Hi E,eketehe said:the LM1875 isolated by mica and rubber paste, I tought tht was safe enough. i also always touch the heatsink for heat test.

well,Tks Daniel,

this also new for me, i need to check this.

can you kindly adv what is the TF and the T chips ?

do you have any exposed conductive parts? (yes?).

These must be connected to Safety Earth.

do you have any exposed conductive parts? (yes?).

Hi andrew,

My real name is eka,

Tks your advs, sorry for i'm really a blind about this,

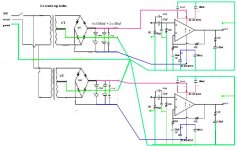

belows attached is my grounding network( in green colour ), which is the safety earth? the ground at a/c input or at the centered?

Attachments

I see in the photos, an exposed heatsink, and I also see metallic audio connectors leading to ground. This means that the amplifier could kill a person or pet unless the chip is electronically isolated from the heatsink. The "TF" chips should be safe; however, the "T" chips need an isolater (micas, insulating washers) kit. So, see if you can measure voltage between the exposed audio grounds and the exposed heatsink. Um, not with your fingers--use voltmeter. We like you and we want you to stay healthy. Sorry about the lecture, but its kind of scary.

Hi Daniel,

I have do the test. with the volt meter 🙂

Well, um, threre is no electrical load. so i touch all over the body 🙂

FYI, the case is plastic goods, all bolted to the plastic body, i set the centered grounding.

the heatsink is isolated from electrical load ( separated by micas, white rubber paste thing, and small plastic thing with center hole ).

Is it good to include the heatsink as gtounding network?

Maybe the correct question sud be : when the exposed parts will containing electrical load?

sorry for bothering with such maybe un-pro things, i'm concerned about the safety, and need to understand, so that your advs will highly appreciated. Thks

Okay, the \"T\" chips are the ones that need micas and insulating washers. Since you can\'t pick up voltage between the sheild of the RCA jack and the heatsink, then its okay.

3rd wire, and \"safety earth\" is also called \"house ground\" here in the U.S. To use it, you\'ll need to make a small device. This devices gives some resistance to \"lift\" the ground by 10R so that your amplifier doesn\'t prefer \"safety earth\" over its own power star ground.

Parts:

10 ohm, 5w or better wirewound resistor (like used in speakers).

pair of diodes

100nF (0.1uF) cap

Assembly:

Turn one of the diodes backwards to the other.

Put all of the parts in parallel with each other.

Connect safety earth on one side of this unit.

Connect power star ground (wood or plastic enclosure) or chassis ground (metal enclosure) to the other side of this unit.

Optional:

While not completely legal in every country, its possible to use only the 10 ohm resistor.

Bear in mind that safety earth (grounded) chassis is about the last step in amplifier assembly, because the #1 way to get shocked is grounding some part of your body. So, don\'t install safety earth until satisfied with the amplifier and ready to put it into service (without tinkering). 😉

3rd wire, and \"safety earth\" is also called \"house ground\" here in the U.S. To use it, you\'ll need to make a small device. This devices gives some resistance to \"lift\" the ground by 10R so that your amplifier doesn\'t prefer \"safety earth\" over its own power star ground.

Parts:

10 ohm, 5w or better wirewound resistor (like used in speakers).

pair of diodes

100nF (0.1uF) cap

Assembly:

Turn one of the diodes backwards to the other.

Put all of the parts in parallel with each other.

Connect safety earth on one side of this unit.

Connect power star ground (wood or plastic enclosure) or chassis ground (metal enclosure) to the other side of this unit.

Optional:

While not completely legal in every country, its possible to use only the 10 ohm resistor.

Bear in mind that safety earth (grounded) chassis is about the last step in amplifier assembly, because the #1 way to get shocked is grounding some part of your body. So, don\'t install safety earth until satisfied with the amplifier and ready to put it into service (without tinkering). 😉

3rd wire, and \"safety earth\" is also called \"house ground\" here in the U.S. To use it, you'll need to make a small device. This devices gives some resistance to \"lift\" the ground by 10R so that your amplifier doesn't prefer \"safety earth\" over its own power star ground.

done!

anyway, the safety seems to be the important thing, so i'm plans to move the amp and all exposed component to a small metal case. maybe i have to make a box design, for i really bored of just a square box.

For 22k nfb, 500R through 2k

i have try them all 😀, i'm back to the above oponent, they're just fit to my speakers, besides, i like the smooth acceleration. maybe retry others for the biger speakers.

Tks for all of your kindly assistance in advance,

Best Regards.

This was an absolutely fantastic discussion--very enjoyable.

I'm so glad that out of the several options I presented that you found some of them useful. I do always like to have options to try, and I'm grateful that you also gave me quite a few options to try as well. The heat versus decoupling cap size discussion was vitally helpful to my portable project. That really cooled it off.

Thank you.

I'm so glad that out of the several options I presented that you found some of them useful. I do always like to have options to try, and I'm grateful that you also gave me quite a few options to try as well. The heat versus decoupling cap size discussion was vitally helpful to my portable project. That really cooled it off.

Thank you.

danielwritesbac said:Bear in mind that safety earth (grounded) chassis is about the last step in amplifier assembly, because the #1 way to get shocked is grounding some part of your body. So, don\'t install safety earth until satisfied with the amplifier and ready to put it into service (without tinkering). 😉

Daniel,

Can you explain this? It sounds 100% wrong and extremely dangerous. I'm sure I'm misunderstanding you, but so might others.

The chassis safety earth must be connected BEFORE it is plugged in and turned on. My advice is to NEVER test an amp without the safety earth connected.

regards

Greg, thank you.

Daniel:

Almost anything you post is not based on any scientific or even common sense approach.

Your experiments are fine as long as you stop presenting them as technically correct.

However, we will not tolerate that you start posting (deliberate or not) unsafe and dangerous false information, bringing other non experienced DIY-ers in danger.

/Hugo

Daniel:

Almost anything you post is not based on any scientific or even common sense approach.

Your experiments are fine as long as you stop presenting them as technically correct.

However, we will not tolerate that you start posting (deliberate or not) unsafe and dangerous false information, bringing other non experienced DIY-ers in danger.

/Hugo

On a more constructive note, you will want to read this good article: http://sound.westhost.com/earthing.htm

Do I get one more point now? 🙂

/Hugo

Do I get one more point now? 🙂

/Hugo

Netlist said:Greg, thank you.

Daniel:

Almost anything you post is not based on any scientific or even common sense approach.

Your experiments are fine as long as you stop presenting them as technically correct.

However, we will not tolerate that you start posting (deliberate or not) unsafe and dangerous false information, bringing other non experienced DIY-ers in danger.

/Hugo

I need your help.

The laws of the United States DON'T allow grounding that increases the surface areas of available voltage reference points for electronics AT at test bench. Increasing the hazard, even under the guise of additional grounding, is a criminal act.

The problem is the unknown voltage of the exposed heatsink, which, if non-isolated, could make a large area of high voltage. With this in question, its illegal to advise creating an large grounded area nearby.

A GFCI, ground fault circuit interrupter is the only exception to the U.S. laws concerning ground planes.

I don't want anybody to get shocked. Now please notice a High Voltage Hazard posted somewhere above, when I spotted an LM1875 with an exposed heatsink, plus a reference (exposed grounded metal parts) and I immediately asked for it to be checked out with a voltmeter. . . before proceeding with anything else.

May I assume the safety check appropriate?

Fortunately, mica insulators were in place. However. . . Were the screws tight? Could the chip slip off the insulator at the test bench? There's too much risk to guess. That risk is illegal.

Do you think it would be better to say something like "Always ground the heatsink" along with "Always use an earth ground"? That would eliminate heatsink test bench hazard, and the build could start with earth grounding in place--if and only if large surfaces of voltage are eliminated.

What do you think?

Please tell me if I should always start with an "always ground the heatsink" approach for any future discussion. Either the heatsink is known to be grounded or a GFCI is in use, else it is illegal for a human to be near a large ground plane with voltage nearby.

What do you suggest?

Also please help me understand the attacks which have their basis on fuses/circuit breakers being sufficient protection for humans--which is dangerous, illegal, false, and. . . I shouldn't describe my feelings about finding half-baked excuses as the basis for attacks. A caution is necesary: Folks, what you're saying is illegal in the U.S. where only a GFCI is lawful sufficient protection for humans.

Hey, after the amplifiers are put inside the enclosure and put into service, then I do like to see the amplifiers grounded. And, they have to be grounded if chassis/knobs are metal.

But, I don't want grounded humans at test benches. That's a guaranteed shock. Don't do it! Perhaps our mains wiring is different in the U.S.?

But, I don't want grounded humans at test benches. That's a guaranteed shock. Don't do it! Perhaps our mains wiring is different in the U.S.?

You make a mix of the terms ground, earth, chassis, and differential current.

I understand this can be a complex matter and a confusing one but at least you should try reading on the subject. Here’s again another very useful link: http://en.wikipedia.org/wiki/Ground_(electricity)

/Hugo

I understand this can be a complex matter and a confusing one but at least you should try reading on the subject. Here’s again another very useful link: http://en.wikipedia.org/wiki/Ground_(electricity)

/Hugo

Thanks for the link. I'll go review terminology.

Ah, but could you do me the favor of pointing out which terms are mixed up? I really don't want a mistake of that sort.

Ah, but could you do me the favor of pointing out which terms are mixed up? I really don't want a mistake of that sort.

Daniel, what law or rule is that?

Federal

NEC (National Electric Code)

OSHA (Occupational Safety and Health Administration)

Federal

NEC (National Electric Code)

OSHA (Occupational Safety and Health Administration)

Oh, for test bench/workbench use? It has to do with the all three. OSHA was involved because of the electrocuted technicians put at risk by overzealous ESD protection requirements (mostly required by employers in accomodating insurance companies). At the time, the newly updated electrical code for, bathrooms (of all things) was used to win the battle, although there are several other laws pertaining to knowingly putting a human (or self) at risk (federal). The risk part, and proving it was most important. That didn't happen until GFCI devices became commonplace (NEC), and thus the risk, common knowledge.

The subject is different between a completed product and test bench work involving prototyping. Basically, when a risk is present, its important to avoid increasing that risk.

The example is a heatsink that may or may not contain voltage and a fastener that may or may not allow the insulator to slip (if the screw got loose on the LM1875 during handling). Therefore, it wasn't an appropriate timeframe to add a large ground plane at close proximity.

Now that its no longer being handled (jostled), and now that its back in service, I think its great that its grounded. I would like to see a "chassis ground" line running to that heatsink, just to make sure that it stays safe.

Thank you so much for bringing up this topic. It has brought a solution. From now on, I will add a wire to the zero volt chassis ground to all of my heatsinks. With it always in a known condition, then I can safely employ earth ground as described here http://sound.westhost.com/earthing.htm and recommended by the moderator.

Will that do?

The subject is different between a completed product and test bench work involving prototyping. Basically, when a risk is present, its important to avoid increasing that risk.

The example is a heatsink that may or may not contain voltage and a fastener that may or may not allow the insulator to slip (if the screw got loose on the LM1875 during handling). Therefore, it wasn't an appropriate timeframe to add a large ground plane at close proximity.

Now that its no longer being handled (jostled), and now that its back in service, I think its great that its grounded. I would like to see a "chassis ground" line running to that heatsink, just to make sure that it stays safe.

Thank you so much for bringing up this topic. It has brought a solution. From now on, I will add a wire to the zero volt chassis ground to all of my heatsinks. With it always in a known condition, then I can safely employ earth ground as described here http://sound.westhost.com/earthing.htm and recommended by the moderator.

Will that do?

Dear Sirs,

I'm still alive ,

Thanks for the guidance. so informative, hope can be followed by all starter for safety procedure/standart n save the living. .

Thks again, n Brgds

----------------

Eka

I'm still alive ,

Thanks for the guidance. so informative, hope can be followed by all starter for safety procedure/standart n save the living. .

Thks again, n Brgds

----------------

Eka

Hey, after the amplifiers are put inside the enclosure and put into service, then I do like to see the amplifiers grounded. And, they have to be grounded if chassis/knobs are metal.

Hi Daniel,

The chasis is not ready yet, i will show you when all ready. I left this project a while.

I'm so lucky to have this discussion, so i awared to check all related, also lucky that we already have 'safety earth in home electricity system, its connected to the buried abandoned water pump pipe. i don't know if it just suficient or not. i talk about and raise this topic to people around me. almost all people hv been known about this issue ( poor me!), but we never know about the law/procedure or something like that controling this. theres maybe a law, but we are not well announced. so, almost all of my neighbour dont have this safety earth.but public building, also my office already have this network.

The safety method in the mentioned ESP pages, is a bit same with what i do with 'the kitchen amp'. i thought thats for sound system purposes ( humming, hissing, noise ) never thought for safety.

10 ohm, 5w or better wirewound resistor (like used in speakers).

this sud be what people call 'Safety loop breaker circuit'. after all, do i still need this circuit? sorry for i maybe mixed up or just don't get any point

back to audio setting 😉 hope you still interest..

i replace the kitchen's amp with LM1875 ( i just can't quit of this . 😀 ). the last setting is fit to my small 2-way speakers, but this is my favourite setting for my '3-way all separated speaker system'. i tell you this is great and detaily in all range,perfect speed of woofers, but the most significant result is at human voice, they're soo identic 😀. the drivers: their only some old speakers and maybe cheap ( metal body tweeters, 5' mid-range and pair of switchable passive crossover all marked pioneer, and pair of 12' eas' or seas' or something made in japan ) their lovely singing in dynamic, you won't stare at the drivers for their existance is not matter anymore but check the music with the singer at center. see i have far from where i start this. my mission to have a better hearing just accomplished. i don't know what will i find if i runs the drivers project. this activity is kinda enjoyable or i'm just addicted.

i give +/- 32.3VDC the heat will be a problem,firstly i felt the amp runs in jeopardy ( jeopardy great! ) for i'm predict that the amp will be over heat, but then just OK. i use pair of extra large heatsink with thermostat bolt on connected to cooler fan will auto on at 65 celcius degree. i think their just stable under 65. only warm ( don't worry, i check the heatsink with my hand after all disconnected ).

you're correct about the thight of ic's srew, once i burn one the ic for its still connected with grounded heatsink. just known that the IC's body is ( - ) as same as the 3rd pin. so then after, i make sure to screwed the ic tight and check connection with ohmmeter.

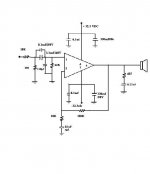

Pls check the diagram, this time i put the parts in PCB for more simple when seting. maybe you will try? see the input caps, this seting is able to present and awake the lowest string of contra basses or volcano sounds. so i plans to take off duty my subwoofer system, for its not necessary anymore.

Regards.

Eka

Attachments

- Status

- Not open for further replies.

- Home

- Amplifiers

- Chip Amps

- lm3886 electrical noise