I don't know if anyone measured that, but at audio frequencies, the cable is electrically short and it is driven from and loaded by impedances that are too high for the cable inductance to matter, so you can see it as just a parallel capacitor. It shouldn't make any difference on which side of the cable you put an extra capacitor.

Two assumptions:

1. I assume that the amplifier has no RF stability problems that depend on source impedance

2. I assume that the capacitors in the tonearm don't make the tonearm too heavy

Two assumptions:

1. I assume that the amplifier has no RF stability problems that depend on source impedance

2. I assume that the capacitors in the tonearm don't make the tonearm too heavy

From an EMC standpoint it is definitely best to have the load cap right at the input connector of the head amp. And a 100R series resistor in front of it, doubling up as low-pass for RFI and line termination.

Let's agree that the MM-EQ preamp belongs directly at the end of the tonearm cabling.

In many ways, this is true. However, since it is impossible to compensate for mechanical resonance electrically—due to the weak coupling of these components—the best solution would be to purchase a new cartridge with an ultra-light needle and a cantilever of conical structure. This way, the resonances will shift into the ultrasonic range, as they do in MC cartridges.Let's agree that the MM-EQ preamp belongs directly at the end of the tonearm cabling.

I'm with you that the lower the ETM the better, but are you sure about tapered cantilevers for MC carts?the best solution would be to purchase a new cartridge with an ultra-light needle and a cantilever of conical structure. This way, the resonances will shift into the ultrasonic range, as they do in MC cartridges.

My 50kHz cart has a solid boron 0.28mm cantilever tube, so not conical.

Hans

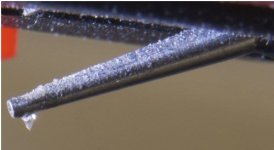

The conical geometry of the cantilever increases rigidity, minimizing parasitic mechanical resonance. Residual vibrations are further damped by a point-applied vibration isolator, typically visible as a dark spot on the cantilever itself.I'm with you that the lower the ETM the better, but are you sure about tapered cantilevers for MC carts?

My 50kHz cart has a solid boron 0.28mm cantilever tube, so not conical.

However, beyond a certain threshold of rigidity, the benefits of the conical shape may diminish, as other structural factors become dominant.

I agree on all that.The conical geometry of the cantilever increases rigidity, minimizing parasitic mechanical resonance.

Can you give some examples of MC carts having tapered cantilever rods or tubes other than lower cost alumimium versions.

Hans

Can you give it to us?Can you give some examples of MC carts having tapered cantilever rods or tubes other than lower cost alumimium versions.

Hans

Especially since all these threads are always about MM and not MC systems?

Ah, you promoted yourself to the role of thread supervisor.Can you give it to us?

Especially since all these threads are always about MM and not MC systems?

Sorry I missed that.

When all MC’s would have tapered cantilevers and MM’s not, it could help to explain some anomalies in MM behaviour.

Hans

I agree on all that.

Can you give some examples of MC carts having tapered cantilever rods or tubes other than lower cost alumimium versions.

Artificial intelligence will help us

Here are examples of high-end Moving Coil (MC) cartridges featuring tapered cantilever rods/tubes made from advanced materials beyond standard aluminum:

1. Boron Tapered Cantilevers

- Lyra Atlas (SL, Lambda) – Uses a tapered boron tube for ultra-low mass and rigidity.

- Ortofon MC Anna Diamond – Features a tapered boron cantilever with diamond-coated stylus for extreme detail.

- Dynavector XV-1t – Tapered boron design for improved tracking and high-frequency response.

2. Sapphire Tapered Cantilevers

- Koetsu Urushi Vermilion/Platinum – Handcrafted with a tapered sapphire cantilever for lush midrange and durability.

- Clearaudio Goldfinger Statement – Uses a hollow tapered sapphire tube for minimal resonance.

3. Diamond-Coated or Solid Diamond Cantilevers

- ZYX Ultimate Airy – Tapered diamond-coated boron for near-zero distortion.

- Phasemation PP-2000 – Solid diamond tapered cantilever (rare and ultra-high-end).

4. Exotic Alloys/Composites

- Ikeda 9TT – Tapered titanium tube for a unique balance of lightness and strength.

- My Sonic Lab Signature Platinum – Tapered beryllium cantilever (rare due to beryllium’s toxicity but offers superb stiffness).

Why Tapered?

Note: Many brands don’t explicitly advertise "tapered" designs, but high-end MC carts often use them. Look for terms like "micro-tapered" or "hyperbolic profile" in specs.

- Lower effective mass at the stylus tip (critical for high-frequency tracking).

- Controlled flex – Reduces unwanted resonances vs. straight tubes.

- Material synergy – Boron/sapphire/diamond maintain stiffness while allowing precise tapering.

Cantilever in MC Phono Cartridges – Materials & Shapes

1. Common Cantilever Materials:

- Borosilicate Glass – Offers rigidity and detailed sound reproduction.

- Aluminum – Lightweight and stiff, a popular mid-range choice.

- Sapphire – Extremely rigid and durable, used in high-end models.

- Carbon Fiber – Lightweight with high strength, reduces resonance.

- Ruby – Sometimes used in ultra-high-end cartridges for its hardness.

2. Cantilever Shapes:

- Straight (Cylindrical) – The most common, provides good tracking.

- Tapered (Conical to Fine Tip) – Improves high-frequency response.

- Bent (Curved) – Rare, sometimes used for specific compliance needs.

- Hollow Design – Reduces mass (found in some high-end models).

3. Key Features in MC Cartridges:

- MC cantilevers are typically shorter and stiffer than MM/MI designs due to the moving coil’s lower mass.

- Many MC cartridges have fixed cantilevers (non-replaceable), requiring a full retip or cartridge replacement when worn.

Examples of MC Cartridges & Their Cantilevers:

- Denon DL-103 – Straight aluminum cantilever.

- Ortofon MC Cadenza – Borosilicate glass.

- Lyra Delos – Sapphire cantilever.

- Hana ML – Carbon fiber.

- Koetsu Urushi – Ruby cantilever (in some models).

Why Does the Cantilever Matter?

- Material affects rigidity, resonance, and detail retrieval.

- Shape influences tracking ability and high-frequency response.

- Mass impacts compatibility with tonearms (low-mass cantilevers suit high-compliance arms).

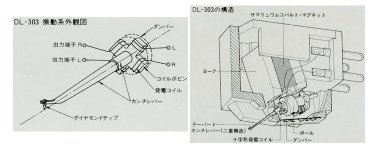

A picture from the past, from a more developed civilization—when marketing was less developed. 😊

LinksTAPERED CANTILEVER VM STEREO CARTRIDGE

The decrease of equivalent mass of oscillating system in viewing from the stylus tip is directly related to the improvement of every distinctive feature. The smaller the equivalent mass is, the better. This is the widely prevailed theory for every kind of cartridges. In fact, it can be safely said that every effort of technicians has been concentrated on how to decrease the equivalent mass while keeping the balance of necessary mechanical strength and efficiency of electrical converter. This newly completed tapered cantilever is the final product of our vigorous efforts and continuous approach to this goal.

The special light-weight alloy pipe is surprisingly minutely finished with the micro sizes of 0.4mm in diameter at the tip, 0.9mm at the base, and 50 microns at the center part. Compared with the thick straight pipe of the original types AT-VM35 and AT-35X (with 0.6φ and 50 microns), the AT-VM35 achieves tremendous high efficiency, though its dynamic mass is relatively small. As shown in the measured graph at the end of this catalogue, the amazingly smooth frequency response is obtained only by using this cantilever.

Attachments

That would be clear confirmation, I agree.When all MC’s would have tapered cantilevers and MM’s not, it could help to explain some anomalies in MM behaviour.

MC cartridges differ somewhat in price and can afford to use lighter and stiffer cantilevers, which are not necessarily conical.

Not direct confirmation of anomalous behavior: the use of conical cantilevers in MM cartridges, being stiffer, extends the frequency response.

Hans,

Thanks for being part of the discussion.

Personally, I find this topic interesting from the perspective of designing the 'ultimate' phono preamp for MM cartridges.

The questions raised in this discussion help shape the technical requirements.

Yet, the answers consistently lead me to the conclusion that it’s impossible to improve upon what already exists.

Manufacturers have long since explored this path

Alex

Thanks for being part of the discussion.

Personally, I find this topic interesting from the perspective of designing the 'ultimate' phono preamp for MM cartridges.

The questions raised in this discussion help shape the technical requirements.

Yet, the answers consistently lead me to the conclusion that it’s impossible to improve upon what already exists.

Manufacturers have long since explored this path

Alex

That is where a flat preamp , gain of 10, should be. At the point of connection where tonearm wires connect to external cable.

Not quite true; semiconductor fabs have become cleaner over the years, resulting in less 1/f noise. As an example a recently made BF256B has 19dB less 1/f noise than shown in the 1986 Siliconix data book. Of course, the real tragedy is that BF862 is no longer made. But 2SK2145 is pretty good. Thus, it is possible now to do better than in the vinyl heyday. Not a huge improvement, but achievable.Yet, the answers consistently lead me to the conclusion that it’s impossible to improve upon what already exists.

Manufacturers have long since explored this path

The components are still available—even the BF862 can be found on the market. But there’s no real need to seek them out, as there are plenty of similar alternatives. If you’re not chasing TI’s top-tier specs, parts like the J113 or BSR57 work perfectly fine for correctors. Toshiba and ONS are definitely underrated, and for those who like exotic options, there’s stuff like IDC Discrete Components.

Fortunately, I have a (very small) stash of genuine BF862. But I have been caught out by fake LSK170C. I struggled and I struggled but the low noise amplifier they were in wasn't low noise. I replaced them with BF862 and the noise dropped to exactly where the BF862 data sheet said it should be.

Yes, it's the ONSemi BF256B that I had in mind.

Yes, it's the ONSemi BF256B that I had in mind.

If you want exceptionally low noise out of a moving-magnet phono preamplifier, the first thing you should do is to replace the termination resistor with an electrically "cold" resistance - but that's the subject of other threads. (Of the first part of this thread, https://www.diyaudio.com/community/threads/im-interested-in-riaa-preamps-design.425946/ , for example.)

Last edited:

Yes. I was quite surprised by how much of a difference that makes. On that note, the lossy core of the Shure V15/III results in a higher r_core that increases noise.

I wouldn't get too worked about noise, I used to work in RF design group and we joked that if you got the system noise figure down to 3 dB that was good enough, The reason why was because your signal source was producing one unit of noise and your system was producing one unit of noise, The total noise out of the system was 1,414 units of noise. Now suppose by super-duper engineering you lower the system noise by 90%, This means the noise output of the system will now be SQRT(1,0**2+0,1**2}, Thats about 30 percent less than 1,414, You probably won't even notice,

- Home

- Source & Line

- Analogue Source

- Load capacitance on MM cartridge