Still it is highly unusual that solid enameled wires bent in 90 degrees corners (without color indicating function) are used. Semantics.

As said PE is also in wrong color (so against EU code) and only to the back cover which is simply inadequate. You could ask an electrical safety professional 🙂

As said PE is also in wrong color (so against EU code) and only to the back cover which is simply inadequate. You could ask an electrical safety professional 🙂

Last edited:

That is not a plug with PE. Your device does have an IEC inlet with PE (also connected) and inadequate internal PE connections. So that is comparing oranges and apples (class I/class II) together with wrong reasoning.

Are you testing my knowledge? That is fine but please take my exam via PM.

Are you testing my knowledge? That is fine but please take my exam via PM.

Last edited:

It does. That's the whole point of a earth-leakage circuit breaker. It detects current difference in the two lines. Then it assumes the current difference goes to earth and concludes it must be the human body. And then trips. You don't need a PE anywhere near this circuit.What do you think how effektiv the FI (Fehlerstrom Schutzschalter) will function without a PE-Leiter?

I have had too many electric shocks in my life. And still I have not dared to deliberately touch a live wire to test the ELCB. On other words, I like my metal cases connected to PE.

Could it be this is some audiophile nonsense? Wire must be as short as possible, so connections are made with straight wire no matter what. And wire insulation adversely affects audio quality. So it has to be heat-resistant and as thin as possible. And certainly not ordinary PVC.Still it is highly unusual that solid enameled wires bent in 90 degrees corners (without color indicating function) are used. Semantics.

I also see the insulation removed from the 4 capacitors near the input. That insulation is bad for audio quality as well of course?

Guys you are not getting what I am after.

Both devices (SMSL and China amp) are fed by 230v ac and both have metal casing.

Even though the SMSL has a European safety sticker and the China amp not they are both protected by the leakage switch (FI)

The China amp from which JP said is not build by European safety standards has even one advantage: Should a loose hot wire touch the case for whatever reason the fuse will go. Not so with the unearthed SMSL.

A safety sticker does not necessarily mean it's saver than a device without one.

Klaus

Both devices (SMSL and China amp) are fed by 230v ac and both have metal casing.

Even though the SMSL has a European safety sticker and the China amp not they are both protected by the leakage switch (FI)

The China amp from which JP said is not build by European safety standards has even one advantage: Should a loose hot wire touch the case for whatever reason the fuse will go. Not so with the unearthed SMSL.

A safety sticker does not necessarily mean it's saver than a device without one.

Klaus

Class I versus Class II.

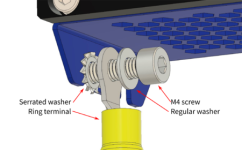

Furthermore my words are totally non important, we have regulations for that. Any electrical (safety) technician can confirm correct PE wiring color and thickness, what washers, bolts and nuts to use and how to have correct grounding. Anodizing, paint, screwed connections, all can be too high ohmic so simple methods have been developed to make it right.

Of course class II devices don’t have and don’t need PE and chances that L will touch chassis are next to nil by design but I can again have the wrong take on that of course 🙂

Furthermore my words are totally non important, we have regulations for that. Any electrical (safety) technician can confirm correct PE wiring color and thickness, what washers, bolts and nuts to use and how to have correct grounding. Anodizing, paint, screwed connections, all can be too high ohmic so simple methods have been developed to make it right.

Of course class II devices don’t have and don’t need PE and chances that L will touch chassis are next to nil by design but I can again have the wrong take on that of course 🙂

Attachments

Last edited:

Let's face it it's more of an insurance issue than safety. When I build or inspect electrical devices for our customers I am to a degree liable after I put the inspection sticker on.

In my home I care less if the right sticker is on or not or if the cables have the right color.

Since my gear is not on display but behind a closed sideboard door I don't even have the lids on most components. Tweaking is more convenient this way.

In my home I care less if the right sticker is on or not or if the cables have the right color.

Since my gear is not on display but behind a closed sideboard door I don't even have the lids on most components. Tweaking is more convenient this way.

Double-check for any accidental short circuits or loose connections when you rewire the input signal. A short could prevent the signal from reaching the amplifier properly. Here are some common issues in PCB manufacturing: https://www.theengineeringprojects.com/2024/07/common-issues-faced-in-pcb-designing.html

I wonder what's more painful a class one death or a class two death?Class I versus Class II.

Are you sure you understand what electrical safety is about? Both Class I and Class II are to prevent nasty stuff. When implemented right death is practically impossible with either one let alone the already low risk of death by mains voltage.

It starts to become quite dangerous with high voltage high current installations but then personnel is both well trained and well aware. Therefor safer installations too.

It starts to become quite dangerous with high voltage high current installations but then personnel is both well trained and well aware. Therefor safer installations too.

Last edited:

Relax JP I am just pulling your legs.

I'm frequently testet in all this. In fact from north to south in Germany you will find specific electrical installations in hospitals public buildings and Airports with my inspection sticker on them.

I'm frequently testet in all this. In fact from north to south in Germany you will find specific electrical installations in hospitals public buildings and Airports with my inspection sticker on them.

As you know in private I am. Love those test setups with minimal safety and full accessibility. Fortunately I have only blown 2 pairs of bass speakers the last 20 years. On my horn setup I play it save though.

What do you mean ?You know what is said about volume potentiometers and their protective features

An "open" power amplifier with electronically controlled volume of a source can burn woofers if unattended stuff just decides to play content. The amplifier will amplify anything that it sees at its inputs, noise, hum, brownouts (!!!), HF/RF, wild content of a streamer ... at maximum gain/volume. With a volume/input level control at the power amplifier one can limit maximum volume to a loud but not damaging volume level thereby protecting the valuable loudspeakers regardless of what the source decides. One learns this normally and definitely at the first pair of burned woofers. Also to never leave (DIY/test/opened) stuff powered on unattended.

Volume control in power amplifiers is a kind of protection just like loudspeaker DC protection is. Effective, low cost, high gains so the opposite of audio druid methods.

Volume control in power amplifiers is a kind of protection just like loudspeaker DC protection is. Effective, low cost, high gains so the opposite of audio druid methods.

Last edited:

Haven't had volume control in my amps since about 20 years. If I ever land on a permanent installation I will limit the max volume with fixed resistor values and do the controlling via my Wiim Ultra. On most modern sources there is the option to always fall back to a minimal loudness on a source change or power up.

Fixed resistors are the same of course but less flexible. Since I sometimes repair the defective stuff of deniers I give the tip to not trust active electronics and software. Always build hardware safety in. Some take high risks and get away with speedy sloppy never finished work but many don’t. A bit like smoking and smokers remarks. Statistics.

There are also not many valid reasons to skip/omit/remove for instance safety and protection.

Same goes for shielding, rigid mounting/construction of stuff and overall quality of design/assembly. Quality always pays off, also in pride of own work.

There are also not many valid reasons to skip/omit/remove for instance safety and protection.

Same goes for shielding, rigid mounting/construction of stuff and overall quality of design/assembly. Quality always pays off, also in pride of own work.

Last edited:

Coming back to the original problem.

The protection relay circuit only works as a delayed speaker turn on as far as I can see.

There is only AC from the transformer and the output wires from the LM4780 going to it. No other pin of the chip is is connected to the relay circuit. Since the amp plays cleanly when I bridge the relay the chip can not be in any fault mode.

Unless there is some logic circuitry underneath the relay board that senses problems on the output of the lm4780 I can see no reason that the change or omission of the pot should cause the relay to switch off.

I can only think of a coincidence between the faulty relay and my doings.

The protection relay circuit only works as a delayed speaker turn on as far as I can see.

There is only AC from the transformer and the output wires from the LM4780 going to it. No other pin of the chip is is connected to the relay circuit. Since the amp plays cleanly when I bridge the relay the chip can not be in any fault mode.

Unless there is some logic circuitry underneath the relay board that senses problems on the output of the lm4780 I can see no reason that the change or omission of the pot should cause the relay to switch off.

I can only think of a coincidence between the faulty relay and my doings.

I must admit that you are absolutely right for 90% of the people on here.Fixed resistors are the same of course but less flexible. Since I sometimes repair the defective stuff of deniers I give the tip to not trust active electronics and software. Always build hardware safety in. Some take high risks and get away with speedy sloppy never finished work but many don’t. A bit like smoking and smokers remarks. Statistics.

There are also not many valid reasons to skip/omit/remove for instance safety and protection.

Same goes for shielding, rigid mounting/construction of stuff and overall quality of design/assembly. Quality always pays off, also in pride of own work.

In my case I love comparing components such as coupling caps, pots (yes them too), discreete opamps, etc... That's just to cumbersome if everything is encased.

And you are right this amp is not an example of good engineering and I never thought I would go back to trying a Chip amp but I'm glad I did.

For 220 Euro I got a 10mm machined front plate, all aluminum chassis and a decent transformer. I couldn't loose even if the amp sounded bad.

It has a nice form factor and sounds way better than any Chip amp I tried in the past.

- Home

- Amplifiers

- Chip Amps

- LM4780 stopped working