Measuring rumble without disc is possible by using that Thorens "Rumpelmesskoppler" device, which pops up on ebay once a year. The Chinese should copy that thing 😎

http://www.diyaudio.com/forums/analogue-source/243656-measuring-rumble-2.html#post3658360

http://www.diyaudio.com/forums/analogue-source/243656-measuring-rumble-2.html#post3658360

It's much simpler. It literally is a piece of film with two terminals.

https://www.sparkfun.com/products/9196

There's links on that page to the datasheets and tech manual.

Thanks, having a quick read it looks like adding a load resistor is all the basics to pick up a signal via a scope. Need to read further to understand the best way to attach. Have you tried one stuck flat as opposed to bouncing in free space?

Looks a simple way to say fit with flying wires to the motor, chassis, bearing housing and armboard.

Whilst this wouldn't capture every variable it might help eliminate some ideas / point a direction to work on.

The strain gauge should be epoxied to what ever your measuring rather than double sided tape

Should make it more accurate overall.

There cheap enough

Regards

David

Should make it more accurate overall.

There cheap enough

Regards

David

Not sure if this piezo one works the same, data sheet shows it as mounting via its pins, or with a weight attached to damp its own resonance.

if it can be glued on it would be simpler if still generates an appropriate signal?

My line of thought so far for a challenge is.

1. Adapt the original chassis Somehow. Not everyone has access to machinery needed to make a quality replacement.

Or

2. Identify the peak frequency vibrations and find an active way to attenuate those alone.

While engineering these out is the best solution it appears it would be an involved/costly process. Im looking for simple but worthwhile improvement if it possibly exists. One most people could do.

if it can be glued on it would be simpler if still generates an appropriate signal?

My line of thought so far for a challenge is.

1. Adapt the original chassis Somehow. Not everyone has access to machinery needed to make a quality replacement.

Or

2. Identify the peak frequency vibrations and find an active way to attenuate those alone.

While engineering these out is the best solution it appears it would be an involved/costly process. Im looking for simple but worthwhile improvement if it possibly exists. One most people could do.

Nigel, I don't actually use the LP12 motor, I found the Project 18v motor to be superior and easier to drive.

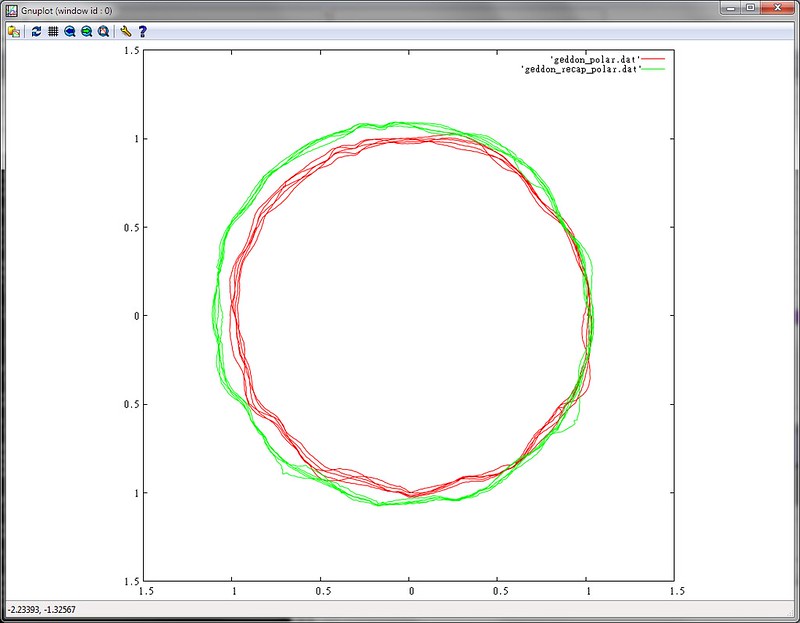

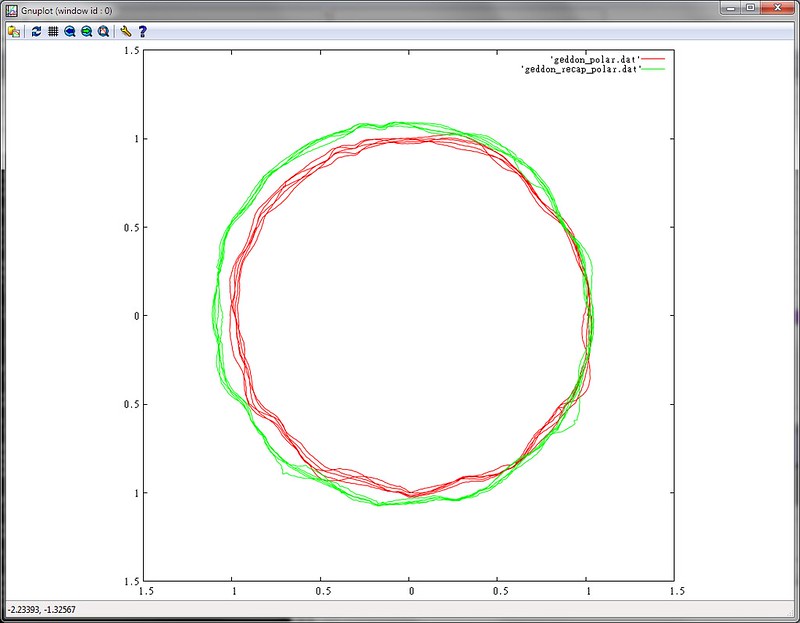

This is the graph with Linn motor and a Geddon style clone psu, just big transformer and common mode chokes.

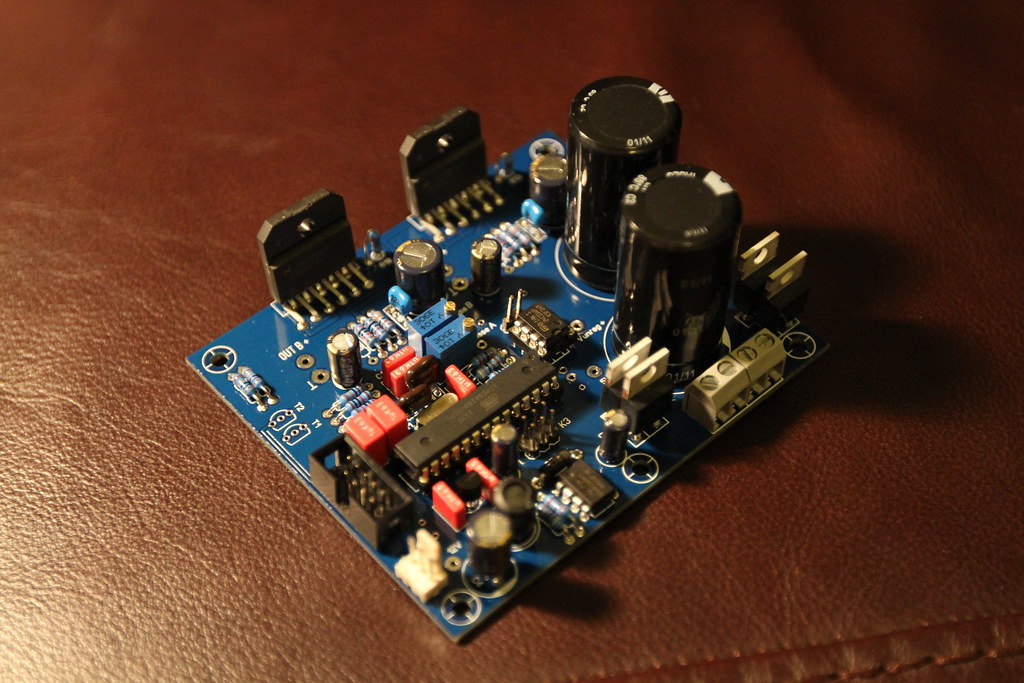

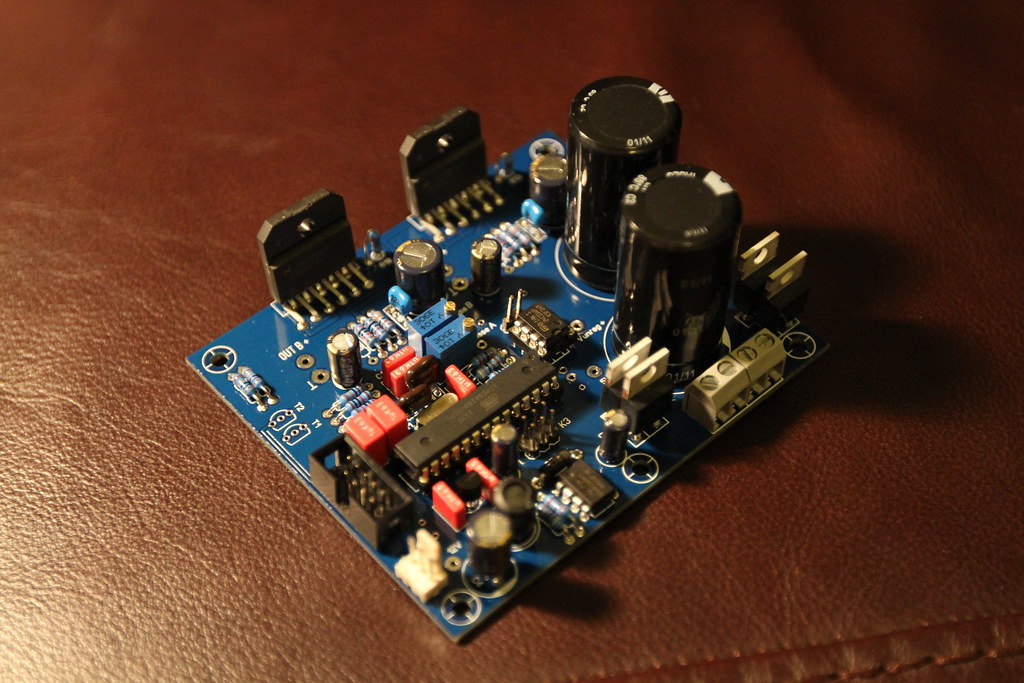

Here's the PSU i use now, Class A 38 watts, dual mono, adjustable everything, voltage, phase offset, frequency, etc.

I'm well aware of the Lenco and Garrard motors, far better built than most things today. Shaded pole and variable reluctance in some cases.

This is the graph with Linn motor and a Geddon style clone psu, just big transformer and common mode chokes.

Here's the PSU i use now, Class A 38 watts, dual mono, adjustable everything, voltage, phase offset, frequency, etc.

I'm well aware of the Lenco and Garrard motors, far better built than most things today. Shaded pole and variable reluctance in some cases.

Nice idea.

The majority of people will have the Valhalla+ Philips motor set up. The motor vibration is part of the way curent is taken by the motor. To extract that wave is easy to show. To anti phase cancel it is easy. To record the resulting wave is easy if CD. As each wave is identical, to control ahead of time should work. If an isoltaion transformer is used the wave could be fed into Valhalla RV1. Here is the difficult part. My hunch is the motor will draw the power as it feels best and not in co-opperation with the supplied waveform. What I didn't test is how the motor works on a squarewave. In theory not very differenently. What I do remember is there was more vibration. What I didn't test was torque. Here is a wild hope. The predistorted wave migh have more torque for a given peak voltage and a vibration advantage. That is it is the ideal shape.

The majority of people will have the Valhalla+ Philips motor set up. The motor vibration is part of the way curent is taken by the motor. To extract that wave is easy to show. To anti phase cancel it is easy. To record the resulting wave is easy if CD. As each wave is identical, to control ahead of time should work. If an isoltaion transformer is used the wave could be fed into Valhalla RV1. Here is the difficult part. My hunch is the motor will draw the power as it feels best and not in co-opperation with the supplied waveform. What I didn't test is how the motor works on a squarewave. In theory not very differenently. What I do remember is there was more vibration. What I didn't test was torque. Here is a wild hope. The predistorted wave migh have more torque for a given peak voltage and a vibration advantage. That is it is the ideal shape.

The motor will take what it needs. Which if you have swamped stylus drag with viscous coupling in the bearing, should be very consistent.

I like the idea of being able to play with the waveform shaping, that would be the icing on the cake. Though from what I hear and measure currently I'm already tilting at windmills.

At some point I'll try one of those external rotor papst motors, a friend has some nos ones.

I like the idea of being able to play with the waveform shaping, that would be the icing on the cake. Though from what I hear and measure currently I'm already tilting at windmills.

At some point I'll try one of those external rotor papst motors, a friend has some nos ones.

During my tests I felt sine gave lower vibration. I really wonder if that is true. Triangle might simply be giving more power. The fourier series for square is F + 1/3 f3 + 1/5 f5 + 1/7 f7...... and triangle F + 1/9 f3 + 1/25 f5 + 1/48 f7...... and ideal sine F + 0. The maths show a triangle is a simple filtering of a square wave. The LP12 motor draws power as if a triangle wave. This seems locked to the resonant frequency of the motor which is about 80 Hz if I remember rightly. That resonant frequency is exactly suggested by stepper motor calculations if pretending it was one.

If you want fun with a stepper as a synchronous this almost can rival the Linn motor. About 4.5 VAC 50Hz suits it. 10 uF ( 8 uF ? ) is near to what the phase shift cap will need to be. It is a very powerful motor and nicely made. Althhough pushing the voltage a bit I got it to rotate between 12 to 90 Hz. The low end I suspect was as there was no load. I think I found by using 37 Hz I could have 78 RPM without a different pulley. From memory 37 Hz was possible. The Linn motor will not do this. A sine -cosine oscillators would be best. TDA 2030 drove it very well. If two are used only a small clip on heat sink needed ( 21 c/w ). A state variable filfter is a good choice. TL074 a good chip. It has both sine and cosine outputs. You don't need the 91K and 10 K 1/3 harmonic null for a turntable. 10 nF COG and about 315 K for 50 Hz. The 1N4148 diodes used as limiters are a bit heat sensetive so keep them at room temperture. They used a 22 K resitor between them to slightly reduce distortion.

BTW. Measure the current at the ideal 50 Hz ( AC current, suggested 4.5 V AC ). If at 90 Hz it is fine to increase voltage to regain that current reading.

2 Phase Bipolar Stepper Motor 12v | Rapid Online

TDA2030 Audio Power Amplifier Board Amp Kit for DIY | eBay

https://books.google.co.uk/books?id...CFgQ6AEwCQ#v=onepage&q=svf oscillator&f=false

If you want fun with a stepper as a synchronous this almost can rival the Linn motor. About 4.5 VAC 50Hz suits it. 10 uF ( 8 uF ? ) is near to what the phase shift cap will need to be. It is a very powerful motor and nicely made. Althhough pushing the voltage a bit I got it to rotate between 12 to 90 Hz. The low end I suspect was as there was no load. I think I found by using 37 Hz I could have 78 RPM without a different pulley. From memory 37 Hz was possible. The Linn motor will not do this. A sine -cosine oscillators would be best. TDA 2030 drove it very well. If two are used only a small clip on heat sink needed ( 21 c/w ). A state variable filfter is a good choice. TL074 a good chip. It has both sine and cosine outputs. You don't need the 91K and 10 K 1/3 harmonic null for a turntable. 10 nF COG and about 315 K for 50 Hz. The 1N4148 diodes used as limiters are a bit heat sensetive so keep them at room temperture. They used a 22 K resitor between them to slightly reduce distortion.

BTW. Measure the current at the ideal 50 Hz ( AC current, suggested 4.5 V AC ). If at 90 Hz it is fine to increase voltage to regain that current reading.

2 Phase Bipolar Stepper Motor 12v | Rapid Online

TDA2030 Audio Power Amplifier Board Amp Kit for DIY | eBay

https://books.google.co.uk/books?id...CFgQ6AEwCQ#v=onepage&q=svf oscillator&f=false

At a bake off a few years ago Sharif brought his Phonosophie 3 deck, this uses a stepper motor and provided very tight timing, despite a dirt cheap capacitor shift psu....

I might give that stepper a go for shirts and giggles. I had a load of lp12 pulleys anchored up last year for motor testing.

I might give that stepper a go for shirts and giggles. I had a load of lp12 pulleys anchored up last year for motor testing.

Please do. Any help I can give I will. I like my TDA 2030 PCB. It even has a voltage control or volume. The SVF is a tested design. Is LP12 3 mm shaft ?

Here it is on first test. The 9 V 6VA gives near 12 V rms at 242 V lightly loaded. This voltage is a bit high. The cap slightly wrong.

http://www.ti.com/sc/docs/apps/msp/journal/aug2000/aug_07.pdf

Here is a very simple quadrature oscillator ( P36 ). As far as I can see make 2.5 V = ground and use any +/- PSU. If 2 x TDA 2030 uses +/- 15 V then +/- 9 V from a filtered section of that PSU is fine. TL072 should be ideal. TL074 if wanting to add a simple active filter and buffer.

I haven't built the circuit and can not say if using 315 K will give circa 50 Hz. The gain might require the capacitor is changed. If so 318 nF.

It is very unusual that a distortion of 0.9/0.5% is possible when so simple. It might need limiter diodes in practice. For a stepper/synchronous 1% THD is more than OK. For a Garrard or Lenco 20 dB better is the goal.

Most polyester caps will be good enough on stability. COG/NPO at 30 ppm equals most crystals. In fact if the resistor is the right sort they can be better, often the standard 50 ppm type is fine. A 50 Hz Wien bridge I made was good for 6 seconds a day using polystyrene ( 100 ppm + 50 ppm Plilips MRS 25, 2 x 33 nF ,4 total, 66 nF per arm , 47 K + 5 K trimmer to one side, RA 53 thermistor + 680 R, TL071 ) running as a clock. IF COG it would have been less.

https://www.calvin.edu/~pribeiro/courses/engr332/Handouts/oscillators.pdf

P18. Slightly more info.

Here is a very simple quadrature oscillator ( P36 ). As far as I can see make 2.5 V = ground and use any +/- PSU. If 2 x TDA 2030 uses +/- 15 V then +/- 9 V from a filtered section of that PSU is fine. TL072 should be ideal. TL074 if wanting to add a simple active filter and buffer.

I haven't built the circuit and can not say if using 315 K will give circa 50 Hz. The gain might require the capacitor is changed. If so 318 nF.

It is very unusual that a distortion of 0.9/0.5% is possible when so simple. It might need limiter diodes in practice. For a stepper/synchronous 1% THD is more than OK. For a Garrard or Lenco 20 dB better is the goal.

Most polyester caps will be good enough on stability. COG/NPO at 30 ppm equals most crystals. In fact if the resistor is the right sort they can be better, often the standard 50 ppm type is fine. A 50 Hz Wien bridge I made was good for 6 seconds a day using polystyrene ( 100 ppm + 50 ppm Plilips MRS 25, 2 x 33 nF ,4 total, 66 nF per arm , 47 K + 5 K trimmer to one side, RA 53 thermistor + 680 R, TL071 ) running as a clock. IF COG it would have been less.

https://www.calvin.edu/~pribeiro/courses/engr332/Handouts/oscillators.pdf

P18. Slightly more info.

Last edited:

At a bake off a few years ago Sharif brought his Phonosophie 3 deck, this uses a stepper motor and provided very tight timing, despite a dirt cheap capacitor shift psu....

I might give that stepper a go for shirts and giggles. I had a load of lp12 pulleys anchored up last year for motor testing.

Hi Simon the Phonosophie P3 uses a quadrature oscillator running a 25hz for 33rpm and the stepper motor is fitted with a larger pulley.

Sharif.

Although I see no point the 2 x TDA 2030 could be made into the quadrature oscillator. With the kit I show I think that would make life more difficult.

Mains distortion at my house is 3% to 5 % and very nasty clipped top wave. I would say subjectively worse than the lumped figure. When absorbed into the motor it can not be easilly detected. The motor has a self filtering action. This means a very simple capacitor shift version should be mostly about voltage. The 1% THD of the Ti version must be 1/3 rd harmonic only ( I ignor 2nd harmonic as it is almost of no interest when this low, motors don't mind it ).

Mains distortion at my house is 3% to 5 % and very nasty clipped top wave. I would say subjectively worse than the lumped figure. When absorbed into the motor it can not be easilly detected. The motor has a self filtering action. This means a very simple capacitor shift version should be mostly about voltage. The 1% THD of the Ti version must be 1/3 rd harmonic only ( I ignor 2nd harmonic as it is almost of no interest when this low, motors don't mind it ).

The Phonosophie P3 which I had was better than any of the LP12 variations I tried (Valhalla, Armagheddon, flipped top plate), regarding resolution, timing and bass structures.

The only area where the LP12 excelled was the warmish golden midrange which the LP12 shares with the Garrard. I always liked what the LP12 did with voices, but at the same time I hated what it did with timing.

regards, Hartmut

The only area where the LP12 excelled was the warmish golden midrange which the LP12 shares with the Garrard. I always liked what the LP12 did with voices, but at the same time I hated what it did with timing.

regards, Hartmut

LP12 sound a bit like good FM radio. Slightly drunk is about right.

Recently my digital radio starts to sound slightly better than FM. This should be true as since 1972 BBC has been a digital service not unlike Nicam. The exact technical side is not what is being said. I have always thought the BBC sounded better than any digital we might be offered. That is a big surprise seeing the 1972 starting point. If making a similar statement about turntables I would say very few make the transition where the LP12 seems yesterdays product. Most of the Verdier clones always sound very odd to me ( 80 % these days ? ). The Verdier was OK. The Technics 1210 is very OK as the starting point of a better turntable. To please someone who worked for me we adapted a Garrard 401 platter to fit a 1210 then housed it in wood. I was a very big surprise. This was with a Lyra pick up and a home made arm.

Recently my digital radio starts to sound slightly better than FM. This should be true as since 1972 BBC has been a digital service not unlike Nicam. The exact technical side is not what is being said. I have always thought the BBC sounded better than any digital we might be offered. That is a big surprise seeing the 1972 starting point. If making a similar statement about turntables I would say very few make the transition where the LP12 seems yesterdays product. Most of the Verdier clones always sound very odd to me ( 80 % these days ? ). The Verdier was OK. The Technics 1210 is very OK as the starting point of a better turntable. To please someone who worked for me we adapted a Garrard 401 platter to fit a 1210 then housed it in wood. I was a very big surprise. This was with a Lyra pick up and a home made arm.

An idea you might not have thought of. If the cheap stepper motor, two can be mechanically joined so as to add or subtract vibration. A simple sleeve coupling to suspend the drone motor under the drive motor. The drone rotates without any coupling except the sleeve. By rotating the motor in the sleeve the vibration null point can be found. There might even be a small amount of contra-rotational force ( try both as reversing is easy ). Although not as good as proper coupling it might be a nice bonus keeping the casework vibration to a minimum.

Nigel

Do you remember if it was Rocksan or? That allowed the motor to slightly rotate (with stops for start up) to absorb vibration and aid stability of rotation?

Your last post made me think of it

Regards

David

Do you remember if it was Rocksan or? That allowed the motor to slightly rotate (with stops for start up) to absorb vibration and aid stability of rotation?

Your last post made me think of it

Regards

David

- Home

- Source & Line

- Analogue Source

- Linn Sondek DIY mods that work