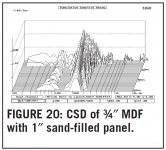

Sand would be very good, how would vermiculite work though?Another technique is to enclose sand in the cabinet walls. If too heavy try vermiculite.

Another technique is to enclose sand in the cabinet walls. If too heavy try vermiculite.

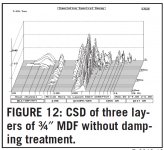

From the moriyasu pdf linked earlier, it appears that a similar weight of solid MDF would do a slightly better job.

This is why I'm seeking measurements > subjective tips and stories.

A simple MDF box would be a faster and more robust build, too. I made speakers with sand filled panels once (side walls were flat MDF/sand/curved MDF), and I was a bit concerned that the weight of the sand would split a seam open if the speaker was shaken or dropped during a move.

Attachments

Error correction on something I said earlier:

A few Australian native woods are very hard, hence I'm leaning towards a core of locally made construction ply that's substantially stiffer than birch, F27 vs F17 (not 14), and that would cost about a quater as much.

Wrong continent, though 🙂

A search on fillers should get plenty of local options.

A few Australian native woods are very hard, hence I'm leaning towards a core of locally made construction ply that's substantially stiffer than birch, F27 vs F17 (not 14), and that would cost about a quater as much.

Oh cool! Thanks. Funny enough I'm just dipping my toes into concrete countertops for my house remodel. That looks like a good supply site.

Wrong continent, though 🙂

A search on fillers should get plenty of local options.

For turntable plinth damping, a few applicable links:

Lenco Reference :: Damping factors

audio qualia - Index page

Good links.

Using a bamboo-ply-fibreglass laminate (with fillers in the fibreglass resin) seems like a good option, based on this info.

1) bamboo, which I want for aesthetics and scratch resistance, is fairly well damped for a 'wood'.

bamboo, resinated

damping factor: 0.200

transmissibility: 3.87

2) the laminates seem much better than their individual components

MDF

damping factor: 0.017

transmissibility: 41.95

perspex (acrylic)

damping factor: 0.07

transmissibility: 10.45

'Page Lacquer' acrylic over mdf

damping factor: 0.315

transmissibility: 2.57

3) The resins + fillers all have very high damping

bentonite powder filled resin

damping factor: 0.518

transmissibility: 1.68

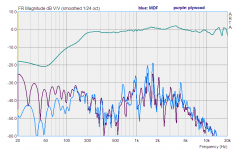

Csaba kindly sent me an additional graph; bare MDF vs. bare ply.

If the threshold for audibility is -30dB, as suggested in that BBC report, then the MDF is worse, as it crosses that line more than the ply.

Also, looking at the 5cm graphs on Csaba's page, plywood is the only material where the addition of sound absorbing material drops all peaks lower than -30dB.

If the threshold for audibility is -30dB, as suggested in that BBC report, then the MDF is worse, as it crosses that line more than the ply.

Also, looking at the 5cm graphs on Csaba's page, plywood is the only material where the addition of sound absorbing material drops all peaks lower than -30dB.

Attachments

a few applicable links:

Twinker, thank you for the links.

This is a very good post:

http://lenco.reference.clicforum.fr/t551-damping-factors.htm#p5211

What is to take away is that not a single isolated mechanical property is to be maximized or minimised in the construction of an enclosure at least for enclosures that will house wide freq range reproducers. It’s good to try for a mix of non uniform mechanical properties (stiffness, mass, damping) across the panel(s), plus as much asymmetric bracing for to make all the potentially vibrating surfaces uneven in area.

George

It is good too work with evidence in the form of measurements but it is vital to understand what has been measured and how it is related to what you want to know. What has been measured here is not cabinet radiation at the ear for an operating speaker. The dominant mechanism for vibrating the cabinet is the reaction of the baffle to the vibrating drivers. This is missing. The air inside the cabinet is being pressurised by a tweeter so there is unlikely to be much if any signal at the low frequencies. The drivers are not moving and so how they react mechanically and electrically to the varying conditions inside the cabinet is not representative. Plus no doubt a few other things.If the threshold for audibility is -30dB, as suggested in that BBC report, then the MDF is worse, as it crosses that line more than the ply.

So what might be learnt from the measurements? The cabinet modes and their shape should be correct but because the forcing is wrong their magnitudes will be wrong. Much of the sound is likely to be emanating from the speaker cones which are almost certainly not responding in a representative manner. This would need further thought to back out the effects. The signal at low frequencies is too low.

Tapping a speaker (knuckle rap test) in a few places will also reveal the modes and their shapes but not the magnitudes. It seems simpler to perform and will excite the lowest frequency modes which I am not sure the tweeter is doing. It will also excite the speaker cones a lot less.

Andy

I agree with what you are saying. I have long thought that these kinds of tests could be very misleading because they make so many assumptions and errors. For example consider this scenario.

I measure one panel which shows a very high vibration at say 200 Hz. and looking at the opposite panel it does the same thing. But if the two panels were vibrating in phase (it's a monopole) then the sound radiation would be many many times greater than if they were vibrating out of phase (a dipole). The mere amplitude of vibration at a single spot is not meaningful of the sound that actually gets radiated.

Taking an accelerator reading on all panels and adding them all together with the correct phase would be closer to reality, but still not very exact if there were mode within the panel.

I agree with what you are saying. I have long thought that these kinds of tests could be very misleading because they make so many assumptions and errors. For example consider this scenario.

I measure one panel which shows a very high vibration at say 200 Hz. and looking at the opposite panel it does the same thing. But if the two panels were vibrating in phase (it's a monopole) then the sound radiation would be many many times greater than if they were vibrating out of phase (a dipole). The mere amplitude of vibration at a single spot is not meaningful of the sound that actually gets radiated.

Taking an accelerator reading on all panels and adding them all together with the correct phase would be closer to reality, but still not very exact if there were mode within the panel.

I'd not thought of the glue between the layers of ply as constrained layers before 😱 13 plys and 12 layers of glue can't be bad🙂

Except the damping coefficient for plywood was given earlier and it is poor. The layers do not act like CLD because the properties of the "damping layer" are inappropriate.I'd not thought of the glue between the layers of ply as constrained layers before 😱 13 plys and 12 layers of glue can't be bad🙂

Now if you were to soak the layers in resin and compress them that would make an excellent material for a speaker cabinet: high stiffness, high damping and the cred of wood. Unfortunately commercial examples are ridiculously priced.

The highest resolved frequency is determined by the fineness of the grid on which the set of point measurements is taken. It is as exact as one wants to make it (or more likely the time one is prepared to spend taking the measurements).Taking an accelerator reading on all panels and adding them all together with the correct phase would be closer to reality, but still not very exact if there were mode within the panel.

Ah, would it be worth doing something DIY with thin plys and a resin of some (which) kind? Say, just for an OBNow if you were to soak the layers in resin and compress them that would make an excellent material for a speaker cabinet: high stiffness, high damping and the cred of wood. Unfortunately commercial examples are ridiculously priced.

The highest resolved frequency is determined by the fineness of the grid on which the set of point measurements is taken. It is as exact as one wants to make it (or more likely the time one is prepared to spend taking the measurements).

Its still not exact because you are not taking diffraction of the sound by the cabinet into consideration even if you do use a fine grid. Sound radiation from complex structures is incredibly difficult.

Ah, would it be worth doing something DIY with thin plys and a resin of some (which) kind? Say, just for an OB

Perhaps.

You are if you add up the sources correctly. For example.Its still not exact because you are not taking diffraction of the sound by the cabinet into consideration even if you do use a fine grid.

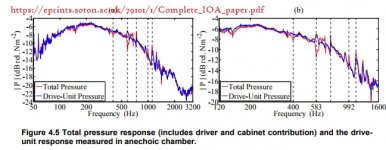

In the attachment of post #115 the author doesn't tell how the cab was made, only that is was plywood. Measurements were laser-based so minimal airborne error. My guess is that it exaggerates the effect of panel resonances in hifi loudspeakers. Here we can read what Sterophile's Atkinson thinks In his reports he shows the highest measured resonance and ringing(csd), but it's relative importance is vague.

Look at the clip from the paper mentioned (attachment here) - should we really be concerned?

In the link of post #114 the Panzerholz baffle is of LX521 by Linkwitz. The baffle is minimal so it's ringing is far less important than edge contour. Thick baffle means higher F of resonance too.

What comes to open baffles, really well designed/minimal baffles of multiways like LX521 almost totally exclude edge diffraction issue! That is because a narrow baffle allows dipole operation (cancellation) even as high as around 4-6kHz and this overrules edge diffs in each driver's passband! Then only doppler effect in front-back dimension (z-coordinate) might be a concern.

Look at the clip from the paper mentioned (attachment here) - should we really be concerned?

In the link of post #114 the Panzerholz baffle is of LX521 by Linkwitz. The baffle is minimal so it's ringing is far less important than edge contour. Thick baffle means higher F of resonance too.

What comes to open baffles, really well designed/minimal baffles of multiways like LX521 almost totally exclude edge diffraction issue! That is because a narrow baffle allows dipole operation (cancellation) even as high as around 4-6kHz and this overrules edge diffs in each driver's passband! Then only doppler effect in front-back dimension (z-coordinate) might be a concern.

Attachments

Last edited:

You are if you add up the sources correctly. For example.

Yes, I am well aware of the technique, but that's not what I said was not exact. A simple sum is not exact no matter how many points you use. You need the Green's functions, but boy what a lot of work!

What comes to open baffles, really well designed/minimal baffles of multiways like LX521 almost totally exclude edge diffraction issue! That is because a narrow baffle allows dipole operation (cancellation) even as high as around 4-6kHz and this overrules edge diffs in each driver's passband! Then only doppler effect in front-back dimension (z-coordinate) might be a concern.

Where did this idea that OB baffles don't diffract come from? They certainly do diffract. The wave don't cancel at the edges, there is an enormous velocity gradient at the baffle edge. The pressure cancels in the plane of the baffle but there will still be a wave sent off from the edge elsewhere.

Can you show me that this is true? I see this assertion come up, but haven't seen it measured. If it is true, why is there not more focus on it (by perfectionists and in megabuck systems)?The dominant mechanism for vibrating the cabinet is the reaction of the baffle to the vibrating drivers.

e.g. Linkwitz will sell you a kit for to 'fix' this, but there's no measurements given, just some subjective talk - based on a sighted and very delayed A/B test.

ORION Revision 1

"What is the sonic benefit? Well, it does not jump out as something you immediately point to"

He uses 20dB of eq. The reference signal is shown right there on each graph, and is pretty flat to 200Hz. Maybe he should have cropped the LF off the graphs.The air inside the cabinet is being pressurised by a tweeter so there is unlikely to be much if any signal at the low frequencies.

There are no drivers, so, yeah, obviously.The drivers are not moving

They don't exist so, yeah, obviously.Much of the sound is likely to be emanating from the speaker cones which are almost certainly not responding in a representative manner.

This is why I like the test. It does a good job of isolating one part of the problem, and getting some comparative test info that shows some material based differences.

I think it is good to know that, with DIY gear, one can easily show the correlation between the technical data about a material, and how it radiates sound when used in a box.

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Multi-Way

- Measuring sound output from speaker cabinet walls