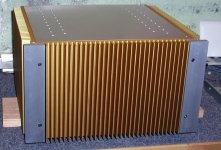

nice casework!

you really like metal works!

are you using 6mm aluminium pannels? if so do you know if they can be cut with a hidraulic gillotine?

how are you going to finhish it? the yellow sinks and the aluminium "grey" panels doesn't look like your job!!

you really like metal works!

are you using 6mm aluminium pannels? if so do you know if they can be cut with a hidraulic gillotine?

how are you going to finhish it? the yellow sinks and the aluminium "grey" panels doesn't look like your job!!

The panels are 10mm thick so they were cut with a saw. Truly it is not my personal work, cause the guy picked the parts and I'm putting everything together, so some of design ideas come from him. I only do what I can to make it look good. He will have it professionally finished by the same company that does Bryston an Sonic Frontiers. Heatsinks will stay probably gold and the rest will be clear anodised. Everything inside will be p2p connected, so by saving on boards we can us Cardas jacks and binding posts.😉

10mm?

why is that?

couldn't you find anything thinner?

I gess 3 or 4 mm for the pannel and ok 10mm for the front panel is good, but 10mm for all sound like a hell of a job. Even with your fine powertools and technics

why is that?

couldn't you find anything thinner?

I gess 3 or 4 mm for the pannel and ok 10mm for the front panel is good, but 10mm for all sound like a hell of a job. Even with your fine powertools and technics

Hell of a job or not.😉 When you cut everythin with circular saw the thickness is not really important. I was cutting 1/2" succesfuly that way.

However by using thicker material we were able to eliminate the inside angles completely, so connections are very easy and the number of parts is reduced drastically. Everything is butt joined. It is still nothing compared to Krell subwoofer with walls of 26mm or more.😉

It's just a different way to do things, maybe something to think about on a next project. Thicker walls also resonate less.

However by using thicker material we were able to eliminate the inside angles completely, so connections are very easy and the number of parts is reduced drastically. Everything is butt joined. It is still nothing compared to Krell subwoofer with walls of 26mm or more.😉

It's just a different way to do things, maybe something to think about on a next project. Thicker walls also resonate less.

Attachments

I also bolt everything to the sinks.

I don't like those angle connectors that everybody uses.

I tap the sinks and bolt the panels to it. easy and if the panel has enough inertia ( 3 or 4mm is good for me in my projects) , it will not bend with self weight and even with the transformers and caps (i make deformation calculations to see if the pannel is thick enough)

my problem with thicker plates is the cutting. I dont have any circular saw like yours nor place to put one of those babies.

I use manual saw and power jigsaw only.

I don't like those angle connectors that everybody uses.

I tap the sinks and bolt the panels to it. easy and if the panel has enough inertia ( 3 or 4mm is good for me in my projects) , it will not bend with self weight and even with the transformers and caps (i make deformation calculations to see if the pannel is thick enough)

my problem with thicker plates is the cutting. I dont have any circular saw like yours nor place to put one of those babies.

I use manual saw and power jigsaw only.

Peter,

Absolutely gorgeous case. You are a craftsman. I’m sure you could stand on that top plate without a problem.

I’m sure you could stand on that top plate without a problem. 😀

😀

Rodd Yamas***a

Absolutely gorgeous case. You are a craftsman.

I’m sure you could stand on that top plate without a problem.

I’m sure you could stand on that top plate without a problem. 😀

😀 Rodd Yamas***a

KEWL 😀

you are really THE MECH GOD. I said it before and i'll say it again!

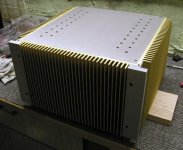

My aleph5 sinks arrived yesterday.

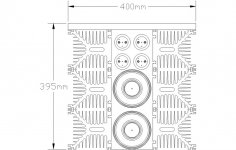

check this layout and say what you think.

how would you guys attach the fet's?

i'm thinking of putting tree in a row in one sink, using four of them for the fets and the two others for bridges and transformers.

you are really THE MECH GOD. I said it before and i'll say it again!

My aleph5 sinks arrived yesterday.

check this layout and say what you think.

how would you guys attach the fet's?

i'm thinking of putting tree in a row in one sink, using four of them for the fets and the two others for bridges and transformers.

Attachments

I'm also thinking of putting the sinks in a horizontal axis config, bolted to the sinks.

the psu caps will be in a inverted position ( I wonder if the might leak?????) and maybe a little on the outside, like valve amps.

the boards, i'll put them in a vertical position bolted to the sinks with 20mm spacers.

the psu caps will be in a inverted position ( I wonder if the might leak?????) and maybe a little on the outside, like valve amps.

the boards, i'll put them in a vertical position bolted to the sinks with 20mm spacers.

Peter,

Very creative and definately a serious looking machine. Do you need a serious amount of tools to get the finishes you achieve or do you get engineering shops to help you.

I really like the big steel brackets in your "not just another aleph post" they hold the to3 fets to the circuit board and sinks. How do you make stuff like that?

Ever thought of making and selling cases here😉

Pedro,

I like your sinks and your old floor boards🙂

I would probably design a case that doesnt detract from the sinks too much, and think they would look really good in black.

How wide is the one you have put together in the photo. Is it standard 19" rack?

Then I would make a nice table with the wood to show off your handy work 😉

Very creative and definately a serious looking machine. Do you need a serious amount of tools to get the finishes you achieve or do you get engineering shops to help you.

I really like the big steel brackets in your "not just another aleph post" they hold the to3 fets to the circuit board and sinks. How do you make stuff like that?

Ever thought of making and selling cases here😉

Pedro,

I like your sinks and your old floor boards🙂

I would probably design a case that doesnt detract from the sinks too much, and think they would look really good in black.

How wide is the one you have put together in the photo. Is it standard 19" rack?

Then I would make a nice table with the wood to show off your handy work 😉

Luke

The height of the sinks is 200mm.

as for the wood front panel, I'm into a wood phase, so there's no way out. I'm using two floor boards together to cover the sinks.

what you say about the caps coming out of the top panel?

and what about inverted big cans? can they be upside down?

The height of the sinks is 200mm.

as for the wood front panel, I'm into a wood phase, so there's no way out. I'm using two floor boards together to cover the sinks.

what you say about the caps coming out of the top panel?

and what about inverted big cans? can they be upside down?

Attachments

Like it😎

Not sure about the big cans being upside down, maybe you loose electrolytic? I also wonder why you would want to do it like that as you would not be saving on any space? Im sure others in here know more about than me, but i remember reading that they dont last as long if they are mounted sideways.

Try it with the caps coming out the top and see how it looks, but I still think those sinks would look mighty mean in black😉

Not sure about the big cans being upside down, maybe you loose electrolytic? I also wonder why you would want to do it like that as you would not be saving on any space? Im sure others in here know more about than me, but i remember reading that they dont last as long if they are mounted sideways.

Try it with the caps coming out the top and see how it looks, but I still think those sinks would look mighty mean in black😉

i'm putting the caps in a vertical axis config and if anyone doesnt says it's bad i'll go for it (the panasonic manual doesn't specify about upsidedown position).

As for the black mean dissipation machine ...

I'm into a grey period also. the black stuff reminds me standard hifi.

I like sinks grey and big, like plinius.

thanks for your advise, Luke 😉

As for the black mean dissipation machine ...

I'm into a grey period also. the black stuff reminds me standard hifi.

I like sinks grey and big, like plinius.

thanks for your advise, Luke 😉

- Status

- Not open for further replies.

- Home

- Amplifiers

- Pass Labs

- Just another Aleph