OT, but I have to chime in on makerbeam chassis. It is very fun to build that way.

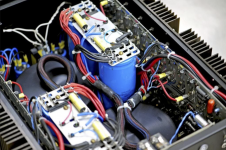

TubSuMo build

I hope this king of latfet amps comes to fruition, makerbeams or not.

TubSuMo build

I hope this king of latfet amps comes to fruition, makerbeams or not.

Attachments

bout $600 per channel

The reason I asked X, what kind of time frame do we need on this? If I can push it down the road a bit, we can get it done. Also, it would be good to have distortion and wave forms looked at. Do you have that ability Ozark?

If you do and you have the money, and time, to build now, I will reship the boards to you. KT needs hard data on this thing, not just a cool build for someone to play with. 🙂

JT

The reason I asked X, what kind of time frame do we need on this? If I can push it down the road a bit, we can get it done. Also, it would be good to have distortion and wave forms looked at. Do you have that ability Ozark?

If you do and you have the money, and time, to build now, I will reship the boards to you. KT needs hard data on this thing, not just a cool build for someone to play with. 🙂

JT

Hey ... Not trying to step on any toes here ...

I can allocate funds to approach building, am in a place to work on this.

Hard data could be a fundamental limitation (for now) with relocation,

limited access to gear and testing. I will hang back for now,

continue with other projects... see what results.

I am not looking for another build, I .am. intent on modeling

a few more circuits, driven by my CLC power supplies.

Besides I have a room full of cool stuff to enjoy!

I can allocate funds to approach building, am in a place to work on this.

Hard data could be a fundamental limitation (for now) with relocation,

limited access to gear and testing. I will hang back for now,

continue with other projects... see what results.

I am not looking for another build, I .am. intent on modeling

a few more circuits, driven by my CLC power supplies.

Besides I have a room full of cool stuff to enjoy!

Attachments

Beautiful build I like... KUDOS von AhOT, but I have to chime in on makerbeam chassis.

Hey ... Not trying to step on any toes here ...

I can allocate funds to approach building, am in a place to work on this.

Hard data could be a fundamental limitation (for now) with relocation,

limited access to gear and testing. I will hang back for now,

continue with other projects... see what results.

I am not looking for another build, I .am. intent on modeling

a few more circuits, driven by my CLC power supplies.

Besides I have a room full of cool stuff to enjoy!

No toes stepped on at all, and I'm happy to ship them, if it forwards the distillation of the amp. The first couple of goes really need to have some solid data to give the the engineer, so they can tweak it; Without empirical data... They really don't know much more than they did with a sim, because anything you feel/say is subjective. If X and KT want me to ship the boards to you, I will.

The other side of the coin is it's better to have a couple of amps with limited data than it is to have one, or none.

I bring this up because I was just on a project like this, along with KT, and the real data feedback is imperative to a positive outcome.

Anyway, no problem with you being excited over the promise of a new amp. 🙂

JT

Hi Ozark,

Send me a PM with your email and mailing address and I’ll forward you the data package including all schematics, BOM, and stuffing diagrams. I’ll ask JT to send you the PCBs once he gets them.

Send me a PM with your email and mailing address and I’ll forward you the data package including all schematics, BOM, and stuffing diagrams. I’ll ask JT to send you the PCBs once he gets them.

Which monos?Thanks! I gotta bring those monos back out into rotation again.

The tubsumo monos I built at the beginning of last year.

https://www.diyaudio.com/community/...er-simple-hybrid-and-more.262450/post-6595906I just installed them in my secondary system. Valery (vzaichenko) is a great amp designer and a super pleasant guy.

https://www.diyaudio.com/community/...er-simple-hybrid-and-more.262450/post-6595906I just installed them in my secondary system. Valery (vzaichenko) is a great amp designer and a super pleasant guy.

Attachments

Hi Ozark,

I think hard data with a DMM at various key points is enough for us to determine many things needed to see if the amp is working correctly. Oscope is nice but not absolutely needed to do a verification build to check DC setpoints but more to check for oscillation. If you have a decent sound card and a dummy load, anyone can measure FFT and THD etc.

https://www.diyaudio.com/community/...urements-with-rew.338511/page-56#post-6897403

From all your amps and heatsinks and donut collection, it looks like you have the means and experience needed to do a verification build. The big ticket items are the lateral FETs from Profusion and the 16x 100v electrolytic caps. Plus the two big Anteks.

I think hard data with a DMM at various key points is enough for us to determine many things needed to see if the amp is working correctly. Oscope is nice but not absolutely needed to do a verification build to check DC setpoints but more to check for oscillation. If you have a decent sound card and a dummy load, anyone can measure FFT and THD etc.

https://www.diyaudio.com/community/...urements-with-rew.338511/page-56#post-6897403

From all your amps and heatsinks and donut collection, it looks like you have the means and experience needed to do a verification build. The big ticket items are the lateral FETs from Profusion and the 16x 100v electrolytic caps. Plus the two big Anteks.

That’s beautiful work! Impressive looking amp and more interesting when we can see the inside glowing.OT, but I have to chime in on makerbeam chassis. It is very fun to build that way.

TubSuMo build

I hope this king of latfet amps comes to fruition, makerbeams or not.

I do like the OPEN CHASSIS... Foremost for functional reasons, as a 3D workspace.

*Erector Set toys (from the 60s) training from my youth serves...

And aesthetically as a metal form, almost like a sculpture... build it "like a motorcycle" with parts exposed... Hey the "old" vintage gear, much modern vacuum tube gear as well was open.

The trick (for me) is a tight wiring ~ tuck and hide ~ clearly for reduction of interference

[build it like a fine Italian suit, with the interior structure, the details and hand stitching exposed]

especially burying the front end AC and rectification.

I am still "haunted by" time spent marveling early amplifiers which drove my inner engineer crazy... I enjoyed listening to, but could not get over... aspects of the wiring, I spent hours studying the original Bryston 4B and the mighty Mark Levinson ML-3, which at least, ML segregated wiring and "circuit activity". *Granted these are ~40 year old legacy products.

Lastly, the frames role (think Goldmund) the importance of good mechanical grounding for the chassis, as well as optimizing the orientation of components. I am questioning and concerned about aspects of enclosed boxes, prospects of resonance within the chassis.

Even with an open chassis(s) it is possible to make monster amp(s) that are tidy.

*Erector Set toys (from the 60s) training from my youth serves...

And aesthetically as a metal form, almost like a sculpture... build it "like a motorcycle" with parts exposed... Hey the "old" vintage gear, much modern vacuum tube gear as well was open.

The trick (for me) is a tight wiring ~ tuck and hide ~ clearly for reduction of interference

[build it like a fine Italian suit, with the interior structure, the details and hand stitching exposed]

especially burying the front end AC and rectification.

I am still "haunted by" time spent marveling early amplifiers which drove my inner engineer crazy... I enjoyed listening to, but could not get over... aspects of the wiring, I spent hours studying the original Bryston 4B and the mighty Mark Levinson ML-3, which at least, ML segregated wiring and "circuit activity". *Granted these are ~40 year old legacy products.

Lastly, the frames role (think Goldmund) the importance of good mechanical grounding for the chassis, as well as optimizing the orientation of components. I am questioning and concerned about aspects of enclosed boxes, prospects of resonance within the chassis.

Even with an open chassis(s) it is possible to make monster amp(s) that are tidy.

Attachments

Hi Ozark,

From all your amps and heatsinks and donut collection, it looks like you have the means and experience needed to do a verification build.

OK man, just say it LOLs...

"Clearly (chasing after) this audio obsession, has overtaken you..."

"Amplifiers appear to multiply like rabbits, out in the Ozarks..." Or something...

xrk971, you should see my Wima cap inventory (literally)

Fantastic work Ozark, where can we get these kind of frames with perfect fitments and angled clamps. These are awesome and easy to build to make an amp to sing.

Thanks

Thanks

TY.Fantastic work Ozark, where can we get these kind of frames with perfect fitments and angled clamps. These are awesome and easy to build to make an amp to sing.

Thanks

Unfortunately, you (or someone) will have to build them... Not a finished commercial product.

Buying the extrusion is a relatively easy part. I used "8020 brand" or the 2020 variant of the design.

The challenge, using (**purchase of) a band saw to get ~exact~ cuts, safely, repeatably

which significantly cuts the amount of filing, to get the pieces 90* and to exact lengths.

Leaning the nuances of and tuning the band saw = a whole other topic.

I ordered a 800 page catalog (I am serious) from 8020, to learn about the hardware.

another learning curve... then modeling fitment, for support and strength.

I spent a l o t of time, building and rearranging = to learn efficient process

and use of parts... there is a certain order = things must be done.

Many sleepless nights, with the "modeling mind" at play.

Last thing would be to recommend working in multiples, standardize

3, 6, 9, 12" (now 15) to *maximize materials, and make all the parts match

~ plug and play ~ nicely. *Materials that you plan to use

and will have access to. Hard to explain.

If you had an Erector (toy) Set growing up,

It will .all come back. to you...

You can also get precut kits from MakerBeam. That’s what I use although smaller than the 8020 that Ozark Doc uses.

https://www.amazon.com/dp/B06XHXJSVL/ref=cm_sw_r_cp_api_glt_fabc_6Y77217AX5XF20E7RZ4Q

Here is the 8020 stuff - larger and more cost effective but requires cutting:

https://www.amazon.com/dp/B08PQPJYHX/ref=cm_sw_r_cp_api_glt_fabc_Y1JQ8R26Z11JX11AJ67H

https://www.amazon.com/dp/B076D76YDD/ref=cm_sw_r_cp_api_glt_fabc_1MF2NGDS5BY6HKR2MBY2

Having a good bandsaw looks like a requirement to get good cuts though.

https://www.amazon.com/dp/B06XHXJSVL/ref=cm_sw_r_cp_api_glt_fabc_6Y77217AX5XF20E7RZ4Q

Here is the 8020 stuff - larger and more cost effective but requires cutting:

https://www.amazon.com/dp/B08PQPJYHX/ref=cm_sw_r_cp_api_glt_fabc_Y1JQ8R26Z11JX11AJ67H

https://www.amazon.com/dp/B076D76YDD/ref=cm_sw_r_cp_api_glt_fabc_1MF2NGDS5BY6HKR2MBY2

Having a good bandsaw looks like a requirement to get good cuts though.

This is the Amazon page that had the most parts or hardware options. There are a few others...

https://www.amazon.com/stores/KOOTANS/page/A58187CC-6D7C-419E-AAF4-1A325BA9C632?ref_=ast_bln

https://www.amazon.com/stores/KOOTANS/page/A58187CC-6D7C-419E-AAF4-1A325BA9C632?ref_=ast_bln

Nice work! You are very fast, Shane! Very neat and tidy. How do you keep solder from coming to the top?

good heat and a less is more attitude.... or maybe its a radio shack solder 😉Nice work! You are very fast, Shane! Very neat and tidy. How do you keep solder from coming to the top?

- Home

- Amplifiers

- Solid State

- Keantoken's Aurum-X 300w Amp with LatFETs