That is not true Mark, it is just the other way around.

Thanks Loek, I stand corrected on that! I guess I was thinking of when the bias device would be open that the bias would max out.

The photos look very good everyone!!!

Mark

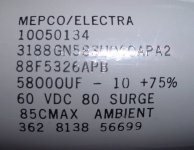

Man, those caps must be 1,000,000 mfds! They are phusically huge..... mine are 58,000 @ 50 vdc and only 3.5" dia X 4" high. Exactly what value are those Al? I could send you some like I got, 10 bucks each.....

Mark

Mark

Thats a good price but they are huge. If you need smaller caps with the same ratings let me know.... It would help keep the size down.....

Mark

Mark

Thanks for the offer, Mark, but I suspect shipping would kill any price advantage. Anyway, what with this project, and the MiniA and A30 pcbs and kits, I've spent my allowance for the next month or so!

You are a SuperMouse!

(i contemplated if i should mention the fabrication date of your capacitors)

What is the charging current you are using, Mouster ?

(i contemplated if i should mention the fabrication date of your capacitors)

What is the charging current you are using, Mouster ?

I started slow, with 100mA. This has been running for about 24 hrs, so I'm going to discharge them nice and gently through a 680W resistor, then give them a go at about 500mA on a bigger 22V traffo.

I read the date code as 1999, is that what you make it?

I read the date code as 1999, is that what you make it?

Sorry that the resistors seem to resist delivery to your place . I know how that is. We are all anxious to see/hear that its up and running

. I know how that is. We are all anxious to see/hear that its up and running

For proper electrolytic re-forming procedures check out this site...... You need to place a resistor in there..... you wouldn't want one of them to go boom........

http://www.vcomp.co.uk/tech_tips/reform_caps/reform_caps.htm

Mark

. I know how that is. We are all anxious to see/hear that its up and running

. I know how that is. We are all anxious to see/hear that its up and runningFor proper electrolytic re-forming procedures check out this site...... You need to place a resistor in there..... you wouldn't want one of them to go boom........

http://www.vcomp.co.uk/tech_tips/reform_caps/reform_caps.htm

Mark

pinkmouse said:I read the date code as 1999, is that what you make it?

MouseyBaby,

try Googling/Ebay for Mepco caps and tell me how many you found with (362- xxxx - 56699) marking.

(btw: such large caps are new 40 Pounds each, at the lowest)

I'd reform them very, very slowly, iiwy.

Jacco,

The more important thing when re-forming is to limit the current to the cap...... this eliminates the possibilitiy of forming pinholes and resultant shorts in the oxide coating. The voltage can and should be set at the caps rating but current limited by a resistor. Wait for the voltage drop across the resistor to fall to its lowest point to tell that the cap has been re-formed.

Its not really how long one takes to do it, its if the cap will re-form at all or not. Generally any cap will re-form in a matter of a half hour to a couple of hours. If it takes longer than that then its probably no good to begin with. I've actually had VERY good luck re-forming 50 year old caps in TV sets that I restore. Generally they re-form in less than an hour..... sometimes a bit longer. If it takes longer and the voltage across the resistor stays high there are already pinholes in the coating and they can't go away! Remember if manufacturers had to spend days just forming electrolytic caps they would cost ALOT more than 40 dollars each! In reality they do it in minuites....

Mark

The more important thing when re-forming is to limit the current to the cap...... this eliminates the possibilitiy of forming pinholes and resultant shorts in the oxide coating. The voltage can and should be set at the caps rating but current limited by a resistor. Wait for the voltage drop across the resistor to fall to its lowest point to tell that the cap has been re-formed.

Its not really how long one takes to do it, its if the cap will re-form at all or not. Generally any cap will re-form in a matter of a half hour to a couple of hours. If it takes longer than that then its probably no good to begin with. I've actually had VERY good luck re-forming 50 year old caps in TV sets that I restore. Generally they re-form in less than an hour..... sometimes a bit longer. If it takes longer and the voltage across the resistor stays high there are already pinholes in the coating and they can't go away! Remember if manufacturers had to spend days just forming electrolytic caps they would cost ALOT more than 40 dollars each! In reality they do it in minuites....

Mark

If I am reading the date code correctly, I think those MEPCO caps were manufactured in '81, Week 38 (8138).

18 years older than you thought 🙂

Rep

18 years older than you thought 🙂

Rep

Mark A. Gulbrandsen said:Jacco,

The more important thing when re-forming is to limit the current to the cap...... this eliminates the possibilitiy of forming pinholes and resultant shorts in the oxide coating. The voltage can and should be set at the caps rating but current limited by a resistor. Wait for the voltage drop across the resistor to fall to its lowest point to tell that the cap has been re-formed.

Mark

Is there any advantage/harm in slowly increasing the

voltage with a variac?

Thanks,

Dennis

Is there any advantage/harm in slowly increasing the

Running the voltage up slowly is ok, it will just take more time. Its also ok to re-form them at their rated voltage provided you limit the current. The resistor in series with the cap will prevent any serious damage to the cap or to yourself. Best thing is to monitor the voltage drop acrioss the resistor while its re-forming. A slow but steady drop indicates a cap with a bit of leakage that can be reofrmed> Usually it will drop slowly over an hour or so. If the voltage across the resistor does not drop after an hour then it shows there is an internal short in the cap and it cannot be re-formed.

Mark

Mark A. Gulbrandsen said:

Running the voltage up slowly is ok, it will just take more time. Its also ok to re-form them at their rated voltage provided you limit the current. The resistor in series with the cap will prevent any serious damage to the cap or to yourself. Best thing is to monitor the voltage drop acrioss the resistor while its re-forming. A slow but steady drop indicates a cap with a bit of leakage that can be reofrmed> Usually it will drop slowly over an hour or so. If the voltage across the resistor does not drop after an hour then it shows there is an internal short in the cap and it cannot be re-formed.

Mark

Hi Mark,

Thanks for your detailed reply. I'll know next time

to just limit the current...and not spend a whole

weekend reforming capacitors. 🙂

Cheers,

Dennis

Well, 1999, or 1981, they seem to be coming back ok, thanks to Mark's link. I'm going very slowly, as I only had a 220K resistor to hand.

I get the nagging feeling I should be graphing this, just like I did at school all those years ago...

I get the nagging feeling I should be graphing this, just like I did at school all those years ago...

Hey guys, thanks for the link.

I have a Hafler P500 that I have fixed and the caps worked initially but not after I replaced the bad parts. I went ahead and bought more caps and threw the old one in the trash. After reading the article I have new hope that I can save the old caps and luckily I was able to rescue them before the trash went out. I intend to pick up some resistors for this today.

I'll let you know how it goes.

Blessings, Terry

I have a Hafler P500 that I have fixed and the caps worked initially but not after I replaced the bad parts. I went ahead and bought more caps and threw the old one in the trash. After reading the article I have new hope that I can save the old caps and luckily I was able to rescue them before the trash went out. I intend to pick up some resistors for this today.

I'll let you know how it goes.

Blessings, Terry

- Home

- Amplifiers

- Solid State

- Krell KSA 50 PCB