Hey, Andy! If you fancy a tour of the earliest of indirectly-heated triodes to compare with the 27, here's some idle suggestions (no meshies I'm afraid):

the Marconi KL1 was one of the very first (1927) -

Link: KL1 advert OSRAM

Or, maybe even better - the first truly reliable indirectly heated. This one uses E. Yeoman Robinson's slip-coated heater assembly for higher gm.

It also appeared in year 1927.- the Met-Vick - COSMOS AC/R, with 4mA/V:

Link: COSMOS AC/R

There are little or no data sheets for COSMOS valves on the web, but I can begin fixing that with uploads from a Septmber 1928 data book I happily acquired for a price of a half-pint.

The refererence to "Short Path" is an indication of how close the grid approached the cathode sleeve, which was apperently only 1mm diameter.

The 4mA/V that resulted was notable for the tim, and a while afterward.

the Marconi KL1 was one of the very first (1927) -

Link: KL1 advert OSRAM

Or, maybe even better - the first truly reliable indirectly heated. This one uses E. Yeoman Robinson's slip-coated heater assembly for higher gm.

It also appeared in year 1927.- the Met-Vick - COSMOS AC/R, with 4mA/V:

Link: COSMOS AC/R

There are little or no data sheets for COSMOS valves on the web, but I can begin fixing that with uploads from a Septmber 1928 data book I happily acquired for a price of a half-pint.

The refererence to "Short Path" is an indication of how close the grid approached the cathode sleeve, which was apperently only 1mm diameter.

The 4mA/V that resulted was notable for the tim, and a while afterward.

Last edited:

Hi Andy,

I am not moderating this thread.

I really don't want to lose the excellent content so far. We can play nice.

I find the history of tube development fascinating. Well worth sharing, I hope we can stay on that path.

I am not moderating this thread.

I really don't want to lose the excellent content so far. We can play nice.

I find the history of tube development fascinating. Well worth sharing, I hope we can stay on that path.

used it because of this very thread.Folks you have an ignore button that brings peace and quiet to this wonderful forum when needed....

I ran into this putting a small stack of books on top of a bookshelf speaker, it did sound better. I opened the speaker up and installed butyl rubber dampening sheets, which in turn added a lot of weight to the speaker and heard this same improvement. This has me wondering it it was simply the weight doing this? Which then relates to this same dampening happening in a mesh vs solid plate tube.Somehow I missed the "Dunker Factor" term, thank you Andy, for bringing it up.

Yes, I find mass of the device, including the speaker, to be highly audible

@stephe Gilbert Briggs found out the same when he designed his Wharfedale Sand Filled Baffle 3 speakers.

http://www.troelsgravesen.dk/download/SFB-review.pdf

http://www.troelsgravesen.dk/download/SFB-review.pdf

Hopefully the elements in a tube are not moving. Not in a significant way.

For speaker boxes, you are probably both stiffening and damping those panels (bottom and top).

For speaker boxes, you are probably both stiffening and damping those panels (bottom and top).

Doesn't work. Once you strip out the micro tonalities in a PP amp they're gone forever. Can't be retrieved. They're gone, extinct, kaput, expired, pushing up the daisies. They are no more, they've vamoosed......

On the subject of "truth", you might like this quote from Ralph Waldo Emerson

"The louder he talked of his honor, the faster we counted our spoons...."

A tube amplifier ends its circuit with a reactive device, the OPT, driven by a modulated high voltage, that gets stepped down to concentrated current to drive the speaker. A SS amplifier ends its circuit with a non-reactive transistor, modulating high current to drive the speaker directly. Most amplifier testers put an 8 ohm dummy load on the OPT and think they've characterized/measured that amp. How can that be? By castrating the interaction between the OPT secondary and a complex voice coil, crossover, ported box which is all over the place impedance wise, back EMF, all reacting with the OPT secondary, which is then reflected to the primary, to react further with the tube and PSU. This is the main difference between SS and tubes, the highly reactive and unpredictable and complex OPT secondary reacting with a speaker. Add to that there are thousands of speakers, all different. How do you measure that and tie those numbers back to how it sounds? Using dummy load I can make a .17 cent LM386 show a flat response, just as well as a $5,000 tube amp with a dummy load. Whats the point of the freq. response test then? Tube amp testing needs to be done electrically at the binding posts with speaker attached, as well as acoustically with a microphone.

''.....Tube amp testing needs to be done electrically at the binding posts with speaker attached, as well as acoustically with a microphone....''

Not necessary. Not realistic. Not practical. That would leave you to modify an amp with a flat FR to accomodate the speaker to get a flat FR. Are you going to do that for all your speakers you may collect? Fantasy. Just get decent speakers and perhaps an EQ if your ears are so inclined.

Not necessary. Not realistic. Not practical. That would leave you to modify an amp with a flat FR to accomodate the speaker to get a flat FR. Are you going to do that for all your speakers you may collect? Fantasy. Just get decent speakers and perhaps an EQ if your ears are so inclined.

Bringing speaker boxes into the conversation makes the SET vs PP vs SS much less of an issue (by the way, I use all 3)…then there is the room. So much for the “straight wire with gain” complete system.Hopefully the elements in a tube are not moving. Not in a significant way.

For speaker boxes, you are probably both stiffening and damping those panels (bottom and top).

Agreed RPMac, bringing speakers into it has no bearing. But, as stephe was drawing a parallel to tube elements I merely offered an idea on the speaker angle.

Hi Windcrest77,

Please read the thread. A complete explanation as to why we measure things the way we do has been detailed. this is an industry and does follow scientific method for experiments in general. 20to20 has it exactly right.

Hi Windcrest77,

Please read the thread. A complete explanation as to why we measure things the way we do has been detailed. this is an industry and does follow scientific method for experiments in general. 20to20 has it exactly right.

I ran into this putting a small stack of books on top of a bookshelf speaker, it did sound better. I opened the speaker up and installed butyl rubber dampening sheets, which in turn added a lot of weight to the speaker and heard this same improvement. This has me wondering it it was simply the weight doing this? Which then relates to this same dampening happening in a mesh vs solid plate tube.

Both mass and dampening effect of butyl rubber.

A mesh has more dampening of a resonance compared to a flat surface. For some reason, I find that the tweaking with materials added to speakers works the same way as towards amplifiers and sources, pretty much everything in the chain. From pure logic, material tweaking cannot have an electric influence on the audio signals, so it should be purely acoustical. Although sser2 mentioned microphonics in some components, from such point of view, materials would have an influence on the electronic signals.

They do, unfortunately:Hopefully the elements in a tube are not moving. Not in a significant way.

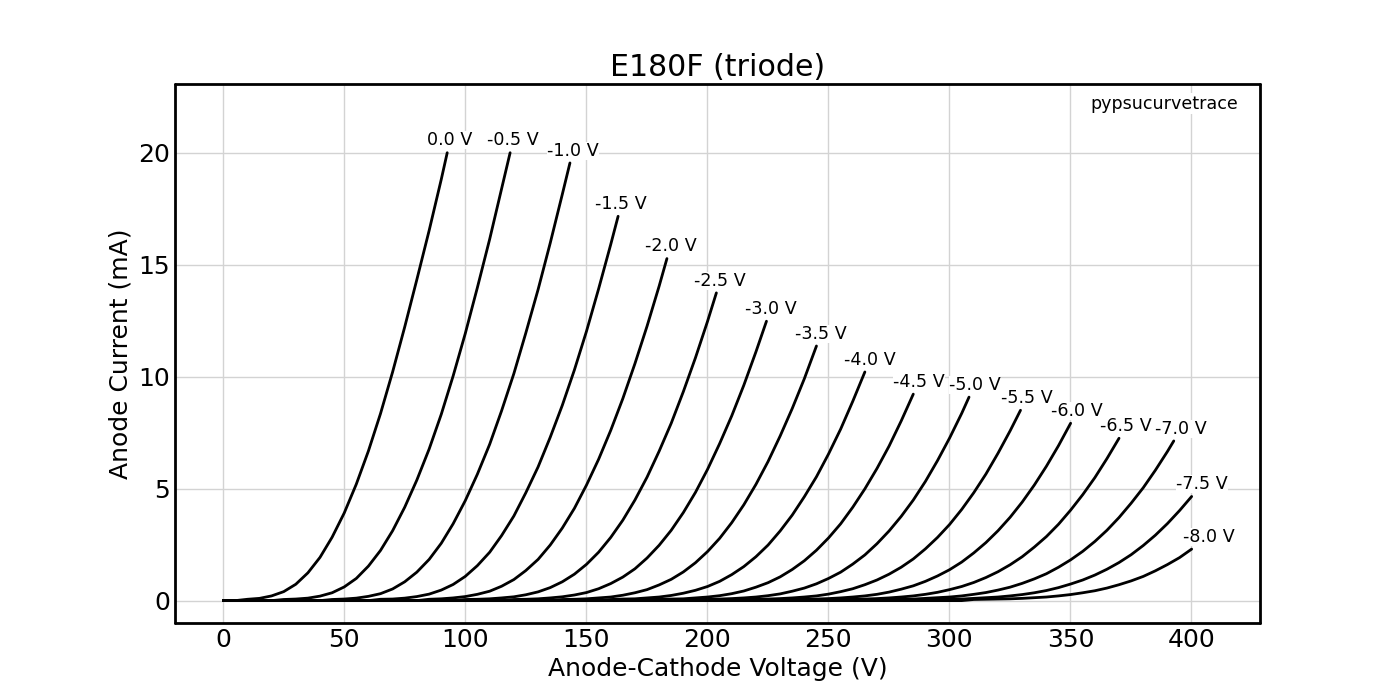

The E180F tubes arrived, so I could take closer look.

Here are curves in triode mode:

Looks about right for what is needed in the OSDEHA, maybe with a tiny little bit of compression at high voltage.

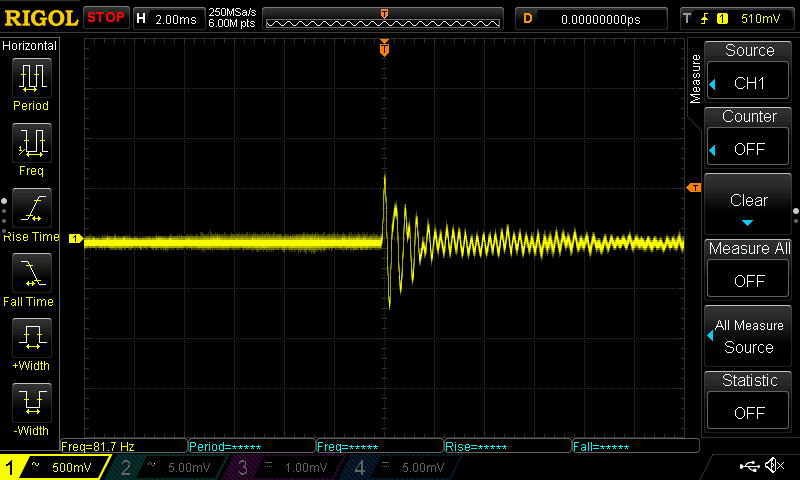

I also wanted to know about the reported issues with microphonics, so I hooked them up to the scope and started knocking with a wooden stick. After a while I was pretty decent at knocking in a reproducible way, and this is what it looked like on the scope:

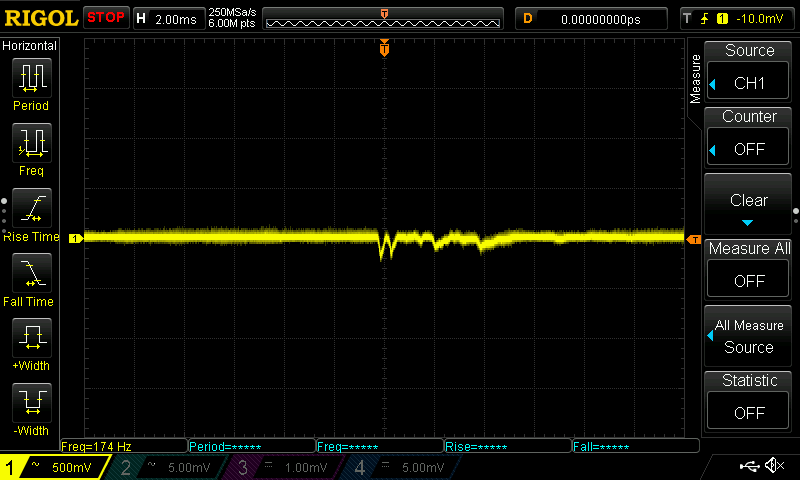

Not knowing if this is good or bad, I also tried an ECC88 (much better):

Or a D3A (also much...

Here are curves in triode mode:

Looks about right for what is needed in the OSDEHA, maybe with a tiny little bit of compression at high voltage.

I also wanted to know about the reported issues with microphonics, so I hooked them up to the scope and started knocking with a wooden stick. After a while I was pretty decent at knocking in a reproducible way, and this is what it looked like on the scope:

Not knowing if this is good or bad, I also tried an ECC88 (much better):

Or a D3A (also much...

I could imagine a mesh construction might reduce the ringing.

Hi mbrennwa,

Absolutely, tubes can act as microphones. We've seen this forever. I guess tapping may give you a relative indication as to which samples are more sensitive than others. As you found, ruggedized tubes for industry and military use are less susceptible. They often use higher heater currents as well. If you really want to see a major difference between tubes, try some 6DJ8 tubes and compare them to half decent 6922 tubes.

The major contributor to microphonics is the movement of the grid wrt the cathode or filament. Not the plate, mesh or otherwise. If I had to guess, a filament type tube might be worse in that regard, depending on how tight the filament spring is. Then you have almost everything moving except the plate. Plates tend to be mounted more securely. With high stiffness, I would expect plate vibration to be higher in frequency and lower amplitude (depending on the circuit). Plate movement wouldn't affect things nearly as much as the grid or cathode.

That's why I wonder how much contribution plate vibration may make. Then the question becomes how much different a mesh and solid plate really are. Given a very small effect due to plate vibration, and an even smaller difference between the two ... how audible would they be, and could you hear the difference?

Hitting some microphone wire on the ground connected to a PA amp can be enlightening. Tapping some capacitors may be more audible than a decent tube. So looking at airborne vibrations effects on a tube plates seem less likely a problem. Electrostatic forces probably count even less.

Given all the variables, there really is only one way to test this hypothesis. Manufacture some tubes in the same production run splitting plates between mesh and sheet. Otherwise you have far to many variables to point your finger at anything. It becomes an imaginary argument without some controlled test.

Absolutely, tubes can act as microphones. We've seen this forever. I guess tapping may give you a relative indication as to which samples are more sensitive than others. As you found, ruggedized tubes for industry and military use are less susceptible. They often use higher heater currents as well. If you really want to see a major difference between tubes, try some 6DJ8 tubes and compare them to half decent 6922 tubes.

The major contributor to microphonics is the movement of the grid wrt the cathode or filament. Not the plate, mesh or otherwise. If I had to guess, a filament type tube might be worse in that regard, depending on how tight the filament spring is. Then you have almost everything moving except the plate. Plates tend to be mounted more securely. With high stiffness, I would expect plate vibration to be higher in frequency and lower amplitude (depending on the circuit). Plate movement wouldn't affect things nearly as much as the grid or cathode.

That's why I wonder how much contribution plate vibration may make. Then the question becomes how much different a mesh and solid plate really are. Given a very small effect due to plate vibration, and an even smaller difference between the two ... how audible would they be, and could you hear the difference?

Hitting some microphone wire on the ground connected to a PA amp can be enlightening. Tapping some capacitors may be more audible than a decent tube. So looking at airborne vibrations effects on a tube plates seem less likely a problem. Electrostatic forces probably count even less.

Given all the variables, there really is only one way to test this hypothesis. Manufacture some tubes in the same production run splitting plates between mesh and sheet. Otherwise you have far to many variables to point your finger at anything. It becomes an imaginary argument without some controlled test.

I think people making "statements of facts" need to start posting references or links to back up their claims or overarching generalizations. It's common practice in the science community to do this, and I see people providing links or data, but then one person shoots it down based on their army of people who they claim agree with them. In an online forum, we are all equal and no one should be acting like they are the sole authority.

Like I have no way of believing that the plate in no way contributes to microphonics or other mechanical disturbances and we know many high gain signal tubes like the 6EJ7 have a mesh shield around the plate, which is obviously there for a reason. When you have a tube amp in the same room with the music playing, especially at louder volume levels, the interaction of the sound waves in the room and the tubes has to be a consideration. I've seen DHT tubes with visibly saggy grids have zero microphonics, which makes me think that isn't what causes it.

Like I have no way of believing that the plate in no way contributes to microphonics or other mechanical disturbances and we know many high gain signal tubes like the 6EJ7 have a mesh shield around the plate, which is obviously there for a reason. When you have a tube amp in the same room with the music playing, especially at louder volume levels, the interaction of the sound waves in the room and the tubes has to be a consideration. I've seen DHT tubes with visibly saggy grids have zero microphonics, which makes me think that isn't what causes it.

Hi AndyHere are photos of 2 types of mesh plate 27 tubes.

Yes this is very good example from Tomas Mayer, with beautiful close-up photos.

But look,

the real mesh is fabric made of wire. This is probably achieved with some thermal + preasure technology?

To make it stiff and not to tear apart the fabric structure?

.

It could be calculated probably, the area of fabric including every wire outside area in same square area as standard metal anode.

And it probably be very close or even a bit more total area in mesh type anode?

.

Next, sinking the heat is much better with mesh or fabric anode.

And with extension of wire-fabric anode to the holders that heat-sink area is significantly extended?

.

The circular shape of anode coresponds to circular structure of the grid. So the distance between Anode and Grid, along the whole length is the same...

.

One more thing could be present:

in the process of making wire fabric for mesh anode, probably not every point of "gluing" with vertical and horizontal wire is the same quality? But that number of "faulty" point connections are probably low. Probably les than 10%?

That is implicating to sort of "random" points distribution in the area?

.

And finaly it is significantly complicated and more expensive to form Anode from wire fabric than the simple lamination?

That could be a reason of transfer to plate anode types?

Imagine first making the special alloy of wire, than probably treat the outside surface of wire with other alloy, then form the fabric, treat the fabric with specific preasure and heat. Probably some additional processes aplied...

.

Cheers 🙂

.

P.S.

I will post one of my mesh old tube that my fellow and me destroyed with gret success, trying to measure them with tube tester - BUT with mistake of 20V heat from 4V... 🙂

Anyway I had a pair now just one...

Hey stephe,

There are no studies on this. Not that I have been able to locate, hence my reasoning.

Many of us have taken a number of tubes apart that were no longer serviceable. We observe their construction, and based on what we have learned in other subjects about materials, we can make educated guesses. Personally speaking, I haven't stated anything as a fact I didn't know to be a fact. I have posed reasonable questions on statements simply to have people think about it.

Often there are characteristics in tube construction that exist for very good reasons. Such as electrostatic shielding around or between plates. 6DJ8 is a good example as it was intended for high frequency use. Basic electrical engineering often tells you why some features are included in a tube design.

So, can excessive vibration of a tube creep into the electrical output? It sure can. That's why several good phono preamplifiers have shock mounted tube sockets, and some shock mount the entire high gain sub chassis. Therefore, I can only say that if this is an issue or consideration, a mechanical design would incorporate features to reduce this.

But. Using this to advance an untested theory between characteristics of mesh and plate tube plate construction is maybe reaching a bit far out. As I said earlier, the only way to prove this is to manufacture identical tubes using both plate and mesh plates to prove what differences there may be. I have no seen or heard of any such tests. Just grabbing some tubes with both characteristics (even the same type number) does not control all other construction variables.

That is all I have said. For the results of an experiment or test to be valid, the test itself must be valid and controlled to take into account all variables and eliminate those from your result except the tested variable.

There are no studies on this. Not that I have been able to locate, hence my reasoning.

Many of us have taken a number of tubes apart that were no longer serviceable. We observe their construction, and based on what we have learned in other subjects about materials, we can make educated guesses. Personally speaking, I haven't stated anything as a fact I didn't know to be a fact. I have posed reasonable questions on statements simply to have people think about it.

Often there are characteristics in tube construction that exist for very good reasons. Such as electrostatic shielding around or between plates. 6DJ8 is a good example as it was intended for high frequency use. Basic electrical engineering often tells you why some features are included in a tube design.

So, can excessive vibration of a tube creep into the electrical output? It sure can. That's why several good phono preamplifiers have shock mounted tube sockets, and some shock mount the entire high gain sub chassis. Therefore, I can only say that if this is an issue or consideration, a mechanical design would incorporate features to reduce this.

But. Using this to advance an untested theory between characteristics of mesh and plate tube plate construction is maybe reaching a bit far out. As I said earlier, the only way to prove this is to manufacture identical tubes using both plate and mesh plates to prove what differences there may be. I have no seen or heard of any such tests. Just grabbing some tubes with both characteristics (even the same type number) does not control all other construction variables.

That is all I have said. For the results of an experiment or test to be valid, the test itself must be valid and controlled to take into account all variables and eliminate those from your result except the tested variable.

PM sent..........Kidding 😉I have for sale a limited quantity of excellent very old stone weights intended for installation on tube amplifiers, I have models of 5 Kg, 20 Kg and 100Kg, the price is $1 per Kg.

Hi RobThere are little or no data sheets for COSMOS valves on the web

I transcribed Anode characteristics to more common graph.

(Using, Graph click, Text Wrangler and MatLab software..)

I was qurious to se how linear it is?

Values are in .TXT file

.

spice model

.

%

% estimated capacitance - no data

% Ccg = 6.0P

% Cgp = 9.0P

% Ccp = 3.6P

%

% Va max. = 180V

% Uh=4V, Ih=1A

% mu=10

filename =

AC-R.m

Running AC?R Cosmos... ERR =0.00185 WEIGHT = 1

.SUBCKT AC-R 1 2 3 ; P G C (Triode)

- PARAMS: MU= 10.29 EX= 1.457 KG1=2582.1 KP= 61.28

- KVB= 857.9 VCT= 0.20

.ENDS

.

Attachments

More clear Graph of AC⁄R Cosmos

from Ug=0V step -2V

Spice model is, say good, curves are crossing so close to points extracted from original datas graph...

There are no datas in original datasheet for capacitances and Pa max 🙁

What is estimated Pa max for AC⁄R?

.

Check with TOOLS

corrected KVB parameter

and spice model.

For 2Vrms input low distortion output, low output impedance (for another tube stage)

all in all, very good tube...

.TXT change to .INC

Dont know if the simulators accept "/" in file name?

If not change to something else, in tha name and in the text on .INC file

.

from Ug=0V step -2V

Spice model is, say good, curves are crossing so close to points extracted from original datas graph...

There are no datas in original datasheet for capacitances and Pa max 🙁

What is estimated Pa max for AC⁄R?

.

Check with TOOLS

corrected KVB parameter

and spice model.

For 2Vrms input low distortion output, low output impedance (for another tube stage)

all in all, very good tube...

.TXT change to .INC

Dont know if the simulators accept "/" in file name?

If not change to something else, in tha name and in the text on .INC file

.

Attachments

Last edited:

- Home

- Amplifiers

- Tubes / Valves

- Mesh plate tubes