according to what have been said previously you might get real velocity problems with the small port holes you need to cross above 1khz

especially if the mids also plays low frequencies

and it might roll off too early if you make the port/pass holes bigger

and the BMS coax compression driver is very expencive 😱

especially if the mids also plays low frequencies

and it might roll off too early if you make the port/pass holes bigger

and the BMS coax compression driver is very expencive 😱

It can be done with separate horns (DSP optional). On one hand, freedom of choice while keeping a clean structure for treble. On the other hand fitting them around each other in the room becomes a restriction. It can be done and yes, sound good.

Try this thread as an example of taking horns to a certain natural limitation. I use only three to cover all but the lower bass. At this point though (if it's a workable foundation) I feel you begin to split hairs.

Try this thread as an example of taking horns to a certain natural limitation. I use only three to cover all but the lower bass. At this point though (if it's a workable foundation) I feel you begin to split hairs.

It can be done with separate horns

ofcourse, and especially if you design mid horn and tweeter so they match each other

this one was just a silly experiment, and could easily be improved, and simpler

but basicly its a big tweeter horn with small mid waveguide

it only needs a big 18" woofer in vented BR 😀

Attachments

Edit: Didn't notice your latest post regarding unity. I went through this dillema myself and came out going for separates. (I'm not saying anything one way or the other) I had a unity design down on paper, optimised with Akabak.. took me months.

First it's circles, then you'll notice irregular spirals. (I'll leave it at that..Enjoy 😉 )

First it's circles, then you'll notice irregular spirals. (I'll leave it at that..Enjoy 😉 )

Just for interests sake I moved on from the corner mounted design which I last posted about (although changes are getting more subtle). Late last year I built a better elliptical midrange horn. Then I changed to a round OS tweeter horn. Currently I'm building a new midbass and midrange (non elliptical) set of horns integrated across the floor and later I'll need to build another tweeter to match them.

Here's how it was last year. I'll see if I can post some updates tonight.a photo ?

Attachments

Thanks AllenB - that looks like an interesting project! I look forward to seeing the updates!

I'm bearing what you have in mind. In hindsight, I wish I'd found out about some of these threads before buying the drivers I have (though some designs weren't communicated until very recently), meaning I would have replicated one of those 'tried and tested' configurations. Alas, I'm not in that situation, so I'll just have to hack away for a bit 🙂

tinitus - the BMS co-axial speaker is definitely on my wish list 🙂 Nice 'mid tweeter'!

So I've been fiddling around with port sizes for the mid driver in a spreadsheet, and came up with this:

That seems rather large, but is that OK?

I might have some time to place the drivers on the 'mock-up' tomorrow.

I'm bearing what you have in mind. In hindsight, I wish I'd found out about some of these threads before buying the drivers I have (though some designs weren't communicated until very recently), meaning I would have replicated one of those 'tried and tested' configurations. Alas, I'm not in that situation, so I'll just have to hack away for a bit 🙂

tinitus - the BMS co-axial speaker is definitely on my wish list 🙂 Nice 'mid tweeter'!

So I've been fiddling around with port sizes for the mid driver in a spreadsheet, and came up with this:

Code:

Desired frequency 1000 Hz

Speed of sound 1130 feet/second pi 3.1415926536

Wavelength/Circumference 1.13 feet

Circle diameter 0.3596901714 feet 10.9633564239 cm

Radius 0.1798450857 feet 5.4816782119 cmThat seems rather large, but is that OK?

I might have some time to place the drivers on the 'mock-up' tomorrow.

Last edited:

tinitus - the BMS co-axial speaker is definitely on my wish list 🙂 Nice 'mid tweeter'!

being a coax it has its own problem

and might even be very over rated at times

but a Synergy could be the optimal home for it 😉

being a coax it has its own problem

and might even be very over rated at times

but a Synergy could be the optimal home for it 😉

It seems a little strange to me...maybe I'm thinking about it incorrectly, but wouldn't a coaxial driver in a horn be just that, considering that the drivers are combined?

Then again, if it's being used with larger woofers for lower frequencies it still makes sense.

Well, I'll try a 4.3162820568" port for the Alpha 8a in a bit. I didn't get anywhere near as much sleep, and my phone died, so it's time for 'zombie chores'...

Last edited:

🙂

Fortunately I have a metric ruler, so it made a bit more sense in centimetres 🙂

Well, I've finally found 15 minutes to cut the hole and mount the Alpha 8. This is all I have so far:

I've got to make a mounting 'plate' for the compression driver to attach to the horn...which will probably take a while considering this last step! 🙂

Fortunately I have a metric ruler, so it made a bit more sense in centimetres 🙂

Well, I've finally found 15 minutes to cut the hole and mount the Alpha 8. This is all I have so far:

I've got to make a mounting 'plate' for the compression driver to attach to the horn...which will probably take a while considering this last step! 🙂

Off the cuff response is that hole for the mid is waaaaay too big and in the wrong spot for a Synergy/Unity horn.

I thought so too, but I didn't really know what I needed to do correctly (I was working solely from the upper cutoff frequency), so I thought I'd start by getting it wrong 😉

Fortunately I still have the piece I'd cut out, so that can be edited, and replaced.

Edit: Doh! I suddenly remembered that HornResp can be used to model the horn:

So that's what the hole needs to be. I'll fix it tomorrow 🙂

Fortunately I still have the piece I'd cut out, so that can be edited, and replaced.

Edit: Doh! I suddenly remembered that HornResp can be used to model the horn:

- Ap1 = 20.20 square centimetres

- Lpt = 1 centimetre

So that's what the hole needs to be. I'll fix it tomorrow 🙂

Last edited:

Then again, if it's being used with larger woofers for lower frequencies it still makes sense.

I was thinking of a small coax, with only midwoofers 'synergy-mounted'

but I'm not sure it really would be a synergy

but missing that 96db midrange coax

seems like all the small coaxes are still designed like woofers, and goes down on sensitivity

I tried the cardboard approach in my Hobohorn, and it worked on mids above 600Hz, although wood turned out better. For the midbass horn (130-600Hz) the difference between paper and wood was too large. The paper midbass horn told me nothing of what the wooden version eventually sounded like.

I would strengthen the cardboard with paint or plaster to have a more solid midbass horn.

I would strengthen the cardboard with paint or plaster to have a more solid midbass horn.

Last edited:

Synergy holes are fairly close to the source which makes them potentially a problem. You can make them small with the right driver. Hiding them in the corners of a square horn can help (although the throat won't be matched to a round driver) . You could also consider Tom Danleys suggested port shape.

The goal would be to put the ports far enough from the compression driver that the waves within its band can at least begin to launch before reaching the ports. The mids would want to be such a distance from the tweeter throat that it creates a null a little above the crossover.

In the case of my spherical OS there were imperfections in the profile as I'd built it by hand, initially up to +/- 5mm toward the end (less toward the throat). A few times I spent a half an hour sanding the ridges and filling the dips, and each time the sound became more clean. Even polishing with finer paper imparted a smoothness to the sound.

The further the problem was from the driver, the lower the frequencies that were involved and the less obvious the problem was. Similarly, I couldn't confidently notice a change regarding the floor and ceiling reflections when changing from ellipsoidal OS.

The goal would be to put the ports far enough from the compression driver that the waves within its band can at least begin to launch before reaching the ports. The mids would want to be such a distance from the tweeter throat that it creates a null a little above the crossover.

In the case of my spherical OS there were imperfections in the profile as I'd built it by hand, initially up to +/- 5mm toward the end (less toward the throat). A few times I spent a half an hour sanding the ridges and filling the dips, and each time the sound became more clean. Even polishing with finer paper imparted a smoothness to the sound.

The further the problem was from the driver, the lower the frequencies that were involved and the less obvious the problem was. Similarly, I couldn't confidently notice a change regarding the floor and ceiling reflections when changing from ellipsoidal OS.

Yes you did!I thought so too, but I didn't really know what I needed to do correctly (I was working solely from the upper cutoff frequency), so I thought I'd start by getting it wrong 😉

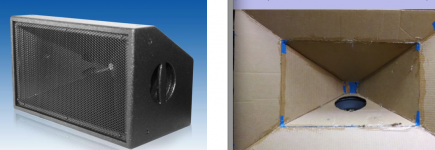

I'll re-post the correct way to do it again (hint- it is the one on the left) 🙂.

To get a sense of the size of the holes for the 8", note that there are two visible mounting screws on the mouth side just before the second part off the horn.

Note that the two frankfurter shaped exit holes are in a low pressure part of the horn, where they will have the least effect on the HF response.

Art

Attachments

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Multi-Way

- Midbass horn