I think your post was for another thread ahahahhaa 😀😀😉

😎

He (Brianco) started it!😀

He (Brianco) started it!😀

Brianco? Where do you see him posting in this thread? that is why I thought it was for something else since you quoted Brianco which quote is for sure from another thread 😱😀😀

😎

Finally I had a chance to start playing a bit with the new curve tracer.

My first impression: I really like it!

It seems to be fast and looks like you can plot, save and recall a lot of curves which should make easty the job to match parts.

On the prototyde side for my masterpiece, I am done with layout for main board and supply board.

Now I am hoinh to work on the board for output stage (laying Calvin and my super bugger with IF3602) and servo board!!

Hopefully this week I will be done with the prototype and get ready to send all the files out.

My first impression: I really like it!

It seems to be fast and looks like you can plot, save and recall a lot of curves which should make easty the job to match parts.

On the prototyde side for my masterpiece, I am done with layout for main board and supply board.

Now I am hoinh to work on the board for output stage (laying Calvin and my super bugger with IF3602) and servo board!!

Hopefully this week I will be done with the prototype and get ready to send all the files out.

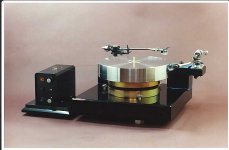

...I will open soon a thread of how to DIY a very good turntable. ......

Good idea.

I appreciate your effort (& with simple tools). I like it.

Do it.

I am sitting on the first row ...

Allez, salukes.

Karel

I will open soon a thread of how to DIY a very good turntable.

We already have the arm playing. It is based on the well Tempered and i think it is improved and easy to make without much machinery.

The bearing is also made. Again very simple without liquid or oil.

We have a brass platter where we will put a POM or PEAK record mat.

We also have a motor, at this time DC but we may find another solution.

I will follow your new thread🙂

Joachim,

Do you have target budget for your new turntable? It seems fairly easy to make a mega bucks design, but to do one for a reasonable amount and get a great end product, that is the art that I would expect of you! I have followed you in a few places and I like how you think. I would love to watch your new thread and as long as I am capable and my machinery can hold the tolerances that you will need to make one of these turntables that would be a worthwhile effort to have something that I would not pay a high end company to make for me. Sign Me Up.

Do you have target budget for your new turntable? It seems fairly easy to make a mega bucks design, but to do one for a reasonable amount and get a great end product, that is the art that I would expect of you! I have followed you in a few places and I like how you think. I would love to watch your new thread and as long as I am capable and my machinery can hold the tolerances that you will need to make one of these turntables that would be a worthwhile effort to have something that I would not pay a high end company to make for me. Sign Me Up.

The arm and the bearing are quite easy to make and inexpensive.

I can not tell at this moment what that will cost but the designer told me that he only has a watchmakers lathe.

I go for a high mass design and the platter is from brass. That is quite expensive but why not using aluminum or acrylic.

I can not tell at this moment what that will cost but the designer told me that he only has a watchmakers lathe.

I go for a high mass design and the platter is from brass. That is quite expensive but why not using aluminum or acrylic.

Why brass and not bronze? Seems like for appearance sake alone bronze would be easier than brass but brass may be easier to get. I understand the concept behind a high mass spinning having a smoother rotational speed but my question for that becomes how do you dynamically balance it? I have a friend who balances crankshafts for engines but I'm not sure it would work for a spinning disk like a platter.

Bronze could be even better but brass was more easy to turn for my supplier.

I think by simply turning the brass with precisson will not require balancing.

The bearing is simply a teflon cylinder with a teflon mirror. The are 3 set screws on the top and 3 set set screws down in the cylinder.

The spindle is from polished steel with a rounded end that runs on the teflon mirror.

This is a bearing without lubrication.

The base will be from slate. Can be granite or artificial stone.

I think by simply turning the brass with precisson will not require balancing.

The bearing is simply a teflon cylinder with a teflon mirror. The are 3 set screws on the top and 3 set set screws down in the cylinder.

The spindle is from polished steel with a rounded end that runs on the teflon mirror.

This is a bearing without lubrication.

The base will be from slate. Can be granite or artificial stone.

Thanks Joachim,

I suspect that a cast or hollow formed platter would have more problems with balance than a solid cylinder so you are probably correct that at the speed of a turntable balance would be a small issue at most. Bronze is probably a bit harder than brass but they both should machine fairly easily if they are not sticky to the cutter. I'll wait for your thread and let the fun begin.

I suspect that a cast or hollow formed platter would have more problems with balance than a solid cylinder so you are probably correct that at the speed of a turntable balance would be a small issue at most. Bronze is probably a bit harder than brass but they both should machine fairly easily if they are not sticky to the cutter. I'll wait for your thread and let the fun begin.

The bearing is simply a teflon cylinder with a teflon mirror. The are 3 set screws on the top and 3 set set screws down in the cylinder.

The spindle is from polished steel with a rounded end that runs on the teflon mirror.

This is a bearing without lubrication.

This is a basic concept "Well Tempered" ...

Normal it's possible to go "near absolute center" ... if with easy-accessible-tuning-micro-screws (& perfect vertical center axle alignment) ....

Chapeau ...

I did the same idea for my concept air bearing TT ...

The base will be from slate. Can be granite or artificial stone.

We obviously have very different taste in sound.

Joachim,

I assume that the base is granite or slate for a mass loading effect. How is that superior to the old spring loaded isolation that is used in most commercial turntables in the past? I have built some massive granite shelving units in the past and I will say that sometimes it is surprising how well certain granite pieces can sing or resonate giving the right input.

I assume that the base is granite or slate for a mass loading effect. How is that superior to the old spring loaded isolation that is used in most commercial turntables in the past? I have built some massive granite shelving units in the past and I will say that sometimes it is surprising how well certain granite pieces can sing or resonate giving the right input.

Slate is quite quiet so to say and i will also minimize size and give it a certain shape.

The tonearm also has some isolation properties because it is an an oil bath.

I never heard a turntable with sub chassis and springs that i liked.

I am more a Platine Verdier, DPS, Spiral Groove guy.

The tonearm also has some isolation properties because it is an an oil bath.

I never heard a turntable with sub chassis and springs that i liked.

I am more a Platine Verdier, DPS, Spiral Groove guy.

Yes, We have highjacked Stephano's thread here for a while now. Start a new thread and let us know the title of the thread. Is that picture you just showed the basis of your design? I see that one is belt driven. So you are saying that the spring damped plinth idea does not isolate the platter well enough and want the massive mass for isolation?

- Status

- Not open for further replies.

- Home

- Source & Line

- Analogue Source

- Masterpiece