Pedro,

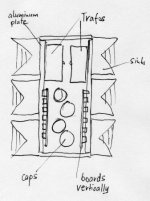

Using two of those heat sinks just for bridges and transformers would be a waste. You don't need cooling for transformers, and bridges require very little of a heatsink. I would use 2 aluminum plates and attach heatsinks to those plates so the all 3 heatsinks would work for FETs. Attach the FETs (and bridges) to those plates. They would have to be at least 1/4" thick. You could mount transformers to ea.side of the heatsink module as well.

The caps I would put between the boards, as close to output devces as you can. Placing them above transformers is not recommended because of the heat. If they will be between the boards in one row, they are also further away from heatsinks.

Luke,

The aluminum bars I used for TO-3 devices were custom made in machine shop.

Using two of those heat sinks just for bridges and transformers would be a waste. You don't need cooling for transformers, and bridges require very little of a heatsink. I would use 2 aluminum plates and attach heatsinks to those plates so the all 3 heatsinks would work for FETs. Attach the FETs (and bridges) to those plates. They would have to be at least 1/4" thick. You could mount transformers to ea.side of the heatsink module as well.

The caps I would put between the boards, as close to output devces as you can. Placing them above transformers is not recommended because of the heat. If they will be between the boards in one row, they are also further away from heatsinks.

Luke,

The aluminum bars I used for TO-3 devices were custom made in machine shop.

Hi Peter Daniel!

thanks.

I know that is a waste of heatsinks, but I don't know if I can stuff 2 mosfets /sink in the heatsink with the trafo. I'll try it out.

whatabout the board? would you put them in horizontal or vertical configuration? If I put them in horizontal config, I could stick the caps in the bottom?.

also, I'm plannig to join the sinks with nut and bolts on the side solts. they are made for placing nuts M5 and M4. I might also melt some lead over the nutsand bolts just in case...

thanks.

I know that is a waste of heatsinks, but I don't know if I can stuff 2 mosfets /sink in the heatsink with the trafo. I'll try it out.

whatabout the board? would you put them in horizontal or vertical configuration? If I put them in horizontal config, I could stick the caps in the bottom?.

also, I'm plannig to join the sinks with nut and bolts on the side solts. they are made for placing nuts M5 and M4. I might also melt some lead over the nutsand bolts just in case...

I would do it like this. If you decide for a aluminum plate, you have to tap holes in a heat sink for better contact. The plate will hold heatsinks together as well it might provide a mounting space for other panels, so putting everything together would be easier. Ultimately I would go for 1/2 thikness and make all panels even with heatsinks (no angles).

Attachments

skaara said:

pedro: wood might burn if heatsinks will run too hot😱

I think the semiconductors will be dead by then....

If the temperature is below 60 deg C (very likely) I think it's quite OK with wood. What type of wood did you have in mind, Pedro?

And Pedro, don't forget to skin the caps. Natural color aluminum looks nice too, nowadays maybe even better than black.😉

Peter.

That Aleph 5 now looks realy nice. Thats what the anodizing is all about.

Very cool.

Trigon.

That Aleph 5 now looks realy nice. Thats what the anodizing is all about.

Very cool.

Trigon.

and what about inverted big cans? can they be upside down?

I don't know Pedro, some of the electrons might spill out. 🙂

Anthony

wood might burn if heatsinks will run too hot

Wood is good to over 300 Deg F. with indirect heat, open flame is far more dangerous. I think your Amp will have other causes for distress if the heat sinks get that hot. If you are concerned there are several practical ways to test the theory. Toss a plank in the oven or on a barbeque over a piece of aluminum foil.

You know that Cedar planks are used at 300 Deg F to cook salmon on.

Anthony

If you are talking about snap in type , I guess the mounting position is not important, but check this caps out. they have some kind of vent on the top...

Be vewy, vewy quite, I'm huntin, ahh what you hunting Doc?

I'm huntin qwacks, ahh don't you mean duck? Their both Daffy aren't they? Ahh you mean Daffy Duck Doc?

Actually modern caps use an Electrolyte Gel, so they can be positioned in any axis. You may be thinking of older oil suspended electrolytes which could be affectd by orientation.

Anthony

I'm huntin qwacks, ahh don't you mean duck? Their both Daffy aren't they? Ahh you mean Daffy Duck Doc?

Actually modern caps use an Electrolyte Gel, so they can be positioned in any axis. You may be thinking of older oil suspended electrolytes which could be affectd by orientation.

Anthony

All caps have a vent, this prevents the pressure from building inside a cap and exploding if there is a short.

Anthony

Anthony

peranders

the wood is the one on the picture (rewind a page or two)

it's portuguese pine (+-200yrs old) that was treated with salt water.

The wood was imersed in sea water for years and then sawed into floor boards.

It's nice and its from an old family house thats under renovation, so I used the old wood. 🙂

the wood is the one on the picture (rewind a page or two)

it's portuguese pine (+-200yrs old) that was treated with salt water.

The wood was imersed in sea water for years and then sawed into floor boards.

It's nice and its from an old family house thats under renovation, so I used the old wood. 🙂

Member

Joined 2002

what did it cost for them heat sinks pedro and i wonder how much it would cost to ship to canada..?

J'

J'

Most, not all, large can caps have vents. If there is a short internally, or if you run far to much voltage through them gas can build up and they will explode, the vent is suppost to prevent this. As long as the vent isn't plugged it doesn't matter for its orientation I don't think. I've seen caps in just about every orientation is older computer equipment, I'm pretty sure it won't effect the cap.

Good old Mr. Fahrenheit

What the is 300 Deg F. in real units?

is 300 Deg F. in real units?

Coulomb said:

Wood is good to over 300 Deg F.

You know that Cedar planks are used at 300 Deg F to cook salmon on.

Anthony

What the

is 300 Deg F. in real units?

is 300 Deg F. in real units?

hehe. Americans will have to switch to metric / SI sooner or later... They're almost the only ones left in the world <i>still</i> stuck in the dark ages of measurement. Silly stubbornness 😉 I'm glad I'm not a Mechanical Engineer, I'd be going bonkers down here in the 'States. Engineering calculations involving US units (often called "English" units, in a vain attempt to pass the buck for unit related problems), are really painful  compared to the same ones done in SI.

compared to the same ones done in SI.

Anyway, conversion from Fahrenheit to Celcius goes something like:

(F - 32) * 5/9 = C

So in this case 300F = 150C roughly, actually just a bit less.

compared to the same ones done in SI.

compared to the same ones done in SI.Anyway, conversion from Fahrenheit to Celcius goes something like:

(F - 32) * 5/9 = C

So in this case 300F = 150C roughly, actually just a bit less.

- Status

- Not open for further replies.

- Home

- Amplifiers

- Pass Labs

- Just another Aleph