Probably 4U x 300mm minimum per channel. Maybe 5U is even better.

28v x 3.1A is about 90w. So assuming ambient is 25C max and we don’t want heatsinks more than 55C we can have 30C rise.

90W/30C = 3W/C or 0.33C/W rated heatsinks needed.

28v x 3.1A is about 90w. So assuming ambient is 25C max and we don’t want heatsinks more than 55C we can have 30C rise.

90W/30C = 3W/C or 0.33C/W rated heatsinks needed.

I am sorry for missing the answer to question if the GB adapter boards are conductive. Is it possible to mount them on common heatsink or should one insulate them?

......Is it possible to mount them on common heatsink or should one insulate them?

The aluminum adapter pcb’s do not need an insulator when mounted to a heatsink. But, you should apply a bit of thermal paste for good contact.

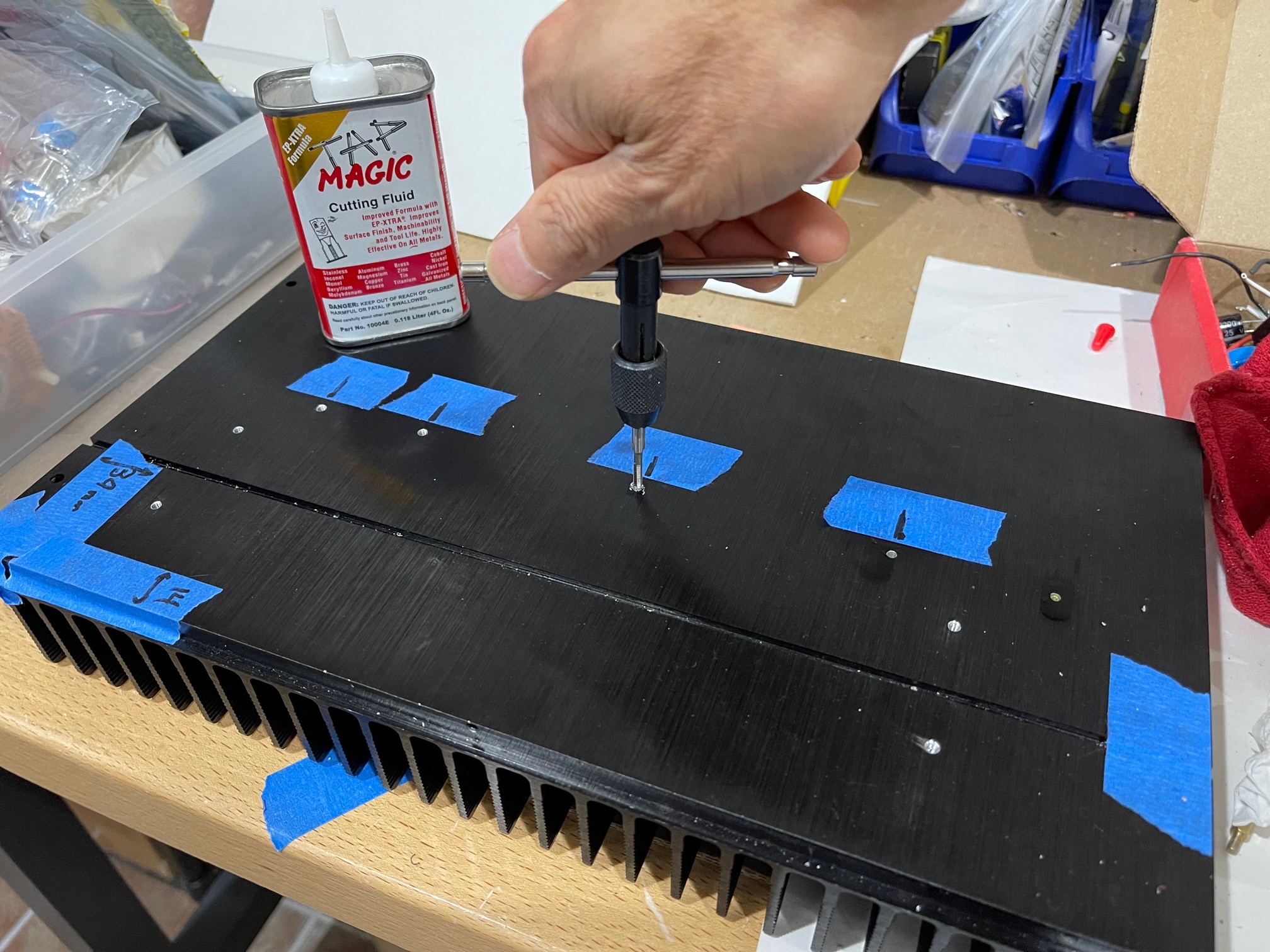

I made some progress today and managed to drill and tap one heatsink to mount LuFo. A new 2.5mm drill bit and Tap Magic worked wonders to help the tapping go smoothly.

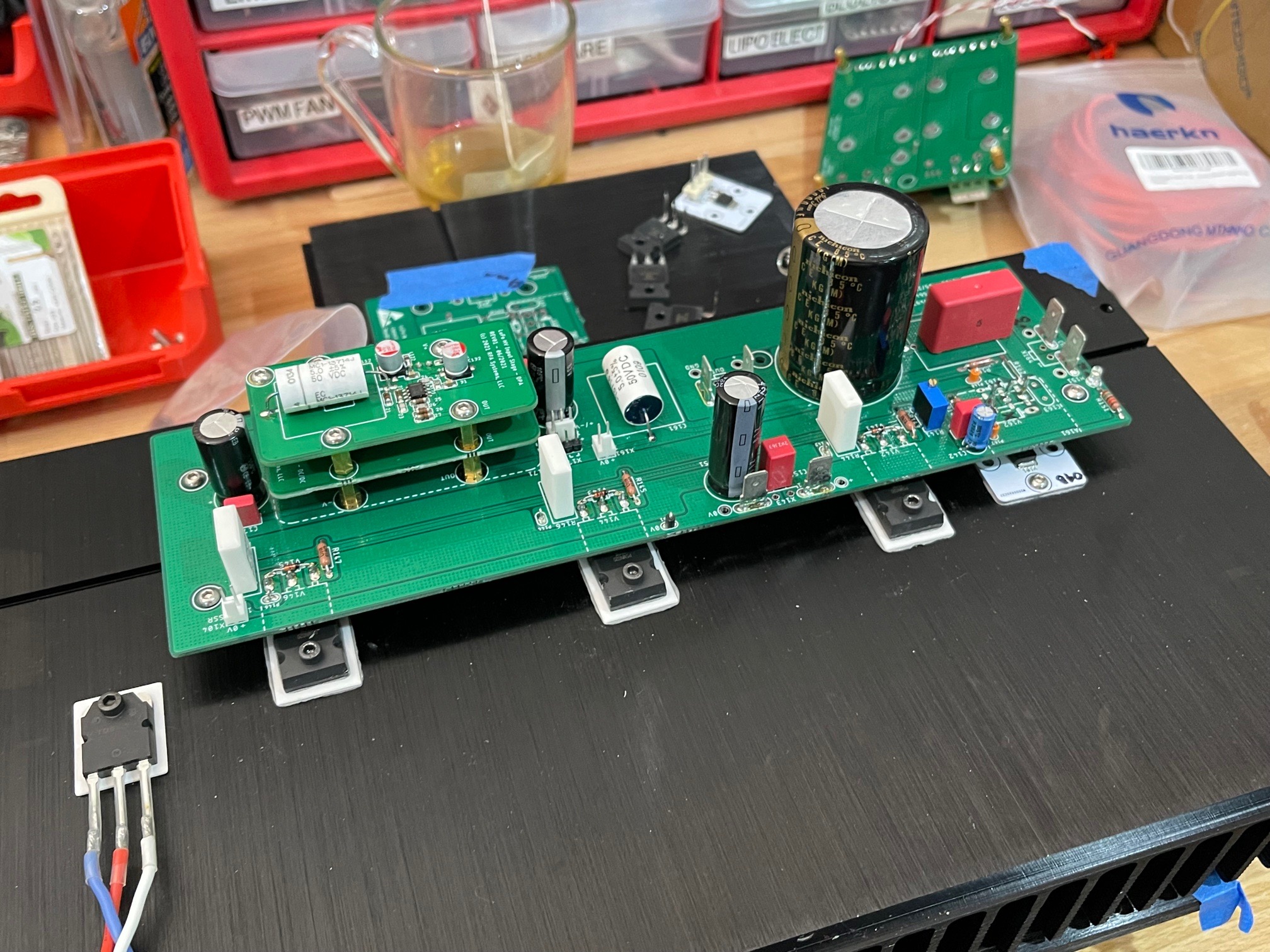

All bolted on with thermal paste goop:

If I can finish the other half I can test out the SuSyLu concept.

All bolted on with thermal paste goop:

If I can finish the other half I can test out the SuSyLu concept.

X, I recommend getting yourself a tap guide - it helps to get consistent taps by making sure the tap is perpendicular to the surface - I found it has made a big improvement to my work, especialy with small thread (like M3) blind holes. You can also use it as a drill guide if you're not using a vertical drill press for anything.

Big Gator Tools - Blog What is a tap guide? Learn more about drilling, tapping, clamping and many other tricks of the trade! We discuss frequently asked questions about our V-DrillGuides & V-TapGuides. www.biggatortools.com

Big Gator Tools - Blog What is a tap guide? Learn more about drilling, tapping, clamping and many other tricks of the trade! We discuss frequently asked questions about our V-DrillGuides & V-TapGuides. www.biggatortools.com

Thanks NB! I’ll try that next time. I managed to finish all 18 tapped holes. They seem pretty perpendicular based on how square the brass standoffs sit.

Here are both sides mounted and ready for testing as single LuFo per side and then as balanced output as SuSyLu for a 100w SE Class A amp.

Here are both sides mounted and ready for testing as single LuFo per side and then as balanced output as SuSyLu for a 100w SE Class A amp.

Attachments

X, it's more about keeping the drill/tap consistently perpendicular whilst drilling/cutting rather than whether the resulting insert is at an angle - if drilling/tapping by hand without a guide we tend to 'wander' a bit and with small diameter holes and fine threads that can leave the hole you're going to tap oversized/eccentric and you can end up with a chewed up hole and poor, or no, thread - I had the T shirt before I bought my tap guide!

As all I pretty much ever tap is M3 it seems a waste to buy a $23 tool with a bunch of other sizes on it. I could just drill a 3mm hole through a piece of aluminum bar stock? But as tools go, not too expensive so I’ll get it for my next heatsink project. 🙂

Big Gator Tools MTG500NP V-Tap Guide https://www.amazon.com/dp/B0076OAODG/ref=cm_sw_r_cp_api_glt_fabc_NJZA6CT7TY14JFJNVPJ3

Big Gator Tools MTG500NP V-Tap Guide https://www.amazon.com/dp/B0076OAODG/ref=cm_sw_r_cp_api_glt_fabc_NJZA6CT7TY14JFJNVPJ3

Good move X, the Big Gator tool is hardened so you'll not chew it up like a hole in a block of aluminium, plus it has a V groove on the bottom which gives the swarf somewhere to go and enables drilling/tapping on round sections.

drill guide at last ..tap bit with tre progressive size

PS don't forget to enlarge The hole to avoid compression of alu under the mosfet

PS don't forget to enlarge The hole to avoid compression of alu under the mosfet

Each channel of LuFo tested to work and playing music. Uneventful first startup. Running 3.1A bias current and 28.6v rail for one channel with 400VA 24v trafo and SLB PSU.

Hi Zman,

Do you mean 2 channel playin balanced mode or 2 channels as in stereo monoblocks of the SuSyLu?

For the latter, I’ll have to build another pair of LuFo boards and LuFo front end daughter boards.

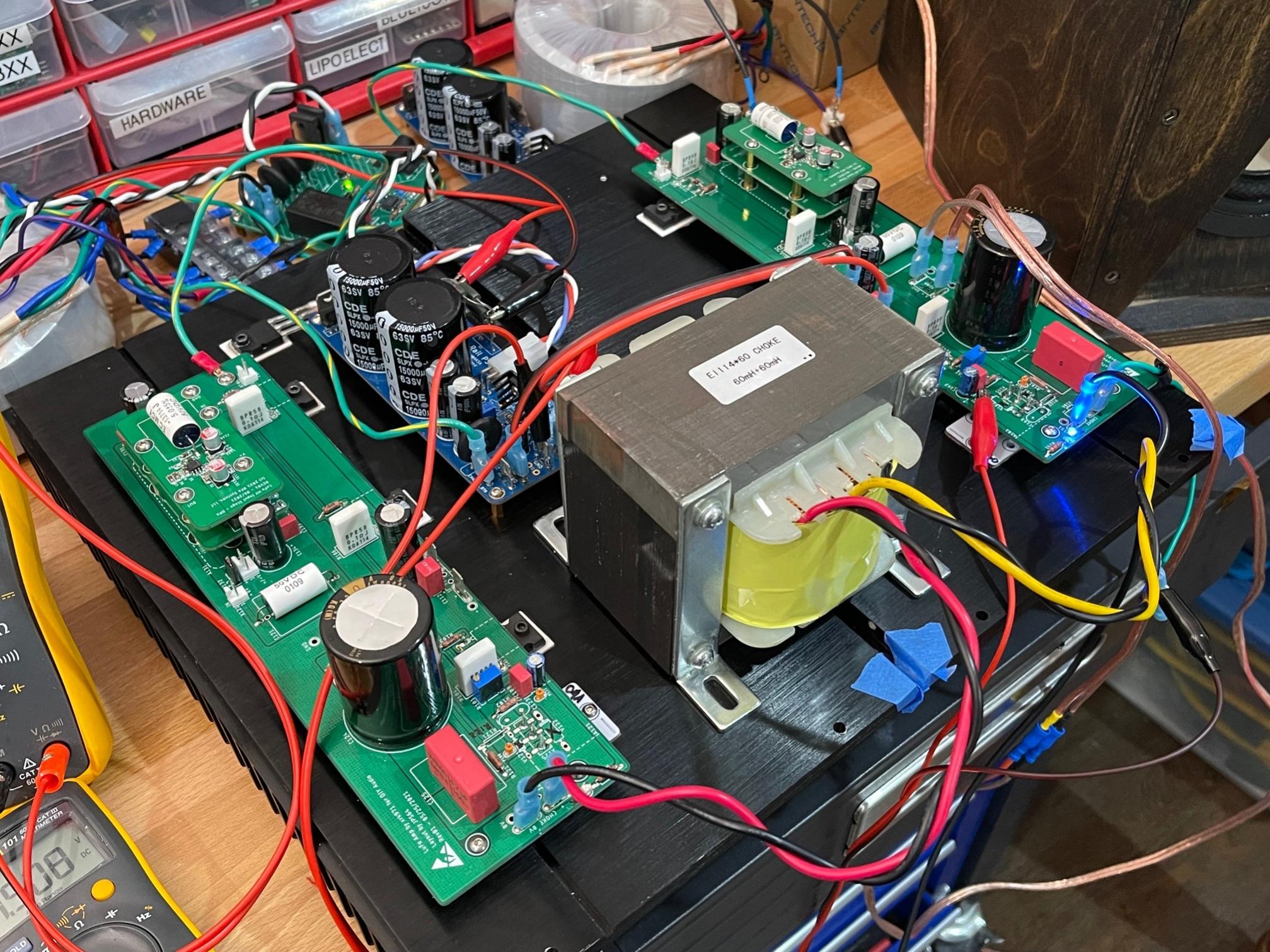

For SuSyLu balanced output operation I am just getting it connected and initial testing is looking really promising. The bifilar wound coupled inductor connected in anti phase is working out nicely. It allows 3A bias current from each leg and cancels out the DC magnetic flux so saturation does not appear to be an issue. The amp is playing music very nicely and balanced operation seems quite feasible with a single power trafo and SLB.

Do you mean 2 channel playin balanced mode or 2 channels as in stereo monoblocks of the SuSyLu?

For the latter, I’ll have to build another pair of LuFo boards and LuFo front end daughter boards.

For SuSyLu balanced output operation I am just getting it connected and initial testing is looking really promising. The bifilar wound coupled inductor connected in anti phase is working out nicely. It allows 3A bias current from each leg and cancels out the DC magnetic flux so saturation does not appear to be an issue. The amp is playing music very nicely and balanced operation seems quite feasible with a single power trafo and SLB.

Last edited:

X, it's more about keeping the drill/tap consistently perpendicular whilst drilling/cutting rather than whether the resulting insert is at an angle - if drilling/tapping by hand without a guide we tend to 'wander' a bit and with small diameter holes and fine threads that can leave the hole you're going to tap oversized/eccentric and you can end up with a chewed up hole and poor, or no, thread - I had the T shirt before I bought my tap guide!

I mount center punch on a drill press and use that to keep the tap tool in line. As I start tapping I keep adjusting the depth down until the tap is far enough in.

I’ve been tapping threads freehand for 30yrs, done pretty good as I am careful with the start alignment by eye. I’ll never attempt to tap copper heatsinks again though. But a tap guide is probably not a bad thing to have. I also have square angle machinists’ blocks that could probably be used as 90deg gauge to do similar.

Wow,

That thing is a beast, how much would a stereo amp weight ? Is that the custom inductor you had made? It looks like that is getting the 39 watts the hard way. If moving my amps around does not kill me, I may have to build your class d amp for summer use and senior citizen convenience.

Bill

That thing is a beast, how much would a stereo amp weight ? Is that the custom inductor you had made? It looks like that is getting the 39 watts the hard way. If moving my amps around does not kill me, I may have to build your class d amp for summer use and senior citizen convenience.

Bill

Hi Bill,

You would not be able to move it if it were a stereo amp. Hence, monoblocks.

Each monoblock will be about 48lbs ea. Chassis is 24lbs of CNC aluminum each, custom inductor is 11lbs, toroidal trafo about 10lbs, misc amp boards and hardware another 3lbs.

But, 48lbs is a small price to pay for a 100w SE Class A amp!

You would not be able to move it if it were a stereo amp. Hence, monoblocks.

Each monoblock will be about 48lbs ea. Chassis is 24lbs of CNC aluminum each, custom inductor is 11lbs, toroidal trafo about 10lbs, misc amp boards and hardware another 3lbs.

But, 48lbs is a small price to pay for a 100w SE Class A amp!

Last edited:

- Home

- Amplifiers

- Pass Labs

- LuFo Amp - 39w SE Class A from 28v Rail