leiade,

Great idea, I get really inspired. One idiot quesion: do you really need fluid to float? If you add the favorite Dice bearing (ruby ball/ teflon thrust plate) to your design, you are there! What this fluid for? If the bearing takes the axial load, and your rubber wheels hold the platter in radial direction, your do not need nothing more.

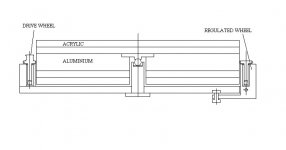

The bearing should be placed at the platter CG plane, so the wheels. Only three wheels needed to define the platter position. Two of them are stable, one of adjustable spring load (rubber pad, spring, whatever). The platter sandwiched from two layers of acrylic with 1" aluminium platter in the middle, which makes the really inertial gyro, and the side wheels make it stable. If the platter tilts, the wheels pressure increases, since the wheels climb on the larger diameter, so the platter tends get back to equilibrum.

Comments?

Great idea, I get really inspired. One idiot quesion: do you really need fluid to float? If you add the favorite Dice bearing (ruby ball/ teflon thrust plate) to your design, you are there! What this fluid for? If the bearing takes the axial load, and your rubber wheels hold the platter in radial direction, your do not need nothing more.

The bearing should be placed at the platter CG plane, so the wheels. Only three wheels needed to define the platter position. Two of them are stable, one of adjustable spring load (rubber pad, spring, whatever). The platter sandwiched from two layers of acrylic with 1" aluminium platter in the middle, which makes the really inertial gyro, and the side wheels make it stable. If the platter tilts, the wheels pressure increases, since the wheels climb on the larger diameter, so the platter tends get back to equilibrum.

Comments?

Attachments

The DIYTT

Ok! it may be good but my idea was to minimize the center sleeve bearing with the ball, it will maybe rumble a lot I don't know but...Ok your drawing looks good. 😉

Ok! it may be good but my idea was to minimize the center sleeve bearing with the ball, it will maybe rumble a lot I don't know but...Ok your drawing looks good. 😉

The ruby??

Why use a ruby ball when there is ceramic balls from Sweden in the market.http://www.skfsport.com/ceramic.htm

Those ceramic balls are a high tech product I think you can find them on the SKF web site.🙂http://www.skfsport.com/friction.htm

http://www.industrialtechnology.co.uk/skf1.htm

N.B. Just use the ceramic balls NOT the ballbearing.🙂

Why use a ruby ball when there is ceramic balls from Sweden in the market.http://www.skfsport.com/ceramic.htm

Those ceramic balls are a high tech product I think you can find them on the SKF web site.🙂http://www.skfsport.com/friction.htm

http://www.industrialtechnology.co.uk/skf1.htm

N.B. Just use the ceramic balls NOT the ballbearing.🙂

Dice: the spun cast metal ribbon is made by VAC. http://www.vacuumschmelze.de/home_vac.nsf/$frameset/Bottom_Amorphe look for vitrovac.

PedroPO: I actually played around some time with the idea of a magnetically levitated copper platter, the field also acting as drive. Sadly the currents, frequencies and power involved did not make it a good idea.

Illusus: these are probably old magneto-optical disks if the layer is between glass. Old HD platters are mostly metal with a brownish layer on the outside. Wish I could get my hands on those!!

PedroPO: I actually played around some time with the idea of a magnetically levitated copper platter, the field also acting as drive. Sadly the currents, frequencies and power involved did not make it a good idea.

Illusus: these are probably old magneto-optical disks if the layer is between glass. Old HD platters are mostly metal with a brownish layer on the outside. Wish I could get my hands on those!!

Illusus

OK Illusus, one more cool thing I like: melting vinyl to make the platter.

I had imagined 2 ways to do this, a pan suspended in a water bath "bain marie" But that only get you up to 100 C which probably isn't enough, but worth trying.

2nd idea: cheap teflon pan on top of or inside a thick aluminum pan or plate over the range.

3rd : put the pieces in a microwave in a non metallic container and slowly increase the power and duration- this might actually be the best, safest and least messy unless an air pocket explodes-then divorce city!!!

I think you want to cut up the old records (Donny & Marie, Kenny G christmas album, etc.) with metal snips. I also have heard that the labels are actually melted into the vinyl, so probably it is impossible to get them off. So I guess you lose the vinyl under the labels. Also very important -don't stir the molten vinyl if possible-you will get more air bubbles, which are going to be a big problem. I think keeping the vinyl hot in the mold for a few hours whould also help rid it of bubbles-if the vinyl is pretty runny!

Arrow shafts are a great under utilized resource. they also have theaded fittings that fit perfectly in the ends of the tube, so it is easy to attach things! The most Highly tempered aluminum or Carbon fiber. Easton got it's start doing arrow shafts I think.

You will probably have to have the platter machined to make it perfect, but if all they have to do is turn the rim, it should be pretty cheap! I have some ideas of cheapo ways to turn things too

OK Illusus, one more cool thing I like: melting vinyl to make the platter.

I had imagined 2 ways to do this, a pan suspended in a water bath "bain marie" But that only get you up to 100 C which probably isn't enough, but worth trying.

2nd idea: cheap teflon pan on top of or inside a thick aluminum pan or plate over the range.

3rd : put the pieces in a microwave in a non metallic container and slowly increase the power and duration- this might actually be the best, safest and least messy unless an air pocket explodes-then divorce city!!!

I think you want to cut up the old records (Donny & Marie, Kenny G christmas album, etc.) with metal snips. I also have heard that the labels are actually melted into the vinyl, so probably it is impossible to get them off. So I guess you lose the vinyl under the labels. Also very important -don't stir the molten vinyl if possible-you will get more air bubbles, which are going to be a big problem. I think keeping the vinyl hot in the mold for a few hours whould also help rid it of bubbles-if the vinyl is pretty runny!

Arrow shafts are a great under utilized resource. they also have theaded fittings that fit perfectly in the ends of the tube, so it is easy to attach things! The most Highly tempered aluminum or Carbon fiber. Easton got it's start doing arrow shafts I think.

You will probably have to have the platter machined to make it perfect, but if all they have to do is turn the rim, it should be pretty cheap! I have some ideas of cheapo ways to turn things too

Illusus

I have to say that since you have the very flat disks, the Dice radial air bearing is very doable. You could then add the big ball constrained or not constrained center bearing- depending on how much work you want to do! Our biggest problem was finding things flat enough to make the plinth and platter out of. If you poured the vinyl onto one of those disks you have after coating it with silicone,then remove the disk, I would think the problem is solved!

Then pour an epoxy layer onto the bigger disk (wiped with silicon) and on top of that a thick layer of epoxy/stone chips.

That's what I meant about shipping the disks around the world!

Of course you could also use the big disk glued onto the plinth

and use the 35cm as the bottom of the platter ands pour vinyl onto it with a dam around it. I don't like this as much because hoe do you machine the edge?

How many disks are available?

I have to say that since you have the very flat disks, the Dice radial air bearing is very doable. You could then add the big ball constrained or not constrained center bearing- depending on how much work you want to do! Our biggest problem was finding things flat enough to make the plinth and platter out of. If you poured the vinyl onto one of those disks you have after coating it with silicone,then remove the disk, I would think the problem is solved!

Then pour an epoxy layer onto the bigger disk (wiped with silicon) and on top of that a thick layer of epoxy/stone chips.

That's what I meant about shipping the disks around the world!

Of course you could also use the big disk glued onto the plinth

and use the 35cm as the bottom of the platter ands pour vinyl onto it with a dam around it. I don't like this as much because hoe do you machine the edge?

How many disks are available?

DIYTT

One thing that just come down, many high tech machine shops uses a type of high pressure sand/water cutting, those devices goes 24 hours and the cost for cutting the most materials including plastics stainless steel and so on is nearly nothing I have heard that they charge 10 to 15 cents per 10 cm plus material.

The result is outstanding, high tech and the best is you can send the drawing by mail.😉

One thing that just come down, many high tech machine shops uses a type of high pressure sand/water cutting, those devices goes 24 hours and the cost for cutting the most materials including plastics stainless steel and so on is nearly nothing I have heard that they charge 10 to 15 cents per 10 cm plus material.

The result is outstanding, high tech and the best is you can send the drawing by mail.😉

leiade

Your latest looks like the greatest (OK, one of the greatest)

Love the shaft if it is really high precision.

I looked up the SKF site and they have a section about Abec precision, and a pop-up you can click on which lists the tolorences of the bearings. (As you said, the balls are what we care about)

I'm beginning to think after this next flurry of activity we should divde into different turntable concepts, and develop them separately. Mainly based on people who are actually making stuff

Your latest looks like the greatest (OK, one of the greatest)

Love the shaft if it is really high precision.

I looked up the SKF site and they have a section about Abec precision, and a pop-up you can click on which lists the tolorences of the bearings. (As you said, the balls are what we care about)

I'm beginning to think after this next flurry of activity we should divde into different turntable concepts, and develop them separately. Mainly based on people who are actually making stuff

The Shafts

Yes Sir, those shafts is high tech rods that you have in your car the helping lifters for the luggage or something like that.

But... you can't make some hole into them, too hard metal the drill will not work.

Just make it with a rondell, and machine the ball holding device of plastic in a lathe.The high precision surface of the shaft is what we will use.😉

Yes Sir, those shafts is high tech rods that you have in your car the helping lifters for the luggage or something like that.

But... you can't make some hole into them, too hard metal the drill will not work.

Just make it with a rondell, and machine the ball holding device of plastic in a lathe.The high precision surface of the shaft is what we will use.😉

Drilling shafts

A friend of mine says that those shafts is surface hardened and some of them is also chrome plated so you can drill in the center but don't do that because you have to fix them into a chuck, not good at all.🙂

SKF also sells those shafts as a part for high tech bearings.😉

A friend of mine says that those shafts is surface hardened and some of them is also chrome plated so you can drill in the center but don't do that because you have to fix them into a chuck, not good at all.🙂

SKF also sells those shafts as a part for high tech bearings.😉

The platter

If somebody could make a pro drawing of the TT platter and save it as a *.dfx then the whole worlds Diyers can make a pro DIYTT, but we have to agree about the platter construction details nice is it not.🙂

It seems that it is only me that overwhelming this part of the thread just for this moment.😉

If somebody could make a pro drawing of the TT platter and save it as a *.dfx then the whole worlds Diyers can make a pro DIYTT, but we have to agree about the platter construction details nice is it not.🙂

It seems that it is only me that overwhelming this part of the thread just for this moment.😉

DIYTT small parts

Small parts like teflon bearing details and so on can be made in some good high tech machine shop somewhere in the world and we can buy the small part from this company but the platter must be made in the neighbourhood because of the heavy weight.

Small plastic parts can be sent by air for just a few dollars. 🙂

Small parts like teflon bearing details and so on can be made in some good high tech machine shop somewhere in the world and we can buy the small part from this company but the platter must be made in the neighbourhood because of the heavy weight.

Small plastic parts can be sent by air for just a few dollars. 🙂

Re: DIYTT

Oh **** I ment 1 to 2 $US/ 10 cm so 50 cm makes about 5 - 10 $US plus material it is yet very cheap.

leiade said:One thing that just come down, many high tech machine shops uses a type of high pressure sand/water cutting, those devices goes 24 hours and the cost for cutting the most materials including plastics stainless steel and so on is nearly nothing I have heard that they charge 10 to 15 cents per 10 cm plus material.

The result is outstanding, high tech and the best is you can send the drawing by mail.😉

Oh **** I ment 1 to 2 $US/ 10 cm so 50 cm makes about 5 - 10 $US plus material it is yet very cheap.

Variac

There are about ten large, twenty medium and about seventy of the small disks available.

There are about ten large, twenty medium and about seventy of the small disks available.

Leiade,

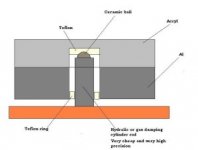

Rotating platter has to obey gyroscope physics rules. One of them says: placing center of mass (CM) below the pivot point leads to the gyro axle precession about CM (platter tilt). Do not do it. The ball will run on small ring track, since the thrust plate applies no lateral constraint, and the real pivot point would be close to the platter CM anyway. The bushing will not help, only makes matters worse, until it is placed on the same plane with CM. To address precession one should:

1.Position the platter CM as close to the pivot point (ball center), as practical, taking LP and clamp into account.

2.Apply stabilizing forces symmetrically relative to the pivot point.

Shortly speaking, this is boring theoretical staff behind my design proposal.

-------------------------------------------------------------------------------

No need to check physics laws at your own expense, just use it.

Regards,

Michael

Rotating platter has to obey gyroscope physics rules. One of them says: placing center of mass (CM) below the pivot point leads to the gyro axle precession about CM (platter tilt). Do not do it. The ball will run on small ring track, since the thrust plate applies no lateral constraint, and the real pivot point would be close to the platter CM anyway. The bushing will not help, only makes matters worse, until it is placed on the same plane with CM. To address precession one should:

1.Position the platter CM as close to the pivot point (ball center), as practical, taking LP and clamp into account.

2.Apply stabilizing forces symmetrically relative to the pivot point.

Shortly speaking, this is boring theoretical staff behind my design proposal.

-------------------------------------------------------------------------------

No need to check physics laws at your own expense, just use it.

Regards,

Michael

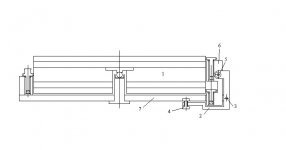

Here is a little more complicated adjusting/stabilizing guide wheels assembly. Should be rock stable, not allowing even tiny platter tilt.

Two guide wheels installed in the carriage (6) with plain bearing/bushes. The carriage is allowed to rotate around its pivot point (5) within the rubber bushing, which introduces torque moment, trying to set the carriage back to its nominal position. The carriage is supported by lever (2), which has its own pivot point (3) on the subchassis (7). Side force/wheels preload adjusted with the bolt (4).

Now the tilt reaction force consists of:

1.Two wheels friction force in axial direction (yes, they must be fixed axially, I’ll think about it).

2.Wheel side force due to climbing in larger platter diameter.

3.Additional wheel side force due to rubber bushing torque. BTW, precise position of the carriage and the platter subsequently is an easy task, rotating the bushing within the lever body.

Open for criticism of all kinds.

Michael

Two guide wheels installed in the carriage (6) with plain bearing/bushes. The carriage is allowed to rotate around its pivot point (5) within the rubber bushing, which introduces torque moment, trying to set the carriage back to its nominal position. The carriage is supported by lever (2), which has its own pivot point (3) on the subchassis (7). Side force/wheels preload adjusted with the bolt (4).

Now the tilt reaction force consists of:

1.Two wheels friction force in axial direction (yes, they must be fixed axially, I’ll think about it).

2.Wheel side force due to climbing in larger platter diameter.

3.Additional wheel side force due to rubber bushing torque. BTW, precise position of the carriage and the platter subsequently is an easy task, rotating the bushing within the lever body.

Open for criticism of all kinds.

Michael

Attachments

Livemusic: I have always thought of the unipivot as maybe not a state of the art turntable, but outstanding in it's simplicity and ease of construction. Since your scheme is very complicayed, it would have to compete witht he very bestI would think. It seems like all those parts might rattle arounfd or rumble a bit.

leiade: I was impressed with your diagram, but now I wonder if the gas struts that your mentioned as a source for the shaft are available reasonably in the diameter you have shown (looks like about 25mm) Maybe Mcpherson struts for autos are this big, but about $6o-to 150 apiece, and it seems a shame to cut them up for just the shaft.

leiade: I was impressed with your diagram, but now I wonder if the gas struts that your mentioned as a source for the shaft are available reasonably in the diameter you have shown (looks like about 25mm) Maybe Mcpherson struts for autos are this big, but about $6o-to 150 apiece, and it seems a shame to cut them up for just the shaft.

Gas Struts

No the drawing is not to scale just an idea I have changed my cars luggage struts and they are available in different diameters and costs just peanuts in Sweden 15 - 20 dollar for two.

However if you want to make a turntable those gas struts is rather nice with high precision maybe the SKF high tech bearing shafts is much better but... very expensive.😉

No the drawing is not to scale just an idea I have changed my cars luggage struts and they are available in different diameters and costs just peanuts in Sweden 15 - 20 dollar for two.

However if you want to make a turntable those gas struts is rather nice with high precision maybe the SKF high tech bearing shafts is much better but... very expensive.😉

- Status

- Not open for further replies.

- Home

- Source & Line

- Analogue Source

- Let's make a DIYAUDIO TT