It's certainly easier to use cardboard!

After this I'm somewhat tempted to make a mold, and use Patrick Bateman's 'hemp rope and Gorilla Glue' method, or Inlow's lazy susan clay mold procedure.

you can use your cardboard horn and 'continue' with papier mache method, and just use plain simple old fashioned water based wall paper glue

no need to complicate it

or if you want it real fancy, use your cardboard horn, and 'finish' it with veneer and a few stripes of plywood

or even a combination of both

but sure, always a few tricky details to handle

and btw, also possible to reinforce the cardboard horn with glassfiber, but it is nasty toxic stuff

Most sane cabinet makers use screws (or nails) and clamps rather than duct tape while the glue sets. Still can be a challenge, always do a dry fit first..Still, is duct taping the pieces together while the glue sets the only sane option?

you can sew it together with steel thread

and then use fiber glass strips on all joins

one side first

then remove steel thread

and fiber glass stipes on other side of joins

you can build race boats that way 😀

and then use fiber glass strips on all joins

one side first

then remove steel thread

and fiber glass stipes on other side of joins

you can build race boats that way 😀

Tony Seaford used dots of hot melt glue to hold pieces together while white glue I nearby areas dried.

My last horns I came up with a way to attach with wood screws and pocket holes so all could be dry fit and seams glued separately. I'm still working on a writeup with photos to show that. Hopefully I'll have it posted this week sometime. Sorry it's taken so long (over a year, now!).

____

BTW, one reason the floor and ceiling reflections don't seem to vary audibly much (between recangular and round symmetric horns) is that the lower pattern control frequency in the vertical, when using a short, wide, rectangular horn will be much higher than for the horizontal. Narrower angles need longer and larger dimensions for the same pattern control cutoff. So neither horn does much to avoid ceiling or floor reflection at sub-tweeter frequencies.

My last horns I came up with a way to attach with wood screws and pocket holes so all could be dry fit and seams glued separately. I'm still working on a writeup with photos to show that. Hopefully I'll have it posted this week sometime. Sorry it's taken so long (over a year, now!).

____

BTW, one reason the floor and ceiling reflections don't seem to vary audibly much (between recangular and round symmetric horns) is that the lower pattern control frequency in the vertical, when using a short, wide, rectangular horn will be much higher than for the horizontal. Narrower angles need longer and larger dimensions for the same pattern control cutoff. So neither horn does much to avoid ceiling or floor reflection at sub-tweeter frequencies.

Foam Core is really easy to use for prototyping horns. Tacks in place with hot melt glue. If you like it you can add layer of stiff shellac or cover back side with fabric and PVA glue.

The Synergy horn writeup mentioned in Post 544 is finally finished, and can be found at http://libinst.com/SynergyCalc/Synergy%20Calc%20V5.pdf for anyone interested.

Bill

My last horns I came up with a way to attach with wood screws and pocket holes so all could be dry fit and seams glued separately. I'm still working on a writeup with photos to show that. Hopefully I'll have it posted this week sometime. Sorry it's taken so long (over a year, now!).

Bill

Member

Joined 2003

I agree Paul! Thanks for the fantastic documentation Bill! I think my next project will be to save up, buy the right drivers, and follow a specific design such as yours 😉

Meanwhile, back in insanityville, I've done a little bit of experimenting with Patrick Bateman's method of Gorilla Glue and Jute Twine. I'm making a mold for the horns, and I'll give it a go once it is complete.

For now, the mold is going to be made of cardboard, and using the data that HornResp outputs as a circular horn, gluing a number of 'fins' (as opposed to petals) to a base board.

The best way to think of it is to imagine spokes on a bicycle wheel. I've started out with 8 copies of the profile (the same as 16 petals), but I might add more if it doesn't appear close enough to a circular shape.

As mentioned before, I have a lot of cardboard that I've managed to pilfer from work, so it's effectively a limitless resource at the moment 🙂

My next challenge is to skin the mold with something that Gorilla Glue won't stick to. I'll have to go through Patrick's posts again, but from what I've read online it doesn't really like cling film (saran wrap?). The hard bit, once I've found a good 'skin' is getting it to be as smooth as possible (without wrinkles), so that the end result doesn't require much in the way of 'patching'...

Meanwhile, back in insanityville, I've done a little bit of experimenting with Patrick Bateman's method of Gorilla Glue and Jute Twine. I'm making a mold for the horns, and I'll give it a go once it is complete.

For now, the mold is going to be made of cardboard, and using the data that HornResp outputs as a circular horn, gluing a number of 'fins' (as opposed to petals) to a base board.

The best way to think of it is to imagine spokes on a bicycle wheel. I've started out with 8 copies of the profile (the same as 16 petals), but I might add more if it doesn't appear close enough to a circular shape.

As mentioned before, I have a lot of cardboard that I've managed to pilfer from work, so it's effectively a limitless resource at the moment 🙂

My next challenge is to skin the mold with something that Gorilla Glue won't stick to. I'll have to go through Patrick's posts again, but from what I've read online it doesn't really like cling film (saran wrap?). The hard bit, once I've found a good 'skin' is getting it to be as smooth as possible (without wrinkles), so that the end result doesn't require much in the way of 'patching'...

I've been wondering how burlap would do in place of the jute twine. (I believe it is also made of jute or hemp.) I was thinking it might be kind of like woven fiberglass, but without the irritating glass fibers.

I've been wondering the same...I suppose the only thing you'd have to consider is how to impregnate the water and glue into it.

Possibly, we could use a hard roller (e.g. the ones that are used to glue down the edges of wallpaper) to force it into the burlap. It certainly would be less time consuming to apply.

Possibly, we could use a hard roller (e.g. the ones that are used to glue down the edges of wallpaper) to force it into the burlap. It certainly would be less time consuming to apply.

Back in the early days of DIY repairing of Corvettes, Devins, etc. and fiberglassing custom stuff, burlap was the poor man's glass mat and bondo the binder/sealer.

GM

GM

The Synergy horn writeup mentioned in Post 544 is finally finished, and can be found at http://libinst.com/SynergyCalc/Synergy%20Calc%20V5.pdf for anyone interested.

Bill

Thank you for putting this together and sharing your expertise! There are some Peerless TC6WD00-04 2 in drivers on sale at PE for $6.87 ea. Do you think these could work as the mids? I am thinking of doing an active qaud-amped system with dual miniDSP 2x4 in vertical integration mode for 4 channels each speaker.

I'm just waiting for the kids to calm down, and then I'll get started with assembling the mold. Once that's done, it'll be a quick job of actually getting the cones made. I'll post some updates soon...hopefully!

As a tangent to this, does anyone know anything about the Nippon NDX6740? They popped up when I was randomly looking at compression drivers (including the Audiopipe ACPD-775), but I've not been able to find any documented experience with them.

Their frequency range is 250-6000Hz, but there's no mention of distortion levels or recommended crossover frequencies. It's a 140W driver, but for home audio I suppose I'd only be using a few watts to power them...

As a tangent to this, does anyone know anything about the Nippon NDX6740? They popped up when I was randomly looking at compression drivers (including the Audiopipe ACPD-775), but I've not been able to find any documented experience with them.

Their frequency range is 250-6000Hz, but there's no mention of distortion levels or recommended crossover frequencies. It's a 140W driver, but for home audio I suppose I'd only be using a few watts to power them...

Sorry about the typo, it was the Audiopipe APCD-775.

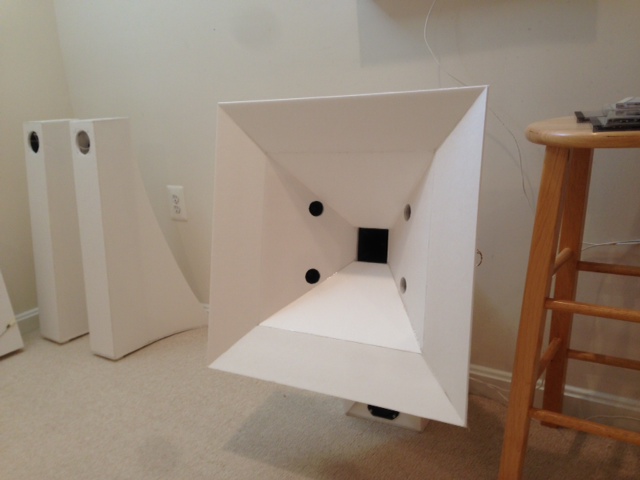

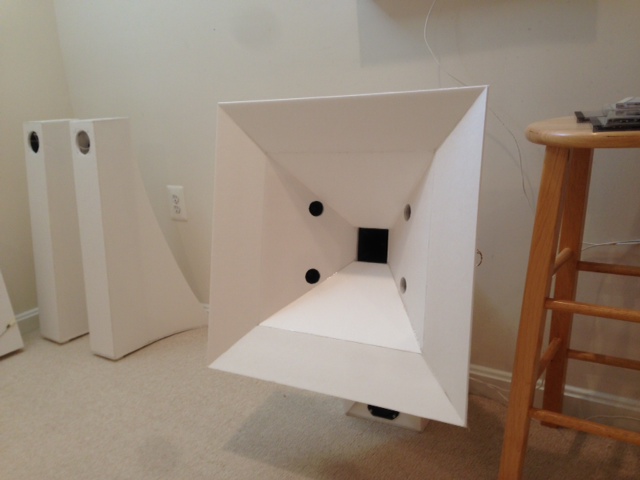

I did manage to get the 'mold' together, although it needs to be skinned:

Now that all of the 'smelly work' has been done, I can now tinker with it during the day, so I hope to make more progress tomorrow.

I did manage to get the 'mold' together, although it needs to be skinned:

Now that all of the 'smelly work' has been done, I can now tinker with it during the day, so I hope to make more progress tomorrow.

After some medical scares, I came back to my mold this evening.

It's terrible! Cling film won't stick to cardboard, so I'll have to probably skin it with something like duct tape, and then put a layer of the wrap on top of that.

I'm finding John Inlow's method of creating a mold more and more enticing:

Inlow Sound DIY Paper Horn

For the clay, I'm tempted to make some home-made clay, as my wife has found:

Play Clay

I think the main reason that I'm taking my time on getting the mold technique right is that I want to try this method of construction for that other than speakers. Gorilla glue and jute/hemp/burlap certainly seems like a strong material that is worthy of note, so I'd also like to see if I can use it for my other construction passion which is making Bass Guitars (seeing as I can never afford the ones I would buy!).

It's terrible! Cling film won't stick to cardboard, so I'll have to probably skin it with something like duct tape, and then put a layer of the wrap on top of that.

I'm finding John Inlow's method of creating a mold more and more enticing:

Inlow Sound DIY Paper Horn

For the clay, I'm tempted to make some home-made clay, as my wife has found:

Play Clay

I think the main reason that I'm taking my time on getting the mold technique right is that I want to try this method of construction for that other than speakers. Gorilla glue and jute/hemp/burlap certainly seems like a strong material that is worthy of note, so I'd also like to see if I can use it for my other construction passion which is making Bass Guitars (seeing as I can never afford the ones I would buy!).

I see you are back to beamy horn design 🙂.S

I did manage to get the 'mold' together, although it needs to be skinned:

As far as alternative materials for upright bass construction, Kay used an innovative, cheap material in their student models.

That material was (and is) called plywood 😉.

I like what PB is doing conceptually, but I would not be copying the building methods.

Depending on how big that mold is, I would get some big panyhose and stretch it over the mold and lay fiberglass on top of that...but first I would skin the mold with aluminum foil, then hit the foil with some PAM for added insurance. But then again if you haven't worked with fiberglass much, you might wouldn't want to tackle that for a first project.

But that's just me...I spent half my life building custom/competition car audio systems and been fiberglassing for 23 years now.

Depending on how big that mold is, I would get some big panyhose and stretch it over the mold and lay fiberglass on top of that...but first I would skin the mold with aluminum foil, then hit the foil with some PAM for added insurance. But then again if you haven't worked with fiberglass much, you might wouldn't want to tackle that for a first project.

But that's just me...I spent half my life building custom/competition car audio systems and been fiberglassing for 23 years now.

Or...this would probably work better for you.

I would skin that whole mold with the cardboard. I would make the 20 or so pedals with cardboard. Then skin that with aluminum foil- just spray glue it down. Then I would coat the foil with PAM, WD40, spray wax or something, then I could fiberglass it. Just make sure the surface of the mold is pretty much since the part you are pulling from it will also have those defects in them once pulled from the mold.

I would skin that whole mold with the cardboard. I would make the 20 or so pedals with cardboard. Then skin that with aluminum foil- just spray glue it down. Then I would coat the foil with PAM, WD40, spray wax or something, then I could fiberglass it. Just make sure the surface of the mold is pretty much since the part you are pulling from it will also have those defects in them once pulled from the mold.

I see you are back to beamy horn design 🙂.

As far as alternative materials for upright bass construction, Kay used an innovative, cheap material in their student models.

That material was (and is) called plywood 😉.

Thanks for pointing that out...I didn't realise! Where am I going wrong? I apologise if you've answered that question in this thread before, and the horn's shape definitely looks 'incomplete' to me as well.

I usually make Electric Bass Guitars, and in recent years I've seen the carbon fibre designs that are lightweight and well-balanced, so I wanted to try something out.

I like what PB is doing conceptually, but I would not be copying the building methods.

Depending on how big that mold is, I would get some big panyhose and stretch it over the mold and lay fiberglass on top of that...but first I would skin the mold with aluminum foil, then hit the foil with some PAM for added insurance. But then again if you haven't worked with fiberglass much, you might wouldn't want to tackle that for a first project.

But that's just me...I spent half my life building custom/competition car audio systems and been fiberglassing for 23 years now.

Or...this would probably work better for you.

I would skin that whole mold with the cardboard. I would make the 20 or so pedals with cardboard. Then skin that with aluminum foil- just spray glue it down. Then I would coat the foil with PAM, WD40, spray wax or something, then I could fiberglass it. Just make sure the surface of the mold is pretty much since the part you are pulling from it will also have those defects in them once pulled from the mold.

Thanks for your input winslow! Your experience definitely has shed light onto where I was going wrong. If I have any time this evening, I'll make another attempt based on your suggestions!

I have answered many of your questions multiple times, I have not kept a running record 😉. You might search my responses regarding horn dispersion starting at #164.Thanks for pointing that out...I didn't realise! Where am I going wrong? I apologise if you've answered that question in this thread before, and the horn's shape definitely looks 'incomplete' to me as well.

I usually make Electric Bass Guitars, and in recent years I've seen the carbon fibre designs that are lightweight and well-balanced, so I wanted to try something out.

A semi-hollow carbon fiber neck can make for a very light, well-balanced, very expensive electric bass. Making the mold is the big expense, a mold is a relatively low cost when amortized over hundreds of units, but the same amount of work is needed for a single unit.

Last time I built a mold for a mid woofer it took around six times the time that it would take to build the acoustically equivalent horn out of plywood. The fiberglass lay up of each horn then took a bit longer for each than it would take to build the acoustically equivalent plywood horn. Later, after the damping material used on the horn started to de-laminate, spent quite a bit of $$ having expandable foam blown in to the cabinet shells to tighten things up.

Ended up building and selling eight copies of the horn before finally throwing it away a decade later 🙁.

Of course, you have already experienced some of the difficulties of making a decent mold

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Multi-Way

- Midbass horn