Black line = 2 divisions (8 panels in total)

Red line = 6 divisions, one per 10cm (24 panels in total)

Green line = 4 divisions, one per 15cm (16 panels in total)

I think it's really clever that HornResp adjusts the panel dimensions based on the number of divisions/increments we specify 🙂

Given that HornResp can do that, would I lose anything if I made the profile based on two panels per side, or is it still advisable to be more detailed?

Last edited:

Maybe it is just me and have been looking at a computer all day, but I really don't see too much difference in two of the 3 lines, and one set of the 3 is for all purposes the same.

If it were me, I would build the one that is the simplest to do. And considering the size of the waves...you don't need millimeter precision IMO.

If it were me, I would build the one that is the simplest to do. And considering the size of the waves...you don't need millimeter precision IMO.

Maybe it is just me and have been looking at a computer all day, but I really don't see too much difference in two of the 3 lines, and one set of the 3 is for all purposes the same.

If it were me, I would build the one that is the simplest to do. And considering the size of the waves...you don't need millimeter precision IMO.

Well, in that case it would be the black line then! 🙂

The other option is to get some hardboard from Lowes (at the moment it's about $9 per 4'x8' sheet, at a 1/8" thickness), and doing the following:

1. Cut out the HornResp profile

2. Dampen the board (by 'painting' water on with a brush)

3. Clamp it to a pre-made jig, and wait for it to dry and harden

I suppose it would be fairly easy to put together a jig that allows me to clamp all of the panels to it for bending, but also to glue the edges together. It might be easier to construct that way, particularly with Gorilla Glue, as it cures on contact with water - so the glue would hold the shape as well, if it cured before the board itself dried.

But, with straight boards, two pieces per side would definitely be the easiest!

although qts is moderate, a Commonwealth 12 might make a decent horn driver (?)

In a truncated horn, one could do a lot worse! If it were a 15", its specs would make it a drop-in replacement for the original Altec 803 right down to the minimal Xmax.

GM

would I lose anything if I made the profile based on two panels per side, or is it still advisable to be more detailed?

Well, the single break expos I did to approximate readily available Altec truncated horns to compare to measured/sounded close enough for their owners, so never bothered to go to all the extra work of making/measuring the customs I did, just calculated the theoretical boundary loading to find its effective acoustic length, mouth area, then with the throat area I calculated the break point. In general, this put it in the 55-65% of its physical length from the throat, so somewhat closer than yours.

GM

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Multi-Way

- Midbass horn

(figure it like one big compression driver)

(figure it like one big compression driver)