That might not be out of the question depending on what the overall enclosure dimensions ended up being.

Qts is really low on that MCM spec. Comments say it works well in vented boxes. Cheap and durable - heavy at 3.8kg. Voice coil height 24mm, gap height 8mm. One unit might do what you want with 3116 - ? BFM's T18 or Autotuba would not be real heavy - but for outdoors I rather XPS foam board.

http://www.farnell.com/datasheets/2329567.pdf

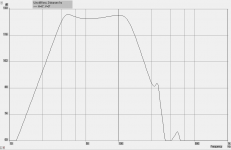

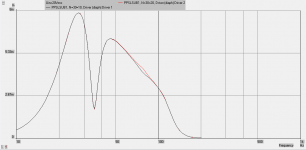

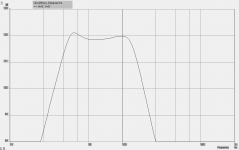

Here's that MCM (bold) in Bill's "T18". - the lighter trace is a Table Tuba

http://www.farnell.com/datasheets/2329567.pdf

Here's that MCM (bold) in Bill's "T18". - the lighter trace is a Table Tuba

Thanks Freddi! What kind of box are you modeling in hornresp? Is that a 4th order bandpass? I'm trying to figure out how to do more of this stuff so I don't have to ask so many questions about box volume, etc. Seems like Hornresp is the default for free software but I am really liking Basta. It doesn't offer enclosure fabrication measurements like some of the online calculators but it does a lot more enclosure types and the graphical overlays are really nice.

Qts is really low on that MCM spec. Comments say it works well in vented boxes. Cheap and durable - heavy at 3.8kg. Voice coil height 24mm, gap height 8mm. One unit might do what you want with 3116 - ? BFM's T18 or Autotuba would not be real heavy - but for outdoors I rather XPS foam board.

http://www.farnell.com/datasheets/2329567.pdf

Here's that MCM (bold) in Bill's "T18". - the lighter trace is a Table Tuba

I've bought and measured about twelve of these over the last sixteen years, and they generally measure like this:

https://www.diyaudio.com/forums/subwoofers/37908-mcm-55-2421-parameters.html#post437592

The specs on the MCM website are totally wrong.

But they're a great little sub, arguably the best driver for horn loaded enclosures that costs less than $100. For $50 each they'd be a bargain, for $25 they're a steal. I don't understand how they can even ship them for $25 each.

your MCMs looked better than spec with regards to suitability for vented boxes. Many of the drivers I've bought measure with higher qts than factory spec - but not all. Audio Nirvana's AN8 pair Fs shifted a half octave up from when I first got them. Two sets of Peavey are abnormally stiff and a half octave high too.

Could a more compact version of this work with the Dayton 6.5 DCS165-4? I know it will be less output-capable compared to the 8" MCMs, but I have a powerful dislike for foam-surrounded-speakers (because it is not a matter of if they will fail, only when they will fail, from embrittled foam) and the Dayton is compact and affordable. I am very intrigued by this slot loaded series 6th order configuration but it's way beyond my current skills to undertake design of it. Thanks

Dayton Audio DCS165-4 6-1/2" Classic Subwoofer 4 Ohm

or, if the 6.5 is pushing so small as to get into absurdly diminishing returns, maybe its 8" sibling?

Dayton Audio DCS205-4 8" Classic Subwoofer 4 Ohm

Dayton Audio DCS165-4 6-1/2" Classic Subwoofer 4 Ohm

or, if the 6.5 is pushing so small as to get into absurdly diminishing returns, maybe its 8" sibling?

Dayton Audio DCS205-4 8" Classic Subwoofer 4 Ohm

Last edited:

mcm 55-2421

Did anyone model tb46's short design for the PPSL using 55-2421? I've just got deliveries of the drivers and 6 sheets of xps foam and can't wait to start cutting

Did anyone model tb46's short design for the PPSL using 55-2421? I've just got deliveries of the drivers and 6 sheets of xps foam and can't wait to start cutting

Theres a group of guys messing with that driver for fun on a FB group. I there was more activity it was intended to be a big sharing of seperate creations outta fun and to study a variety of ways to use any driver with anyone else's ideas...

Quarter wave theory

Benjermin dodson.

Quarter wave theory

Benjermin dodson.

I've had a go at modelling MCM 55-2421in Akabak using Zaph's measured specs and tb46's short model dimensions - the short and long models looks identical in performance. 20-22v gets to xmax. First time using Akabak so not 100% confident in what I've done with xrk971's code.

The graph below models the original vent size - the short model smooths out the 200hz peak

The graph below models the original vent size - the short model smooths out the 200hz peak

Code:

System 'S1'

| Push Pull Slot Loaded Subwoofer

| PPSLSUB1

| July 16, 2014

| by xrk971 / modified bigbrowncow 2021 [but first time using Akabak!]

| with dual MCM 55-2421 8 in drivers

Def_Const

{

Q=0.707;

Speaker_pos=5.0*0.0254; | Height of centerline of exit port above floor

Width=41.75*0.0254; | Width of cabinet external

Height=63.9*0.0254; | Height of cabinet external, 24 in long chamber ea + slot

Depth=16.5*0.0254; | Depth of cabinet 14 in deep internal

Dist_wall=5000*0.0254; | Distance from wall

| ****

Backchamber_vol=37.0*0.001; | 37 L gives 12.5in L x 10in H x 9in deep

Slot_width=4.75*0.0254; | needs to wide enough to fit driver in push-pull

Slot_height=10.0*0.025; | height accounts for bracing reduction in CSA

Slot_length=10.0*0.0254; | lenght of two ducts that form slot deep enough to house 18 in driver

| *** dual rear resistance vents

Vent_width=0.75*0.0254;

Vent_height=10.0*0.0254;

Vent_length=23.0*0.0254; | Code bodged below to have two vents merging into one

}

System 'PPSLSUB1'

Def_Driver 'MCM55-2421' | Bateman/Zaph specs

SD=208.7cm2 |Piston

fs=30.95Hz

Mms=59.8g

Qms=12.2863

Qes=0.2365

Re=3.4ohm

Le=2.42mH

Vas=23.88L

| OFF

Filter 'High Pass' | 4th order Butterworth -24dB/oct

fo=27Hz vo=1.0

{b4=1;

a4=1; a3=2.613126; a2=3.414214; a1=2.613126; a0=1; }

|OFF

Filter 'LowPass' |Lowpass filter - 48dB Butterworth (change 'fo=***' and refresh for changes)

fo=120Hz vo=1

{b0=1;

a8=1; a7=5.125831; a6=13.137071; a5=21.846151; a4=25.688356; a3=21.846151; a2=13.137071; a1=5.125831; a0=1; }

|OFF

| Speaker placed in corner with driver at Driver_pos above floor in corner

Def_Reflector BottomCorner

Bottom={Speaker_pos} Left=17in Right=17in

HAngle=0 VAngle=0

OFF

| Speaker with driver at Driver_pos above floor Dist_wall away from wall

Def_Reflector HorizEdge

Bottom={Speaker_pos} Top={Depth + Dist_wall}

HAngle=0 VAngle=0

Enclosure 'Back chamber 1' Node=10

Vb={Backchamber_vol/2} Qb/fo={Q} Lb=10in

Enclosure 'Back chamber 2' Node=20

Vb={Backchamber_vol/2} Qb/fo={Q} Lb=10in

Driver Def='MCM55-2421' 'Driver 1'

Node=1=0=30=10

Driver Def='MCM55-2421' 'Driver 2' | driver 2 is reverse mounted with phase reversed

Node=1=0=30=20

Duct 'D3' Node=70=30 | rear half of output slot

WD={Slot_width} HD={Slot_height} Len={Slot_length/2}

Duct 'D4 Slot' Node=30=32 | front half of output slot

WD={Slot_width} HD={Slot_height} Len={Slot_length/2}

Duct 'D1 Vent' Node=10=31 | resistance vent 1 leading to mixed vent

WD={Vent_width} HD={Vent_height} Len={3.0*0.0254}

Duct 'D2 Vent' Node=20=31 | resistance vent 2 leading to mixed vent

WD={Vent_width} HD={Vent_height} Len={3.0*0.0254}

Duct 'D7 Vent' Node=31=70 | mixed vent from vent 1 and vent 2 leading to slot

WD={2*Vent_width} HD={Vent_height} Len={Vent_length - 3.0*0.0254}

Radiator 'Vent_rad'

Def='D4 Slot'

Node=32

x=0 y=0 z=0

HAngle=0 VAngle=0

WEdge={Width/2} Hedge={Height/2}

ReflectionAttachments

Last edited:

Well it's built and it sounds fantastic.😀

I've optimised the layout to use European 1000x600x20 xps sheets. Used Sticks Like Sh*t Turbo to glue it together and powering each speaker through a channel of a Nobsound NS-10G (TPA3116).

I'm pretty sure it won't take 120dB though without covering everything in pink foam snow.

I've optimised the layout to use European 1000x600x20 xps sheets. Used Sticks Like Sh*t Turbo to glue it together and powering each speaker through a channel of a Nobsound NS-10G (TPA3116).

I'm pretty sure it won't take 120dB though without covering everything in pink foam snow.

Attachments

Very cool bigbrowncow,

i think i found the same thing out...foamboard is ok for small, relatively weaker subs, but with big subs that can crank it falls apart...both sonically and literally.

i think i found the same thing out...foamboard is ok for small, relatively weaker subs, but with big subs that can crank it falls apart...both sonically and literally.

Well it's built and it sounds fantastic.😀

Where are the pics???

Very cool bigbrowncow,

i think i found the same thing out...foamboard is ok for small, relatively weaker subs, but with big subs that can crank it falls apart...both sonically and literally.

What do you think regarding the little Tang band w5 - 1138 pair? or not?

Where are the pics???

Well it doesn't look like much.

That is a deflector from a Ron Clarke Austin on top to stop some of the panel vibrations

I've resolved to rebuild the sub. The way I did the bracing is completely inadequate - just a few random bits of foam here and there. I've seen many more pictures of sub bracing and will build it more robustly.

So onto the pics that matter.

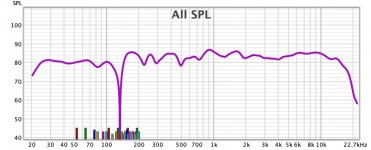

Here is the the in-room response (room is 2.2mx2.3mx3.2m) unequalised.

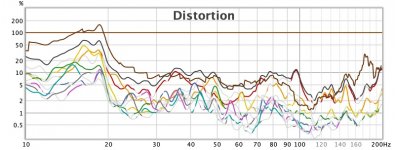

The distortion is pretty high which is unsurprising given the box is bouncing around and rattling a fair amount

Here is there response in room response equalised with two tc9fd nautaloss speakers

Attachments

Thanks for the data. Perhaps THD would be nicer if tested at lower loudness.

You say, "I've resolved to rebuild the sub. The way I did the bracing is completely inadequate - just a few random bits of foam here and there". With all the aggressive debates about (1) bracing and wall vibration and (2) stuffing, it would be truly helpful if you could do before-and-after tests as you modify the sub.

You'd have to establish exactly the drive signal, mark the floor with masking tape where the speaker and the mic were placed, etc.

You say, "I've resolved to rebuild the sub. The way I did the bracing is completely inadequate - just a few random bits of foam here and there". With all the aggressive debates about (1) bracing and wall vibration and (2) stuffing, it would be truly helpful if you could do before-and-after tests as you modify the sub.

You'd have to establish exactly the drive signal, mark the floor with masking tape where the speaker and the mic were placed, etc.

A good way to find out if bracing is going to make any appreciable difference in before / after testing is to first measure the sub, then measure it again while you're sitting on it. Unless you're a very small person, your body weight should serve to damp vibrations quite a bit.

A good way to find out if bracing is going to make any appreciable difference in before / after testing is to first measure the sub, then measure it again while you're sitting on it. Unless you're a very small person, your body weight should serve to damp vibrations quite a bit.

Even then i want to strap it to the side of the fireplace! Or hug and sit on it forever! Its never enough. Its so hard! 🙁 But if horizontally opposed drivers... then there's some hope it seems. Then i can even put foam antifatigue mat under the sub and isolate it from the floor thats still making buzzzzzzzzes..

If i run all thread through in the 3 fold cab i can crank down on individual nuts and jam nuts to preload all walls as individuals... the its only a matter of turns on a fine thread that creates

More than ‘rigid’ would.

oddly enough , this is exactky how i tune suspensions on triple rate spiring coil over shocks and the valve shims that damp the piston oil flow ate staggered in thickness too. Not tapered or smoothed.. ‘flutter stack’ is the term and its key to going fast on very bad terrain while being smmooth and handling well on very smmooth simultaneously

Last edited:

Well Booger weldz, I too have a lot of experience with tuning shocks, like motorcycle front ends. Great fun.

Can't draw inferences about buzzing of a speaker cabinet on a floor. A rubber mat just lets the cab vibrate as it pleases in free space. While many argue about it, I think best is weighting it to floor to stop it shaking so any command to the voice coil becomes sound to your ear. because the driver frame is stationary in space.

Clever suggestion from Brian Steele. But no way to interpret what you mic picks up with you putting your body in different locations in the room between tests and other effects of sitting on your cab.

Do work scientifically - one variable at a time and post results.

Can't draw inferences about buzzing of a speaker cabinet on a floor. A rubber mat just lets the cab vibrate as it pleases in free space. While many argue about it, I think best is weighting it to floor to stop it shaking so any command to the voice coil becomes sound to your ear. because the driver frame is stationary in space.

Clever suggestion from Brian Steele. But no way to interpret what you mic picks up with you putting your body in different locations in the room between tests and other effects of sitting on your cab.

Do work scientifically - one variable at a time and post results.

- Home

- Loudspeakers

- Subwoofers

- Light as Air Slot Loaded Band Pass Sub