Wow, there's a lot of nice people here. I think i have enough to look at for the next loooong time, hehe.

Looks like i should concentrate on Sprint-layout first, and give it a chance. One of the problems i've found is, that i only want 1 layer, and most of the time the components i want to use is not in the library.

Guess there's no way out but learn to define my own.

Thanks a lot everybody, and a big thanks to Carlos for bringing this subject up.

All the best

Ebbe

Looks like i should concentrate on Sprint-layout first, and give it a chance. One of the problems i've found is, that i only want 1 layer, and most of the time the components i want to use is not in the library.

Guess there's no way out but learn to define my own.

Thanks a lot everybody, and a big thanks to Carlos for bringing this subject up.

All the best

Ebbe

Hi all,

I use this http://diptrace.com/downloads/dipfree_en.exe

Freeware up to 250 pins.

Really easy to use.

Cheers.

I use this http://diptrace.com/downloads/dipfree_en.exe

Freeware up to 250 pins.

Really easy to use.

Cheers.

Great informs Conrad...so, maybe i am not really stupid.... need weeks to learn

This seems to me that many software are not really simple, and tutorial not clear.... i imagine they could make a PPS or something alike, presentation, or a small movie showing steps of software "adjustments" and showing result of clicks....moving things, deleting, editing, including details, bending wires and so on.

Some of them (CAD programs, boards maker programs) produces to you a lot of work, hundreds of clicks to obtain small result... slow and boring... something (computers and software)that goes against my belief that computers were made to make our life easier, but producing to me hundred more work to produce a board, when i can make it faster with a pen and a papper..of course, software makes better and more precise...but the cost of time and patience is enormous!

So, in my point of view, interface not friendly, creating to us a problems instead to give us effective tool, simple, to help us to make better and faster.... we can make better, but not faster.

I remember, when i was young..entering a bank, our bank account was controled by a small card of papper, the guy had to obtain your signature and go to observe that, also your face compared with the picture into your Registration Card, identity document.... driver license or something alike, and you money movement was written with a pencil and latter, in the nigth everything was checked.... the long strip waiting long time each guy having all those movements beeing made by the cashier man... computers came and made things faster, more efficient... a password and finish..all date inside the main frame computer and ready to go in microseconds....but related boards software, it spend from you more time you can spend with a a pen and a papper... i can prepare nice boards in 20 minutes, with a pen and papper and will need some weeks, maybe 20 days to learn how to use the software...of course, maybe after that learning period i will be able to make a board in 20 minutes...but i doubt that.

I conclude i am not clever to learn those things..but the software creators were not clever too, as they made things not simple, not easy and not fast.

The problem i felt is that they are not clear.

For instance.... a command i will call XXX.

They say, click into command XXX and do this and do that.

But they do not say where is the command XXX, and what is the result you have when you click and the adjustments results...so you have to discover by yourself clicking almost everywhere.

Well..... this last one, from Abacom seems really very well explainded...you see that a "real teacher" have prepared the tutorial..... teacher i mean the one that really knows how to teach, not the one that has knowledge and do not knows how to teach.... real teachers born this way...not an effect from College..you are, naturally, or you are not.

regards, Conrad and Ebbe.

Carlos

This seems to me that many software are not really simple, and tutorial not clear.... i imagine they could make a PPS or something alike, presentation, or a small movie showing steps of software "adjustments" and showing result of clicks....moving things, deleting, editing, including details, bending wires and so on.

Some of them (CAD programs, boards maker programs) produces to you a lot of work, hundreds of clicks to obtain small result... slow and boring... something (computers and software)that goes against my belief that computers were made to make our life easier, but producing to me hundred more work to produce a board, when i can make it faster with a pen and a papper..of course, software makes better and more precise...but the cost of time and patience is enormous!

So, in my point of view, interface not friendly, creating to us a problems instead to give us effective tool, simple, to help us to make better and faster.... we can make better, but not faster.

I remember, when i was young..entering a bank, our bank account was controled by a small card of papper, the guy had to obtain your signature and go to observe that, also your face compared with the picture into your Registration Card, identity document.... driver license or something alike, and you money movement was written with a pencil and latter, in the nigth everything was checked.... the long strip waiting long time each guy having all those movements beeing made by the cashier man... computers came and made things faster, more efficient... a password and finish..all date inside the main frame computer and ready to go in microseconds....but related boards software, it spend from you more time you can spend with a a pen and a papper... i can prepare nice boards in 20 minutes, with a pen and papper and will need some weeks, maybe 20 days to learn how to use the software...of course, maybe after that learning period i will be able to make a board in 20 minutes...but i doubt that.

I conclude i am not clever to learn those things..but the software creators were not clever too, as they made things not simple, not easy and not fast.

The problem i felt is that they are not clear.

For instance.... a command i will call XXX.

They say, click into command XXX and do this and do that.

But they do not say where is the command XXX, and what is the result you have when you click and the adjustments results...so you have to discover by yourself clicking almost everywhere.

Well..... this last one, from Abacom seems really very well explainded...you see that a "real teacher" have prepared the tutorial..... teacher i mean the one that really knows how to teach, not the one that has knowledge and do not knows how to teach.... real teachers born this way...not an effect from College..you are, naturally, or you are not.

regards, Conrad and Ebbe.

Carlos

Some "high tech" behavior use to be not efficient

For instance...if you face an amplifier that has defect... and you intend to fix it.

You can have informs about how happened the damage,

You can think about what circuit could be damaged

You can make measurements to find strange voltages, strange VBEs ... and you can make notes, writting this data over a schematic, real or virtual schematic.

Then you can make efforts to understand those voltages to discover what part is damaged.

In the real world, this takes 10 times more time (time wasted) than to remove all transistors and measure them out from the board and to sniff, alike a dog, searching for smells that shows you something had burned and making a fast, almost instantaneous visual inspection.

Transistor inspection and replacement is very fast compared with the "logical circuit operation inspectors".

So..you see that applying the technical procedure you can, sometimes, waste your time.

You see..one is the "complicator" and the other is "efficient"... some softwares are complicator and others may be efficient.

The eagle one is more a venture than the eagle...as eagle is clever, very fast, and the software is slow, have not kind interface, complicated to learn and to operate, awkward and boring...and interesting, considered the best... this is very strange..seems i have to learn a lot to understant that.

regards,

Carlos

For instance...if you face an amplifier that has defect... and you intend to fix it.

You can have informs about how happened the damage,

You can think about what circuit could be damaged

You can make measurements to find strange voltages, strange VBEs ... and you can make notes, writting this data over a schematic, real or virtual schematic.

Then you can make efforts to understand those voltages to discover what part is damaged.

In the real world, this takes 10 times more time (time wasted) than to remove all transistors and measure them out from the board and to sniff, alike a dog, searching for smells that shows you something had burned and making a fast, almost instantaneous visual inspection.

Transistor inspection and replacement is very fast compared with the "logical circuit operation inspectors".

So..you see that applying the technical procedure you can, sometimes, waste your time.

You see..one is the "complicator" and the other is "efficient"... some softwares are complicator and others may be efficient.

The eagle one is more a venture than the eagle...as eagle is clever, very fast, and the software is slow, have not kind interface, complicated to learn and to operate, awkward and boring...and interesting, considered the best... this is very strange..seems i have to learn a lot to understant that.

regards,

Carlos

What i mean when i say simple software..easy.. and clever

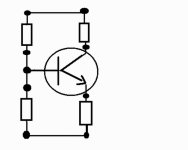

Imagine ou have a schematic.... i am presenting you an example only..and there is a image attached.

Then you have the "clever" software.... a good one that i imagine people have not made yet.

You drag your schematic and drop it into the work area..inside the board maker program... the clever one, not made yet, i mean.

Then the program will "see", will understand, will give attention only to dots and horizontal lines (not rectangles as resistances) and vertical lines...so...the program will see the copper lines.

See the first image.

regards,

Carlos

Imagine ou have a schematic.... i am presenting you an example only..and there is a image attached.

Then you have the "clever" software.... a good one that i imagine people have not made yet.

You drag your schematic and drop it into the work area..inside the board maker program... the clever one, not made yet, i mean.

Then the program will "see", will understand, will give attention only to dots and horizontal lines (not rectangles as resistances) and vertical lines...so...the program will see the copper lines.

See the first image.

regards,

Carlos

Attachments

So, ready!... there's your copper lines, there's your board.

Now you click to move horizontal lines up and down, to make short or bigger, depending your needs.....also vertical lines... when you reach the standard 1/4 watt resistor size..the program produces a sign, audio sign or image shake alike you have in MSN when you call someone....so...you will know you got the standard distance between lines to allow resistance to be introduced... distance now ready.

You see...you enter the schematic...sketch or nice draw... program will recognize only dots, vertical lines and horizontal lines that will be keept...parts will be erased... when you erase parts what results?... the board lines!

Of course the program can pop up questions alike?

- Do you want to increase copper line thickness?... click the one and enter the thickness you want.

You know...something easy, if you want a lot of details then the program will allow you to adjust everything you can imagine..but will offer you, immediattelly, a simple board with standard thickness lines and dots to solder parts..holes standard, parts standard and following the schematic...a real "image linked thing"

To a program alike the one i am dreaming, i would pay 200 dollares, happy, without any complain, smilling i would pay..for the others that complicates my life in the place to make it easier..i would ask a cracked copy of them... do not deserve my money to create me problems instead to make my life easier.

Now you know what i mean with the word simple.... you click and Gerbers ready into a zip package... FINISH!... a fast, efficient, easy tool... clever thing i think....the brain masturb..... brain exercising folks can go with eagle, the venture.

My personal conclusion is that i am not very clever..but thousands of software designers are less clever than i am... they have the know how to make software, but i imagine they have spend 20 years to learn to do that...and this is not clever...because life is too short...it goes very fast...we cannot loose our time with foolishes.

ahahahahah!

regards,

Carlos

Now you click to move horizontal lines up and down, to make short or bigger, depending your needs.....also vertical lines... when you reach the standard 1/4 watt resistor size..the program produces a sign, audio sign or image shake alike you have in MSN when you call someone....so...you will know you got the standard distance between lines to allow resistance to be introduced... distance now ready.

You see...you enter the schematic...sketch or nice draw... program will recognize only dots, vertical lines and horizontal lines that will be keept...parts will be erased... when you erase parts what results?... the board lines!

Of course the program can pop up questions alike?

- Do you want to increase copper line thickness?... click the one and enter the thickness you want.

You know...something easy, if you want a lot of details then the program will allow you to adjust everything you can imagine..but will offer you, immediattelly, a simple board with standard thickness lines and dots to solder parts..holes standard, parts standard and following the schematic...a real "image linked thing"

To a program alike the one i am dreaming, i would pay 200 dollares, happy, without any complain, smilling i would pay..for the others that complicates my life in the place to make it easier..i would ask a cracked copy of them... do not deserve my money to create me problems instead to make my life easier.

Now you know what i mean with the word simple.... you click and Gerbers ready into a zip package... FINISH!... a fast, efficient, easy tool... clever thing i think....the brain masturb..... brain exercising folks can go with eagle, the venture.

My personal conclusion is that i am not very clever..but thousands of software designers are less clever than i am... they have the know how to make software, but i imagine they have spend 20 years to learn to do that...and this is not clever...because life is too short...it goes very fast...we cannot loose our time with foolishes.

ahahahahah!

regards,

Carlos

Hi Carlos,

Stop wasting time, pick any package and start learning !!! Once you learn one you can jump to another easily. You don't have the knowledge to judge anything yet. 😀

DELETED

regards

Stop wasting time, pick any package and start learning !!! Once you learn one you can jump to another easily. You don't have the knowledge to judge anything yet. 😀

DELETED

regards

Yes...you are rigth Greg... i will study something, and them i will be able

to analise those things better.

Thank you to remember me that... really, we cannot judge without know deeply the software.

Also we cannot bother people that have spent time learning venture...ahahahahaha

regards,

Carlos

to analise those things better.

Thank you to remember me that... really, we cannot judge without know deeply the software.

Also we cannot bother people that have spent time learning venture...ahahahahaha

regards,

Carlos

My vote goes for Eagle. It's annoying at first but you can get the work done very quickly once you get used to it (even adding new component patterns becomes easy).

Is there any PCB design program that allows to selectively remove the dummy non-connected top and bottom pads in non-plated double-sided boards to preserve continuous ground planes and filled polygons?

Is there any PCB design program that allows to selectively remove the dummy non-connected top and bottom pads in non-plated double-sided boards to preserve continuous ground planes and filled polygons?

Yes...it is interesting..everybody likes Eagle.

It may be very good after we learn how to use it.

Venture may be too much...ehhehehe.... we call here Urubú, not a very respectable bird..always flying into the garbage..surrounding garbage..everything that smells bad....maybe too much.

Greg was not very happy with my Eagle criticisms.

I do not think because everybody likes it that it may be good because of that.... everybody loves Religions and i do not like...so..there are things that wide world love do not matches my personal evaluations.

But a lot of good guys, experienced guys, use Eagle.

Well, i thank all of you, i am already very satisfied, i have a good program to study... so.... because of me nothing more to discuss..but if you want to continue to have a good debate about the subject, please, go ahead.

Related my own needs the thread already acomplished the mission.

thanks,

Carlos

It may be very good after we learn how to use it.

Venture may be too much...ehhehehe.... we call here Urubú, not a very respectable bird..always flying into the garbage..surrounding garbage..everything that smells bad....maybe too much.

Greg was not very happy with my Eagle criticisms.

I do not think because everybody likes it that it may be good because of that.... everybody loves Religions and i do not like...so..there are things that wide world love do not matches my personal evaluations.

But a lot of good guys, experienced guys, use Eagle.

Well, i thank all of you, i am already very satisfied, i have a good program to study... so.... because of me nothing more to discuss..but if you want to continue to have a good debate about the subject, please, go ahead.

Related my own needs the thread already acomplished the mission.

thanks,

Carlos

Attachments

I think where a lot of people go wrong with EAGLE is when they try and use it only for boards. Really, EAGLE wants you to do a schematic in it, and then create the board from the schematic.

The advantage of this is that you can be sure the board will always match the schematic, and part changes etc automatically get shown up.

I must admit when I first started to learn EAGLE, it got on my nerves... but the only other package I knew about was OrCAD and that was even worse!!

The advantage of this is that you can be sure the board will always match the schematic, and part changes etc automatically get shown up.

I must admit when I first started to learn EAGLE, it got on my nerves... but the only other package I knew about was OrCAD and that was even worse!!

If you are comfortable with Linux, have a look at the gEda suite.

This includes a schematic capture application called gschem. You draw your circuit in gschem. You then use a utility to turn it into various sorts of other files. For example, you can generate a spice file, to simulate the circuit to verify operation.

You can also generate a netlist to import into PCB, a layout programme. This then has all the components, and knows how they should be connected. You have to drag them into place, and connect the wires yourself, but it keeps track and verifies that the layout corresponds to the schematic.

PCB supports complex multi-layer technologies as well as single and double sided.

This is all Free in both sense of the word (libre and gratis)

This includes a schematic capture application called gschem. You draw your circuit in gschem. You then use a utility to turn it into various sorts of other files. For example, you can generate a spice file, to simulate the circuit to verify operation.

You can also generate a netlist to import into PCB, a layout programme. This then has all the components, and knows how they should be connected. You have to drag them into place, and connect the wires yourself, but it keeps track and verifies that the layout corresponds to the schematic.

PCB supports complex multi-layer technologies as well as single and double sided.

This is all Free in both sense of the word (libre and gratis)

On the margin I'm using Eagle and I'm pleased with that. Eagle gives relief after Protel.

Carlos asked for something really easy-to-use and simple software for designing conventional boards (no SMD, not many layers, etc.).

Sprint Layout is cheap too: 40 Euro vs. 500...600 Euro (that costs Eagle).

I'm sure that Carlos will be contented with this Abacom software! Only a few hours will needed to learn using the software.

Good luck!

Carlos asked for something really easy-to-use and simple software for designing conventional boards (no SMD, not many layers, etc.).

Sprint Layout is cheap too: 40 Euro vs. 500...600 Euro (that costs Eagle).

I'm sure that Carlos will be contented with this Abacom software! Only a few hours will needed to learn using the software.

Good luck!

A long list here.

http://www.olimex.com/pcb/dtools.html

There are some free utilities availbale thru which you can do a layout of pcb using Coral Draw if you already using Coral draw

for some application.

Easytrax from Altium is free software from DOS era, work well in Win xp.

regards

http://www.olimex.com/pcb/dtools.html

There are some free utilities availbale thru which you can do a layout of pcb using Coral Draw if you already using Coral draw

for some application.

Easytrax from Altium is free software from DOS era, work well in Win xp.

regards

Yes.... we have to link the schematic with the layout into Eagle

There's a command to do that... and i found the command and have use it...also others use the same way... they seems that have made copies from Eagle....if not copies... inspired..you know..had Eagle knowledge and this was the starting point to develop other software.... naturally...nothing strange in that behavior... as not clever to start from zero when we have a lot of good things to use as reference.

I am very happy with those Abacom software...and now will be waiting the CD from Sakis...nice gift...problem is that i know already the price he paid.... not nice to know, in advance the things price.

Sakis, you have asked me if there's something i want from Greece.

I want health to you and Maria.

I want a very small piece of marble from Greece... Ancient white Marble from Greece... alike that one you have in Partenon and other temples...very small... do not tell people...i love stones.... but not heavy stone please..this will increase mail cost..something small..alike 15 milimetres sides and 4 milimeters thick.

Not needed to go to the Partenon....Marble from an old kitchen is ancient Greek Marble..so.... use a hammer and produce a small piece to me please...send it together.

You have asked... and them...i am telling what i want.

Termophiles.... termópilas passage... that Cannyon picture is interesting too.... The Ravine is the place... where Greeks face the enemie..ancient Greek hystory.

But i can survive without that stuff, so...do not bother yourself too much with that stuff.

regards,

Carlos

There's a command to do that... and i found the command and have use it...also others use the same way... they seems that have made copies from Eagle....if not copies... inspired..you know..had Eagle knowledge and this was the starting point to develop other software.... naturally...nothing strange in that behavior... as not clever to start from zero when we have a lot of good things to use as reference.

I am very happy with those Abacom software...and now will be waiting the CD from Sakis...nice gift...problem is that i know already the price he paid.... not nice to know, in advance the things price.

Sakis, you have asked me if there's something i want from Greece.

I want health to you and Maria.

I want a very small piece of marble from Greece... Ancient white Marble from Greece... alike that one you have in Partenon and other temples...very small... do not tell people...i love stones.... but not heavy stone please..this will increase mail cost..something small..alike 15 milimetres sides and 4 milimeters thick.

Not needed to go to the Partenon....Marble from an old kitchen is ancient Greek Marble..so.... use a hammer and produce a small piece to me please...send it together.

You have asked... and them...i am telling what i want.

Termophiles.... termópilas passage... that Cannyon picture is interesting too.... The Ravine is the place... where Greeks face the enemie..ancient Greek hystory.

But i can survive without that stuff, so...do not bother yourself too much with that stuff.

regards,

Carlos

Firstly eagle allready does those lines you mentioned carlos, but it will not place the components for you... you have to move them in place... then you change the lines into traces... or you could click autoroute if you trust the program to be more clever than a human.... at this stage I don't

I would also like it if eagle would calculate trace dissipation useing current passed and lenght of trace to apply an auto width, fitting the trace tables/calculators available...

I have so much respect for Greg's schematics and parts choices as you can normaly build his schematics EXACTLY in the layout of his schematic...

give me a shout on MSN and i'll give you a starter course, I guess it is time I teach you something. But the thing I can't teach you, patience, you will have to work on yourself.... producing larger boards takes the patience of a bonzai grower...

The easiest way I guess for first time success, is to buy the components inyour schematic, take their measurements and apply that to the parts selection in the schematic, this will produce the minimum amount of re-work.

Eagle can autoplace partnumbers and values, but only on boards with components that are very seperated as you can not move that text manualy... I preffer to hide value and number layers and manualy type my own silkscreen...

I know Greg goes one further and draws in silkscreen for the parts too.... I don;t have that kind of patience, and it has no use unless you plan to send the boards to a factory.

Gerbers will never be a one button story, as there are many gerber formats and many PCB makeing machines... so there is no standard file type, same applies to drills, many diffirent drilling machines useing diffirent programs and files...

You can however save the gerber setup for a board, and have it produce all the files needed with one button... afterwards, of that specific board... or I guess other boards too but it will overwrite the file locations then.

Eagle also has some advance features, yuo can supply it with things like minimum trace with or spaceing your manufacturer can handle, and it will check and identify errors in this regard for you...

If you have two screens like me, you can use the eye icon on the schematic, and it highlights the part for you on the board in the other screen.. (guess it can work if you minimise one of the screens slightly...) It also works the other way around...

the other packages may be okay for the occasional small board but nothing more than that, everytime you want to make a modification you may as well start from scratch... and will waste more time in the long run than just learning eagle....

I would also like it if eagle would calculate trace dissipation useing current passed and lenght of trace to apply an auto width, fitting the trace tables/calculators available...

I have so much respect for Greg's schematics and parts choices as you can normaly build his schematics EXACTLY in the layout of his schematic...

give me a shout on MSN and i'll give you a starter course, I guess it is time I teach you something. But the thing I can't teach you, patience, you will have to work on yourself.... producing larger boards takes the patience of a bonzai grower...

The easiest way I guess for first time success, is to buy the components inyour schematic, take their measurements and apply that to the parts selection in the schematic, this will produce the minimum amount of re-work.

Eagle can autoplace partnumbers and values, but only on boards with components that are very seperated as you can not move that text manualy... I preffer to hide value and number layers and manualy type my own silkscreen...

I know Greg goes one further and draws in silkscreen for the parts too.... I don;t have that kind of patience, and it has no use unless you plan to send the boards to a factory.

Gerbers will never be a one button story, as there are many gerber formats and many PCB makeing machines... so there is no standard file type, same applies to drills, many diffirent drilling machines useing diffirent programs and files...

You can however save the gerber setup for a board, and have it produce all the files needed with one button... afterwards, of that specific board... or I guess other boards too but it will overwrite the file locations then.

Eagle also has some advance features, yuo can supply it with things like minimum trace with or spaceing your manufacturer can handle, and it will check and identify errors in this regard for you...

If you have two screens like me, you can use the eye icon on the schematic, and it highlights the part for you on the board in the other screen.. (guess it can work if you minimise one of the screens slightly...) It also works the other way around...

the other packages may be okay for the occasional small board but nothing more than that, everytime you want to make a modification you may as well start from scratch... and will waste more time in the long run than just learning eagle....

Thank you dear Nordic...not really needed that teaching in MSN

I have already give up to Eagle..now a days i am studying other.

I remember i have asked you to send me, once more, the HRII files, including Gerber and also this Last Precision 1 board.

Waiting for ya.... take the time you would spend with me teaching me Eagle and prepare this stuff and send to me , please.

I have sent you, minutes ago, a lot of work to be done into the last board... small details... i am glad i do not know how to operate the Eagle, at least in this moment..because if i had the knowledge i would be working on it rigth now and to read the Abacom software is much more interesting, and pleasant, to my heart for now on.

I am happy our last very important board design...you have made naturally, are almost ready to go.... Precision II means small modifications only..and seems will not be a problem as we have the Precision I made.

I also have respect by those folks use Eagle... i just do not know how they can walk and sit...because they have the biggest bells someone can have.... a bell to tell them time to stop to lunch!

ahahahahaha!.... cannot write bad words man!.... bells man...do your understand?

Greek people call Orchidea the bells (Ïó÷åïõ) i am intending to say.... and this seems, in my language.... people that has "a lot of patience"

regards,

Carlos

I have already give up to Eagle..now a days i am studying other.

I remember i have asked you to send me, once more, the HRII files, including Gerber and also this Last Precision 1 board.

Waiting for ya.... take the time you would spend with me teaching me Eagle and prepare this stuff and send to me , please.

I have sent you, minutes ago, a lot of work to be done into the last board... small details... i am glad i do not know how to operate the Eagle, at least in this moment..because if i had the knowledge i would be working on it rigth now and to read the Abacom software is much more interesting, and pleasant, to my heart for now on.

I am happy our last very important board design...you have made naturally, are almost ready to go.... Precision II means small modifications only..and seems will not be a problem as we have the Precision I made.

I also have respect by those folks use Eagle... i just do not know how they can walk and sit...because they have the biggest bells someone can have.... a bell to tell them time to stop to lunch!

ahahahahaha!.... cannot write bad words man!.... bells man...do your understand?

Greek people call Orchidea the bells (Ïó÷åïõ) i am intending to say.... and this seems, in my language.... people that has "a lot of patience"

regards,

Carlos

One other bit of advice- almost every mistake I've ever had on a board has been the result of using a library part without checking it. Unless you just do logic, libraries can't be trusted. I've found this true for many packages, free to very expensive. Now I just throw out all the libraries except maybe the logic, and generate all my own parts. It takes more time, but the boards work.

Another Murphy's Law: A three pin voltage regulator cannot be laid out correctly on a PCB, and if it is, the holes will be too small to insert it.

Another Murphy's Law: A three pin voltage regulator cannot be laid out correctly on a PCB, and if it is, the holes will be too small to insert it.

- Status

- Not open for further replies.

- Home

- Amplifiers

- Solid State

- Layout and Pcboard software... please friends, suggest me something really simple