Frank: locking the bearing of an arm????? What kind of pressure do you need for that? I tought arms where quite light. Anyway, any TT needs to be level.

Peterr & livemusic: First I thought the balls needed less precision parts, but a bit pondering makes it clear you need more precision parts. Both need a high precision central ball.

In the single ball case, the centering cone needs to be really axial, and that for both thrust plates.

In the multi-ball case, you need a very axial centred cone in the retaining ring locking the balls AND the screwthread between the retaining ring and the housing need to have no radial play. That last one is difficult.

Peterr & livemusic: First I thought the balls needed less precision parts, but a bit pondering makes it clear you need more precision parts. Both need a high precision central ball.

In the single ball case, the centering cone needs to be really axial, and that for both thrust plates.

In the multi-ball case, you need a very axial centred cone in the retaining ring locking the balls AND the screwthread between the retaining ring and the housing need to have no radial play. That last one is difficult.

DIY

Havoc,

Well,it was easier to damage and lock them then I thought possible too.

On another occasion I overtightened it again and one ball jumped out of its cage never to be found again.

It solved the chatter though.😀

It would surprise you how little are set up correctly.

I couldn't agree more,here.

From what I've seen so far on the drawings the cone is carrying all the load and it still will not prevent any sideways tilt IMO.

I fail to understand it's use here, I'm afraid.

And why would it be so bad to pressfit that ball on the stator side

and use a classic thrust and sleeve ball bearing.

Also if you have a lot of time on your hands,I would value your opinion on the airbearing I have proposed a few posts ago.

I don't think that it would be impossible to manufacture being as KISS as I could come up with.

Rgds,🙂

Havoc,

Well,it was easier to damage and lock them then I thought possible too.

On another occasion I overtightened it again and one ball jumped out of its cage never to be found again.

It solved the chatter though.😀

Anyway, any TT needs to be level

It would surprise you how little are set up correctly.

First I thought the balls needed less precision parts

I couldn't agree more,here.

the centering cone needs to be really axial

From what I've seen so far on the drawings the cone is carrying all the load and it still will not prevent any sideways tilt IMO.

I fail to understand it's use here, I'm afraid.

And why would it be so bad to pressfit that ball on the stator side

and use a classic thrust and sleeve ball bearing.

Also if you have a lot of time on your hands,I would value your opinion on the airbearing I have proposed a few posts ago.

I don't think that it would be impossible to manufacture being as KISS as I could come up with.

Rgds,🙂

Mark,

i see myself forced to give you a formal warning. I have to agree with the person complaining (am i supposed to like it? ), this is a personal offense which should not appear in public, which should be processed over private email. So, sentence

), this is a personal offense which should not appear in public, which should be processed over private email. So, sentence  you stand in the corner and blush in shame, ... for atleast 3 seconds ... hey, the three seconds are not yet over .... ok over.

you stand in the corner and blush in shame, ... for atleast 3 seconds ... hey, the three seconds are not yet over .... ok over.

Hmmh, i faintly remember we two, you and me had a row already concerning such personal attacks. Please do not let it happen again.

Formal requirements

Frank,

i felt tempted to write you what comes below in a private email but have come to the conclusion this would do no good.

IMMO (second M is for moderator) you have earned way more than what Variac handed to you.

Agreed, he could have been a bit more polite and respectful as his accuses are hard to backup with waterproof facts. He is just not up to desired diplomantic standard. But he is dead right with what he complains about.

Let's talk about what i consider as facts

Since you entered this thread, you have written a lot of lengthy posts and you managed to adress almost every statement and question here, you adressed it but in the very most cases you failed to answer it.

You failed to follow suit in this card game, to nail your colours to the mast and to tell about your TT design when asked for it..

A rough investigation would probably show that you post as much or more as we all together in this thread, as far as post count is concerned maybe but certainly as far as count of written lines is concerned. Statistically, you dominate the communicaton happening here. A mischievous observer could replace the term "dominate" by "control" and would not be far off the truth.

Your first long post managed to let every idea described here look questionable while you claimed to have only the best intentions and to help anyone with your wisdom. You kept this style and you spiced your postings up with a lot of smilies. I would not be surprised if i let our database search for the ;angel; string and order by maximum count of use per member and find you on top of this list.

smilies. I would not be surprised if i let our database search for the ;angel; string and order by maximum count of use per member and find you on top of this list.

Why do i peck on this? because i am not buying it. I am not buying the use of the emoticon you are using so often to be honest. I see a considerable discrepancy between how you claim to be and how the effects of your actions come out.

As far as i can judge it from the responses, your post confuse others. I can tell you: your posts confuse me thoroughly and confusing me is not an easy task.

Then, you claimed to have thoroughly read the thread from the start and just a page or two ago, i turns out you have not, you have mistaken Variac's snooker ball air bearing as a friction bearing with a grossly mis-sized axial bearing ball.

So far the so-called facts.

And you expect me to back you up!? Now that was a good one

--------------------------

Bernhard

(dice45, diyAudio moderator)

--------------------------

Frank,

I am putting my moderator hat off now and speak as member.

For me results, effects of your participance here are devastating, soon after you entered the thread, the fun was gone for me, down the tubes. You even asked me if you have my permission to post here (a quite unique thing here, noone has a say who may post and even the almighty moderator does not intercede if not someting nasty or sticky happens or struggles occur). This was a rhetoric question, a trap question IMO, as in my position i could answer nothing else but yes (although my mind's alert bells were ringing me deaf allthemore as before you asked, i had not the tiniest reason to say no).

Although Pedro started the thread, it was my initial idea to have a diy TT design sit-in here (and so is the whole analogue board, long before i became moderator, i pestered Jason with it and i pestered others to pester Jason). Before you entered, this was a happy crowd sharing ideas, so it appeared to me.

Soon after you entered the thread, the fun was gone for me and i feel you were the cause. I took my daily duty to if all are nice and friendly with each other and if i could throw in some helpful remarks. Sorry, but no more fun for me.

if all are nice and friendly with each other and if i could throw in some helpful remarks. Sorry, but no more fun for me.  Boring duty.

Boring duty.

So today, after several other members have expressed their unease about your person, about your actions, i feel permitted to join them.

Today i say: yes, i do mind you participating here. I feel your actions did this diy TT design sit-in no good. I would be very glad if you leave.

--------------------------

Bernhard

(diyAudio member)

Variac said:Well Frank, I guess it comes down to the drawing.

If the design is brilliant enough then it was worth it to put up with your inmaturity, inability to participate in a dialogue, unwillingness (inability) to explain your ideas, and generally obnoxious attitude . I suspect some on this thread are thinking we will never see it. All we get are excuses.

P.S. "My dog ate it" won't work. 🙂

i see myself forced to give you a formal warning. I have to agree with the person complaining (am i supposed to like it?

), this is a personal offense which should not appear in public, which should be processed over private email. So, sentence

), this is a personal offense which should not appear in public, which should be processed over private email. So, sentence  you stand in the corner and blush in shame, ... for atleast 3 seconds ... hey, the three seconds are not yet over .... ok over.

you stand in the corner and blush in shame, ... for atleast 3 seconds ... hey, the three seconds are not yet over .... ok over.

Hmmh, i faintly remember we two, you and me had a row already concerning such personal attacks. Please do not let it happen again.

Formal requirements

Frank,

i felt tempted to write you what comes below in a private email but have come to the conclusion this would do no good.

IMMO (second M is for moderator) you have earned way more than what Variac handed to you.

Agreed, he could have been a bit more polite and respectful as his accuses are hard to backup with waterproof facts. He is just not up to desired diplomantic standard. But he is dead right with what he complains about.

Let's talk about what i consider as facts

Since you entered this thread, you have written a lot of lengthy posts and you managed to adress almost every statement and question here, you adressed it but in the very most cases you failed to answer it.

You failed to follow suit in this card game, to nail your colours to the mast and to tell about your TT design when asked for it..

A rough investigation would probably show that you post as much or more as we all together in this thread, as far as post count is concerned maybe but certainly as far as count of written lines is concerned. Statistically, you dominate the communicaton happening here. A mischievous observer could replace the term "dominate" by "control" and would not be far off the truth.

Your first long post managed to let every idea described here look questionable while you claimed to have only the best intentions and to help anyone with your wisdom. You kept this style and you spiced your postings up with a lot of

smilies. I would not be surprised if i let our database search for the ;angel; string and order by maximum count of use per member and find you on top of this list.

smilies. I would not be surprised if i let our database search for the ;angel; string and order by maximum count of use per member and find you on top of this list.Why do i peck on this? because i am not buying it. I am not buying the use of the emoticon you are using so often to be honest. I see a considerable discrepancy between how you claim to be and how the effects of your actions come out.

As far as i can judge it from the responses, your post confuse others. I can tell you: your posts confuse me thoroughly and confusing me is not an easy task.

Then, you claimed to have thoroughly read the thread from the start and just a page or two ago, i turns out you have not, you have mistaken Variac's snooker ball air bearing as a friction bearing with a grossly mis-sized axial bearing ball.

So far the so-called facts.

And you expect me to back you up!? Now that was a good one

--------------------------

Bernhard

(dice45, diyAudio moderator)

--------------------------

Frank,

I am putting my moderator hat off now and speak as member.

For me results, effects of your participance here are devastating, soon after you entered the thread, the fun was gone for me, down the tubes. You even asked me if you have my permission to post here (a quite unique thing here, noone has a say who may post and even the almighty moderator does not intercede if not someting nasty or sticky happens or struggles occur). This was a rhetoric question, a trap question IMO, as in my position i could answer nothing else but yes (although my mind's alert bells were ringing me deaf allthemore as before you asked, i had not the tiniest reason to say no).

Although Pedro started the thread, it was my initial idea to have a diy TT design sit-in here (and so is the whole analogue board, long before i became moderator, i pestered Jason with it and i pestered others to pester Jason). Before you entered, this was a happy crowd sharing ideas, so it appeared to me.

Soon after you entered the thread, the fun was gone for me and i feel you were the cause. I took my daily duty to

if all are nice and friendly with each other and if i could throw in some helpful remarks. Sorry, but no more fun for me.

if all are nice and friendly with each other and if i could throw in some helpful remarks. Sorry, but no more fun for me.  Boring duty.

Boring duty.

So today, after several other members have expressed their unease about your person, about your actions, i feel permitted to join them.

Today i say: yes, i do mind you participating here. I feel your actions did this diy TT design sit-in no good. I would be very glad if you leave.

--------------------------

Bernhard

(diyAudio member)

DIY TT

All,

Dice45,

I will take this opportunity to clarify a few things as a participant on this thread here,

And I didn't intend to either: the idea was to give a few (turned out to be much more than that) pointers as to the do's and don'ts in TT design.

I notice not many are actually saying that I'm wrong technically,they either don't understand it or assume it does not apply to them,whatever.

When they do feel it applies to what they present,it upsets them.

A very normal reaction.

Designing a TT is like designing a car : you don't design the wheels,body and engine and than hope it's all somehow going to live together symbiotically.

In the real world it doesn't work that way.

As far as TT's go getting the bearing right is the most important part,I think all will agree to that?

Still,I keep on noticing most consider only one aspect when doing that:the bearing as a static part not a part that has to operate in a dynamic sometimes conflicting area.

That in turn upsets me.

I think this is a misconception:

I can not remember to have claimed I would present my design.No such intentions here,Im happy with what I have.

If anyone of the participants were to ask me to help me design together whith them,here on the forum, it would then be an entirely different matter.

I would then gladly put pencil to paper and come up with drawings.

Was bringing in a design of one's own a mandatory requirement?

Was the idea of this thread showing off one's design and then build it or leave it?

That's not my opinion of a forum:I would expect input and feedback.

If in the end the person presenting the design neglects the advice than that is fine by me.

From experience I can only say,as I can with a tube design,when I look at a design I can precisely predict what it is going to sound like.

I'm sure you can too.

So, are you being overly polite and forgiving by taking a back seat ?

Which brings me to the following statement:

As I feel strongly about my music,especially when it comes to TT's,

I hate to see people make mistakes that can easily and cost-effectively be avoided.

I am a succer for TT's,I won't deny that and it shows,doesn't it?

If that sometimes comes across as "taking control",I can live with that.

And precisely that and nothing else was the reason for my private e-mail to you.

I did see it coming and was asking for your advice,nothing else was to be read into it.

And yes I can be dominant and overpowering.But only when I feel I need to. I never laid claims to being perfect.(That would be boring.)

I don't think anyone would argue if I said this thread has become the hardest ever to keep under control,and you've done a great job in doing that.

However if you think that every time people notice you comment (as a member,to your mind) they will stop to see you as a moderator think again ,that doesn't work like that.

The purpose of this particular thread however slowly starts to elude me...Wiki or not.

If for instance in the electronic section people were to present the same mistakes as have been presented here,the reaction would have been to point to the flaw in the designs and help those people to correct it.

Here however it is "bon ton" to let them gracefully go ahead with it leaving them the impression they finally got it together??

That leaves me with a rather bitter taste in my mouth.

A word on the use of emoticons;on one hand you promote it,on the other hand you seem to say don't do it?

Me I like it,it helps putting things in perspective.

Fact remains,be it air bearing or ball bearing,be that ball big or small is irrelavant.

Let me ask you,would you build that turntable for yourself?

And if I would claim I design for a certain budget,I would do my homework and establish that budget.

I fail to see how this particular design is going to sound better than any other within the budget I see it will need.

And if he sends me back to a certain page (number 3) and I can't find anything there that would in any way alter my opinion,why doesn't he then not just copy and paste the relevant part into a post ?

Which is what he should have done in the first place?

No need to tell you that wading through a pile of non related posts on a Sunday afternoon is not my idea of a good time.

Still that's exactly what I did on several occasions.

All expect you to pick up on whatever they have in mind that particular instance,they all present their design and all that runs in the same thread with relative comments sometimes pages,weeks of lapse in between.

They don't actually addres anything in these posts but still manage to demand the utmost attention.

When someone then thus give a few pointers you effectively have then their ego shot to pieces ?

I somehow don't see that happen in say the tube section even when people ask help on basics.

Me too I could make my life a lot easier and say:"Take a course and than come back"

What I'm trying to say is that the sequence of the posts,the different people doing the posts, often do not addres the problem of the person under discussion in a chronological manner as it would be expected.

If they would make the effort of saying : O.K. it's non related to what you are discussing here but could you be so kind as to clarify this or that?

Frankly I've never seen a thread getting jacked as often as here.

And if one answers to a particular problem wouldn't it be just polite to addres that person by the name?

If say,I have a question or a comment to X I would then start my post with:Hello X, I have this or that I'd like you to look into??

It sure avoids a lot of misunderstandings and sour grapes afterwards IMO.

So much for politics.

You as a member,

As I said before,I did see this coming.

Naturally I will respect your feelings and those of the other members and refrain form commenting.

No hard feelings here.

Sincerely,

All,

Dice45,

I will take this opportunity to clarify a few things as a participant on this thread here,

Since you entered this thread, you have written a lot of lengthy posts and you managed to adress almost every statement and question here, you adressed it but in the very most cases you failed to answer it.

And I didn't intend to either: the idea was to give a few (turned out to be much more than that) pointers as to the do's and don'ts in TT design.

I notice not many are actually saying that I'm wrong technically,they either don't understand it or assume it does not apply to them,whatever.

When they do feel it applies to what they present,it upsets them.

A very normal reaction.

Designing a TT is like designing a car : you don't design the wheels,body and engine and than hope it's all somehow going to live together symbiotically.

In the real world it doesn't work that way.

As far as TT's go getting the bearing right is the most important part,I think all will agree to that?

Still,I keep on noticing most consider only one aspect when doing that:the bearing as a static part not a part that has to operate in a dynamic sometimes conflicting area.

That in turn upsets me.

You failed to follow suit in this card game, to nail your colours to the mast and to tell about your TT design when asked for it..

I think this is a misconception:

I can not remember to have claimed I would present my design.No such intentions here,Im happy with what I have.

If anyone of the participants were to ask me to help me design together whith them,here on the forum, it would then be an entirely different matter.

I would then gladly put pencil to paper and come up with drawings.

Was bringing in a design of one's own a mandatory requirement?

Was the idea of this thread showing off one's design and then build it or leave it?

That's not my opinion of a forum:I would expect input and feedback.

If in the end the person presenting the design neglects the advice than that is fine by me.

From experience I can only say,as I can with a tube design,when I look at a design I can precisely predict what it is going to sound like.

I'm sure you can too.

So, are you being overly polite and forgiving by taking a back seat ?

Which brings me to the following statement:

A mischievous observer could replace the term "dominate" by "control" and would not be far off the truth.

As I feel strongly about my music,especially when it comes to TT's,

I hate to see people make mistakes that can easily and cost-effectively be avoided.

I am a succer for TT's,I won't deny that and it shows,doesn't it?

If that sometimes comes across as "taking control",I can live with that.

And precisely that and nothing else was the reason for my private e-mail to you.

I did see it coming and was asking for your advice,nothing else was to be read into it.

And yes I can be dominant and overpowering.But only when I feel I need to. I never laid claims to being perfect.(That would be boring.)

I don't think anyone would argue if I said this thread has become the hardest ever to keep under control,and you've done a great job in doing that.

However if you think that every time people notice you comment (as a member,to your mind) they will stop to see you as a moderator think again ,that doesn't work like that.

The purpose of this particular thread however slowly starts to elude me...Wiki or not.

If for instance in the electronic section people were to present the same mistakes as have been presented here,the reaction would have been to point to the flaw in the designs and help those people to correct it.

Here however it is "bon ton" to let them gracefully go ahead with it leaving them the impression they finally got it together??

That leaves me with a rather bitter taste in my mouth.

A word on the use of emoticons;on one hand you promote it,on the other hand you seem to say don't do it?

Me I like it,it helps putting things in perspective.

Then, you claimed to have thoroughly read the thread from the start and just a page or two ago, i turns out you have not, you have mistaken Variac's snooker ball air bearing as a friction bearing with a grossly mis-sized axial bearing ball.

Fact remains,be it air bearing or ball bearing,be that ball big or small is irrelavant.

Let me ask you,would you build that turntable for yourself?

And if I would claim I design for a certain budget,I would do my homework and establish that budget.

I fail to see how this particular design is going to sound better than any other within the budget I see it will need.

And if he sends me back to a certain page (number 3) and I can't find anything there that would in any way alter my opinion,why doesn't he then not just copy and paste the relevant part into a post ?

Which is what he should have done in the first place?

No need to tell you that wading through a pile of non related posts on a Sunday afternoon is not my idea of a good time.

Still that's exactly what I did on several occasions.

All expect you to pick up on whatever they have in mind that particular instance,they all present their design and all that runs in the same thread with relative comments sometimes pages,weeks of lapse in between.

They don't actually addres anything in these posts but still manage to demand the utmost attention.

When someone then thus give a few pointers you effectively have then their ego shot to pieces ?

I somehow don't see that happen in say the tube section even when people ask help on basics.

Me too I could make my life a lot easier and say:"Take a course and than come back"

What I'm trying to say is that the sequence of the posts,the different people doing the posts, often do not addres the problem of the person under discussion in a chronological manner as it would be expected.

If they would make the effort of saying : O.K. it's non related to what you are discussing here but could you be so kind as to clarify this or that?

Frankly I've never seen a thread getting jacked as often as here.

And if one answers to a particular problem wouldn't it be just polite to addres that person by the name?

If say,I have a question or a comment to X I would then start my post with:Hello X, I have this or that I'd like you to look into??

It sure avoids a lot of misunderstandings and sour grapes afterwards IMO.

So much for politics.

You as a member,

Today i say: yes, i do mind you participating here. I feel your actions did this diy TT design sit-in no good. I would be very glad if you leave.

As I said before,I did see this coming.

Naturally I will respect your feelings and those of the other members and refrain form commenting.

No hard feelings here.

Sincerely,

Peter,

Every solid body needs minimum 3 base points to define its exact position in 3-dimentional space. The tetra-bearing idea is about to keep the number of the base point to an absolute minimum.

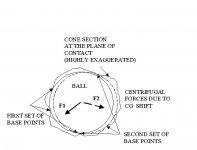

Your shallow cone comprises the line contact with the central ball. Think this contact line as infinite number of points. Than, taking into consideration the form and surface imperfections, only three of them are used as a base points every single moment of time. Moreover, because the platter center of mass of is not perfectly coincides with rotation axle, and thus dynamic side force present; the ball is constantly seeking those 3 base points on the cone surface, causing rumble. Actually the ball is jumping from one socket to another, like a golf ball (thinking microscopically). Two cone surfaces are making ball micro-movement more complex and the rumble spectrum wider. Lubricant is dumping those jumps (like jumping into the hole half-filled with water), but not canceling them.

As for the tetra bearing, the base points stay the same forever, making the platter mass balancing (CG on rotation axle) less critical. BTW, radial platter play would be easily zeroed with larger-than-bolt holes in the upper housing being bolted to the platter - Thorens-style, as described in one of previous threads.

Soft Teflon thrust plate has no drawback from this point of view, but slow lateral drift is unavoidable, since no additional journal bearing is used. Just to avoid misunderstandings (we have enough of it in this discussion): it is all about single pivot platter bearing.

Regards,

Michael

Every solid body needs minimum 3 base points to define its exact position in 3-dimentional space. The tetra-bearing idea is about to keep the number of the base point to an absolute minimum.

Your shallow cone comprises the line contact with the central ball. Think this contact line as infinite number of points. Than, taking into consideration the form and surface imperfections, only three of them are used as a base points every single moment of time. Moreover, because the platter center of mass of is not perfectly coincides with rotation axle, and thus dynamic side force present; the ball is constantly seeking those 3 base points on the cone surface, causing rumble. Actually the ball is jumping from one socket to another, like a golf ball (thinking microscopically). Two cone surfaces are making ball micro-movement more complex and the rumble spectrum wider. Lubricant is dumping those jumps (like jumping into the hole half-filled with water), but not canceling them.

As for the tetra bearing, the base points stay the same forever, making the platter mass balancing (CG on rotation axle) less critical. BTW, radial platter play would be easily zeroed with larger-than-bolt holes in the upper housing being bolted to the platter - Thorens-style, as described in one of previous threads.

Soft Teflon thrust plate has no drawback from this point of view, but slow lateral drift is unavoidable, since no additional journal bearing is used. Just to avoid misunderstandings (we have enough of it in this discussion): it is all about single pivot platter bearing.

Regards,

Michael

Attachments

maxon motors and shellac records

All,

since last weekend i am testing random samples of the maxon if they keep speed and beahve well if fed with and oversized lab supply. They do, no dropout so far.

I took the occasion to have a motor capable of >6000 rpm to have my trusty old TT spin its 1st shellac 78rpm records.

I wanted to have a fresh impression, not this listening comparison 10ys ago and memory becoming faint.

Admitted, this is not a relevant test, as i did not use appropriate phono78 EQ, and i did not use a spherical 60µm stylus.

I used my Ortofon Rohmann cartridge with ultra-sharp Orto-Line styylus shape.

The noise level was high, as expected.

Treble and bass limited.

The stylus got not enough lateral guidance which became apparent on load passages and transients.

Some records were not that amazing but nevertheless very good and naturally sounding. Some records however, made by Mercury (JATP with Charlie Parker, Roy Eldrige, Lester Young, Coleman Hawkins) and a Columbia recording of Oscar Levant playing Gershwin's Rhapsody in Blue were outstanding and on par with the best vinyls i know. As far as lushness, tonecolour saturation, body was concerned, they were better. On low volume passages only due to wrong stylus, of course. And ambience and soundstaging on the Rhapsody were equalling if not outperforming the fancy 1954 Kleiber Beethoven's 5th and coming close to medium-soundstage-sized stereo recordings.

A small reminder, shellacs are mono-only.

I cannot make any valid statement now, all preliminary, but if this test setup crap sounds like this, then i want to hear shellacs with the correct stylus and preamp EQ. Wow!

All,

since last weekend i am testing random samples of the maxon if they keep speed and beahve well if fed with and oversized lab supply. They do, no dropout so far.

I took the occasion to have a motor capable of >6000 rpm to have my trusty old TT spin its 1st shellac 78rpm records.

I wanted to have a fresh impression, not this listening comparison 10ys ago and memory becoming faint.

Admitted, this is not a relevant test, as i did not use appropriate phono78 EQ, and i did not use a spherical 60µm stylus.

I used my Ortofon Rohmann cartridge with ultra-sharp Orto-Line styylus shape.

The noise level was high, as expected.

Treble and bass limited.

The stylus got not enough lateral guidance which became apparent on load passages and transients.

Some records were not that amazing but nevertheless very good and naturally sounding. Some records however, made by Mercury (JATP with Charlie Parker, Roy Eldrige, Lester Young, Coleman Hawkins) and a Columbia recording of Oscar Levant playing Gershwin's Rhapsody in Blue were outstanding and on par with the best vinyls i know. As far as lushness, tonecolour saturation, body was concerned, they were better. On low volume passages only due to wrong stylus, of course. And ambience and soundstaging on the Rhapsody were equalling if not outperforming the fancy 1954 Kleiber Beethoven's 5th and coming close to medium-soundstage-sized stereo recordings.

A small reminder, shellacs are mono-only.

I cannot make any valid statement now, all preliminary, but if this test setup crap sounds like this, then i want to hear shellacs with the correct stylus and preamp EQ. Wow!

Michael,

Imagine the vinyl record groove. Maximum amplitude is about 60µm, the record has a total of 60dB in best case. As the cartridge is a velocity sensor and velocity increases linearly with amplitude, lowest groove amplitude of interest is 0.6nm . This is way lower than the roughness profile of the bearing balls.

In rough words: a bearing in a ball race bearing is like a chunk of rock bouncing valleywards in the bed of a little mountain river.

And i would not be as optimistic as you are about the ruggedness of the ball surface. As you say, you have punctual contact. Hardeded metal against herdened metal, about same rockweel hardness. teeneweeny chips pop off the surface all the time, coloring the grease.

If you open an unused and a used ball bearing, even if only used for an hour or so, you will notice the considerable darkening of the yellowish lubricant.

Now the rumble caused by the balls rolling is injected into the platter and hopefully its amplitude has decayed enough before reaching the platter top surface.

From my experiments with the ball/trustplate friction bearing i was reluctant to try a ball bearing out. In fact, i never did, i skipped this risky thing as my friction bearing with ruby ball and Teflon trustplate works so well.

but you can exchange your axial bearing way easier than i can with my construction. If you want to try it, go ahead, i would be very curious to learn about the results.

Now this is interesting. 0.3 efficiency. I already was prepared to make own experimants with that. Thank you very much.! 🙂

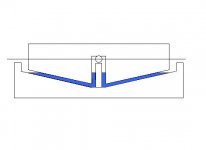

Gap:

I do not see a problem, arriving at a gap as intended before. Gap size, nozzle count and nozzle size are results from dimensioning calculations. Look at my drawing on page 3 or so: i let 3 differnetial screws pull the bearing cup against lower half sphere. With my design the air gap is adjustable; the only required precise dimensions are ball/cup gap and sphericity and the planarity of the flat bearing surfaces.

no, this is not my concern.Originally posted by livemusic Ball bearing chatter caused mainly by retainer/separator sliding on balls surface, IMHO. Area of contact is very substantial, and relatively light separator is realy shaking. For deep groove bearing, the ball-groove multiply contacts also contribute.

Imagine the vinyl record groove. Maximum amplitude is about 60µm, the record has a total of 60dB in best case. As the cartridge is a velocity sensor and velocity increases linearly with amplitude, lowest groove amplitude of interest is 0.6nm . This is way lower than the roughness profile of the bearing balls.

In rough words: a bearing in a ball race bearing is like a chunk of rock bouncing valleywards in the bed of a little mountain river.

And i would not be as optimistic as you are about the ruggedness of the ball surface. As you say, you have punctual contact. Hardeded metal against herdened metal, about same rockweel hardness. teeneweeny chips pop off the surface all the time, coloring the grease.

If you open an unused and a used ball bearing, even if only used for an hour or so, you will notice the considerable darkening of the yellowish lubricant.

Now the rumble caused by the balls rolling is injected into the platter and hopefully its amplitude has decayed enough before reaching the platter top surface.

From my experiments with the ball/trustplate friction bearing i was reluctant to try a ball bearing out. In fact, i never did, i skipped this risky thing as my friction bearing with ruby ball and Teflon trustplate works so well.

but you can exchange your axial bearing way easier than i can with my construction. If you want to try it, go ahead, i would be very curious to learn about the results.

The sphere air bearing efficiency is about 0.3, so your air pressure should be multiplied by 3, if you are using the only ball air bearing. Actually for 5 cm ball and 10 kg platter we are speaking about 40 – 50 psi air souce. Of cource, if the lower platter surface used for air cushion, the pressure required is way lower, but the air flow is much more substantial (see the pump pressure/flow characteristics)- "no free lanches in physics". Moreover, the small air gap, which is essential for for the rigid air bearing, needless to say, is the challenge by itself, and it is hard to imagine how can one adjust exactly he same gap for the plane and spherical part of the bearing..

Now this is interesting. 0.3 efficiency. I already was prepared to make own experimants with that. Thank you very much.! 🙂

Gap:

I do not see a problem, arriving at a gap as intended before. Gap size, nozzle count and nozzle size are results from dimensioning calculations. Look at my drawing on page 3 or so: i let 3 differnetial screws pull the bearing cup against lower half sphere. With my design the air gap is adjustable; the only required precise dimensions are ball/cup gap and sphericity and the planarity of the flat bearing surfaces.

new tests

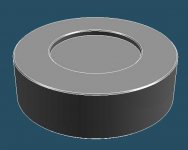

I did an extra test last nght. I have modified the platter so that the submerged part is about halved. (only the outer half of the bottom. see drawing)

It is not an improvement.

The platter goes on rotating a bit longer but stability is much worse. I think Livemusic predicted this before.

Anyway one learns by trial and error

I did an extra test last nght. I have modified the platter so that the submerged part is about halved. (only the outer half of the bottom. see drawing)

It is not an improvement.

The platter goes on rotating a bit longer but stability is much worse. I think Livemusic predicted this before.

Anyway one learns by trial and error

Attachments

belt load; different belts

Peterr,

Experience is not transferrable nor teachable. 🙂

DTopic:

i have the maxons under test. One observation: if the motor changes its position, even minutely, the speed stability is to the dogs. IMO the changing belt load is the cause, my test setup has no mechanism to keep the belt tension constant.

If the motor faces an unvarying static belt load, the speed does not change. It is not as longterm stable as it would be with a digital I-reg like Manfred Huber uses, but it is way stable enough.

In this respect i have to remind all of you intending to use a maxon that maxon specifies a maximum radial static load

of 5.5 Newton (at lever arm length 5mm, measured from the flange). Therefore i do not recommend belts with 1/2" / 12.7mm width.

I made other tests also: belts of different tensile stiffness. To my ears an elastic belt is a NoNo ... the better the tensile stiffness, the better

... the better the tensile stiffness, the better  . My trusty old TT uses a kevlar string as belt. The sonics are best with this, but the knot drives me crazy regularly. I tested a rubber belt, conmpact cassette tape and 38µm thick 1/4" tape. Kevlar string was best with the 1/4" tape close second. Cassette tape was closer to the rubberbelt than tho the 1/4" tape. The stiffer the belt, the better and clearer transients and

. My trusty old TT uses a kevlar string as belt. The sonics are best with this, but the knot drives me crazy regularly. I tested a rubber belt, conmpact cassette tape and 38µm thick 1/4" tape. Kevlar string was best with the 1/4" tape close second. Cassette tape was closer to the rubberbelt than tho the 1/4" tape. The stiffer the belt, the better and clearer transients and  the wider, nearer, clearer and bigger the soundstaging. In this respect, i understand why Redpoint uses a 1/2" / 12.7mm tape as belt. It just creates a lever arm too long and is prone to kill their motors soon. Some of the Teres people learned this the hard way; the maxon radial load spec has only a few % of headroom.

the wider, nearer, clearer and bigger the soundstaging. In this respect, i understand why Redpoint uses a 1/2" / 12.7mm tape as belt. It just creates a lever arm too long and is prone to kill their motors soon. Some of the Teres people learned this the hard way; the maxon radial load spec has only a few % of headroom.

My conclusion: The motor has to be mounted on a lever arm with vertical pivot axis ot on a sled with a linear ball race bearing and then the proper load has to be generated and adjusted by a spring or a thread and a weight like SME antiskating.

The pulley will be accept up to 8mm tape width and i will use professional grade 1/4" tape with 50µm thickness.

Peterr,

i was sure he was right with this. but that was an assumption. Only the experiment shows if we engineers have build a model of the realitiy and chosen the right simplifications. Thank you for the experimental result.I think Livemusic predicted this before.

Experience is not transferrable nor teachable. 🙂

DTopic:

i have the maxons under test. One observation: if the motor changes its position, even minutely, the speed stability is to the dogs. IMO the changing belt load is the cause, my test setup has no mechanism to keep the belt tension constant.

If the motor faces an unvarying static belt load, the speed does not change. It is not as longterm stable as it would be with a digital I-reg like Manfred Huber uses, but it is way stable enough.

In this respect i have to remind all of you intending to use a maxon that maxon specifies a maximum radial static load

of 5.5 Newton (at lever arm length 5mm, measured from the flange). Therefore i do not recommend belts with 1/2" / 12.7mm width.

I made other tests also: belts of different tensile stiffness. To my ears an elastic belt is a NoNo

... the better the tensile stiffness, the better

... the better the tensile stiffness, the better  . My trusty old TT uses a kevlar string as belt. The sonics are best with this, but the knot drives me crazy regularly. I tested a rubber belt, conmpact cassette tape and 38µm thick 1/4" tape. Kevlar string was best with the 1/4" tape close second. Cassette tape was closer to the rubberbelt than tho the 1/4" tape. The stiffer the belt, the better and clearer transients and

. My trusty old TT uses a kevlar string as belt. The sonics are best with this, but the knot drives me crazy regularly. I tested a rubber belt, conmpact cassette tape and 38µm thick 1/4" tape. Kevlar string was best with the 1/4" tape close second. Cassette tape was closer to the rubberbelt than tho the 1/4" tape. The stiffer the belt, the better and clearer transients and  the wider, nearer, clearer and bigger the soundstaging. In this respect, i understand why Redpoint uses a 1/2" / 12.7mm tape as belt. It just creates a lever arm too long and is prone to kill their motors soon. Some of the Teres people learned this the hard way; the maxon radial load spec has only a few % of headroom.

the wider, nearer, clearer and bigger the soundstaging. In this respect, i understand why Redpoint uses a 1/2" / 12.7mm tape as belt. It just creates a lever arm too long and is prone to kill their motors soon. Some of the Teres people learned this the hard way; the maxon radial load spec has only a few % of headroom.My conclusion: The motor has to be mounted on a lever arm with vertical pivot axis ot on a sled with a linear ball race bearing and then the proper load has to be generated and adjusted by a spring or a thread and a weight like SME antiskating.

The pulley will be accept up to 8mm tape width and i will use professional grade 1/4" tape with 50µm thickness.

Dice, if you like non-elastic belts, try to get hold of some spun cast metal ribbon. It consists of metal that is poured on a spinning wheel to cool it rapidly. A bit brittle, and I don't know how you would join the ends (you like experimenting don't you?). It is only a couple of mm wide. This is used in things like cores for transformers. We have some transformers at the office using these cores, will try to send you a type number. Took one apart one day, just to know 🙂

Havoc,

.. interested.

.. interested.

do you think your metal ribbon will make it a couple of thousand times taut around the pulley? 🙂

do you think your metal ribbon will make it a couple of thousand times taut around the pulley? 🙂

.. interested.

.. interested.  do you think your metal ribbon will make it a couple of thousand times taut around the pulley? 🙂

do you think your metal ribbon will make it a couple of thousand times taut around the pulley? 🙂Peter,

Your experiment weights 100 times more than my prediction.

There was another famous historical precedent with sweden royal ship Vasa, turned upside down in view of shocked crowd shortly after entering to water. Buoyant force is actually DEstabilizing, unless the center of buoyancy is above CG. Just try to imagine fishing float floating hevy part up…

Bernhard,

You right, the bearing balls tolerances are way larger than average groove modulations amplitude. But direct comparison it is not correct. It is about induced vibrations level. The platter mass and dumping properties are the major players here. By no means I am not to say the balls are better than air bearing. Just cost effective solution which may be not so bad , if the bearing is far enough from surface of massive and well dumped platter , like on my sketch. BTW, it is better to get rid of upper three balls, and glue the central ball to the housing/platter instead. I would use the lead cast cup as a housing.

The bearing balls tolerances defined by the ball grade: the upper 100 grade has 2.54 micron tolerance for roundness and surface imperfections (not bad, even compare to the groove peaks and valleys!), the lower 2000 grade is 20 times worse. BTW, try to find best grade ball available making socket for the air bearing, since really stiff industrial air bearins have 3 to 5 micron air gap typically (see Speciality Components site – worth looking).

About pressured air source: why do not try industrial hydrogen tank? I saw 2 gallon compact resevoir for 200 bar with pressure regulator at 100 USD price. Refilling with clean and dry hydrogen costs less than 5 bucks; it should last a long time. Not so expensive, clean and dead quiet. I know, pressure regulator introduces pulsations; may be effectively addressed with anti-pulsation tank (may be partly filled with good grade syntetic foam – for auto seats – I read it in Audio Asylum forum).

Regards

Michael

Your experiment weights 100 times more than my prediction.

There was another famous historical precedent with sweden royal ship Vasa, turned upside down in view of shocked crowd shortly after entering to water. Buoyant force is actually DEstabilizing, unless the center of buoyancy is above CG. Just try to imagine fishing float floating hevy part up…

Bernhard,

You right, the bearing balls tolerances are way larger than average groove modulations amplitude. But direct comparison it is not correct. It is about induced vibrations level. The platter mass and dumping properties are the major players here. By no means I am not to say the balls are better than air bearing. Just cost effective solution which may be not so bad , if the bearing is far enough from surface of massive and well dumped platter , like on my sketch. BTW, it is better to get rid of upper three balls, and glue the central ball to the housing/platter instead. I would use the lead cast cup as a housing.

The bearing balls tolerances defined by the ball grade: the upper 100 grade has 2.54 micron tolerance for roundness and surface imperfections (not bad, even compare to the groove peaks and valleys!), the lower 2000 grade is 20 times worse. BTW, try to find best grade ball available making socket for the air bearing, since really stiff industrial air bearins have 3 to 5 micron air gap typically (see Speciality Components site – worth looking).

About pressured air source: why do not try industrial hydrogen tank? I saw 2 gallon compact resevoir for 200 bar with pressure regulator at 100 USD price. Refilling with clean and dry hydrogen costs less than 5 bucks; it should last a long time. Not so expensive, clean and dead quiet. I know, pressure regulator introduces pulsations; may be effectively addressed with anti-pulsation tank (may be partly filled with good grade syntetic foam – for auto seats – I read it in Audio Asylum forum).

Regards

Michael

Hydrogen would be fun 🙂 You could light the side of the bearing for some nice light effects. Also Helium is available in balloon shops but more expensive. If you really play a lot of records, you can install a liquid nitrogen tank and let it top up every week 🙂

Dice: 60dB for a record? 0.6nm? Sorry, but I have serious doubts about that. The hysteresis in the rubber suspension of the cantilever will see to that. Even then, their is no bearing ever going to give that, certainly not any sleeve bearing. I would account the darkning of the grease to heat.

Dice: 60dB for a record? 0.6nm? Sorry, but I have serious doubts about that. The hysteresis in the rubber suspension of the cantilever will see to that. Even then, their is no bearing ever going to give that, certainly not any sleeve bearing. I would account the darkning of the grease to heat.

Havoc,

60dB: measured on Mercury SR90316/ Vienna 1908-14:

noise carpet at -43dB, loudest peak (massive brass) at +17dB, completely undistorted. I can show you. My assumption concerning the amplitudes may be flawed but not much, the 60 dB are experimental data.

This Mercury is a special record, it has music on it i love very much (Schoenberg, Webern, Berg) but many others consider as acoustic warfare and it has the most breathtaking sonics in any respect. The best recording i know and a masterpiece regarding the mastering. Transients hit you like a

and it has the most breathtaking sonics in any respect. The best recording i know and a masterpiece regarding the mastering. Transients hit you like a  accident. Oh, and the best performance of those works by far. Also a masterpiece, Dorati and the LSO do a gorgeous job. Cannot resist to tease a bit, i own this record 4x, one of them a white promo in M condition of which the measurements are taken.

accident. Oh, and the best performance of those works by far. Also a masterpiece, Dorati and the LSO do a gorgeous job. Cannot resist to tease a bit, i own this record 4x, one of them a white promo in M condition of which the measurements are taken.

Michael,

my last intention is to talk you out of your ball bearing experiment. Do it.

Afterwards ask me for a quote for shipping a precision ruby ball and a chunk of 3mm Teflon to you. I use such since 17 ys and hifidaddy considers my trusty old TT to be better than a Platine Verdier. I never had reason to change either ball or Teflon trustplate. I am not enthusing about conical trustpieces, trustpiece has to be flat to make precise centering unnecessary.

Nitrogen flask: pressure reg is prone to whistle, to oscillate. I prefer a silent airbrush compressor and a decent pneumatic RCRC filter. JunAir makes nice silent compressors. And if you buy a big one, compressor power is sufficient for an air bearing tonearm too. Ladegaard comes in mind.

60dB: measured on Mercury SR90316/ Vienna 1908-14:

noise carpet at -43dB, loudest peak (massive brass) at +17dB, completely undistorted. I can show you. My assumption concerning the amplitudes may be flawed but not much, the 60 dB are experimental data.

This Mercury is a special record, it has music on it i love very much (Schoenberg, Webern, Berg) but many others consider as acoustic warfare

and it has the most breathtaking sonics in any respect. The best recording i know and a masterpiece regarding the mastering. Transients hit you like a

and it has the most breathtaking sonics in any respect. The best recording i know and a masterpiece regarding the mastering. Transients hit you like a  accident. Oh, and the best performance of those works by far. Also a masterpiece, Dorati and the LSO do a gorgeous job. Cannot resist to tease a bit, i own this record 4x, one of them a white promo in M condition of which the measurements are taken.

accident. Oh, and the best performance of those works by far. Also a masterpiece, Dorati and the LSO do a gorgeous job. Cannot resist to tease a bit, i own this record 4x, one of them a white promo in M condition of which the measurements are taken.Michael,

my last intention is to talk you out of your ball bearing experiment. Do it.

Afterwards ask me for a quote for shipping a precision ruby ball and a chunk of 3mm Teflon to you. I use such since 17 ys and hifidaddy considers my trusty old TT to be better than a Platine Verdier. I never had reason to change either ball or Teflon trustplate. I am not enthusing about conical trustpieces, trustpiece has to be flat to make precise centering unnecessary.

Nitrogen flask: pressure reg is prone to whistle, to oscillate. I prefer a silent airbrush compressor and a decent pneumatic RCRC filter. JunAir makes nice silent compressors. And if you buy a big one, compressor power is sufficient for an air bearing tonearm too. Ladegaard comes in mind.

Peter

Floating platter stability problem may be solved on the same way the ship designers used to use more than 200 years: conical shape of the submerged part. The trick is that buoyancy center shifts in desirable direction, acting to compensate the heel moment.

Of course, it not an easy task to build the cone part, but if you can manage, worth trying.

Regards

Michael

Floating platter stability problem may be solved on the same way the ship designers used to use more than 200 years: conical shape of the submerged part. The trick is that buoyancy center shifts in desirable direction, acting to compensate the heel moment.

Of course, it not an easy task to build the cone part, but if you can manage, worth trying.

Regards

Michael

Attachments

Bernhard

Would you mind me asking some more stupid questions, please? Is the side load compensated by your teflon thrust plate socket alone? And the ball is still there on the same point you placed it 17 years ago? Or is there some sort of bushing dealing with the side force anyway? I thought we were speaking about single/unipivot bearing all the time. Sorry, wrong number.

Using one pressure source for the platter bearing and tonearm: exactly the point. I need 40 psi for the platter and 5-10 psi for tonearm. I do not need more pressure for tonearm, because one should add more weight on the slider to keep the air gap small, and I do not want to. My light wooden arm/ compliant cartrige manage to play unconcetric LP, because it is light. That is why I need the pressure regulator anyway. BTW, does JunAir compressor have build-in pressure regulator? It does, IMHO.

Regards

Michael

Would you mind me asking some more stupid questions, please? Is the side load compensated by your teflon thrust plate socket alone? And the ball is still there on the same point you placed it 17 years ago? Or is there some sort of bushing dealing with the side force anyway? I thought we were speaking about single/unipivot bearing all the time. Sorry, wrong number.

Using one pressure source for the platter bearing and tonearm: exactly the point. I need 40 psi for the platter and 5-10 psi for tonearm. I do not need more pressure for tonearm, because one should add more weight on the slider to keep the air gap small, and I do not want to. My light wooden arm/ compliant cartrige manage to play unconcetric LP, because it is light. That is why I need the pressure regulator anyway. BTW, does JunAir compressor have build-in pressure regulator? It does, IMHO.

Regards

Michael

Let's look at leiade's TT

If any is curious about to have glance at my DIY TT I will send a picture, it was two of this beast made in my hometown one is mine the other is a friend's he has upgraded his with two big magnets to overcome to much bearing tear.🙂

If any is curious about to have glance at my DIY TT I will send a picture, it was two of this beast made in my hometown one is mine the other is a friend's he has upgraded his with two big magnets to overcome to much bearing tear.🙂

Michael,

there are no stupid QQ, only stupid answers 🙂

My bearing is a conventional bushing bearing, not even inverted. No, the trust plate has not radial forces to comensate, this is done by shaft and bushing.

The ball would be on the same place if i hadn't dismantled it from time to time to inspect it. The plate has 3 ball dents if my memory serves me right.

If you want to use Teflon/Ruby for the unipivot platter, you could use an o-ring for compensating radial forces. Located as close to the pivot as possible.

Air pressure:

of course you need two separate pressure regs, one for the platter, one for the tonearm. The JunAir comes with one pressure reg.

Hmmmh, you want to discuss linear tracking tonearms here 🙂 (or do you intend to have an airbearing for a pivoted arm??) well this is quite another league. Anyway, i give you some hints:

1st,

a Ladegaard arm is fine as it is very simple to build and it works fine. But bearing construction is not a closed one. On another forum i called the Ladegaard a lineartracking unipivot arm therefore, as the bearing is lamost working like a hovercraft.

Variac got me right, i am a fan of closed bearing constructions. So if you have a bearing similiar to the Rockport or Versa or Walker, then increased air pressure makes your bearing stiffer . If you have an open construction like Ladegaard and Dennesen, then pressure has to be right to lift the arm but not widening the air gap all too much.

There is one thing the Ladegaard is benefitting from: as the tonearm wand has a knife bearing as connection to the slider, the slider's rotational inertia (in reference to the tonearm wand centerline) is added to the tonearm wands one. By this the hovercraft-like lack of rotational stiffness of the bearing is counteracted. If you increase the mass of the slider by adding bluetack and leadshot, and then you increase the air pressure, you increase the whole units rotational inertia, the over-critical damping works better due to lowered rotational resonqace frequency and the arm has a better bass reporduction. See my lenghty rants on unipivot tonearms, search the site for my unipivot and Mayware posts.

2nd,

Excentric records are a NoNo with a passive linear tracker. Excentricity has to be cancelled. For centric records, it does not hurt if the lateral mass yields to a lateral tonearm resonance located between 3 and 6 Hz. I would not go lower than 3 Hz. Resonance frequency is proportional to the squareroot of laterally effective mass (all other parameters held constant), so i would not be concerned all too much about keeping the weight of the slider as low as possible.

Okok, the tonearm's mass has to fit the cartridge's compliance and provided the cartridge itself is not too heavy, then arm wand and counterweight also is light weight and this contributes about 80-90% of the slider mass vertically. In most cases matching nicely. Laterally, well the bearing mass is added. It depends how lightweight you manage to build your bearing unit. But better the unit is a bit heavier (not much!!) and stiff enough.

One thing i would do if i build a Ladegaard: i would feed the air to the slider, not to the rail. As i do it with my LT-1.

there are no stupid QQ, only stupid answers 🙂

My bearing is a conventional bushing bearing, not even inverted. No, the trust plate has not radial forces to comensate, this is done by shaft and bushing.

The ball would be on the same place if i hadn't dismantled it from time to time to inspect it. The plate has 3 ball dents if my memory serves me right.

If you want to use Teflon/Ruby for the unipivot platter, you could use an o-ring for compensating radial forces. Located as close to the pivot as possible.

Air pressure:

of course you need two separate pressure regs, one for the platter, one for the tonearm. The JunAir comes with one pressure reg.

Hmmmh, you want to discuss linear tracking tonearms here 🙂 (or do you intend to have an airbearing for a pivoted arm??) well this is quite another league. Anyway, i give you some hints:

1st,

a Ladegaard arm is fine as it is very simple to build and it works fine. But bearing construction is not a closed one. On another forum i called the Ladegaard a lineartracking unipivot arm therefore, as the bearing is lamost working like a hovercraft.

Variac got me right, i am a fan of closed bearing constructions. So if you have a bearing similiar to the Rockport or Versa or Walker, then increased air pressure makes your bearing stiffer . If you have an open construction like Ladegaard and Dennesen, then pressure has to be right to lift the arm but not widening the air gap all too much.

There is one thing the Ladegaard is benefitting from: as the tonearm wand has a knife bearing as connection to the slider, the slider's rotational inertia (in reference to the tonearm wand centerline) is added to the tonearm wands one. By this the hovercraft-like lack of rotational stiffness of the bearing is counteracted. If you increase the mass of the slider by adding bluetack and leadshot, and then you increase the air pressure, you increase the whole units rotational inertia, the over-critical damping works better due to lowered rotational resonqace frequency and the arm has a better bass reporduction. See my lenghty rants on unipivot tonearms, search the site for my unipivot and Mayware posts.

2nd,

Excentric records are a NoNo with a passive linear tracker. Excentricity has to be cancelled. For centric records, it does not hurt if the lateral mass yields to a lateral tonearm resonance located between 3 and 6 Hz. I would not go lower than 3 Hz. Resonance frequency is proportional to the squareroot of laterally effective mass (all other parameters held constant), so i would not be concerned all too much about keeping the weight of the slider as low as possible.

Okok, the tonearm's mass has to fit the cartridge's compliance and provided the cartridge itself is not too heavy, then arm wand and counterweight also is light weight and this contributes about 80-90% of the slider mass vertically. In most cases matching nicely. Laterally, well the bearing mass is added. It depends how lightweight you manage to build your bearing unit. But better the unit is a bit heavier (not much!!) and stiff enough.

One thing i would do if i build a Ladegaard: i would feed the air to the slider, not to the rail. As i do it with my LT-1.

- Status

- Not open for further replies.

- Home

- Source & Line

- Analogue Source

- Let's make a DIYAUDIO TT